Patents

Literature

52results about How to "Meet the requirements of actual production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

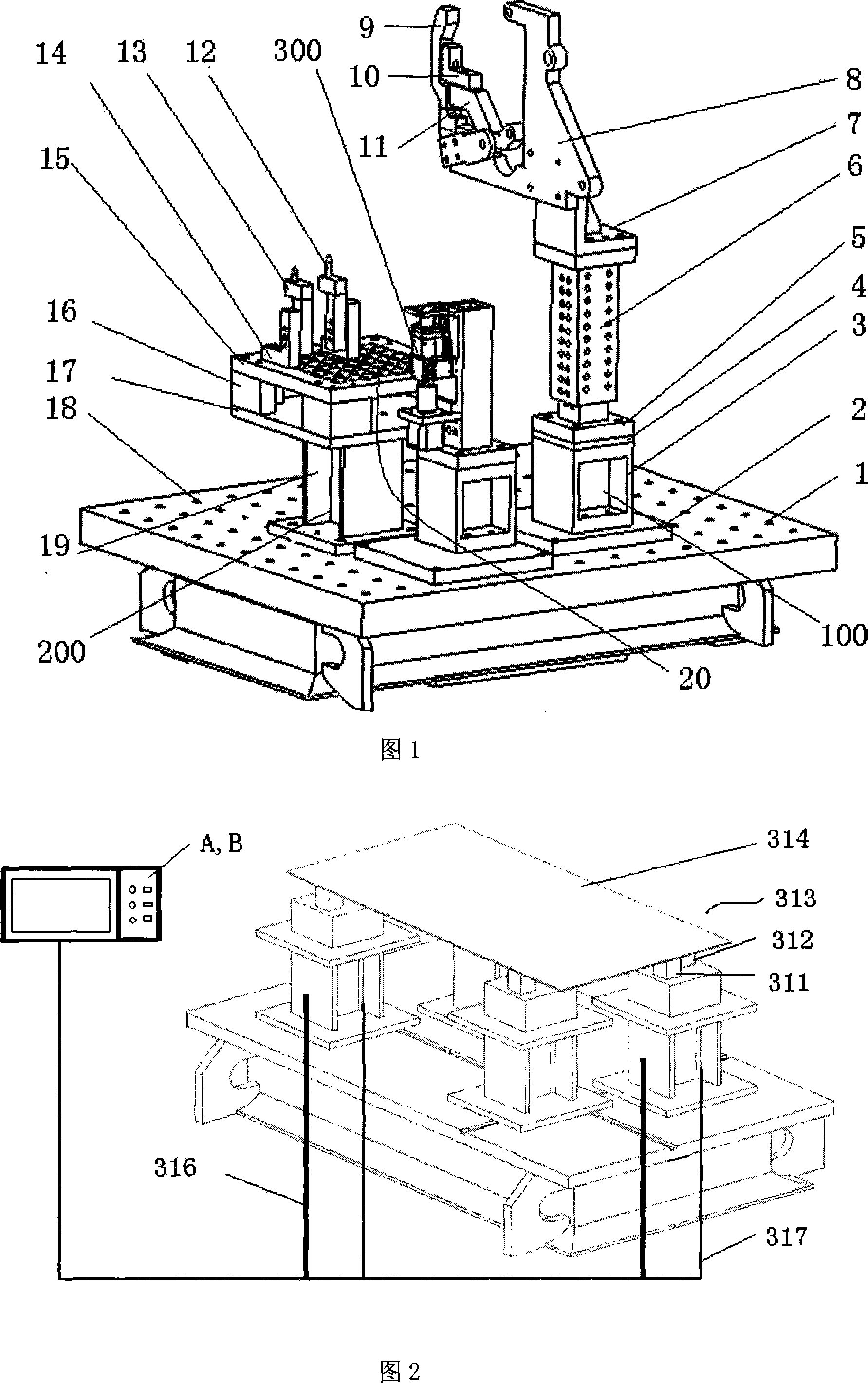

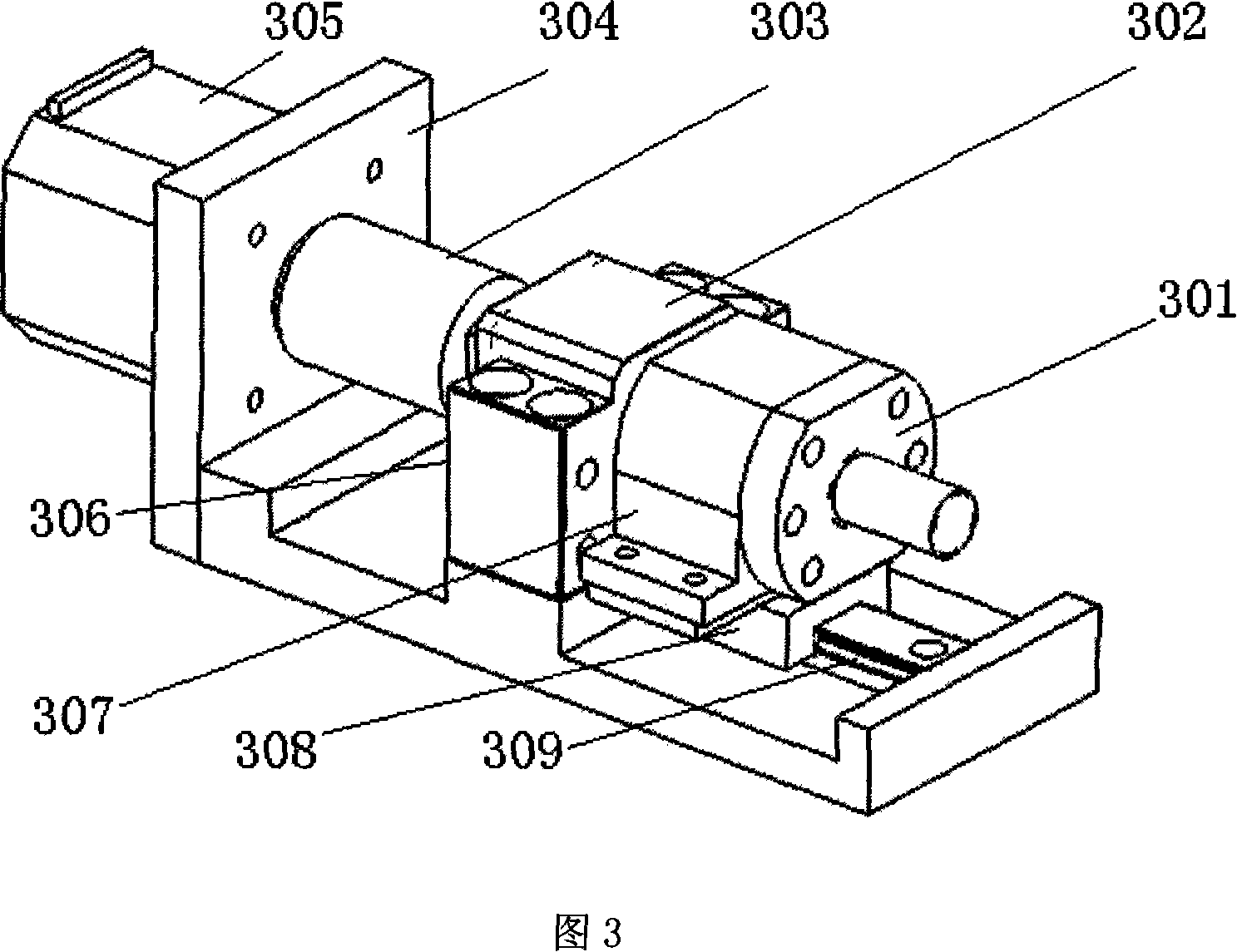

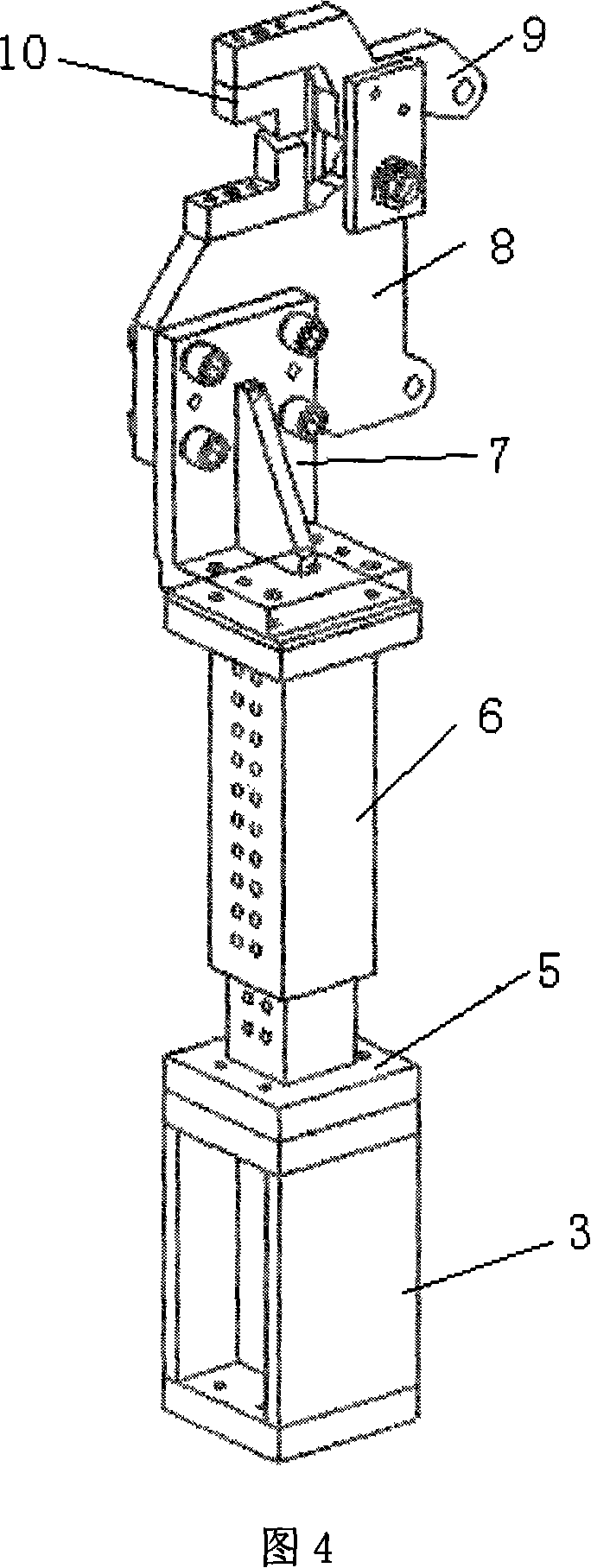

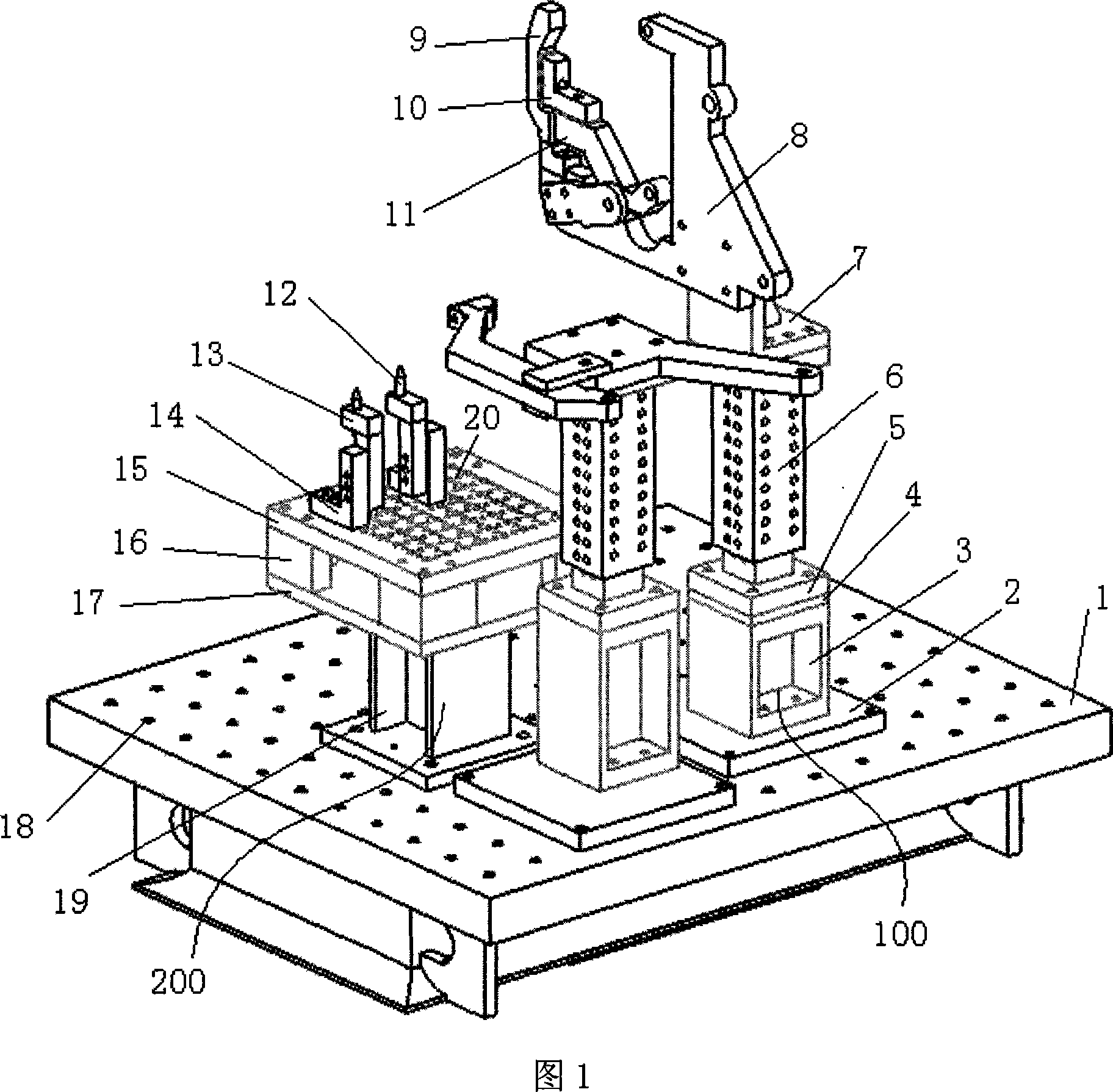

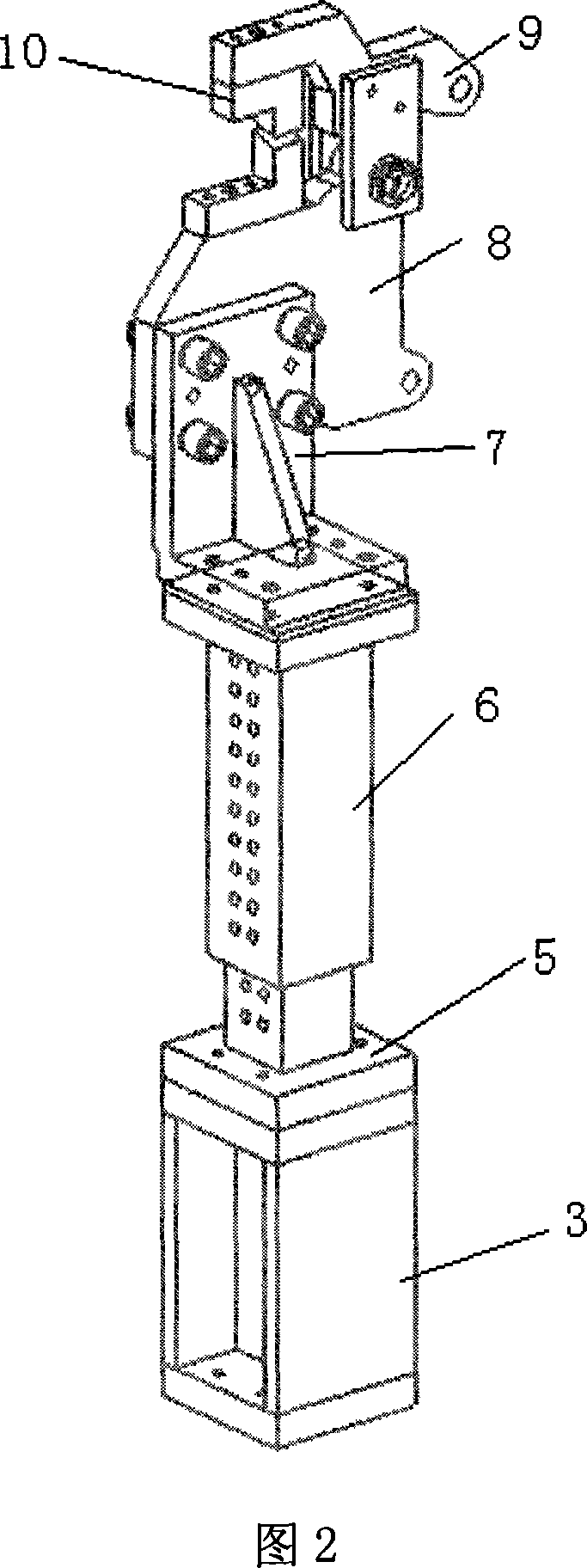

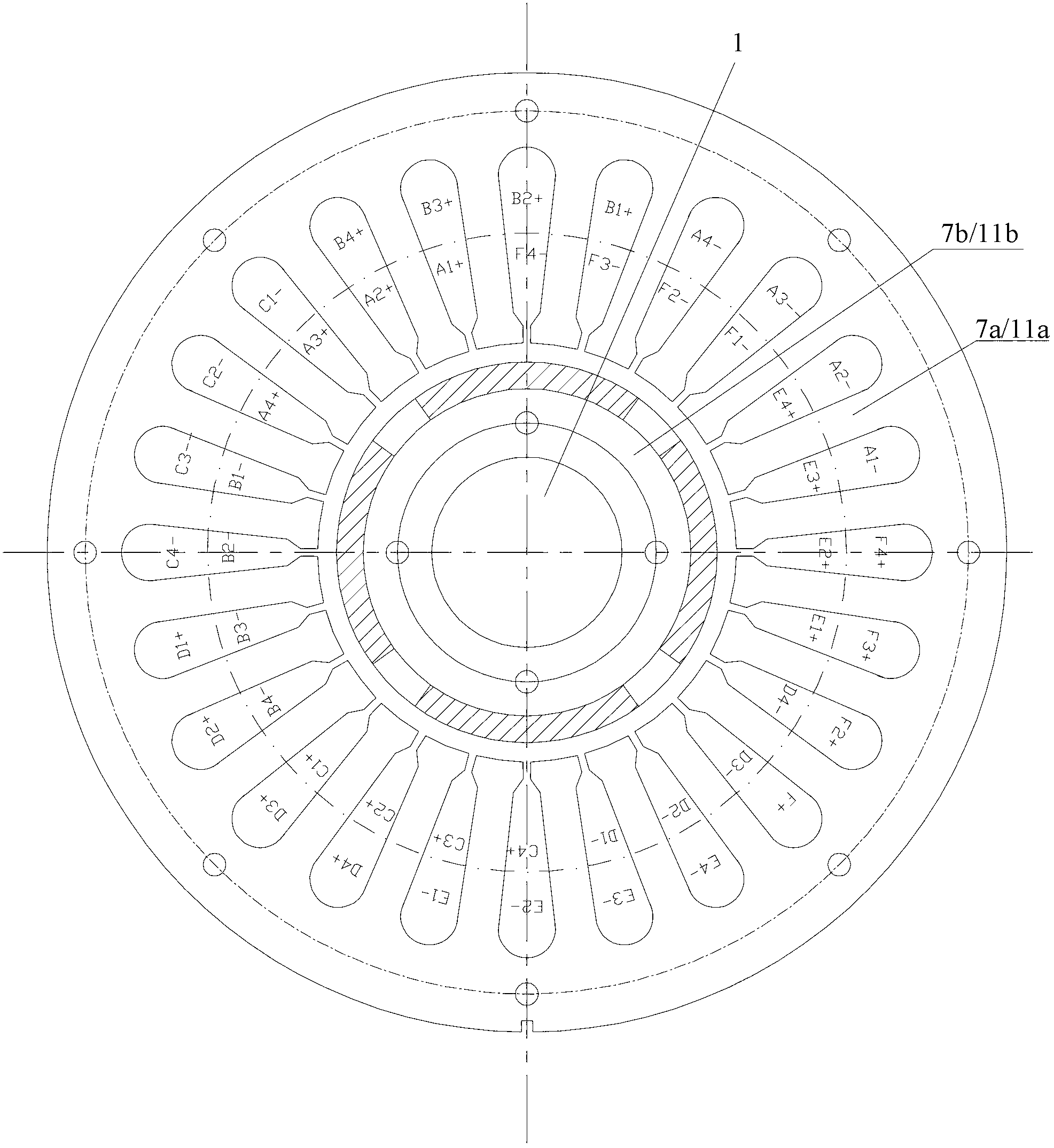

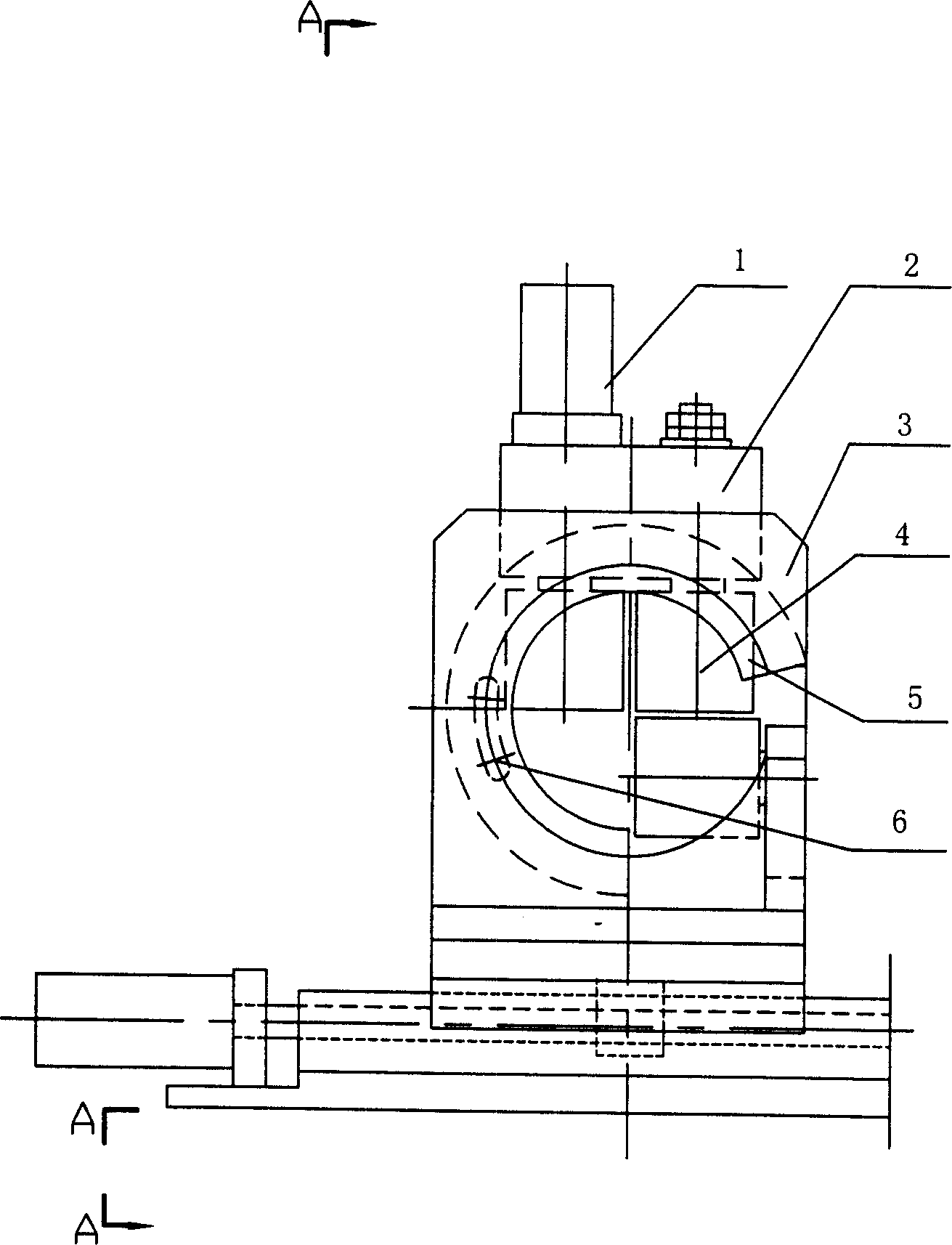

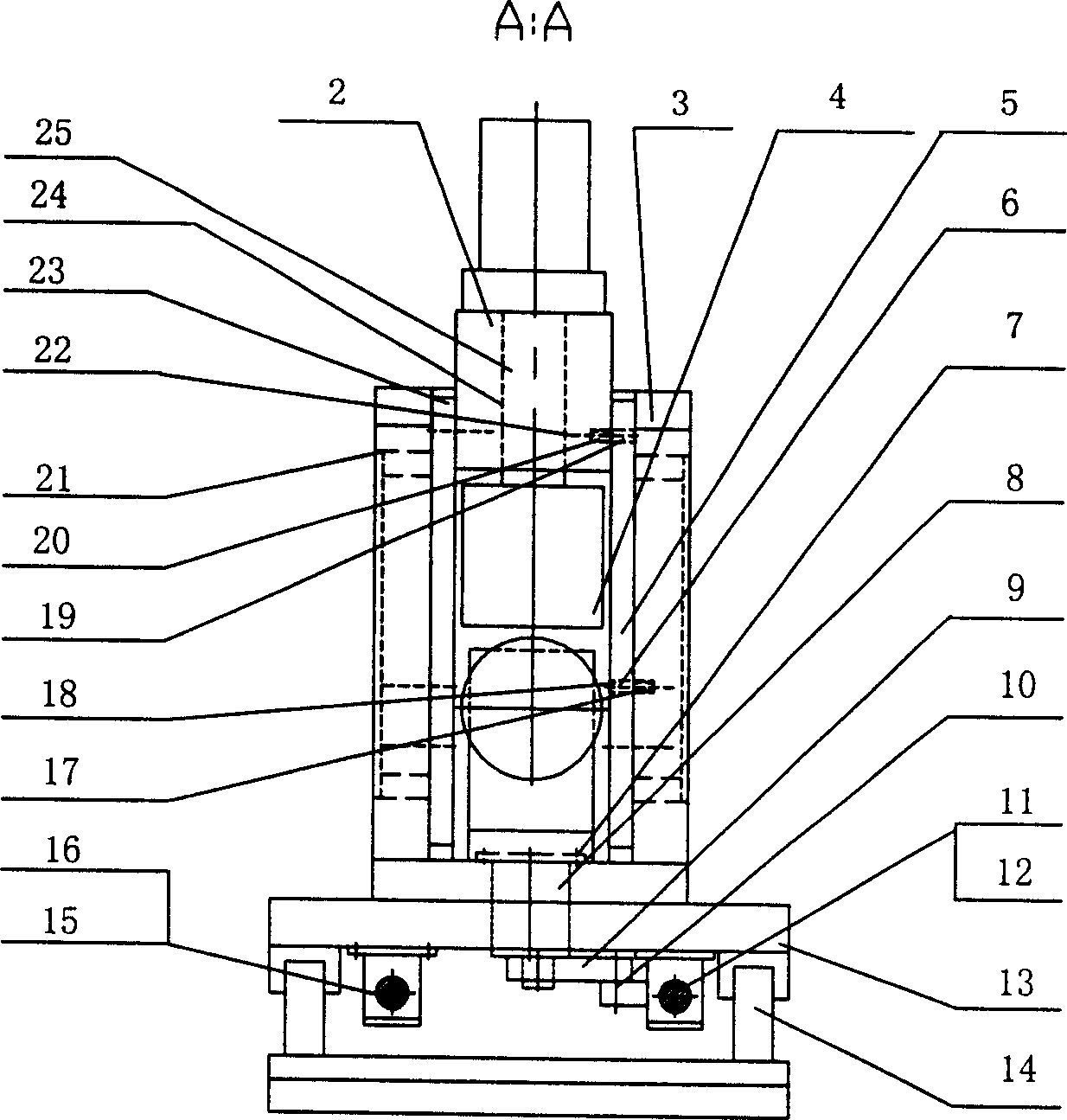

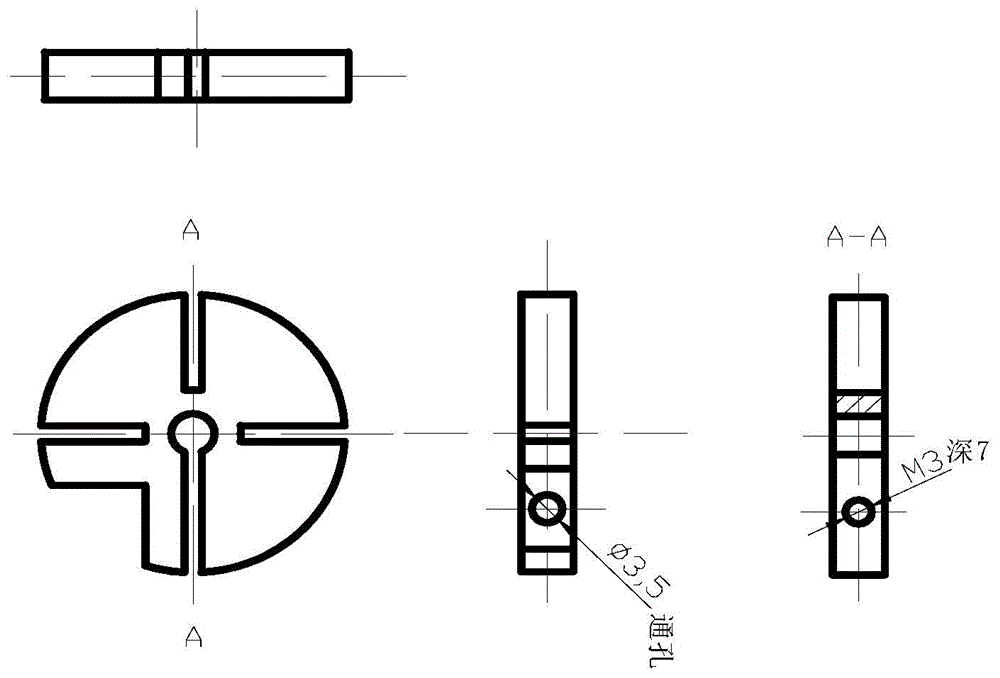

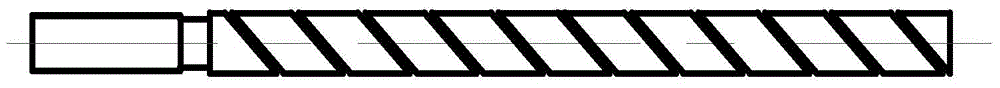

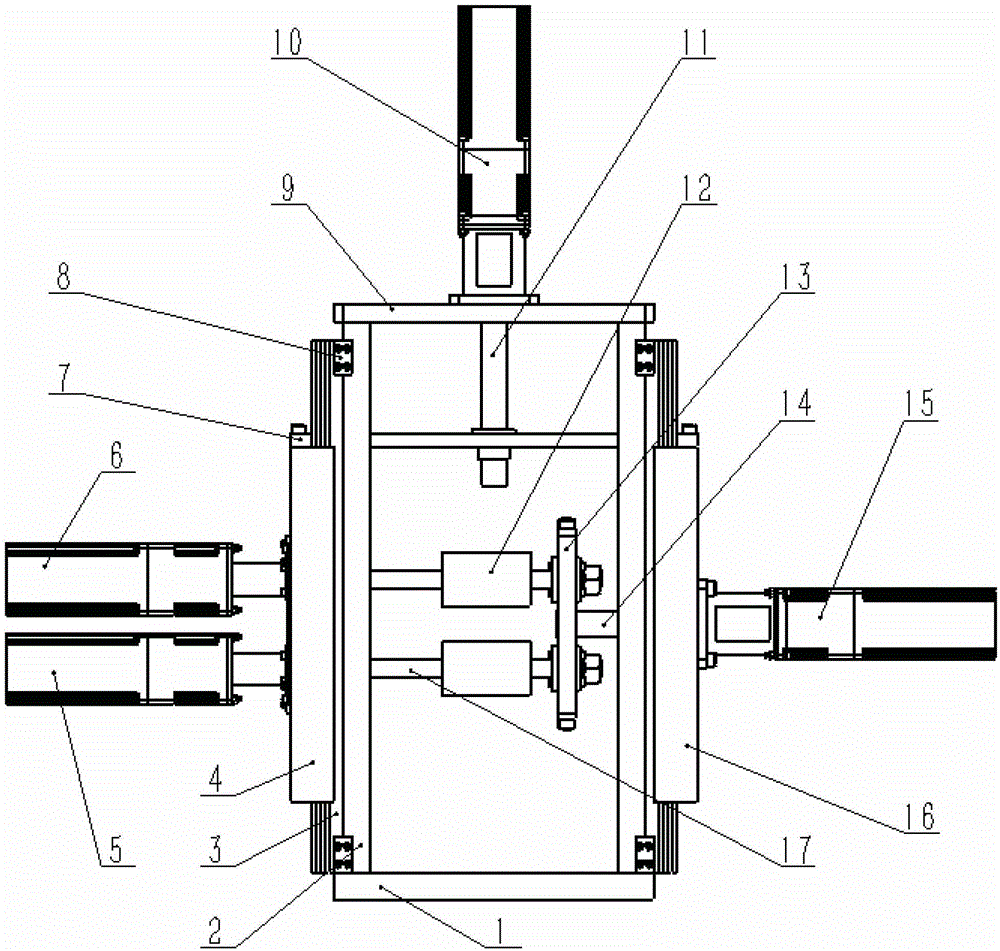

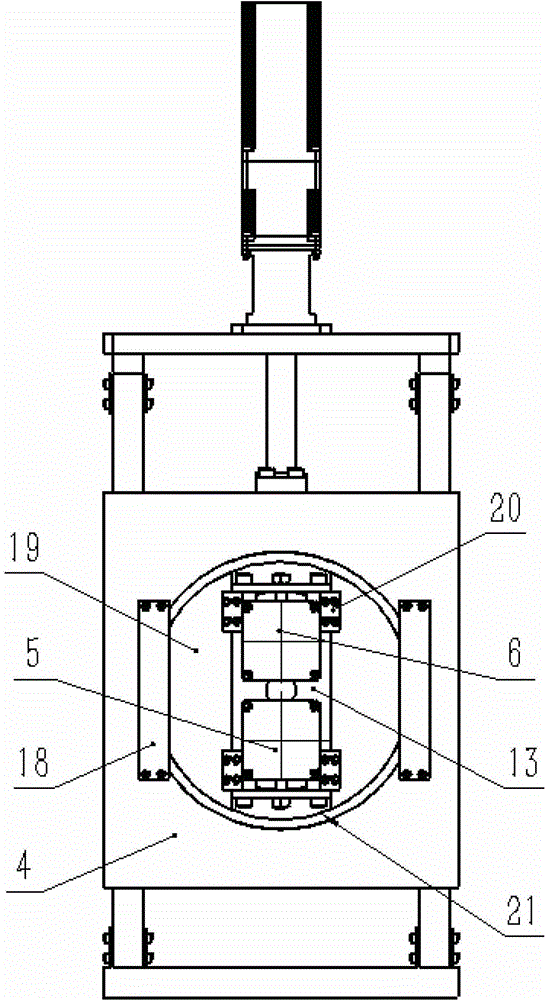

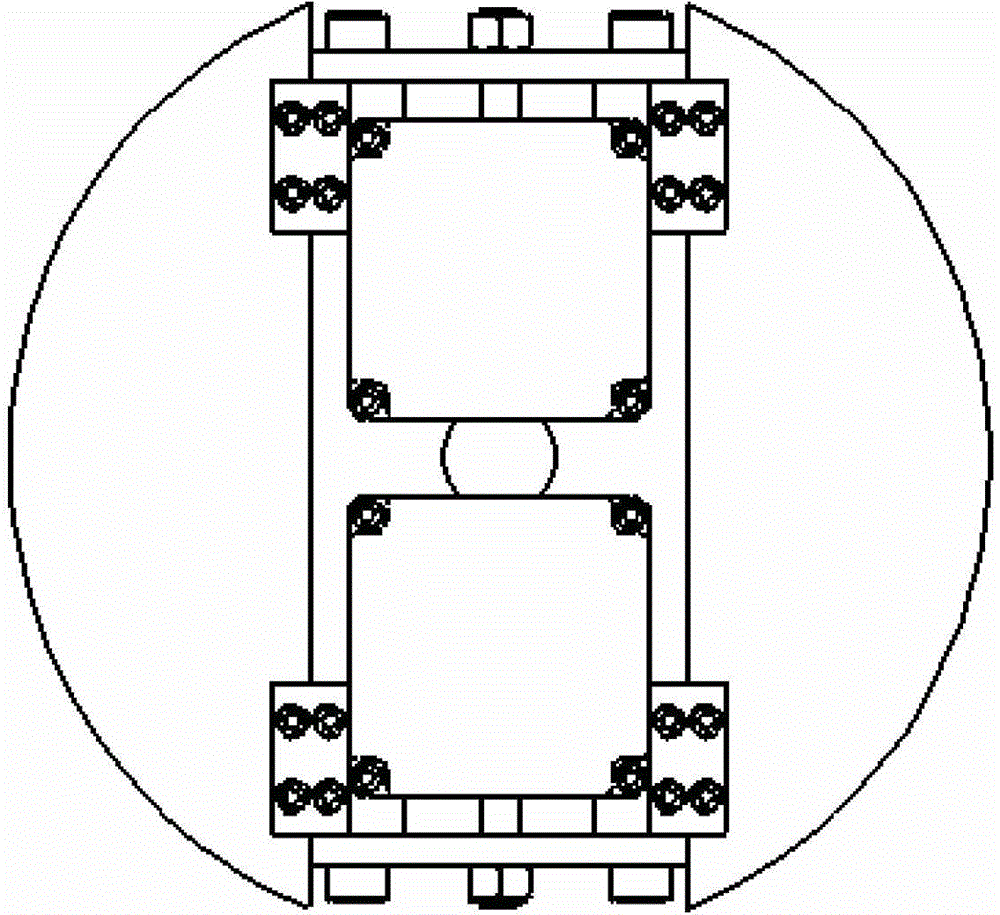

Modular self-adaptive regulation clamp to weld car and its regulating method

InactiveCN101104233AEasy to connectImprove flexibilityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSelf adaptive

The invention relates to a modularizing self-adaptation adjusting clamp used in the automobile welding, comprising a based station(1), a clamping mechanism(100) fixed on the based station(1) , an independent principal positioning mechanism(200), and an online real-time detecting and self-adaptation adjusting device(300). The online real-time detecting and self-adaptation adjusting device (300) is composed of a stepping motor (305), a slider (308), a straight-line guiding rail (309) and a transmission device. The transmission device, which is driven by the stepping motor (305), pushes a pushing rod (301) and the slider to slide along the straight-line guiding rail (309). The invention is more flexible and is convenient for the connection and combination of every component by means of modularized, standardized and serialized clamp elements, can be adapted to various work within a certain range and type, can effectively reduce the manufacturing cost, effectively controls the precision of the key points of workpieces and improves the welding quality and efficiency.

Owner:DONGHUA UNIV

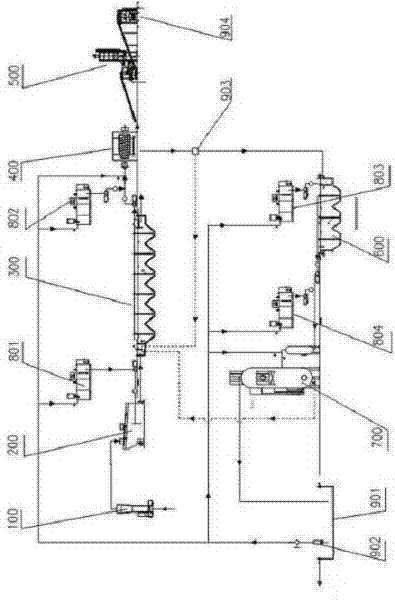

An integrated process of ecological dredging and sludge solidification and disposal

ActiveCN102267797AMeet the requirements of actual productionRich and perfect processing methodsSludge treatment by de-watering/drying/thickeningSludgeFirming agent

The invention discloses an integral process for ecologically desilting and curing sludge. The process comprises the following treatment steps of: I, absorbing riverbed sludge in an undistributed way; II, pretreating landed slurry based on high-frequency oscillation; III, decreasing and concentrating slurry-containing sewage while adding a flocculating agent A; IV, performing solid-liquid separation on the concentrated slurry, conveying the concentrated slurry in a decreasing and concentrating pond to a horizontal centrifuge, adding a flocculating agent B and centrifuging to obtain dehydrated slurry cakes; V, inputting the dehydrated slurry cakes into curing equipment, adding a curing agent to obtain cured sludge, introducing sewage drained from the centrifuge into an adjusting pond, adding a flocculating agent C, homogenizing, blending, elevating to a purifying tower through an elevating pump, and adding a flocculating agent D; and VI, making a purified liquid part drained from the purifying tower reflow for utilizing, and making precipitated concentrated slurry reflow to the decreasing and concentrating pond for retreating. The integral process has the advantages of high desilting efficiency, low cost, no secondary pollution, small floor area, and detachability and assembly for rapid transition.

Owner:中国船舶重工集团公司第七〇二研究所

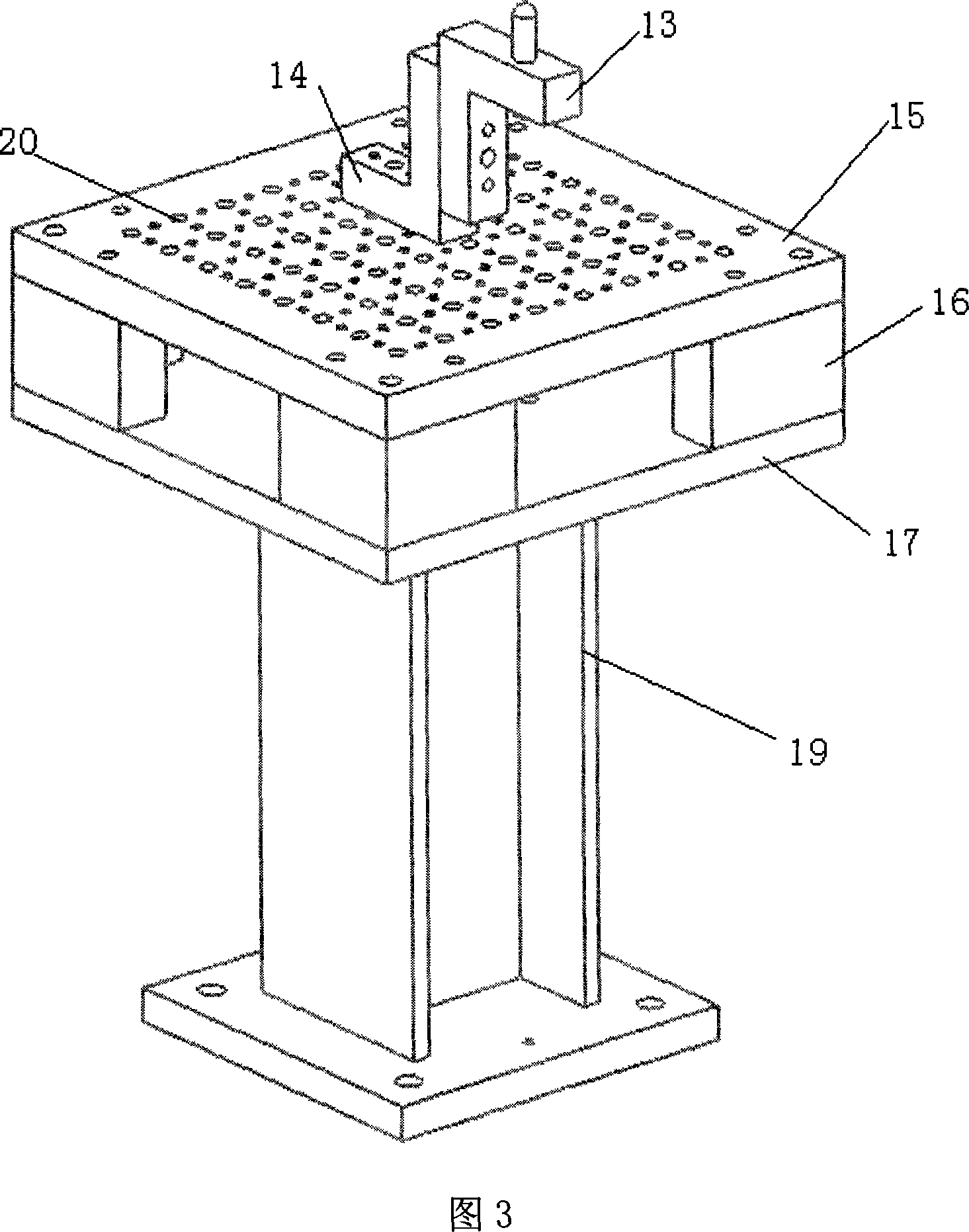

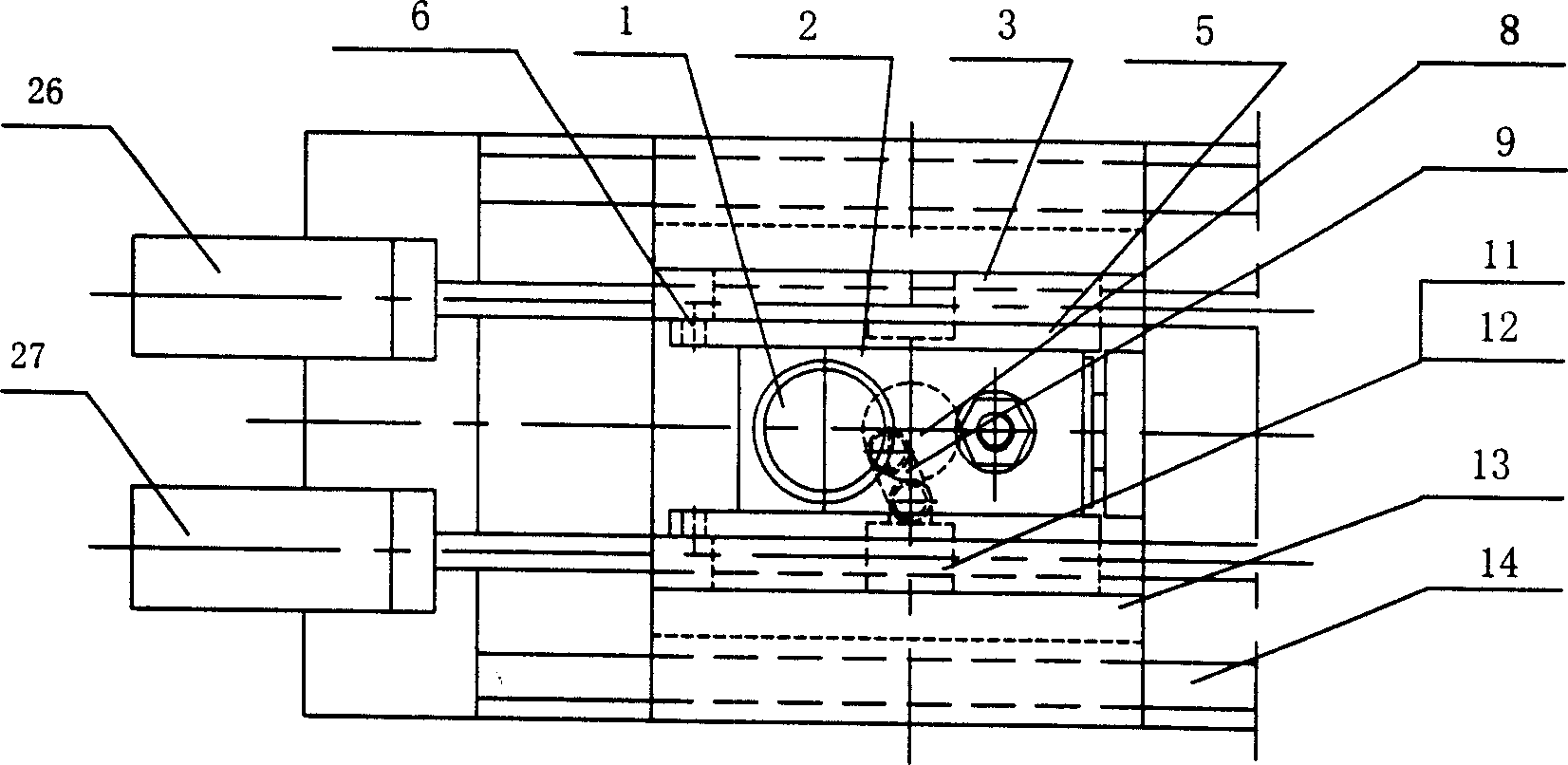

Flexible reconstruction automobile welding and assembling clamp

InactiveCN101053933AImprove flexibilityReduce manufacturing costWelding/cutting auxillary devicesAuxillary welding devicesAgricultural engineeringDesk

The present invention relates to a flexible reconfigurable automobile welding clamp comprising a base desk, a clamping mechanism and an independent main positioning mechanism. The present invention is characterized in that the clamping mechanism comprises an upright post, an inner sleeve, an outer sleeve, a L-shaped upright post, a flat plate connecting piece, a compacting block and a compacting connecting bar; the inner sleeve is fixed on the upright post; the outer sleeve is sheathed outside of the inner sleeve and the inner sleeve and the outer sleeve is adjustably connected with each other; the L-shaped upright post is fixed on the outer sleeve and is fixedly connected with the flat plate connecting piece on the side surface; the front end of the flat plate connecting piece is fixedly connected with the compacting block by the compacting connecting bar; the independent main positioning mechanism comprises a positioning piece, a middle transition piece, a L-shaped block, a flat plate provided with holes, a L-shaped connecting block and a flat plate; the flat plate provided with holes is fixedly connected on the flat plate by the L-shaped connecting block; the L-shaped block is connected with the flat plate provided with holes and is connected with the middle transition piece. The clamp of the present invention has a high flexibility, is adapted to a plurality of different workpieces, can be reconfigured rapidly, thereby the cost is reduced and the production efficiency is improved.

Owner:DONGHUA UNIV

Additive for reducing the content of coke tar and whitedamp in the cigarette smoke and method of use thereof

An additive capable of reducing tar and carbon monoxide contained in cigarette is provided, as well as the application method of the additive, which contains inorfil loaded with metal-salt. The accretion provided by the present invention prepared and added conveniently with low cost is suitable for requirement of industrialized production, capable of well decreasing the tar and carbon monoxide contained in cigarette smoke and greatly reducing the harm to the smoker.

Owner:CHINA TOBACCO HUNAN INDAL CORP

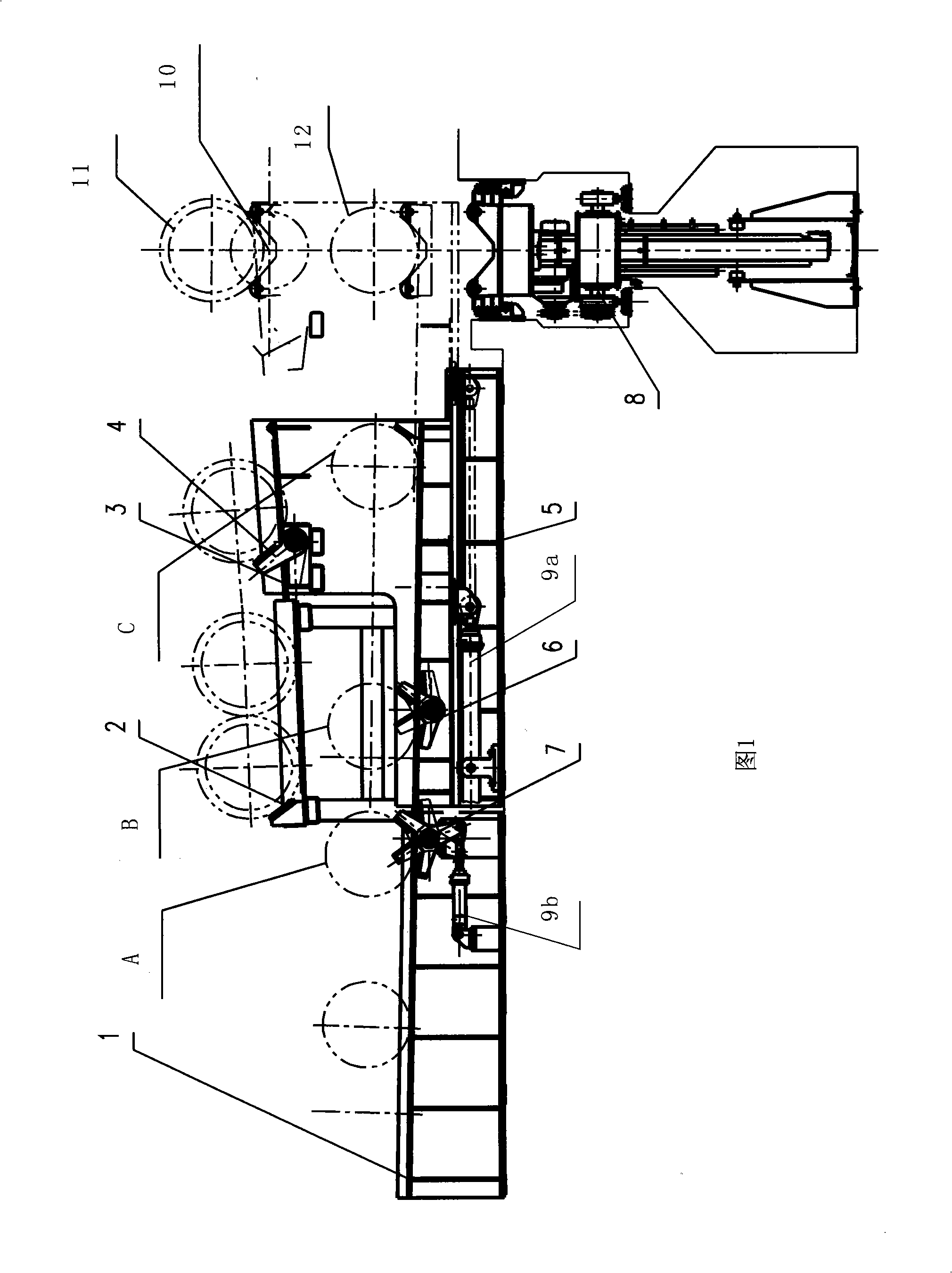

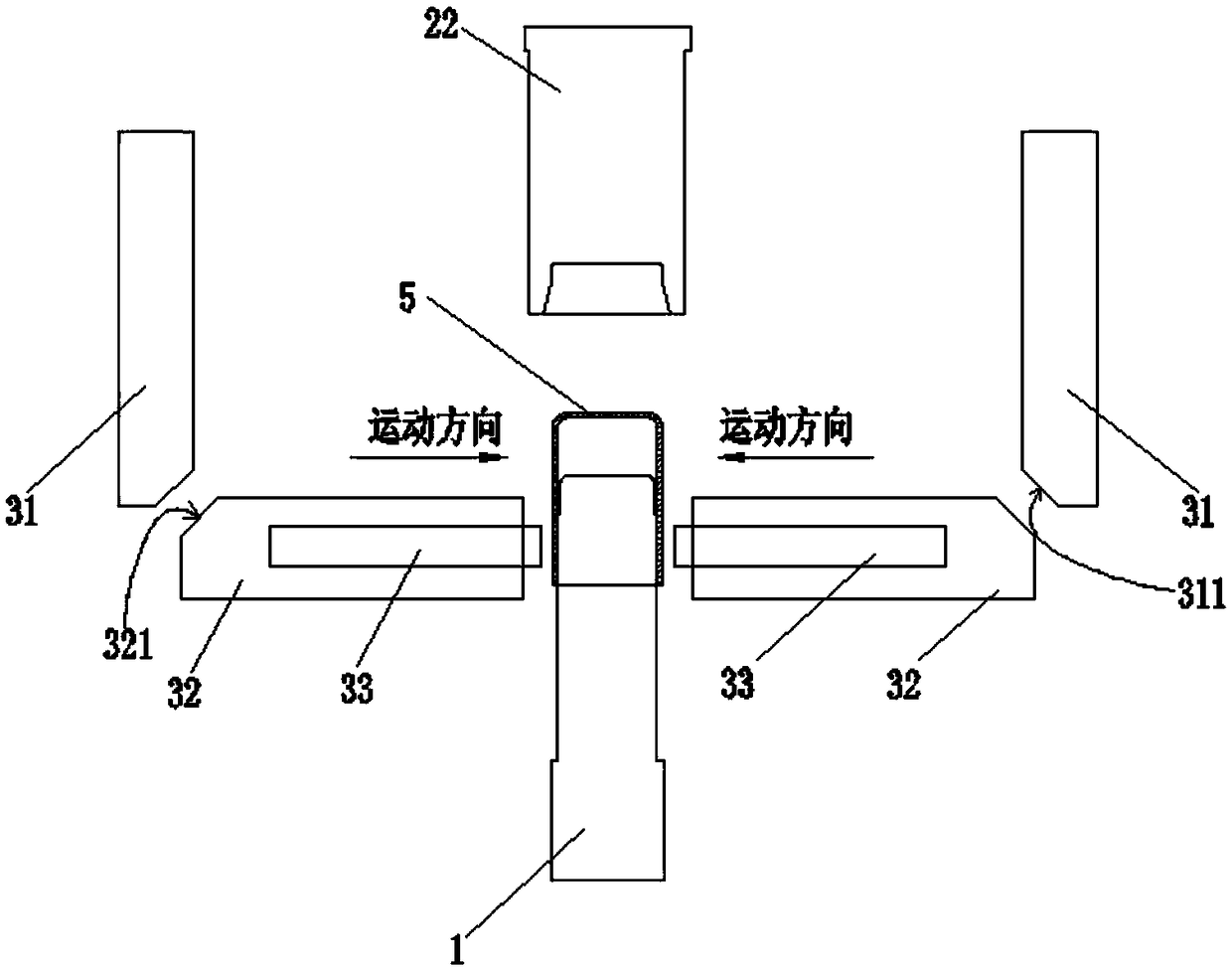

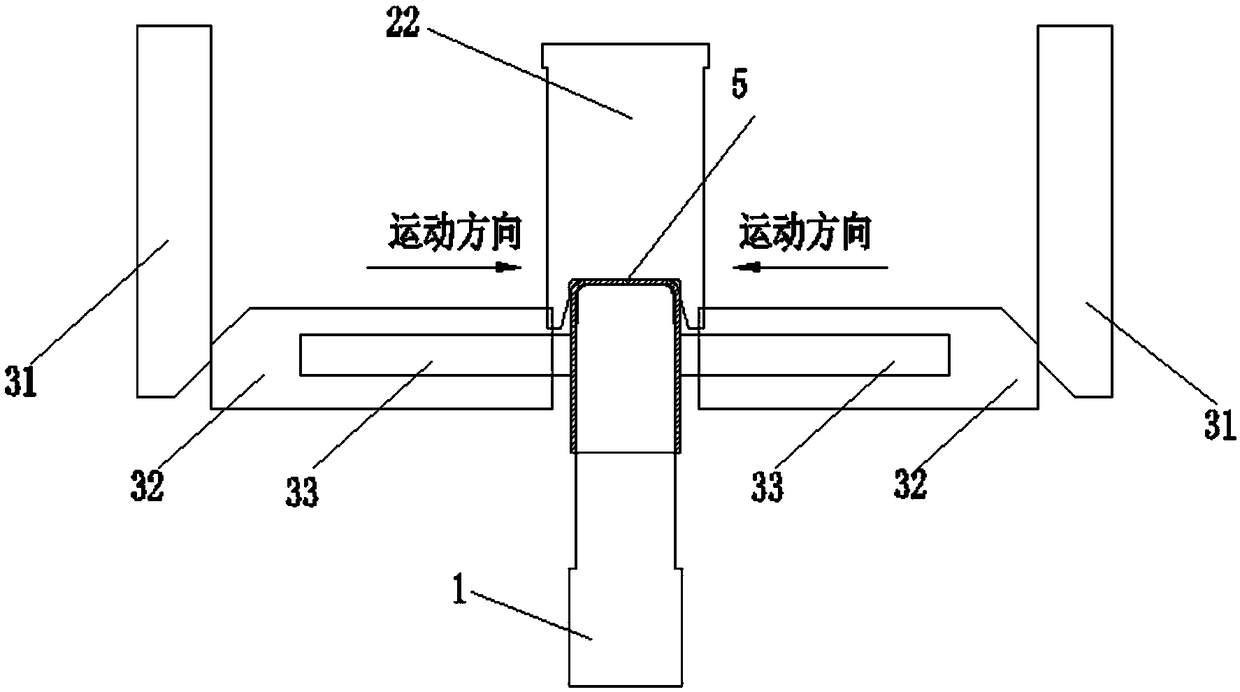

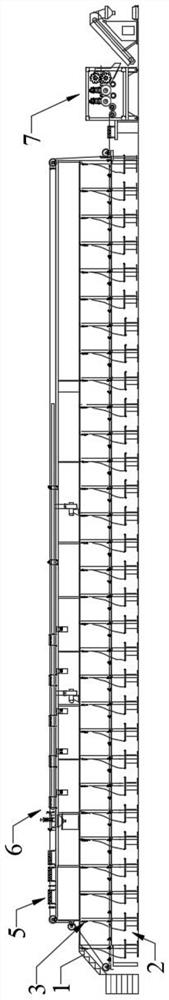

Novel method for discharging residual winding from sleeve barrel

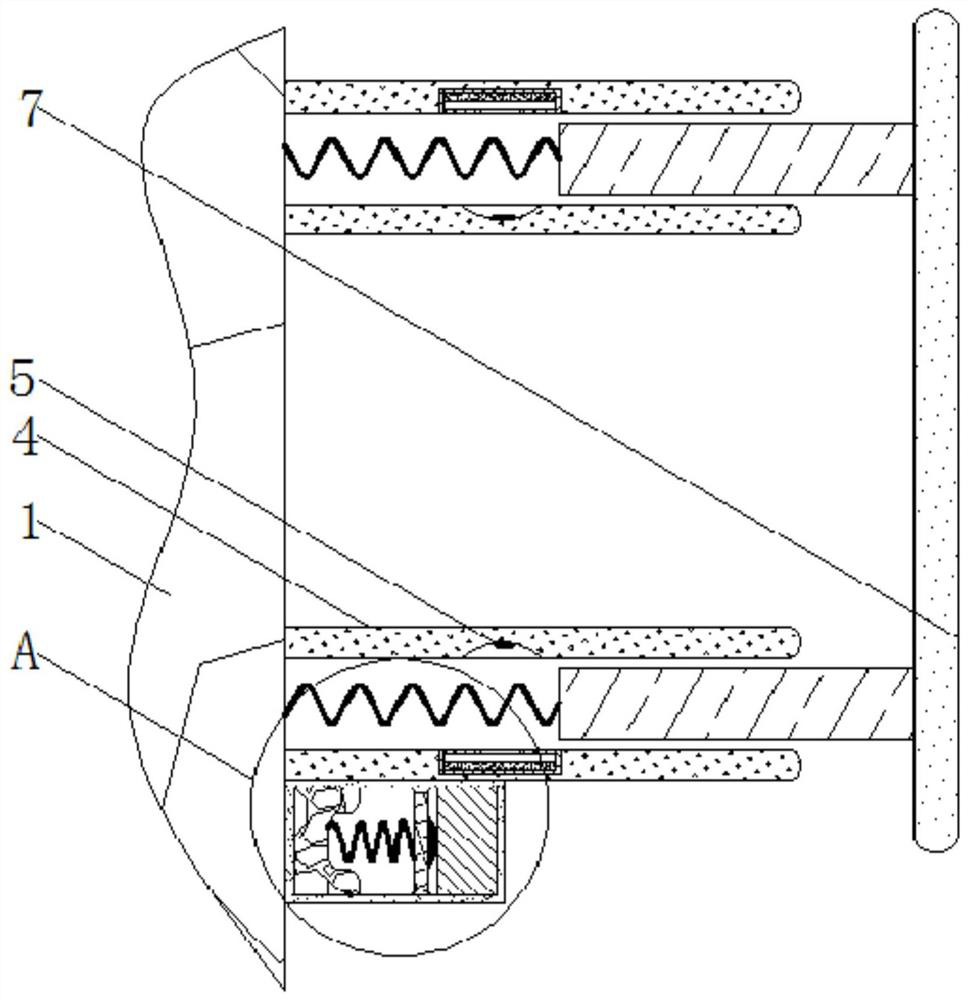

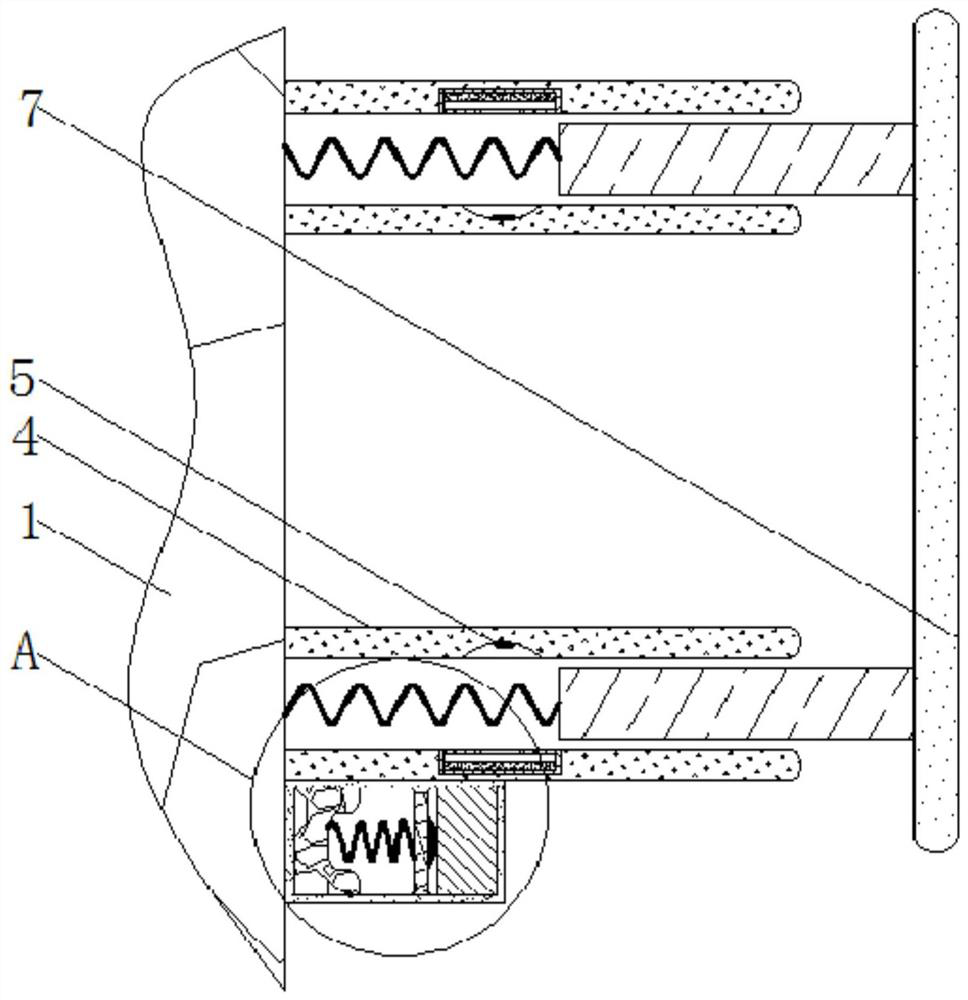

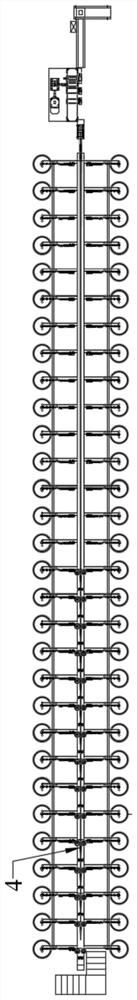

InactiveCN101402109AMeet the requirements of actual productionReduce manufacturing costBogieSmall footprint

The invention discloses a method for a novel upper-sleeve coil stripper, which integrates an upper sleeve device and a coil stripper device into a whole. The method is as follows: the lower layer of the novel upper-sleeve coil stripper is provided with the upper sleeve device; one end of the novel upper-sleeve coil stripper is provided with a fixed sleeve storage platform (1) and a coil stripper stacking frame (2); the sleeve storage platform is provided with a striking fork c(7) for striking a sleeve; the middle of the novel upper-sleeve coil stripper is provided with a movable slide block (3) which is double-layered; a misshapen coil can be temporarily placed on the upper layer of the slide block, and the sleeve can be temporarily placed on the lower layer of the slide block; striking forks are arranged on the upper layer and the lower layer of the slide block respectively; the other end of the upper-sleeve coil stripper is provided with a coil stripping bogie (8); and the bottom of the slide block is slidably connected with a pedestal (5). The work flow of the novel upper-sleeve coil stripper is as follows: the coil stripping bogie (8) unloads the misshapen coil from a coiler (10); the slide block (3) moves to place the misshapen coil on the upper layer of the slide block; a striking fork b of the slide block strikes the sleeve (12) which is placed on the lower layer of the slide block from the B position to the C position; and the coil stripping bogie (8) moves upwards to support the sleeve. The method can well solve the problems, and has low manufacturing cost, small floor space, and short auxiliary time during the production process.

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD

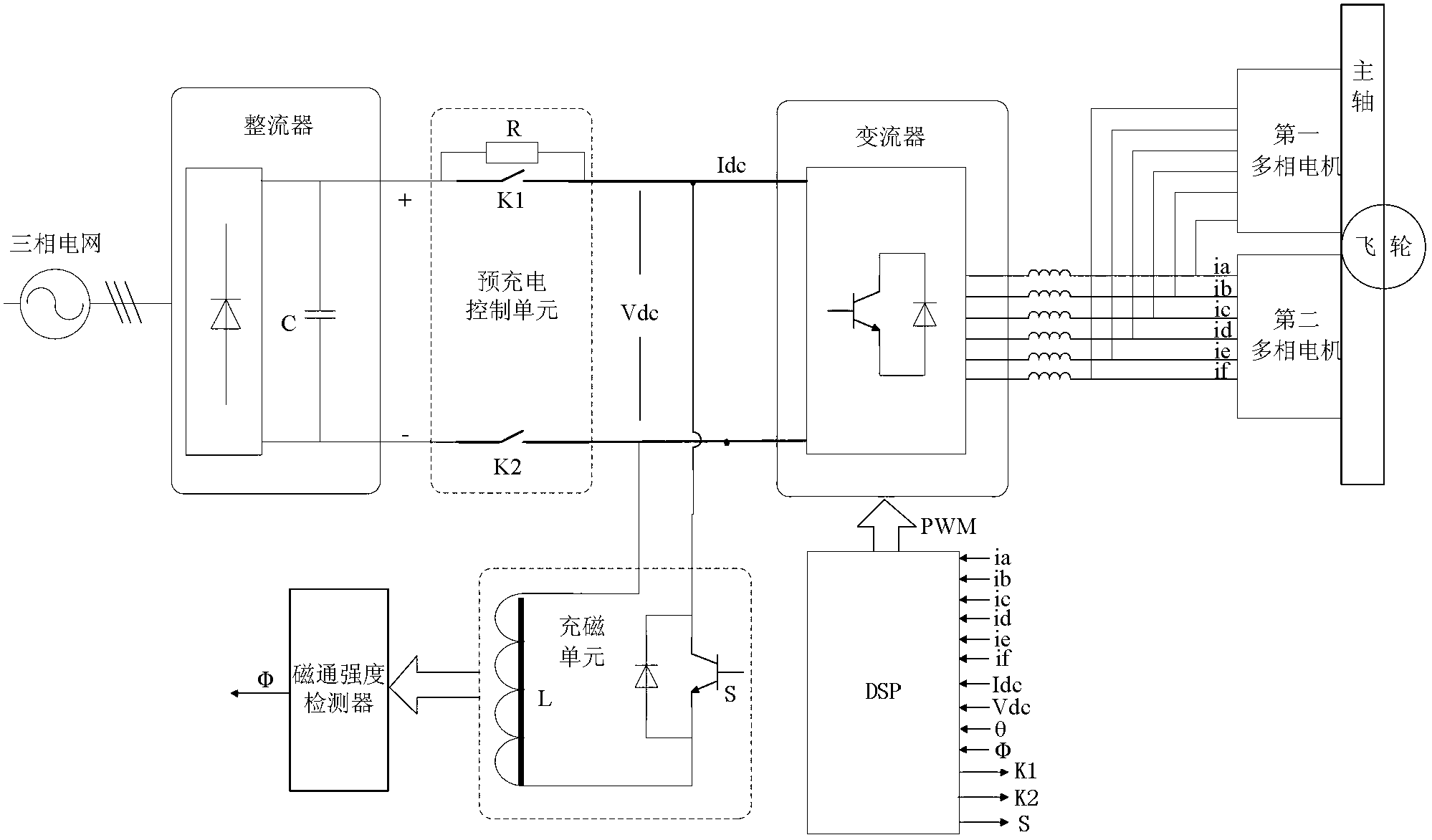

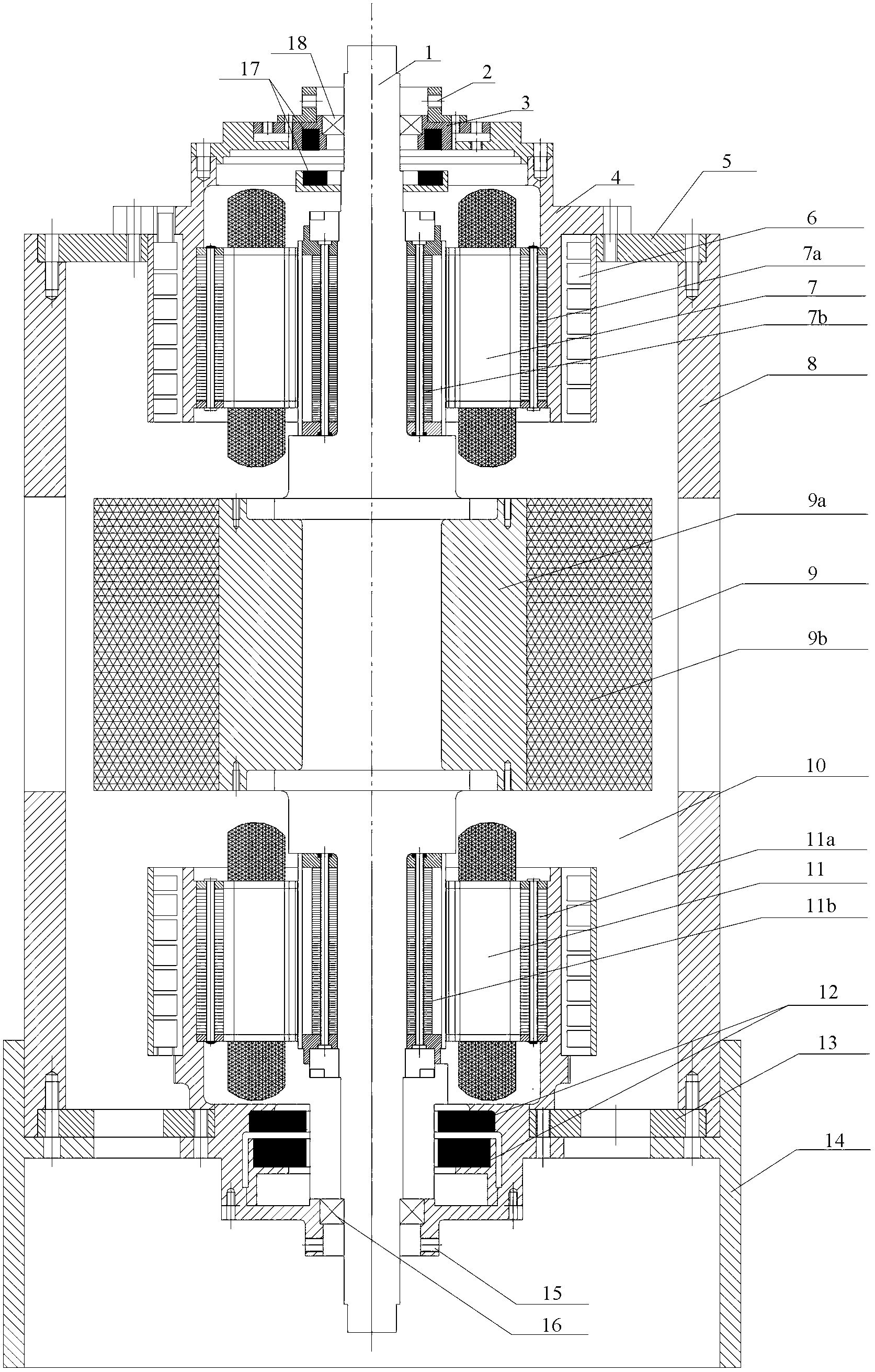

Magnetizing apparatus on basis of flywheel energy storage

ActiveCN103065763AWill not polluteImprove power densityMagnetic bodiesApparatus with intermediate ac conversionCapacitanceFlywheel energy storage

The invention discloses a magnetizing apparatus on the basis of flywheel energy storage. The magnetizing apparatus comprises an energy storage unit and a magnetizing unit; and the energy storage unit is a flywheel energy storage device comprising a rectifier, a converter, a controller, a motor unit and a flywheel mechanism. A flywheel energy storage technology and a magnetizing apparatus technology are combined with each other, the flywheel energy storage device is used as a high-power pulse discharge power supply and provides energy to the magnetizing unit, and obvious characteristics of high power density, long service life, capability of preventing environmental pollution and the like of a flywheel when the flywheel is used as an energy storage element are sufficiently played. Compared with the traditional capacitance magnetizing apparatus, the magnetizing apparatus has the advantages that the magnetizing apparatus is high in number of charge-discharge, long in service life and low in cost, is efficient and effectively meets requirements of actual production, and the charge-discharge time is short.

Owner:ZHEJIANG UNIV

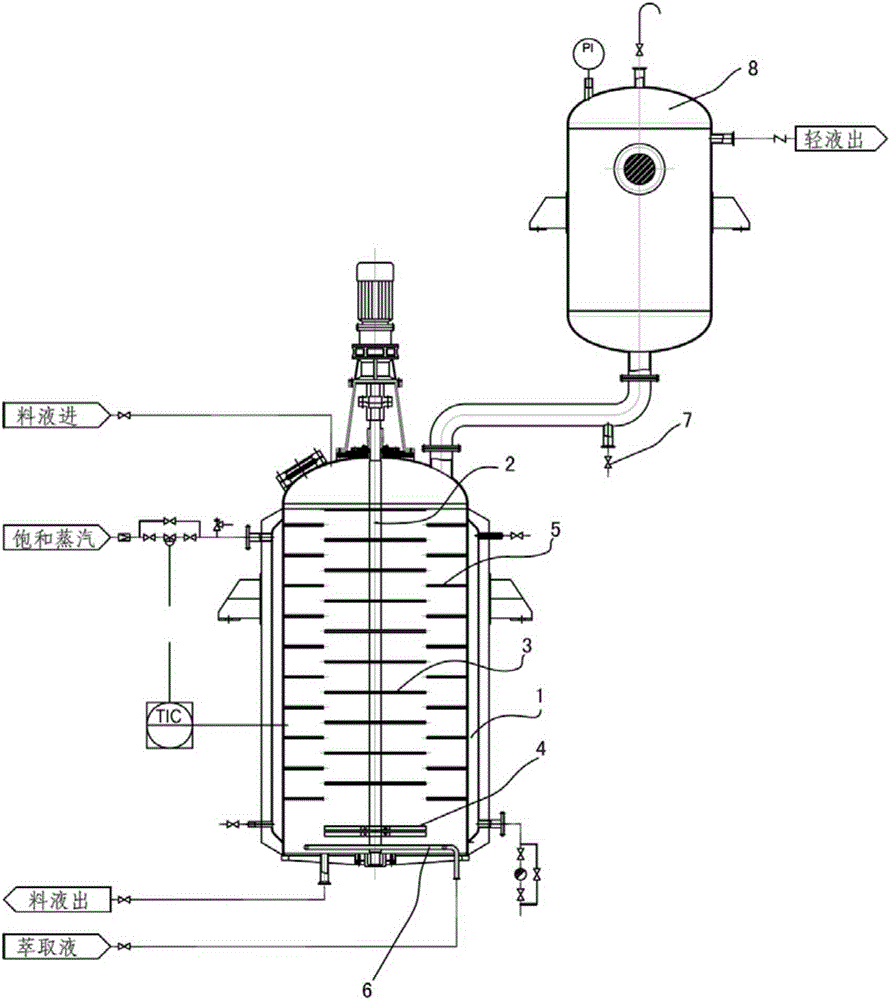

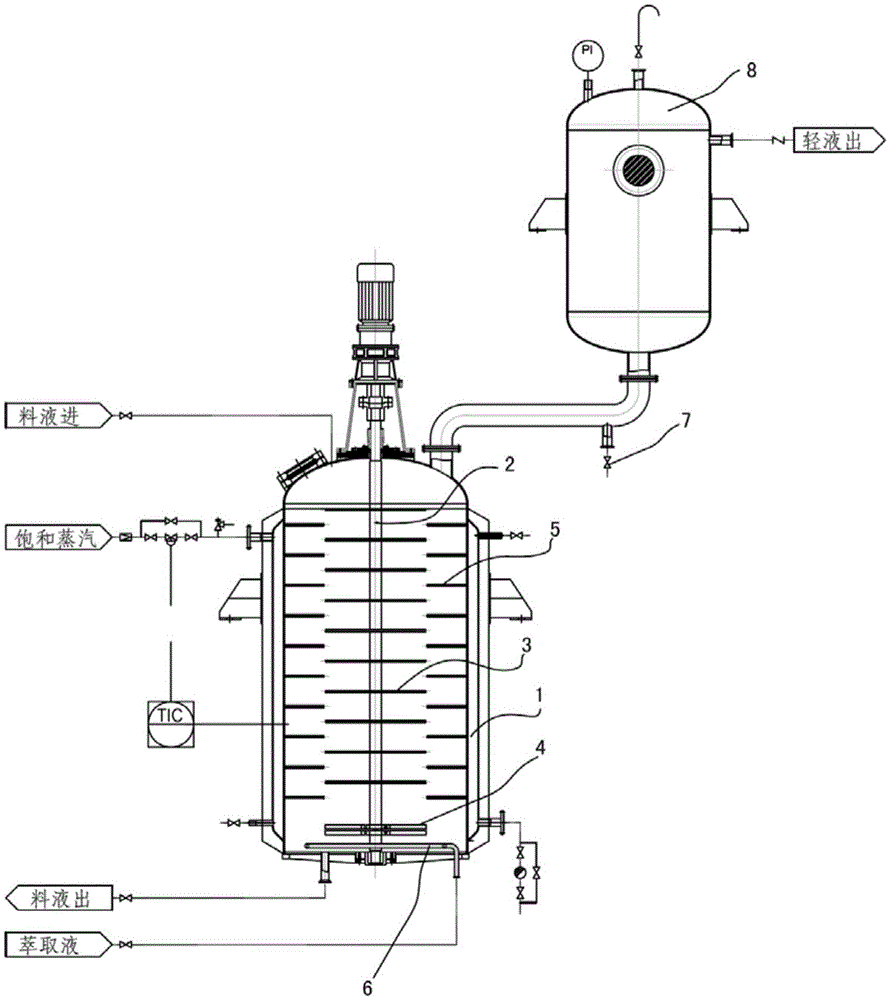

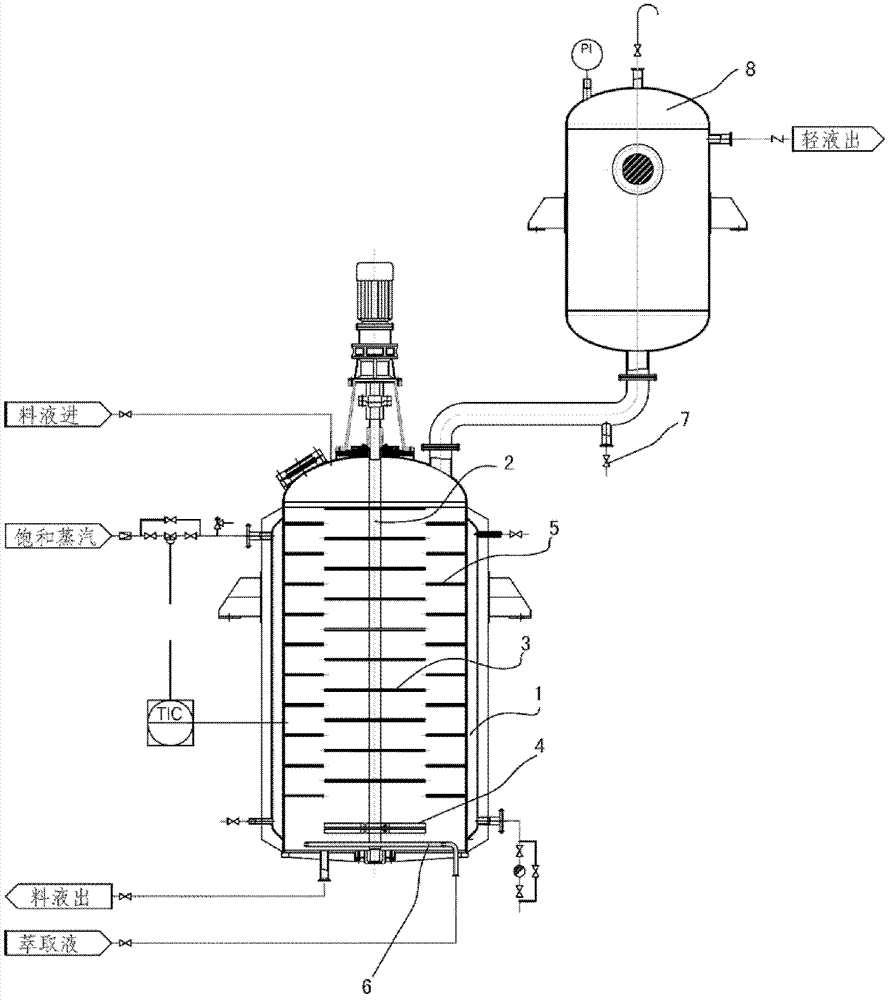

Method for extracting rare earth elements and rare earth extraction system

InactiveCN102936664AReduce dosageImprove work efficiencyProcess efficiency improvementRare-earth elementSolvent

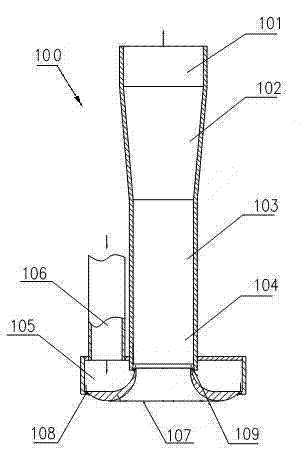

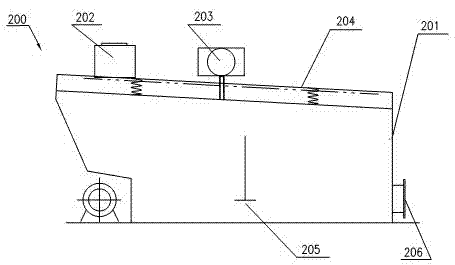

The invention relates to a method for extracting rare earth elements and a rare earth extraction system. The method comprises the following steps: inputting quantitative water solution or suspension, as heavy liquid, of rare earth elements into an extraction tank via a heavy liquid inlet at the top of the extraction tank; starting a stirring shaft; filling an extraction solvent as light liquid into the extraction tank uniformly from a liquid distributor at the bottom of the extraction tank, ensuring step-by-step mixing and mass transfer from bottom to top between the light liquid and the heavy liquid in the stirring process and enabling the light phase liquid completing mass transfer to overflow into a decanting tank from the top of the extraction tank; after the light phase liquid is decanted in the decanting tank, discharging the light components via a light liquid outlet at the top of the decanting tank; judging whether extraction is completed by detecting the concentrations of the needed rare earth elements in the light component solution discharged from the decanting tank; after extraction is completed, stopping input of the light liquid and starting an emptying valve below the decanting tank to empty the decanting tank; and discharging the heavy liquid in the extraction tank via a heavy liquid outlet at the bottom of the extraction tank.

Owner:陆文光

Dual-shaft variable-section roll-bending shaping machine

InactiveCN1850388AMeet the requirements of actual productionRealize the forming requirements of longitudinal variable sectionElectric machineryRoll forming

The present invention discloses a double-shaft variable cross-section roll forming machine. It includes machine seat, motor connected on the machine seat, guideway and driving mechanism connected between the machine seat and guideway for making the machine seat be turned around vertical direction and driving mechanism for making the machine seat be horizontally moved. Said roll forming machine can be used for manufacturing parts and members in the fields of car and building material.

Owner:NORTH CHINA UNIVERSITY OF TECHNOLOGY

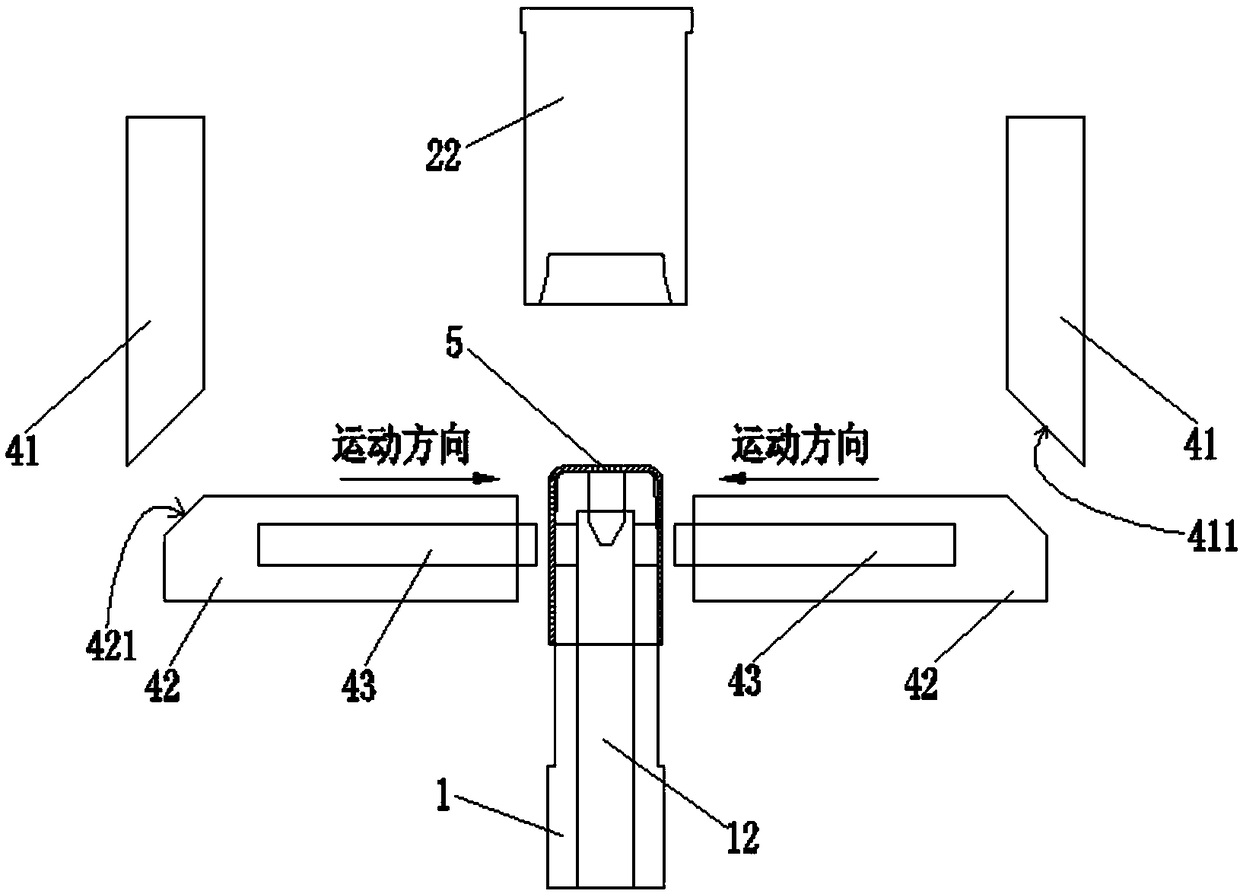

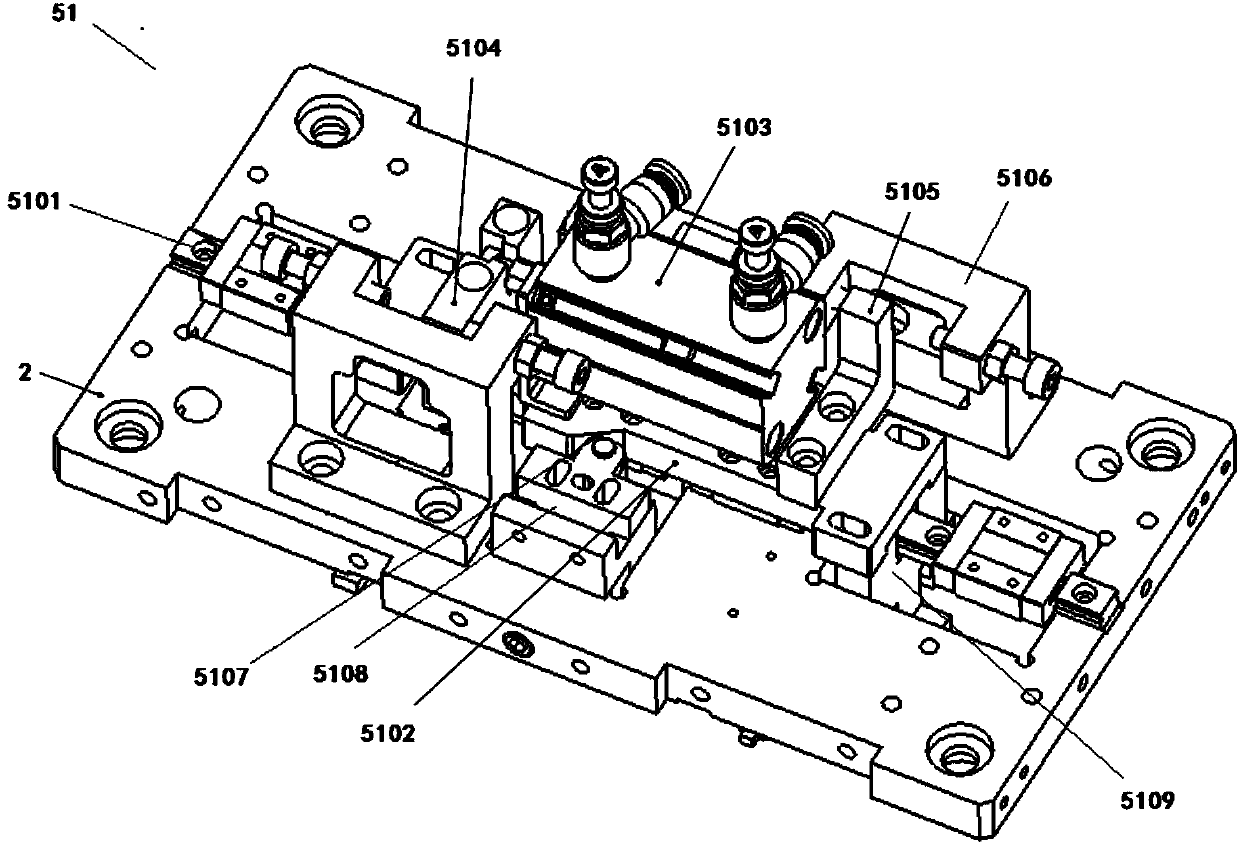

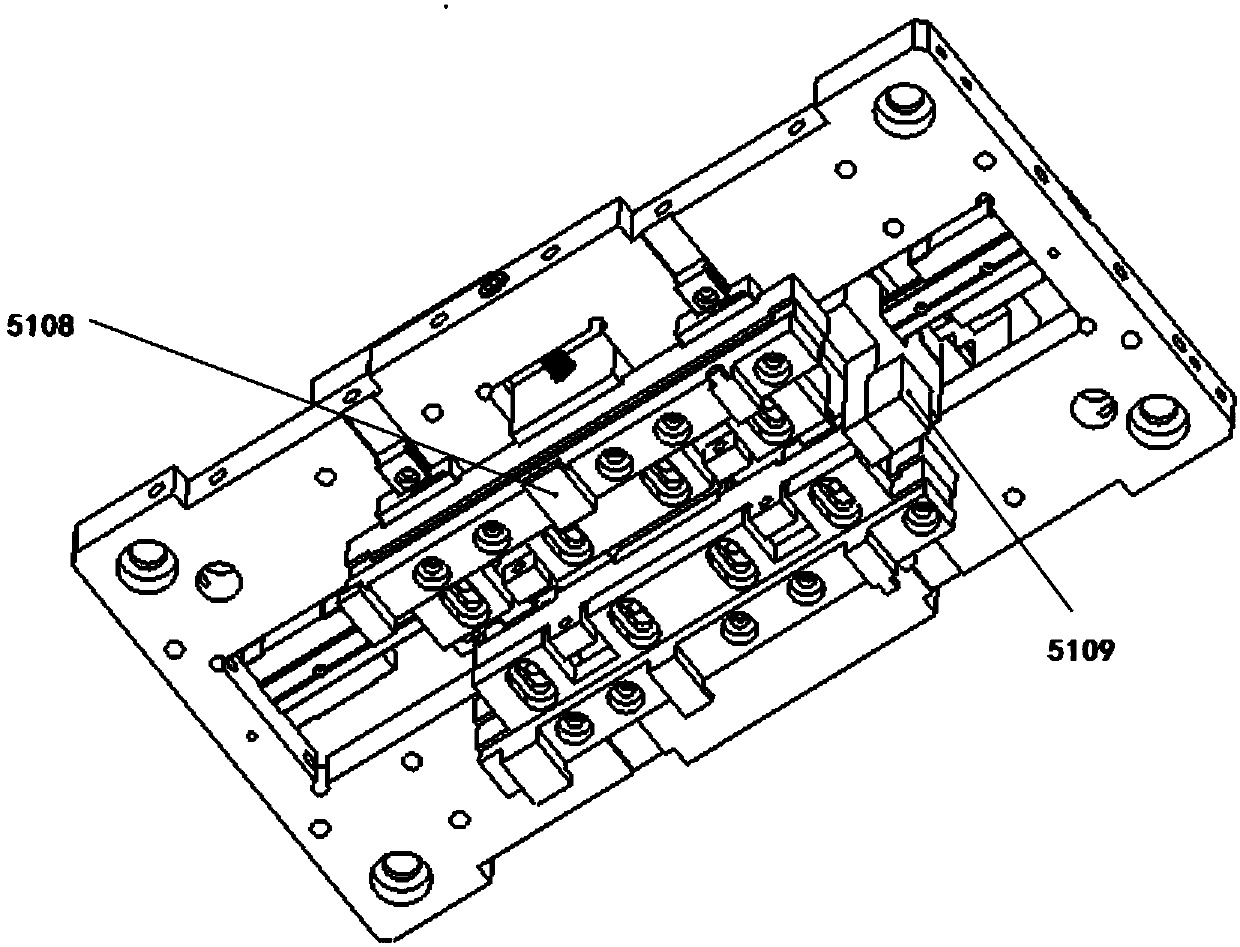

Side punching and balancing mechanism and side punching method for automobile vehicle-mounted power source shell type parts

ActiveCN109290427AGuaranteed not to shiftGuaranteed accuracyPerforating toolsEjection devicesPunchingLocking mechanism

The invention discloses a side punching and balancing mechanism and a side punching method for automobile vehicle-mounted power supply shell type parts. The mechanism comprises a lower mold base, a lower mold base balance locking mechanism and a side punching mechanism, wherein the shell type parts are arranged on the lower mold base in a sleeve mode, and the side surface of the lower mold base isprovided with a punching concave portion; the lower mold base balance locking mechanism is used for fixing the lower mold base; and the side punching mechanism is used for carrying out side punchingon the shell parts pressed on the lower mold base. According to the mechanism, the side punching and balancing mechanism is additionally provided with the lower mold base balance locking mechanism, and the lower mold base is fixed through the lower mold base balance locking mechanism, when the side punching mechanism is used for carrying out side punching on the shell type parts, the lower mold base can be ensured not deviated, shaken and inclined after being stressed, and the vertical direction is kept; the roundness of the side punching circular holes is guaranteed, and the precision of thespecial-shaped holes is guaranteed; and the the lower mold base is stably arranged, the service lives of the lower mold base and a male mold can be guaranteed, the punching smoothness is guaranteed, the production efficiency is improved, punching burrs of products are reduced, and the product quality is improved.

Owner:CHANGZHOU GONGLI SEIKI TECH

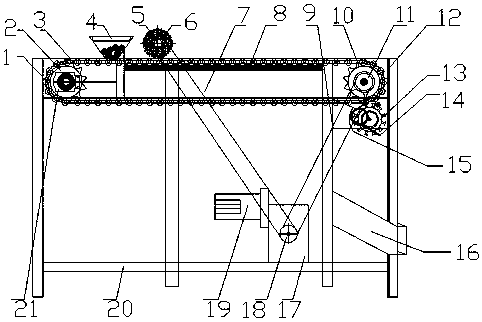

Hawthorn fruit slicing device

InactiveCN108556030ASimple and safe operationGuaranteed uptimeMetal working apparatusSide chainWire cutting

The invention discloses a hawthorn fruit slicing device, which comprises a machine frame, a feeding mechanism and a cutting device, wherein a chain wheel is arranged at each of two sides of the upperend of the machine frame; a transmission chain is in transverse horizontal arrangement; the transmission chain is mutually engaged with the left and right chain wheels; a roller is arranged on the transmission chain; a friction plate is arranged on the lower surface of the upper side chain wheel; the friction plate is in contact with the roller; the top of the machine frame is provided with a feeding hopper; a hair brush belt wheel is also arranged on the top of the machine frame; a rolling hair brush is arranged on the hair brush belt wheel; the right side chain wheel drives a cutter groove type feeding disc to rotate through an engaging gear; a fixed steel wire cutting cutter is arranged on the cutter groove type feeding disc; a motor is arranged at the bottom of the machine frame; the motor is connected with a speed reducer; a belt wheel is arranged on the speed reducer; the belt wheel drives the hair brush belt wheel and the right side chain wheel to rotate through two synchronousbelts. The hawthorn fruit slicing device has the advantages that the operation is safety; the operation is reliable; the practical production requirements can be completely met.

Owner:HUZHOU GAOYUANJIN MACHINERY

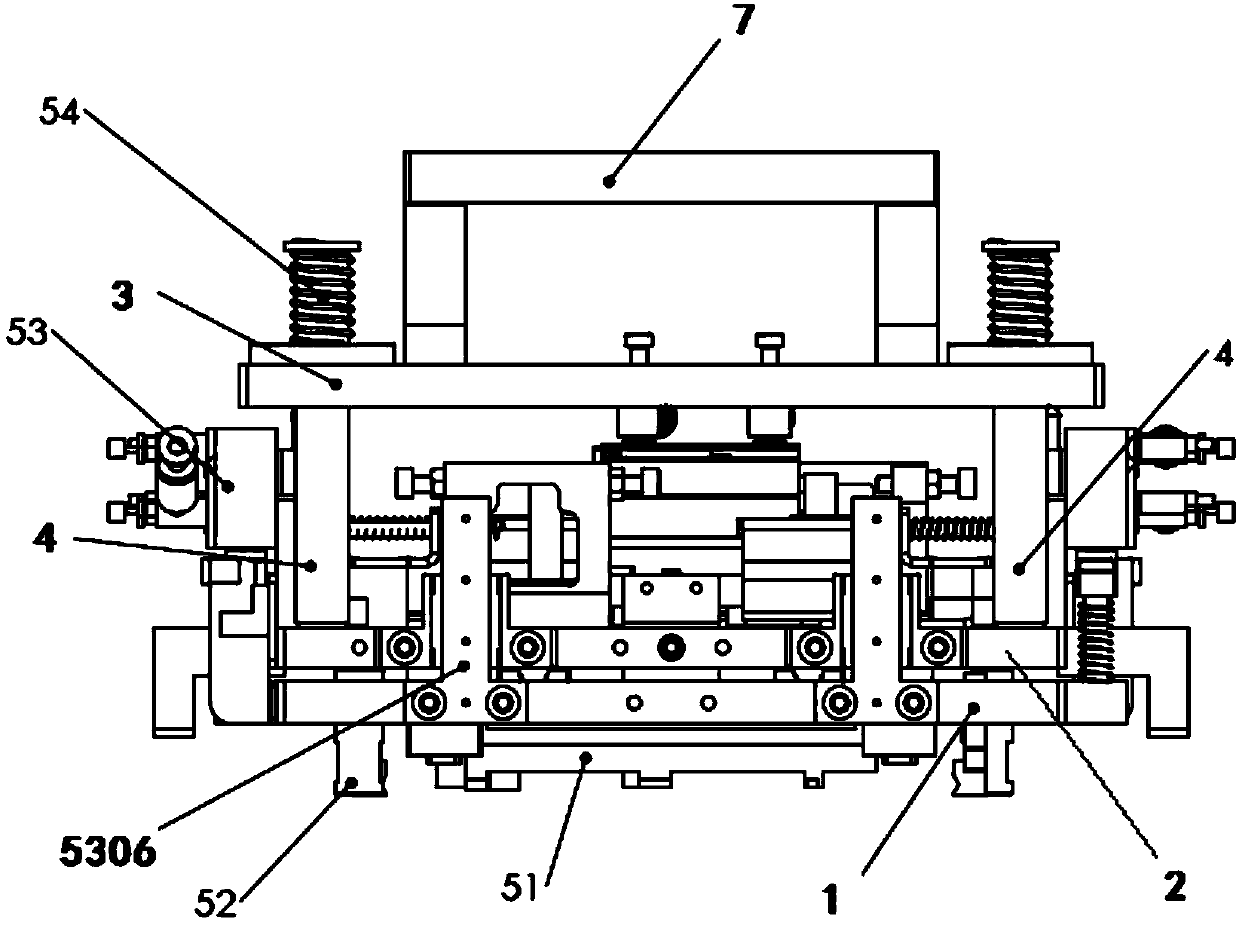

Transplanting and reclaiming device capable of internally supporting and externally clamping materials

PendingCN107826739AImprove reliabilityCompact structureConveyor partsEngineeringMechanical engineering

The invention discloses a transplanting and reclaiming device capable of internally supporting and externally clamping materials. The device comprises a lower fixing plate, an installing plate and anupper fixing plate. A horizontally arranged guide rail is arranged on the installing plate; a sliding block is fixed onto the guide rail; a first air cylinder is arranged on the sliding block; obliqueplanes are arranged on two sides of the sliding block; internal supporting parts are arranged on positions, corresponding to the oblique planes, on the installing plate; connecting blocks are arranged on two horizontal ends of the installing plate; sliding blocks are further arranged on two horizontal ends of the guide rail; blocking parts are fixed onto the sliding blocks; clamping jaws are arranged under the blocking parts; elastic elements connected with the connecting blocks and used for enabling the clamping jaws to move along the guide rail are arranged above the blocking parts; and second air cylinders opposite to actions forces of the elastic elements are further arranged on one sides, far away from the connecting blocks, of the blocking parts. According to the transplanting and reclaiming device capable of internally supporting and externally clamping the materials provided by the invention, materials are transplanted from one station to the other station through an internally supporting and externally clamping way, so that the reliability in reclaiming products is greatly improved, and the device has the advantages of compact structure, low manufacturing cost, safety andreliability, and meets the requirement of actual production.

Owner:苏州华智诚精工科技有限公司

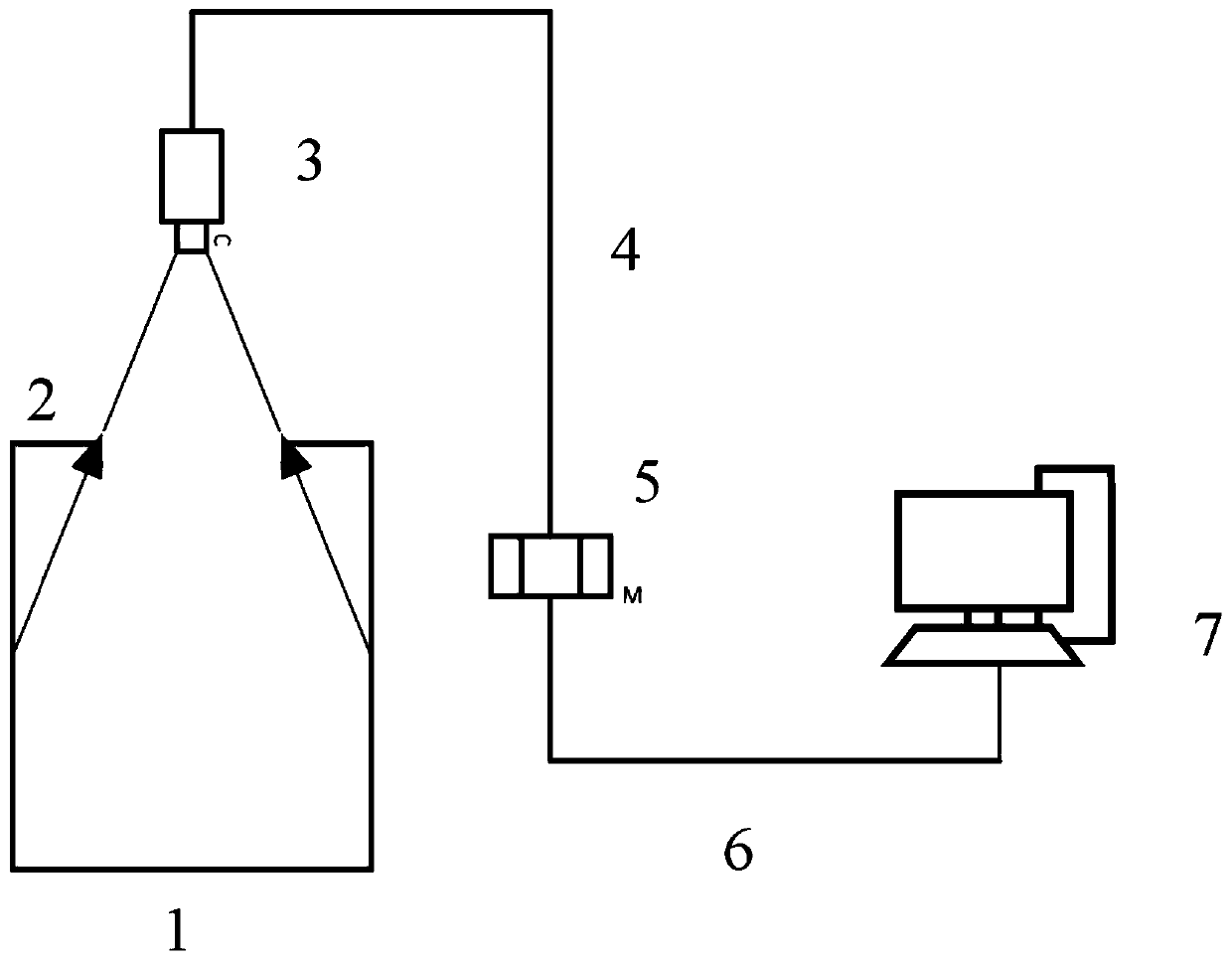

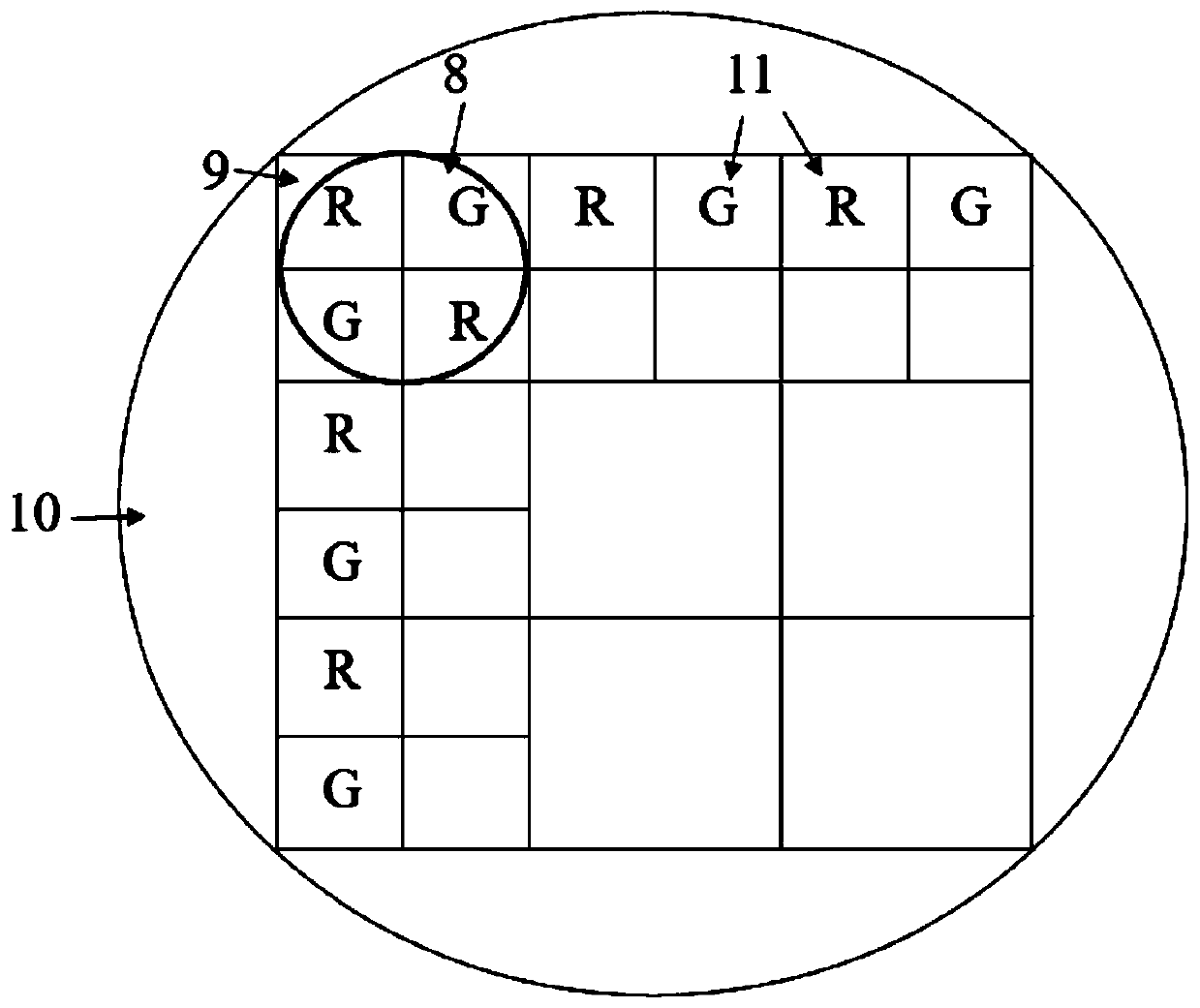

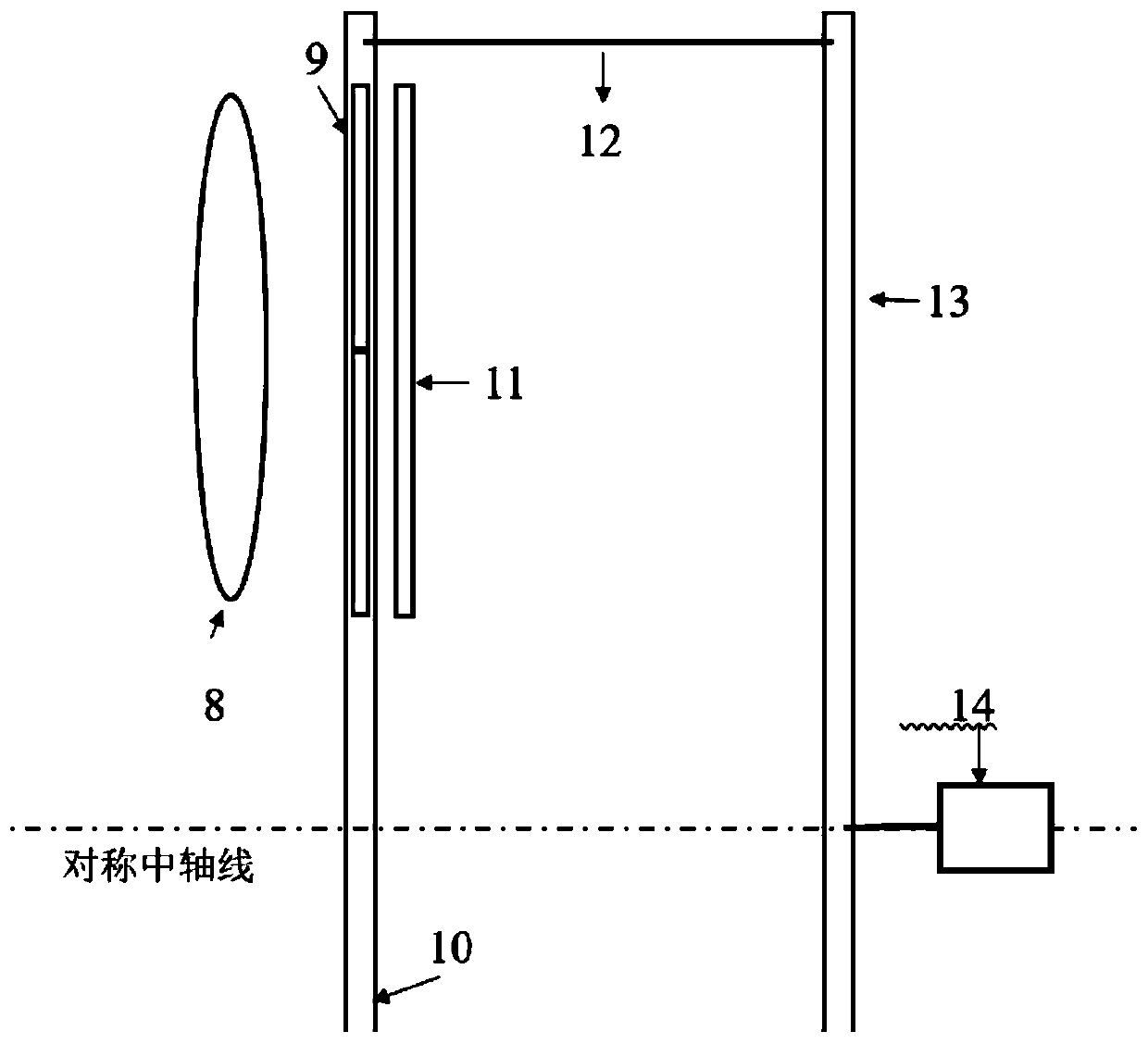

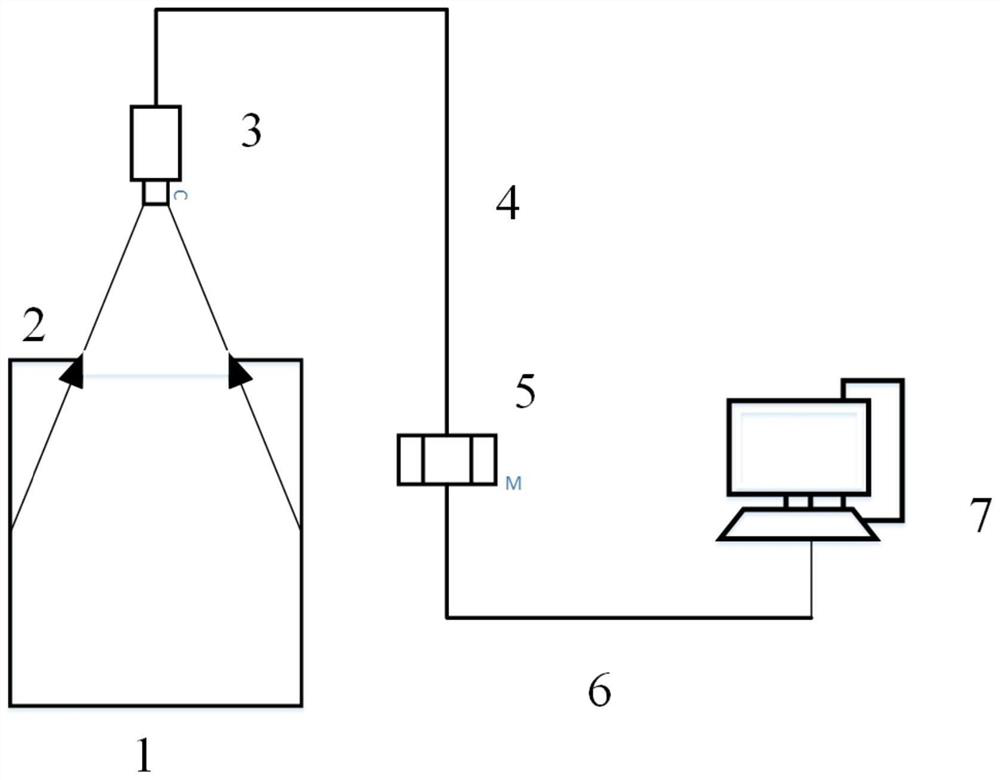

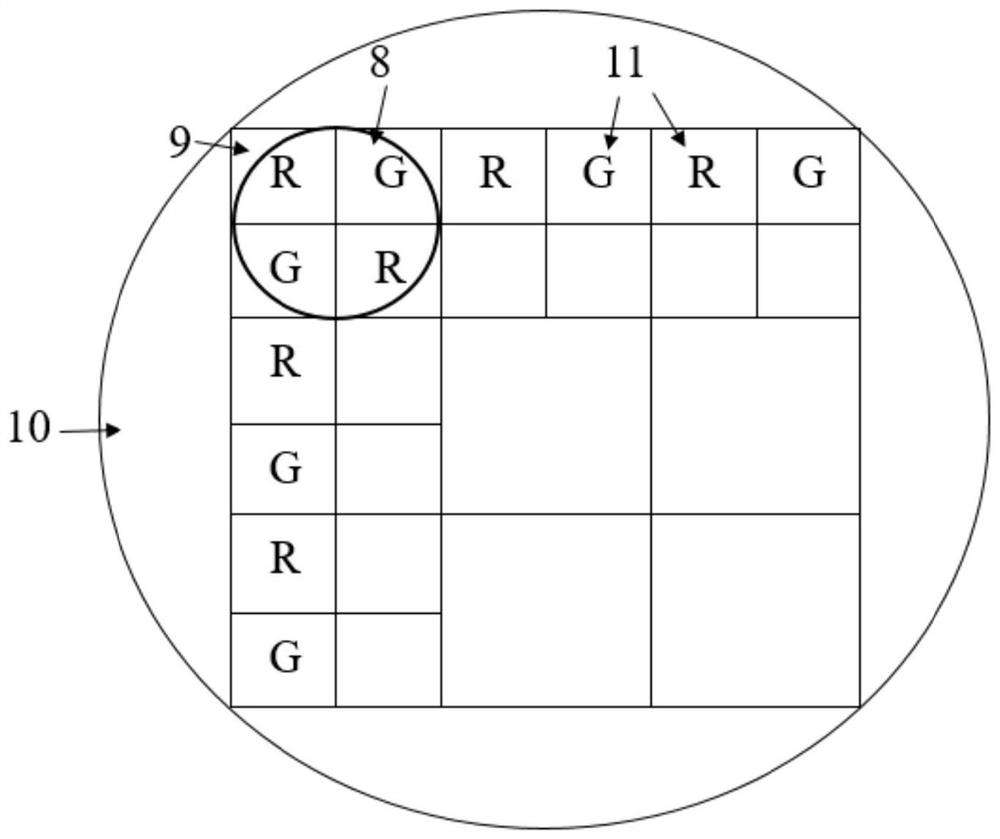

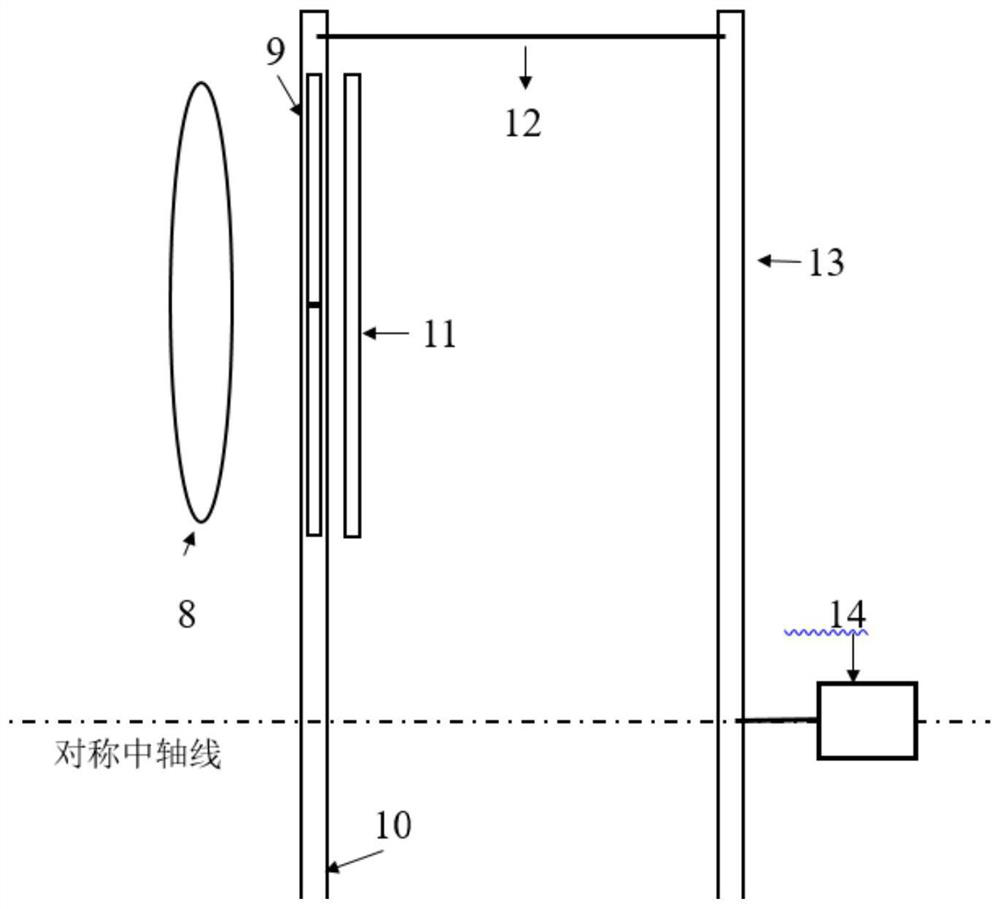

System and method for measuring hearth temperature distribution by utilizing CCD camera

ActiveCN111307320AAvoid damageAvoid pollutionThermometers using physical/chemical changesEngineeringCcd camera

The invention discloses a system and method for measuring hearth temperature distribution by utilizing CCD camera. The system comprises a boiler, the CCD camera, a signal collecting device and an operation processing system. The CCD camera comprises a CCD sensor area array consisting of a plurality of groups of sensors; the sensor comprises a micro lens, a fast moving optical filter group and a photosensitive element. An optical filter disc is arranged between the micro lens and the photosensitive element, and the fast moving optical filter group is embedded on the optical filter disc in an array mode. According to the method, the CCD camera is used for collecting signals, the signals are processed by the signal collecting device and enter the operation processing system, an image matrix is generated, a projection gray level image is formed, and an LFBP-SART algorithm is used for reconstructing a temperature field. All radiation irradiated on the sensor can be more accurately received,the measurement precision is high, the flame boundary can be accurately divided, the beneficial effects of radiation intake are obtained, and the requirements of actual production are met.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

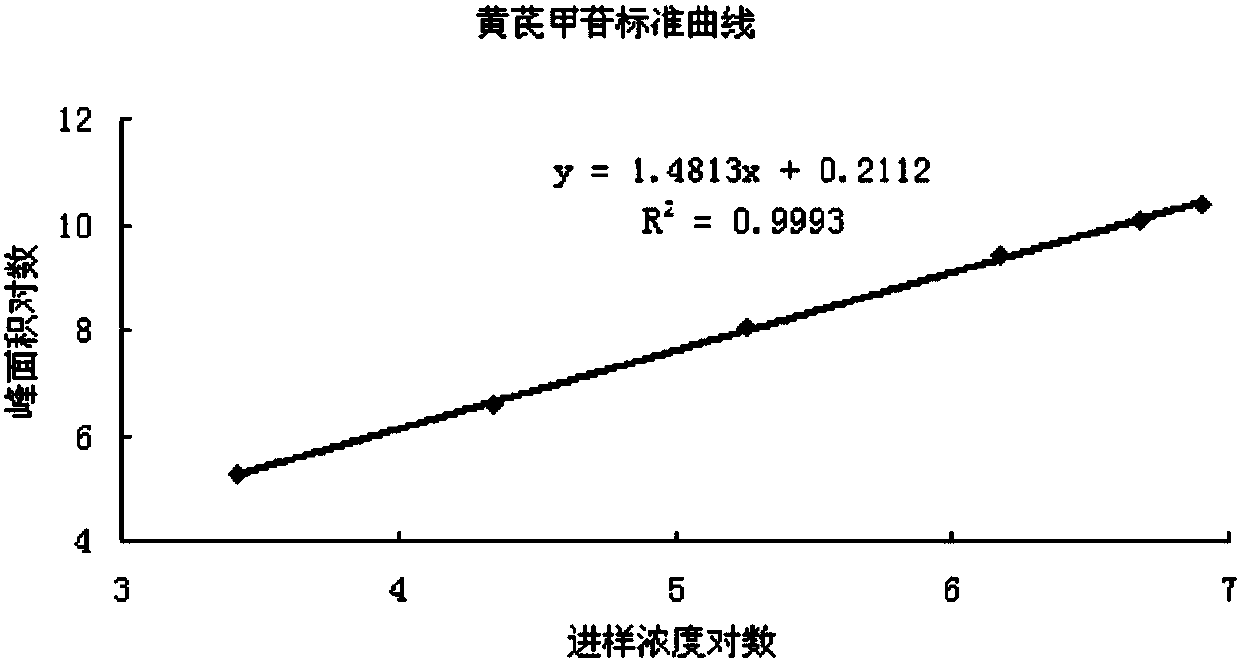

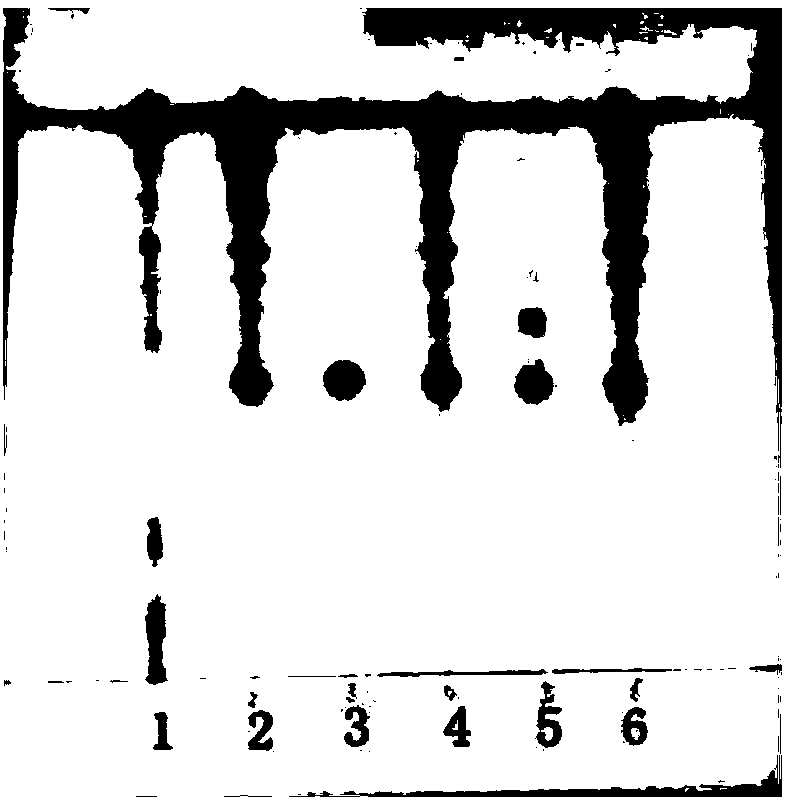

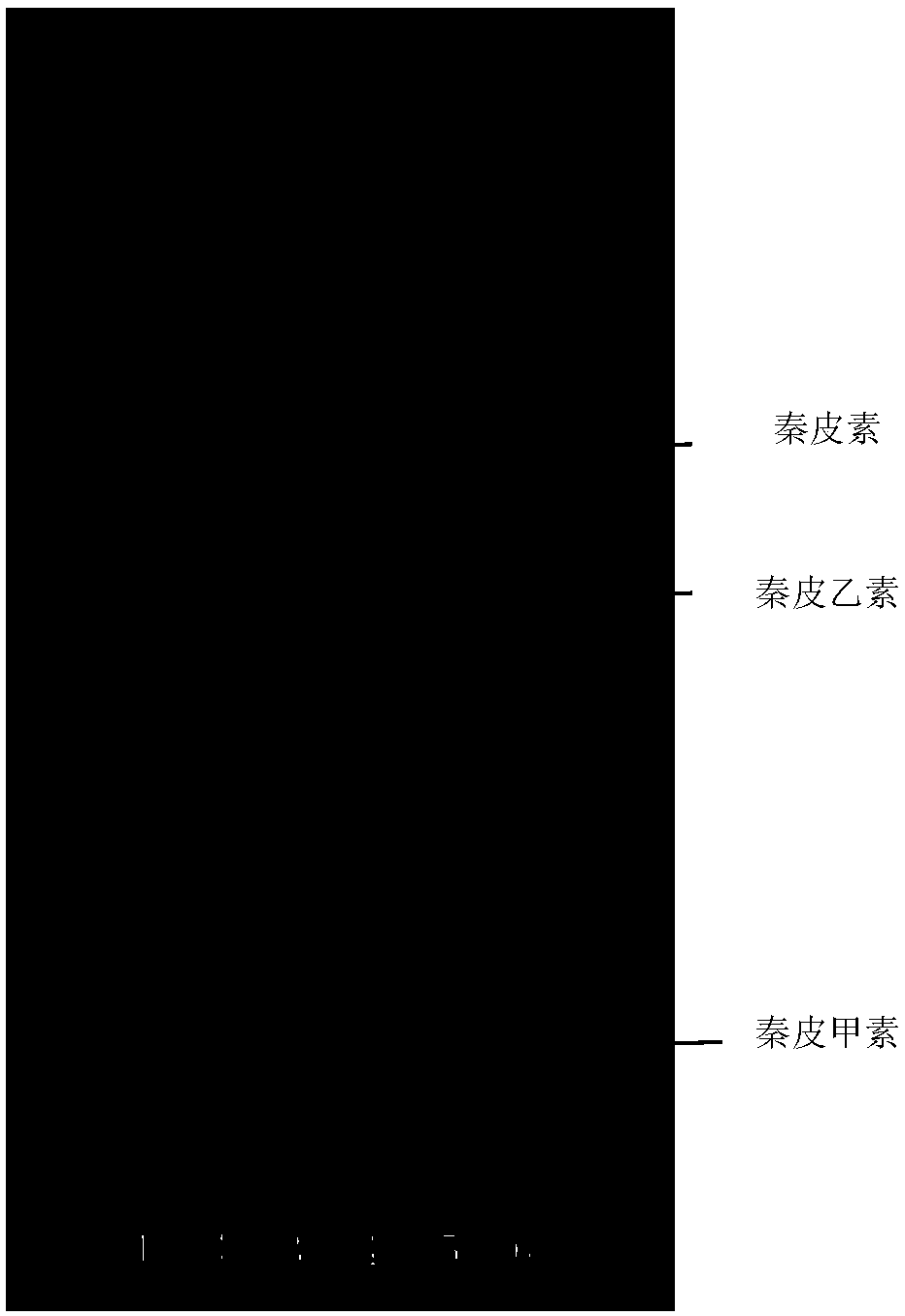

Preparation method and testing method of tablets for treating gouty arthritis

InactiveCN107753724ASolve the defect of identification lack of specificityIncrease assayComponent separationSkeletal disorderDrugThin layer

The invention relates to the field of drugs, in particular to a preparation method and testing method of tablets for treating gouty arthritis. The testing method is obtained through screening with creative experiments, and in the testing method, through the screening of sample treatment methods and the selection of a developing solvent system, distinguishing specialization is good, the testing method is economical and applicable, a result can be quickly obtained, and the defects that existing thin-layer identification of cassia twig and cortex acanthopanacis has no specialization are overcome.In a content testing method, the test of the astragaloside content is added through the optimization of the test sample treatment methods, so that the quality of the product can be effectively controlled by means of the content testing method, and the practical production requirements can be met.

Owner:JIANGSU KANION PHARMA CO LTD

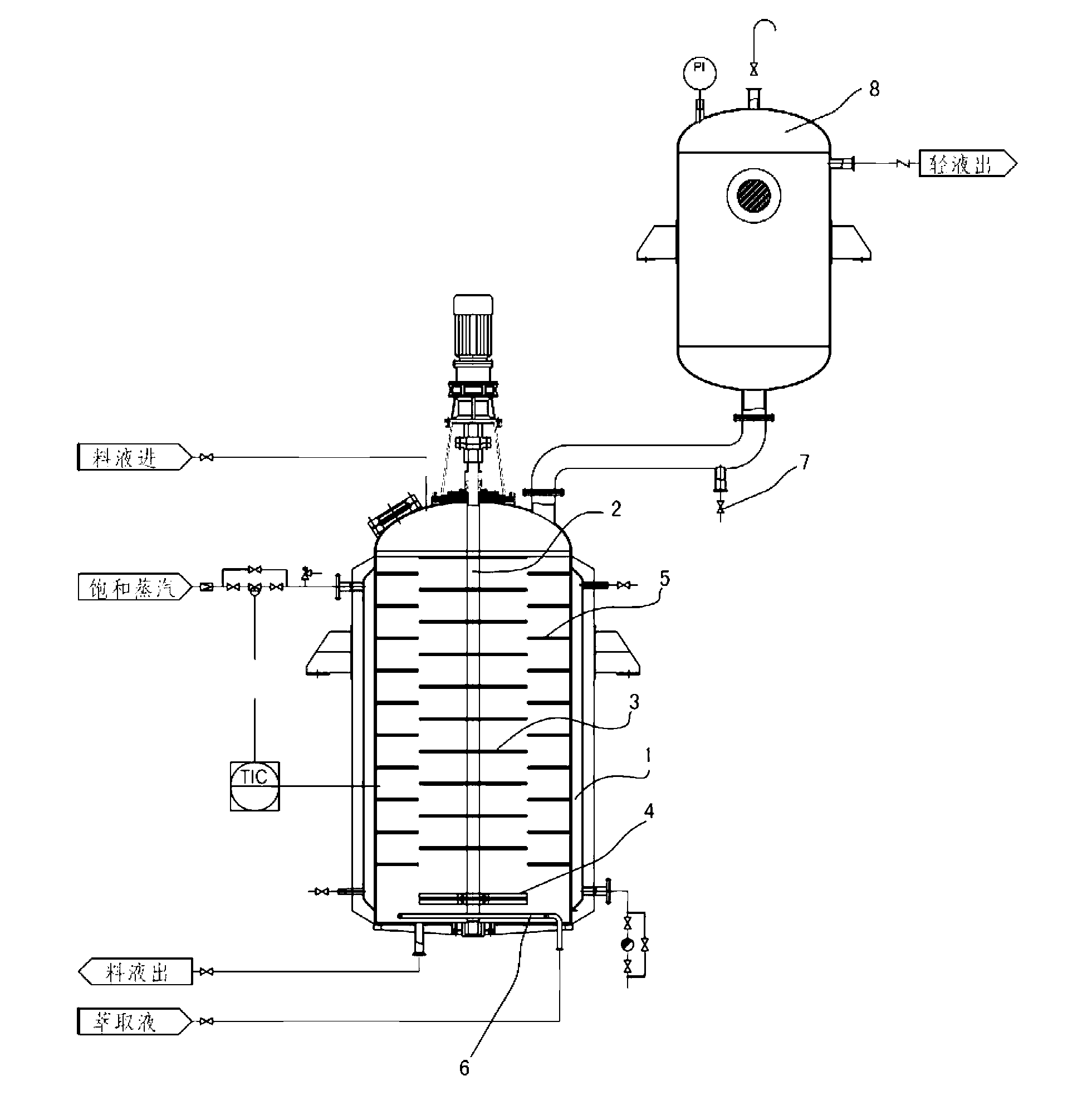

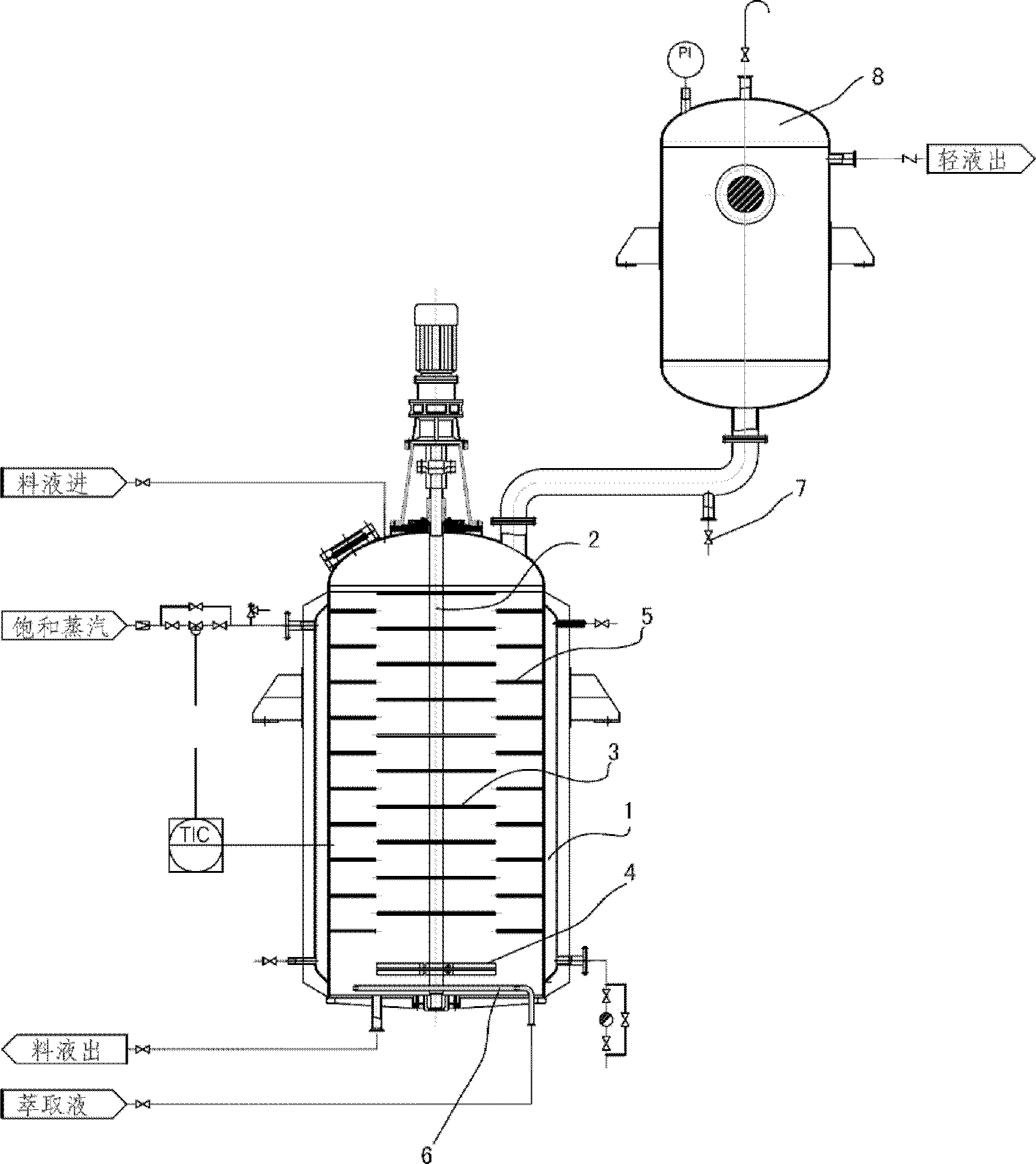

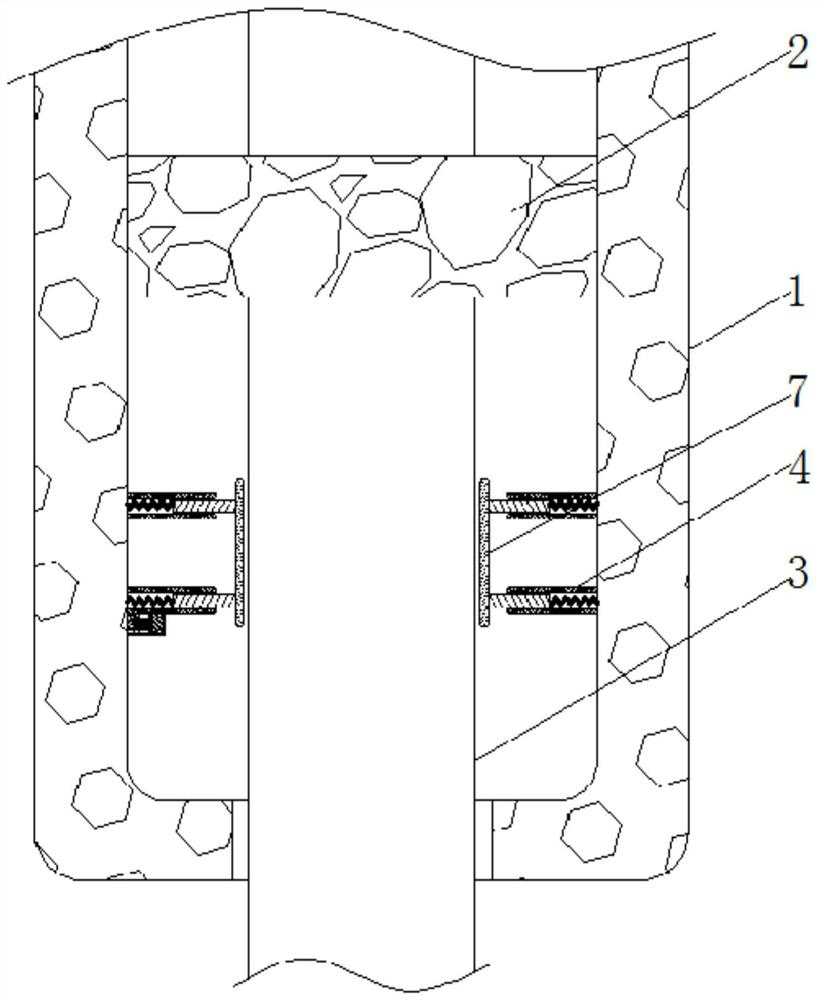

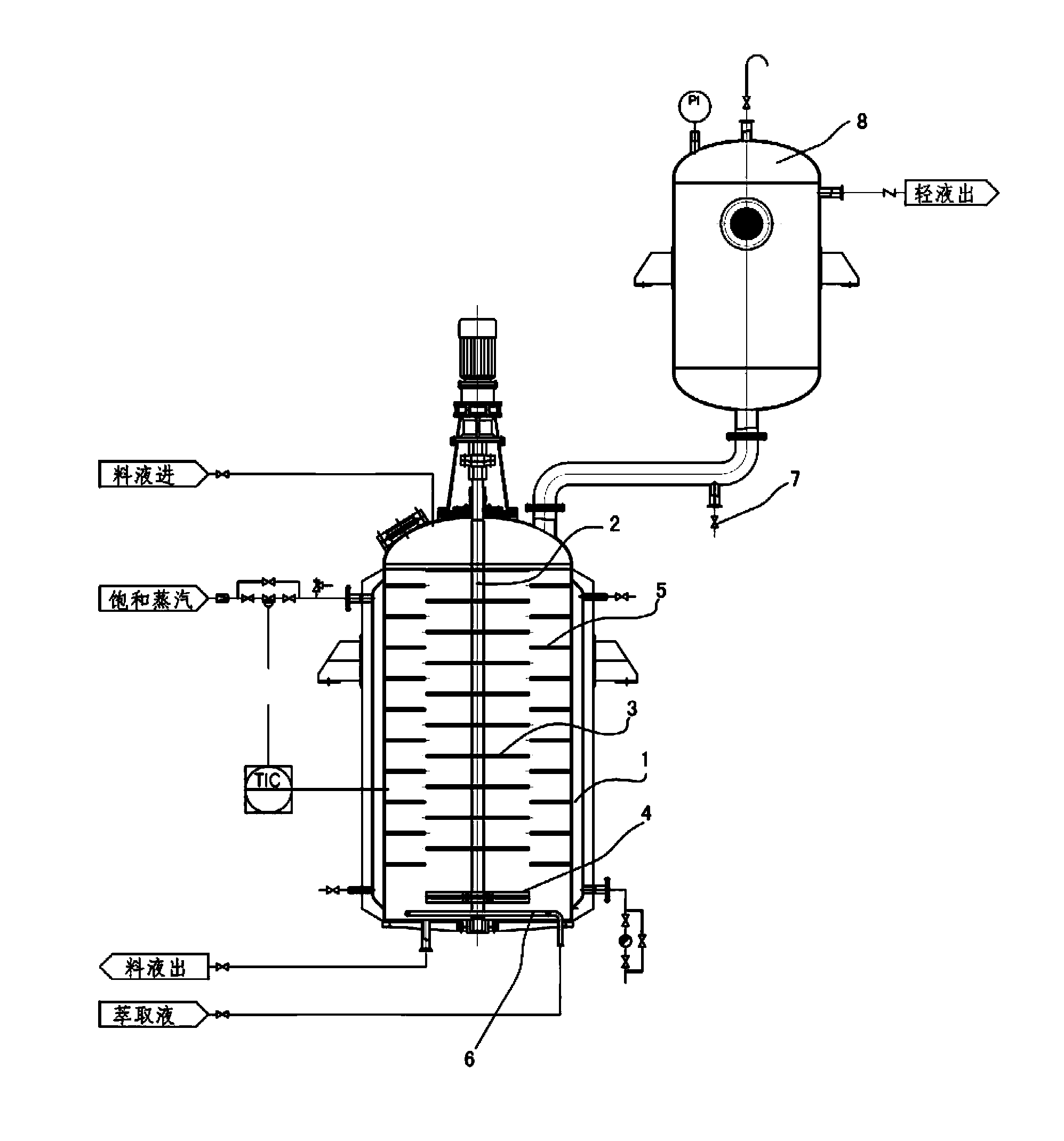

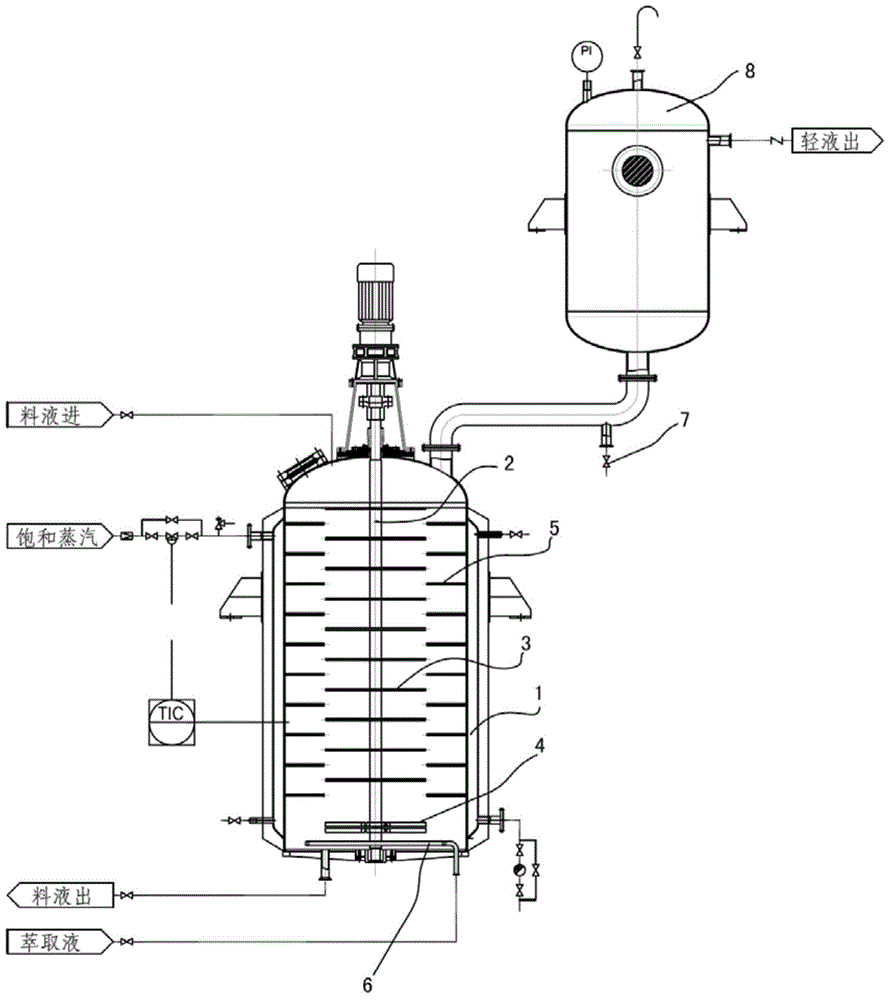

Extraction and abstraction dual-purpose integrated machine and working method thereof

InactiveCN102335523BReduce dosageImprove work efficiencyLiquid solutions solvent extractionWork periodEngineering

The invention relates to an extraction and abstraction dual-purpose integrated machine and a working method thereof, and the integrated machine comprises an extraction tank, wherein a heavy liquid inlet and a light phase outlet are arranged at the top of the extraction tank, and a light liquid inlet and a heavy phase outlet are arranged at the bottom of the extraction tank; and a clarification tank is arranged above the extraction tank, and the light phase outlet of the extraction tank is connected with the bottom of the clarification tank, and a light liquid outlet is arranged at the top of the clarification tank. The integrated machine breaks through the traditional process, shortens the extraction section and is made into the tank which is similar to a traditional stirring tank, the heavy phase is fixed in the tank, and the working time can be adjusted at any time according to the concentration monitoring of light phase discharge. When in use, the heavy phase is loaded into the tank, and the flow rate of the light phase can be regulated arbitrarily, thereby enabling the light phase to achieve the maximum saturated concentration and further meeting the actual production needs. The integrated machine adopts the working method of enabling the heavy phase to be fixed and enabling the light phase to be continuous, can enable the interphase mass transfer to be full and thoroughly, is simple to operate and can reduce the using amount of an extraction agent to the greatest extent.

Owner:CHANGZHOU YUTONG DRYING EQUIP

Abnormal vibration detection device for machine tool drill rod

InactiveCN112045498AGuaranteed to be normalAvoid damageMeasurement/indication equipmentsEngineeringStructural engineering

The invention relates to the technical field of mechanical vibration, and discloses an abnormal vibration detection device for a machine tool drill rod. The device comprises a first housing and a second housing, the interior of the first housing is movably connected with the drill rod, the interior of the first housing is fixedly connected with a sliding rail, the interior of the sliding rail is fixedly connected with a direct illumination lamp, and the interior of the sliding rail is fixedly connected with a photosensitive assembly. A pressing rod is movably connected to the exterior of the sliding rail, and an insulating shell is fixedly connected to the inner side of the first housing. Under the interaction of the first housing, the drill rod, the sliding rail, the direct illumination lamp, the photosensitive assembly, the pressing rod, the insulating shell, a movable plate and an electromagnet, the device can detect whether the drill rod vibrates abnormally or not, and then whetheran emergency braking mechanism is started or not is judged, so that normal operation of drilling operation can be guaranteed, the real-time detection is more suitable for being used under the actualcondition, and personnel injuries caused by collision between the drill rod and a machine shell are further prevented.

Owner:徐佳俊

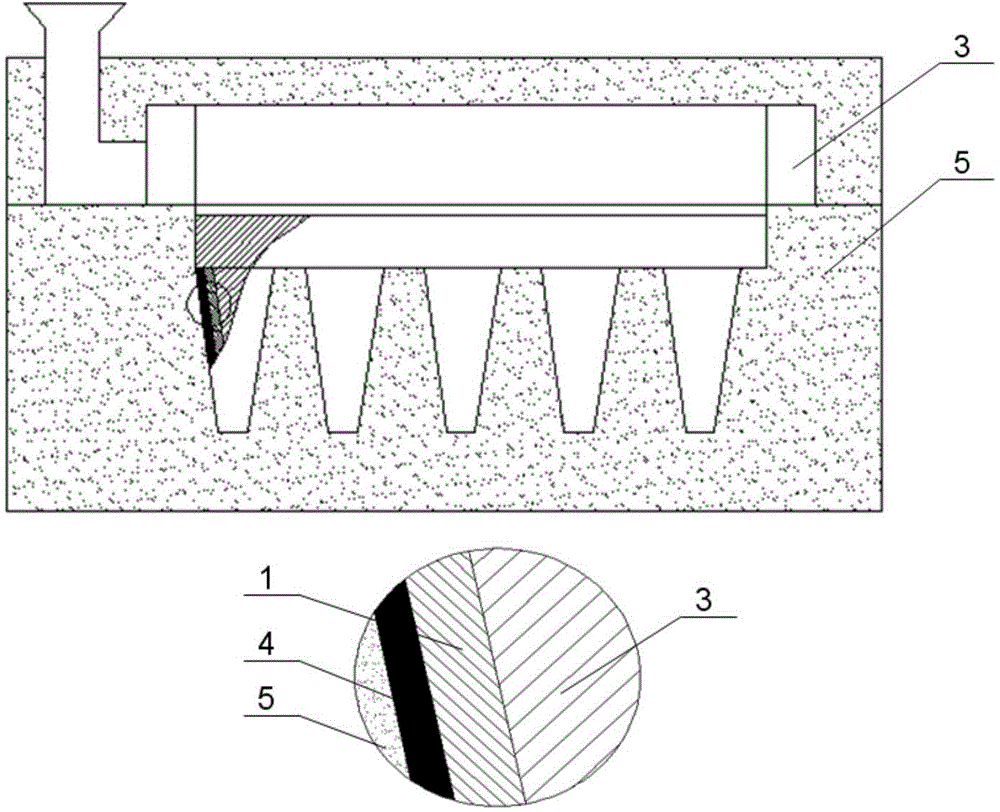

Jaw plate and production method thereof

ActiveCN104525299AImprove mechanical propertiesApparent quasi-single crystal structureGrain treatmentsMetal substrateMicrometer

The invention provides a jaw plate and a production method thereof. The work surface of the jaw plate contacting with a material is provided with a carbide coating The surface of the jaw plate is provided with the carbide coating. The carbide coating includes a V2C dense ceramic layer, and further includes a micrometer V8C7 dense ceramic layer and a V8C7-substrate fusion layer. The V2C dense ceramic layer, the micrometer V8C7 dense ceramic layer and the V8C7-substrate fusion layer are distributed in a gradient manner. The carbide coating can be applied to the surface of high manganese steel. The coating and the substrate are metallurgically bonded, and the bonding force is strong, so the problems of non-metallurgical bonding between present hard particles and a metal substrate, weak bonding force and easy shedding of the particles are overcome, and the wear resistance of the work surface of the jaw plate is greatly improved.

Owner:XIAN UNIV OF TECH

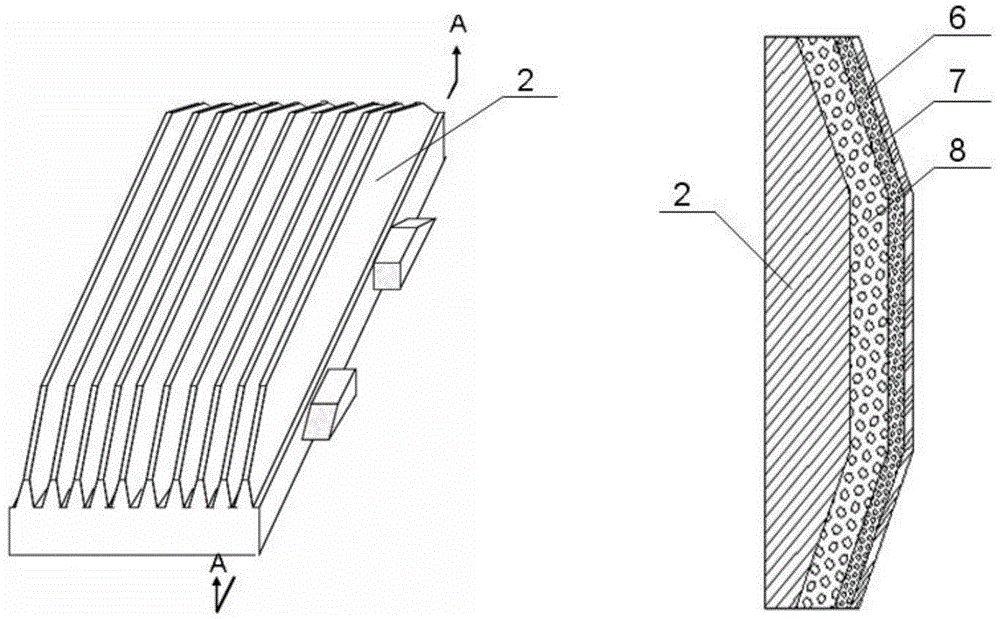

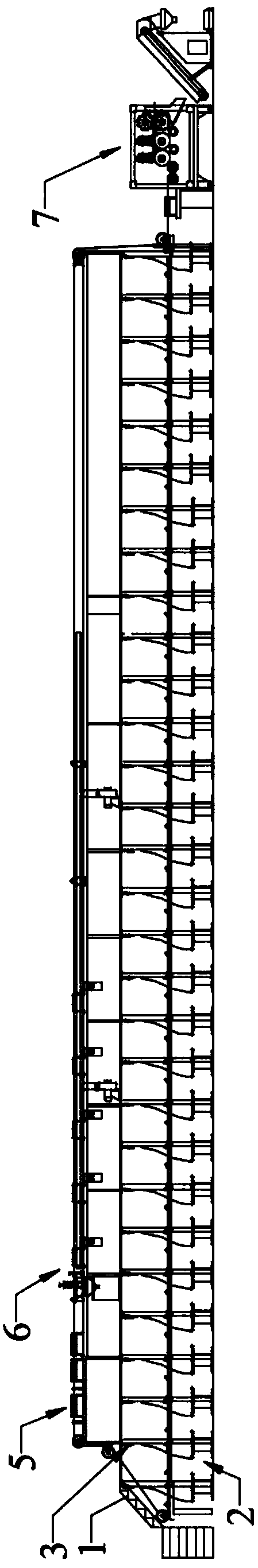

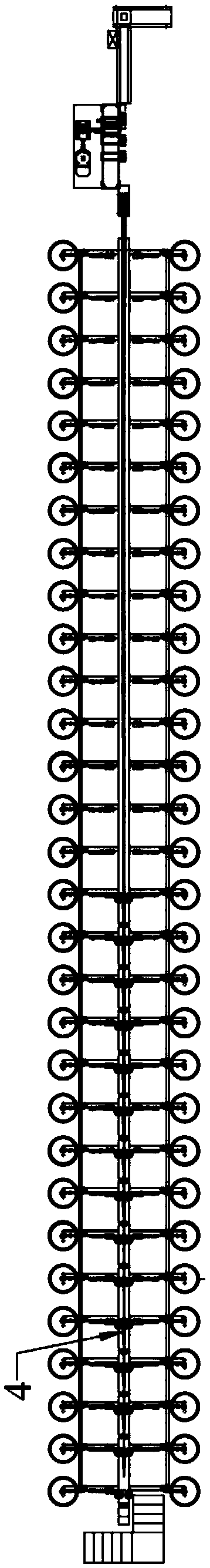

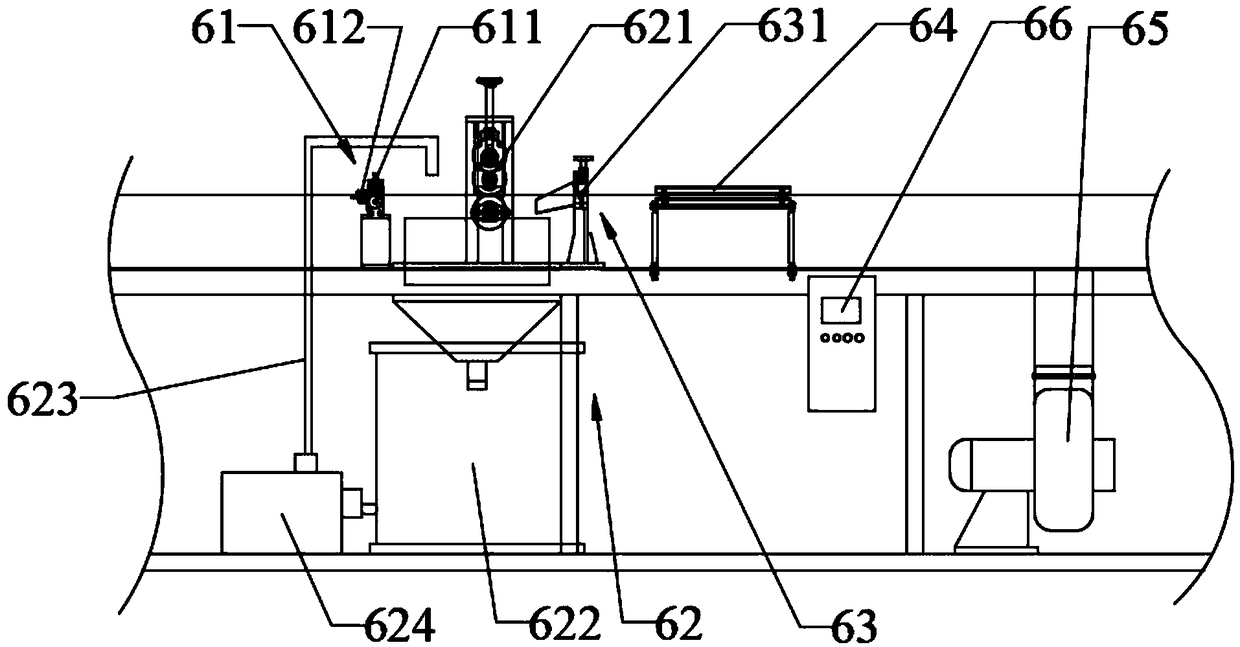

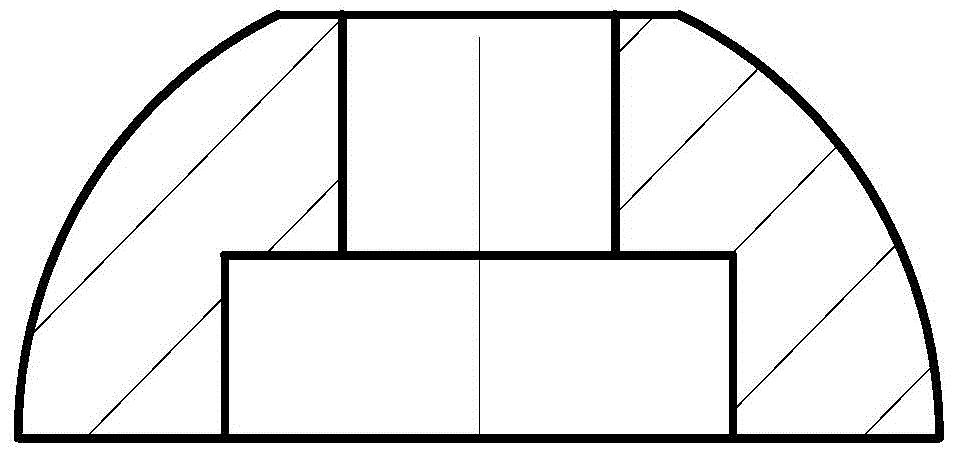

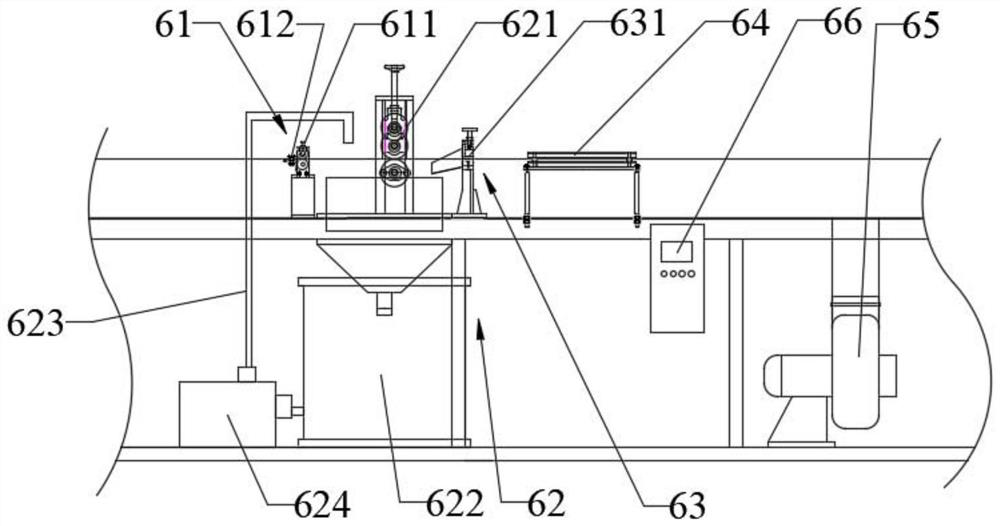

Manufacturing equipment for rows of steel fibers

ActiveCN109395983AGuaranteed adhesive performanceGood coagulationLiquid surface applicatorsCoatingsFiberIntermediate frequency

The invention relates to the technical field of building materials, in particular to manufacturing equipment for rows of steel fibers. The equipment comprises a gluing heating device which is providedwith a cleaning and shaping mechanism, a gluing mechanism, an evenly gluing mechanism, a heating device, an air blower and a controller. According to the manufacturing equipment for the rows of the steel fibers, before gluing is conducted, steel wires are subjected to cleaning and purification, after gluing is conducted, glue is applied evenly, the gluing effect of the rows of the steel wires isguaranteed, and meanwhile by means of recycling and reuse of the glue, the cost is greatly lowered; the glue is dried through intermediate frequency induction, warming is rapid, the heat efficiency ishigh, pollution discharge is less, the rows of the steel wires can be heated uniformly, by means of repeated heating and cooling operation, the solidification effect of the glue is better, and the steel fiber adhesive performance is fully guaranteed; manufacturing of the steel fibers is completed on an entire assembly line, no manual operation is needed, the process is simple, and the productionefficiency is high.

Owner:福建蓝美新材料有限公司

Grinding method of high-precision beryllium semi-spherical through hole

ActiveCN104858721ASolving the key to research and matchingMeet design accuracy requirementsSurface roughnessDynamic pressure

The invention relates to the technical field of high-precision grinding of special materials and especially relates to a grinding method of a beryllium semi-spherical part through hole of a dynamic-pressure motor. The invention puts forward practical and effective methods such as rational selection of a grinding material formula, and improvement of a grinding tool shape and materials, etc. In this way, the design drawing requirements that cylindrical degree precision of the semi-spherical through hole is less than 0.5 Mum and surface roughness Ra is 0.02 Mum are satisfied, and key problems of grinding and matching between the semi-spherical hole and a shaft are solved. It is proved in practice that the method satisfies requirements for design precision, has high efficiency, and is operated conveniently and now applied in actual work widely.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

Height-adjustable three-shaft rounding forming machine

InactiveCN102873142AMeet the requirements of actual productionSolve the technical problems of variable curvature bendingFixed frameEngineering

a height-adjustable three-shaft rounding forming machine comprises a fixed frame, an up-down movable frame, a horizontal rotating frame and a roller, wherein the up-down movable frame is movably arranged on the fixed frame in an up-down direction; the horizontal rotating frame is horizontally and rotatably arranged on the up-down movable frame; and the roller is arranged on the horizontal rotating frame. The invention effectively solves the technical problem that a plate can not realize rounding forming in the height direction, can better meet the requirement of actual production, and enables the fields where the rounding forming technology can be applied to be more extensive. The invention effectively solves the technical problem of variable-curvature rounding of roll bending profile, and can better meet the requirements of actual production. Meanwhile, the height-adjustable three-shaft rounding forming machine provided by the invention can enable a profile to realize variable-curvature rounding in the height direction according to the design requirements so as to meet more and more demands of customers.

Owner:NORTH CHINA UNIVERSITY OF TECHNOLOGY

Method for extracting rare earth elements

InactiveCN102936665BReduce dosageImprove work efficiencyProcess efficiency improvementRare-earth elementSolvent

The invention relates to a method for extracting rare earth elements and a rare earth extraction system. The method comprises the following steps: inputting quantitative water solution or suspension, as heavy liquid, of rare earth elements into an extraction tank via a heavy liquid inlet at the top of the extraction tank; starting a stirring shaft; filling an extraction solvent as light liquid into the extraction tank uniformly from a liquid distributor at the bottom of the extraction tank, ensuring step-by-step mixing and mass transfer from bottom to top between the light liquid and the heavy liquid in the stirring process and enabling the light phase liquid completing mass transfer to overflow into a decanting tank from the top of the extraction tank; after the light phase liquid is decanted in the decanting tank, discharging the light components via a light liquid outlet at the top of the decanting tank; judging whether extraction is completed by detecting the concentrations of the needed rare earth elements in the light component solution discharged from the decanting tank; after extraction is completed, stopping input of the light liquid and starting an emptying valve below the decanting tank to empty the decanting tank; and discharging the heavy liquid in the extraction tank via a heavy liquid outlet at the bottom of the extraction tank.

Owner:INNER MONGOLIA SHENGYILUN RARE EARTH MATERIAL CO LTD

Working method of isolation-extraction dual-purpose all-in-one machine

InactiveCN103949085AReduce dosageImprove work efficiencyLiquid solutions solvent extractionWork periodEngineering

The invention relates to a working method of an isolation-extraction dual-purpose all-in-one machine. The isolation-extraction dual-purpose all-in-one machine comprises an extraction tank; the top of the extraction tank is provided with a heavy liquid inlet and a light phase outlet; the bottom of the extraction tank is provided with a light liquid inlet and a heavy phase outlet; a clarification tank is arranged above the extraction tank; the light phase outlet of the extraction tank is connected with the bottom of the clarification tank; and the top of the clarification tank is provided with a light liquid outlet. According to the isolation-extraction dual-purpose all-in-one machine, traditional technology is improved, an extraction section is shortened to be the extraction tank similar to a traditional stirring tank, heavy phase is immobilized in the extraction tank, and working time can be adjusted at any time based on concentration monitoring on light phase discharging. When the isolation-extraction dual-purpose all-in-one machine is used, heavy phase is delivered into the extraction tank, flow amount of light phase can be adjusted optionally so as to reach a maximum saturation concentration, and satisfy actual production requirements. According to the working method, heavy phase immobilization and light phase continuous delivering are adopted, so that interphase mass transfer is sufficient and complete, operation is simple, and using amount of extraction agents is reduced as far as possible.

Owner:陆文光

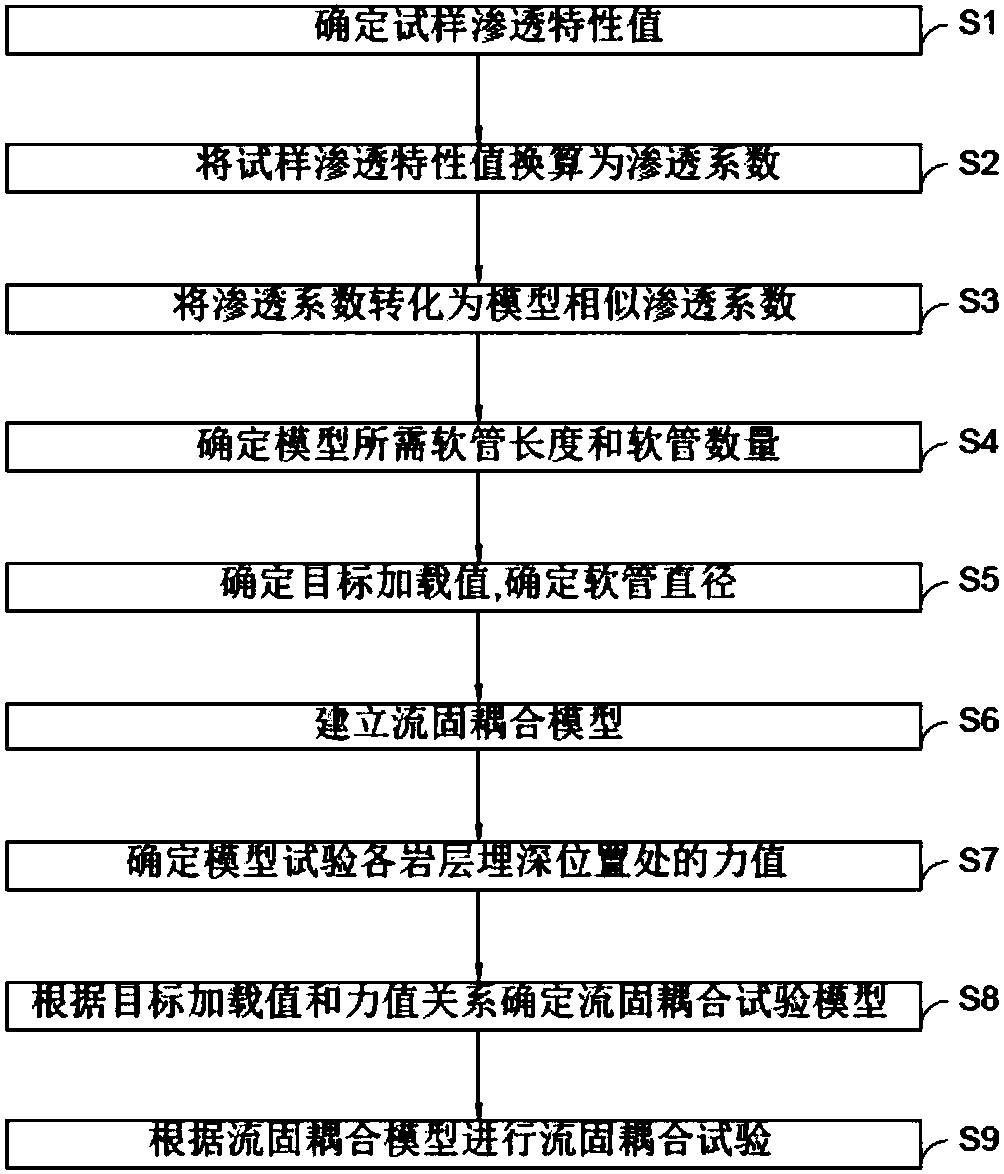

Method for building fluid-structure interaction test based on post-peak rock stress and permeability characteristic

ActiveCN108375535AMeet the requirements of actual productionFuel testingPermeability/surface area analysisModel testPermeability coefficient

The invention provides a method for building a fluid-structure interaction test based on a post-peak rock stress and a permeability characteristic. The method belongs to the technical field of coal mining, and comprises the steps of determining a permeability characteristic value of the post-peak rock stress; converting a permeability characteristic value of a sample prototype test into a permeability coefficient; converting the permeability coefficient into a model similarity permeability coefficient; adopting flexible pipes as model test materials, and determining the flexible pipe length and the flexible pipe quantity required for a model; enabling flexible pipe permeability coefficients under different loading values to correspond to the corresponding model similarity permeability coefficients; determining the flexible pipe diameter according to a target loading value; determining a force value at each rock stratum buried depth position of the model test; determining a fluid-structure interaction test model according to relations between the target loading values and the force values; carrying out the fluid-structure interaction test according to the fluid-structure interactionmodel. The fluid-structure interaction test simultaneously meets the requirements on a mechanical property and the material permeability characteristic, realizes the research of an interaction modeltest of a seepage field and a gravity field, and meets the requirement of actual production.

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

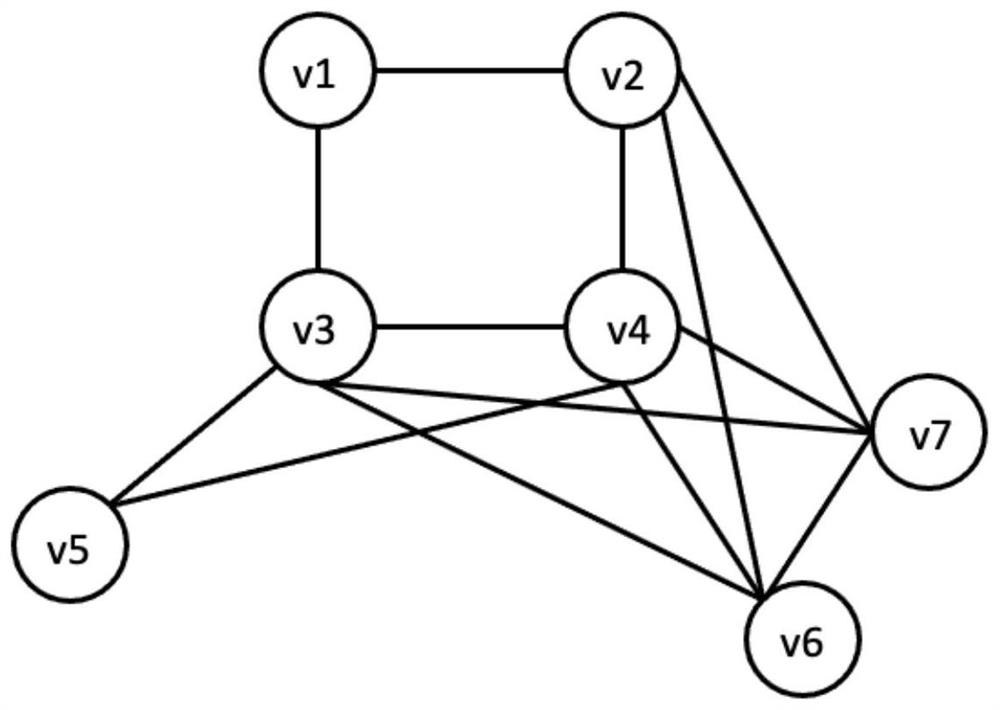

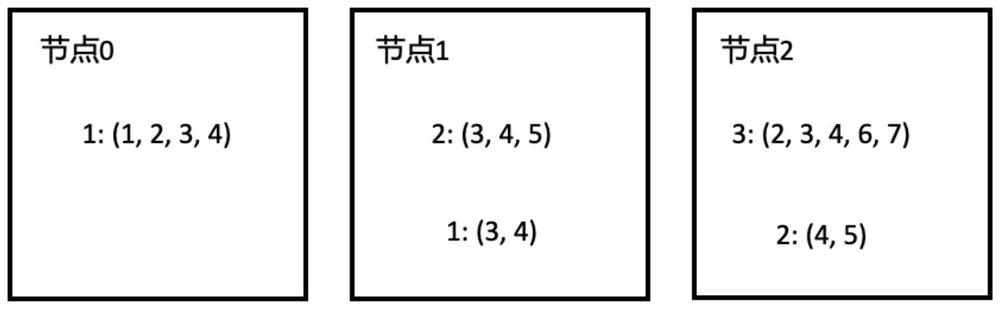

An Overlapping Method for Community Discovery

ActiveCN112948712BFacilitate horizontal expansionEasy to handleOther databases indexingSpecial data processing applicationsAlgorithmTheoretical computer science

The invention discloses a method for discovering overlapping communities, the steps are as follows: S1 for all the maximum cliques in the distributed computing graph G, count the information on the number of the maximum cliques and send the information on the number of the maximum cliques to all computing nodes Middle; S2 sorts and codes all the maximal cliques, assigns a unique code to each maximal clique to determine the maximal clique; S3 calculates the subclusters in the maximal clique, and sends the subclusters to different computing nodes; S4 In each computing node, construct an inverted index; S5 uses the inverted index for each extremely large clique to calculate the extremely large clique that has k-1 shared vertices with each extremely large clique and the same computing node, Use the union search set to save the ID of the extremely large group in the same set; S6 merge the union search sets in different clusters to find the corresponding faction. An overlapping community discovery method using the above structure increases the system's ability to process large graphs, making horizontal expansion easier and lower in cost.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Preparation method and detection method of Gongyanping dispersible tablet

ActiveCN103977121BReduce dosageStable and uniform qualityComponent separationPill deliveryFicus simplicissimaGallic acid ester

The invention relates to a preparation method and a detection method of hysteritis-treating dispersible tablets. The preparation method differs from ordinary tablets in that a preferred prescription is adopted, a disintegrating agent is applied internally and externally, and Chinese medicinal tablets are prepared into Chinese medicinal dispersible tablets which have stable and uniform quality and can be totally disintegrated within three minutes. A quality detection method provided by the invention relates to thin-layer chromatography identification of melastoma dode candrum lour, zanthoxylum nitidum and ficus simplicissima Lour as well as high performance liquid chromatography content determination and limit of gallic acid.

Owner:JIANGXI MINJI MEDICINE

A manufacturing equipment for rows of steel fibers

ActiveCN109395983BGuaranteed adhesive performanceGood coagulationLiquid surface applicatorsCoatingsAdhesive glueAssembly line

The invention relates to the technical field of building materials, in particular to a manufacturing equipment for rows of steel fibers, which includes a gluing heating device, and the gluing heating device is sequentially provided with a cleaning and shaping mechanism, a gluing mechanism, Glue leveling mechanism, heating device, blower and controller; the manufacturing equipment for rows of steel fibers provided by the present invention cleans and removes impurities from the steel wires before gluing, and spreads the glue evenly after gluing, ensuring that the steel wires in rows At the same time as the effect of glue, the recycling and reuse of glue has greatly reduced the cost; the drying of glue is carried out by medium frequency induction, which has fast heating, high thermal efficiency and less sewage discharge, and can evenly heat rows of steel wires. And after repeated heating and cooling operations, the solidification effect of the glue is better, which fully guarantees the adhesive performance of the steel fiber; and the manufacture of the steel fiber is completed on an entire assembly line without any manual operation, the process is simple, and the production efficiency is high. high.

Owner:福建蓝美新材料有限公司

A kind of working method of extracting and extracting dual-purpose all-in-one machine

InactiveCN103949085BReduce dosageImprove work efficiencyLiquid solutions solvent extractionWork periodDual purpose

The invention relates to a working method of an isolation-extraction dual-purpose all-in-one machine. The isolation-extraction dual-purpose all-in-one machine comprises an extraction tank; the top of the extraction tank is provided with a heavy liquid inlet and a light phase outlet; the bottom of the extraction tank is provided with a light liquid inlet and a heavy phase outlet; a clarification tank is arranged above the extraction tank; the light phase outlet of the extraction tank is connected with the bottom of the clarification tank; and the top of the clarification tank is provided with a light liquid outlet. According to the isolation-extraction dual-purpose all-in-one machine, traditional technology is improved, an extraction section is shortened to be the extraction tank similar to a traditional stirring tank, heavy phase is immobilized in the extraction tank, and working time can be adjusted at any time based on concentration monitoring on light phase discharging. When the isolation-extraction dual-purpose all-in-one machine is used, heavy phase is delivered into the extraction tank, flow amount of light phase can be adjusted optionally so as to reach a maximum saturation concentration, and satisfy actual production requirements. According to the working method, heavy phase immobilization and light phase continuous delivering are adopted, so that interphase mass transfer is sufficient and complete, operation is simple, and using amount of extraction agents is reduced as far as possible.

Owner:陆文光

The working method of the extraction and extraction dual-purpose all-in-one machine

ActiveCN103949086BReduce dosageImprove work efficiencyLiquid solutions solvent extractionWork periodDual purpose

The invention relates to a working method of an isolation-extraction dual-purpose all-in-one machine. The isolation-extraction dual-purpose all-in-one machine comprises an extraction tank; the top of the extraction tank is provided with a heavy liquid inlet and a light phase outlet; the bottom of the extraction tank is provided with a light liquid inlet and a heavy phase outlet; a clarification tank is arranged above the extraction tank; the light phase outlet of the extraction tank is connected with the bottom of the clarification tank; and the top of the clarification tank is provided with a light liquid outlet. According to the isolation-extraction dual-purpose all-in-one machine, traditional technology is improved, an extraction section is shortened to be the extraction tank similar to a traditional stirring tank, heavy phase is immobilized in the extraction tank, and working time can be adjusted at any time based on concentration monitoring on light phase discharging. When the isolation-extraction dual-purpose all-in-one machine is used, heavy phase is delivered into the extraction tank, flow amount of light phase can be adjusted optionally so as to reach a maximum saturation concentration, and satisfy actual production requirements. According to the working method, heavy phase immobilization and light phase continuous delivering are adopted, so that interphase mass transfer is sufficient and complete, operation is simple, and using amount of extraction agents is reduced as far as possible.

Owner:CHANGZHOU YUTONG DRYING EQUIP

A system and method for measuring furnace temperature distribution by using ccd camera

ActiveCN111307320BAvoid damageAvoid pollutionThermometers using physical/chemical changesEngineeringCcd camera

The invention discloses a system and method for measuring the temperature distribution of a furnace by using a CCD camera. The system includes a boiler, a CCD camera, a signal acquisition device and an operation processing system; the CCD camera includes a CCD sensor area array composed of several groups of sensors; the sensor Comprising a micro lens, a fast-moving filter group and a photosensitive element; a filter disc is arranged between the micro-lens and the photosensitive element, and the fast-moving filter group is embedded on the filter disc in a matrix form, and the method of the present invention utilizes a CCD The camera collects the signal, and the signal is processed by the signal acquisition device and enters the computing processing system to generate an image matrix, form a projected grayscale image, and use the LFBP-SART algorithm to reconstruct the temperature field. The invention can more accurately receive all the radiation irradiated on the sensor, has high measurement accuracy, can accurately divide the flame boundary, obtains the beneficial effect of absorbed radiation, and meets the requirements of actual production.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Method and system for extracting rare earth elements

ActiveCN102277493BReduce dosageImprove work efficiencyLiquid solutions solvent extractionProcess efficiency improvementRare-earth elementAqueous solution

The invention relates to a method and a system for extracting rare earth elements. The method for extracting rare earth elements comprises: filling a fixed amount of rare earth aqueous solution or suspension serving as heavy liquid into an extraction tank from a heavy liquid inlet on the top of the extraction tank; starting a stirring shaft; allowing an extracting agent serving as light liquid touniformly enter the extraction tank from a liquid distributor at the bottom of the extraction tank, stirring to allow the light liquid and heavy liquid to mix and transfer mass gradually from bottom up, and allowing the light phase liquid accomplishing mass transfer to overflow from the top of the extraction tank into a clarifying tank; clarifying the light phase liquid in the clarifying tank, and discharging the liquid component from a light liquid opening on the top of the clarifying tank; detecting the concentration of required rare earth elements in the light component solution dischargedfrom the clarifying tank and judging if the leaching or extraction is finished; after the leaching or extraction is finished, stopping inputting light liquid, opening an emptying valve below the clarifying tank to empty the clarifying tank; and discharging the heavy liquid in the extraction tank from a heavy liquid outlet at the bottom of the extraction tank.

Owner:CHANGZHOU YIMIN DRYING EQUIP

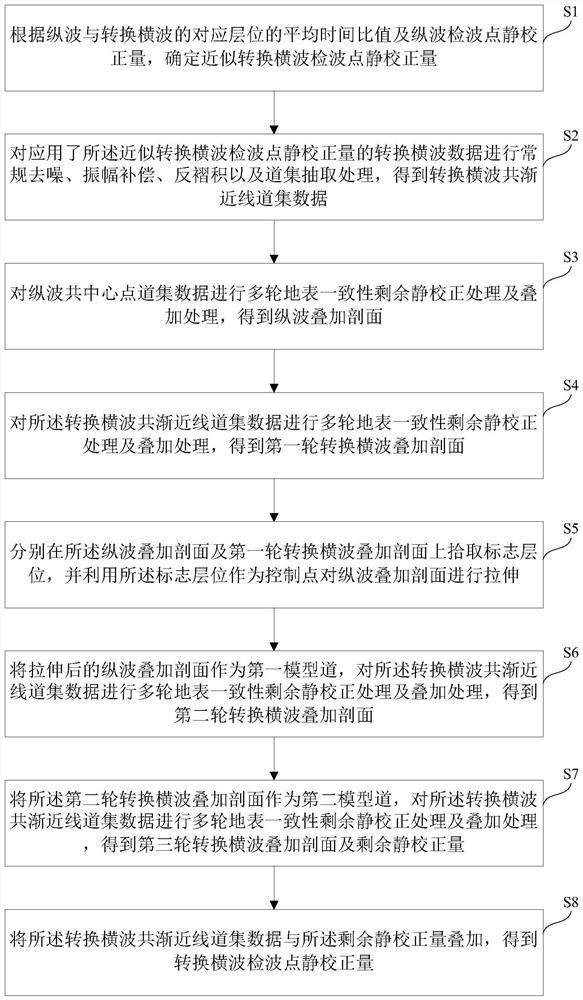

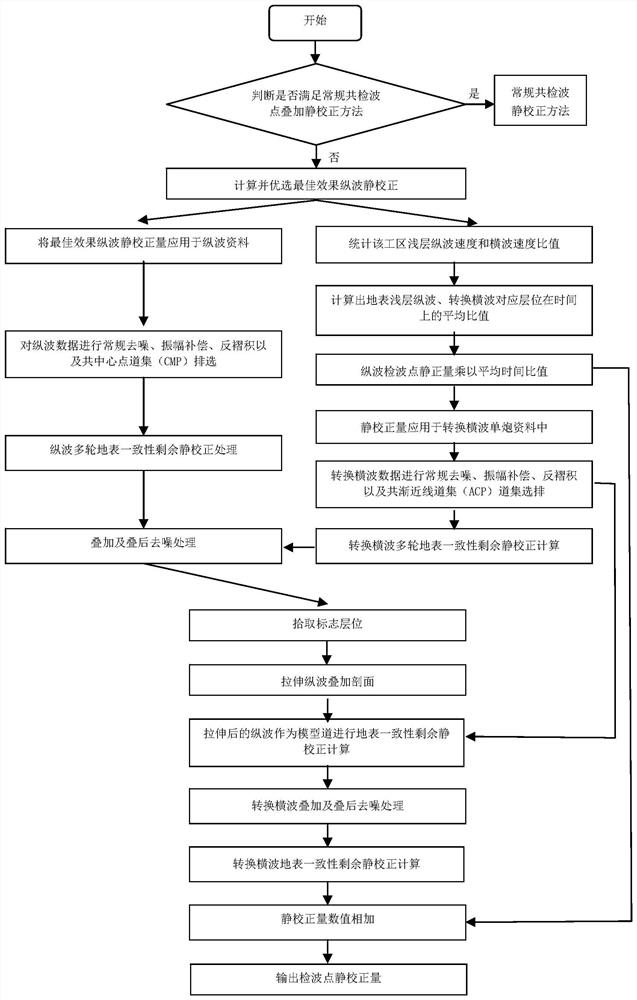

Converted transverse wave detection point static correction method and device

PendingCN112305613AGood effectQuality improvementSeismic signal processingICT adaptationLongitudinal waveMechanical engineering

The invention provides a converted transverse wave detection point static correction method and device. The method comprises the following steps: determining an approximate conversion transverse wavedetection point static correction value according to an average time ratio and a longitudinal wave detection point static correction value; performing trace gather extraction processing on the converted transverse wave data to obtain common asymptotic line trace gather data; performing multiple rounds of earth surface consistency residual static correction processing and superposition processing on the longitudinal wave common midpoint gather data; processing the common asymptote gather data to obtain a first round of converted transverse wave superposition profile; picking up mark layers on the longitudinal wave superposition section and the first round of conversion transverse wave superposition section, and stretching the longitudinal wave superposition section; taking the stretched longitudinal wave superposed section as a first model channel to obtain a second round of converted transverse wave superposed section; repeating the processing to obtain a third round of converted transverse wave superposition profile and a residual static correction value; and superposing the approximate converted transverse wave detection point static correction value with the third round of residual static correction value to obtain a final converted transverse wave detection point static correction total amount.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com