Hawthorn fruit slicing device

A slicing device and the technology of the cutting device, which are applied in metal processing and other directions, can solve the problems of unsuitable hawthorn slicing, low degree of automation, and low efficiency of hawthorn slicing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

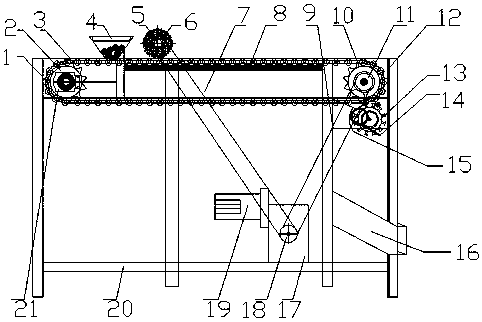

[0017] A hawthorn slicing device, including a frame, a feeding mechanism and a cutting device. A sprocket is arranged on both sides of the upper end of the frame. The transmission chain is horizontally arranged and meshes with the left and right sprockets. The sprocket is equipped with a roller , there is a friction plate on the lower surface of the upper sprocket, and the friction plate is in contact with the roller; there is a feeding hopper on the top of the frame, and there is also a brush pulley on the top of the frame, and a rolling brush is installed on the brush pulley. The chain drives the rollers to move and rubs against the friction plate. The rollers rotate to arrange the hawthorns horizontally between the two rollers, and brush back the hawthorns that are not in a row through the rolling brush. The sprocket on the right side drives the trough-type feeding plate to rotate through the meshing gear. The trough-type feeding plate is equipped with a fixed steel wire cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com