Magnetizing apparatus on basis of flywheel energy storage

A flywheel energy storage and magnetizer technology, which is applied to magnetic objects, electromechanical devices, electromechanical converters, etc., can solve the problems of large space occupation, environmental friendliness, limited number of capacitor charging and discharging, and achieve space utilization and The electromagnetic efficiency is improved, the magnetic bearing control components at both ends of the radial direction are reduced, and the number of charge and discharge times is increased.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

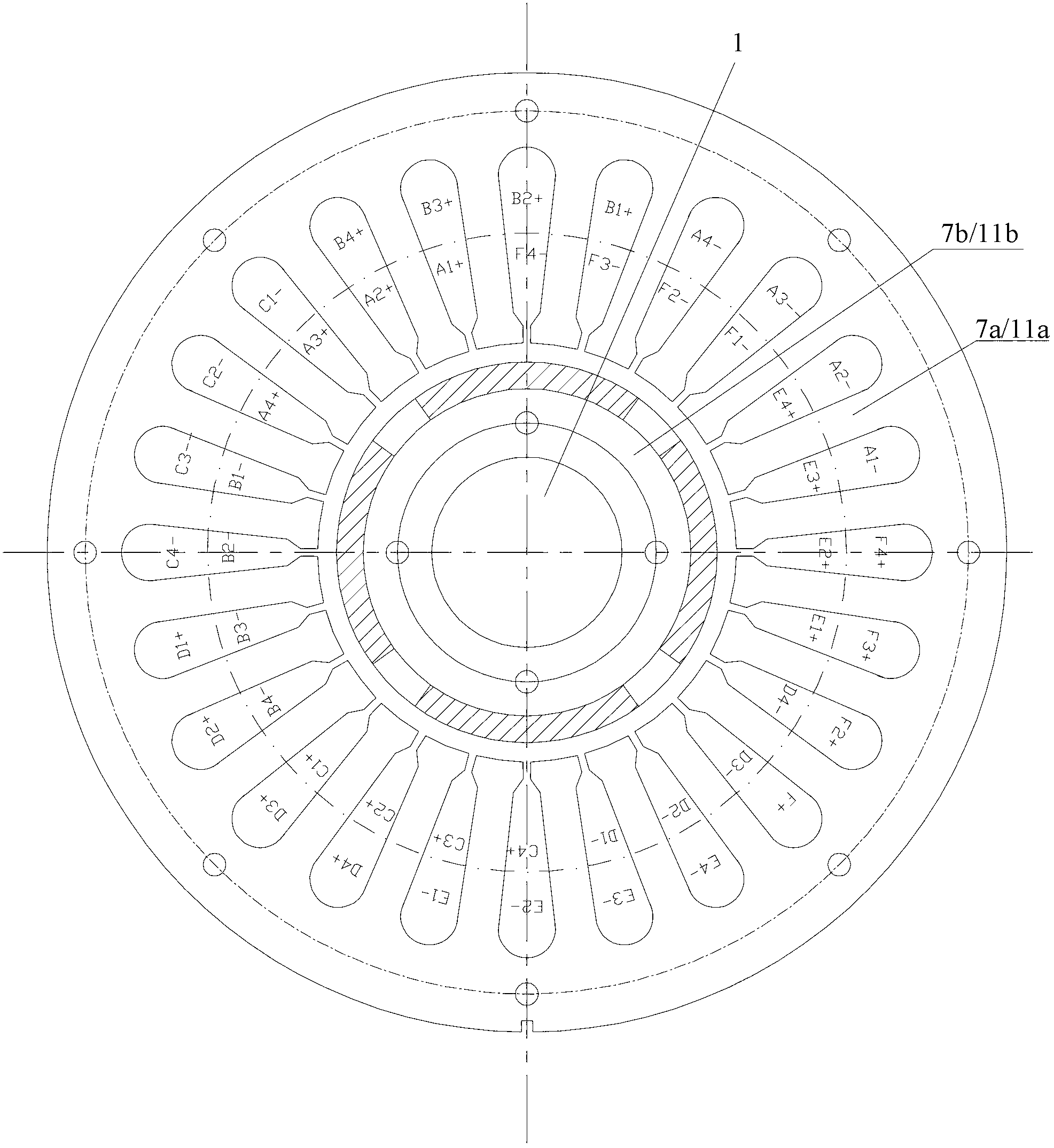

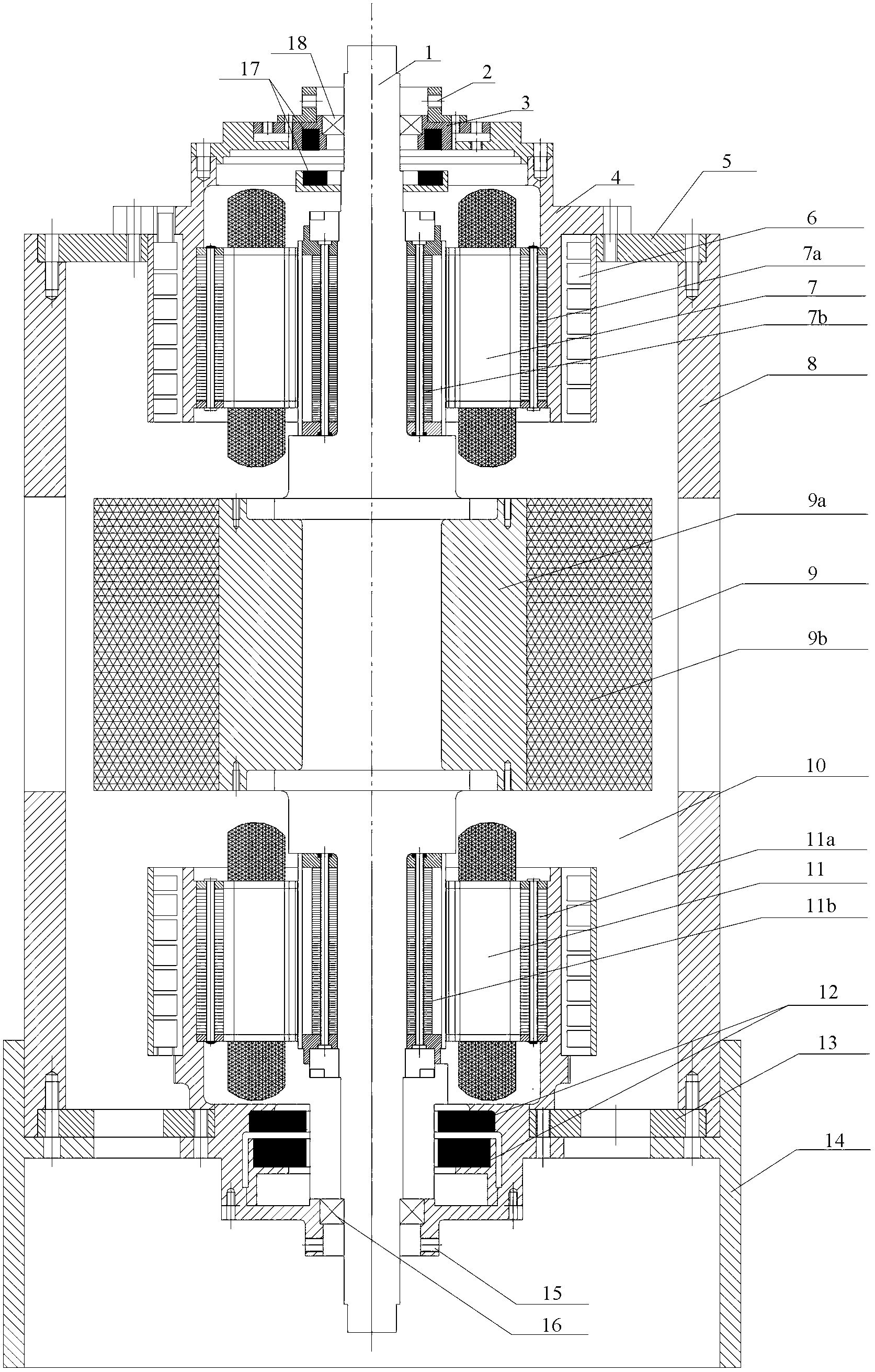

[0043] In order to describe the present invention more specifically, the technical solutions and related working principles of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

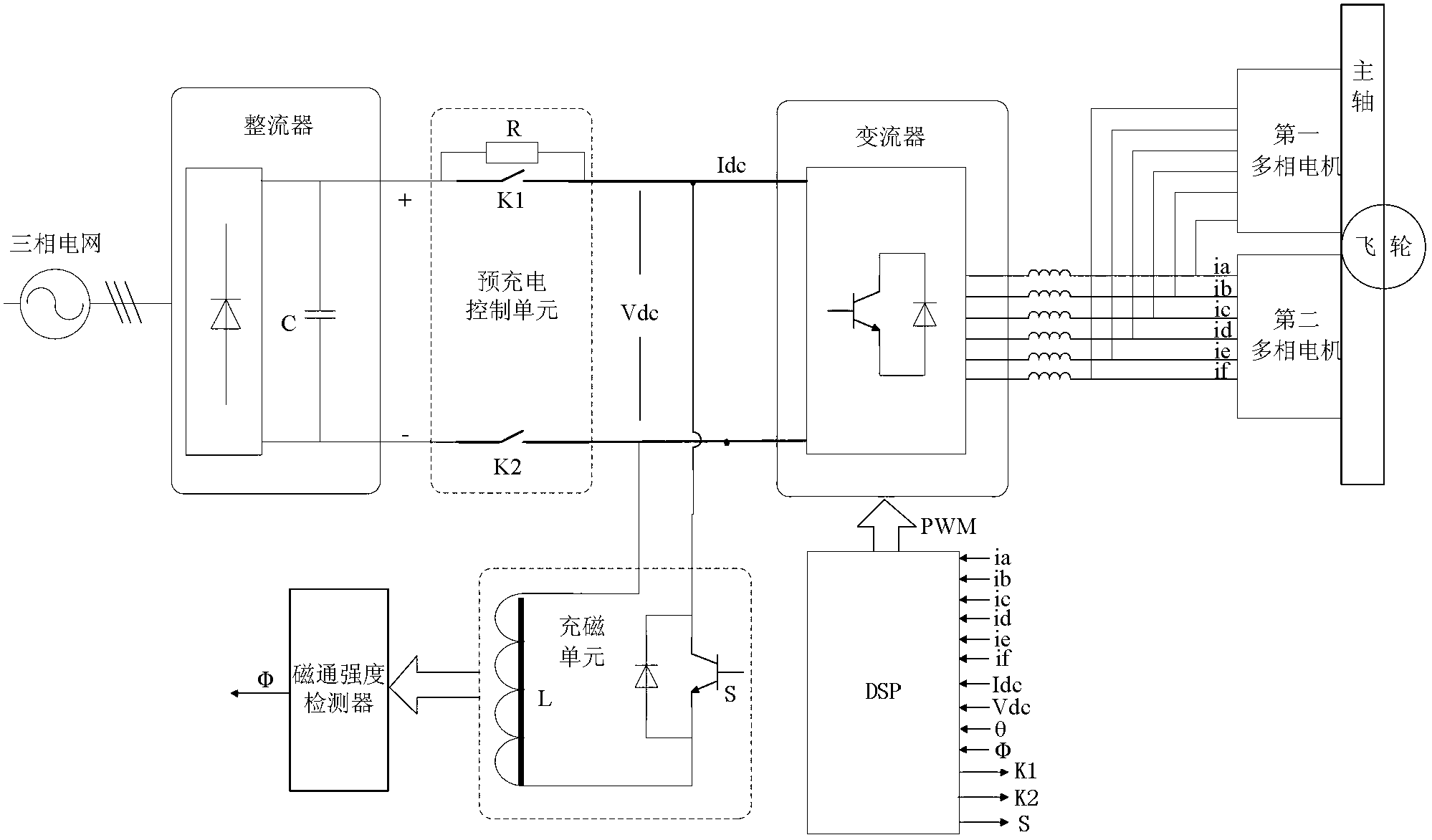

[0044] Such as figure 1As shown, a magnetizer based on flywheel energy storage includes a flywheel energy storage device and a magnetization unit; wherein:

[0045] The flywheel energy storage device is used to supply power to the magnetizing unit through charging and discharging, which includes a rectifier, a converter, a controller, a motor unit and a flywheel mechanism;

[0046] The rectifier is used to convert the alternating current of the three-phase power grid into direct current; in this embodiment, the rectifier adopts an uncontrolled rectifier bridge with a three-phase six-leg structure, and each bridge arm is formed by connecting several diodes in series; the positive and negative output terminals of the rectifier...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com