The working method of the extraction and extraction dual-purpose all-in-one machine

A working method and integrated machine technology, applied in the direction of liquid solution solvent extraction, etc., can solve the problems of large loss of light phase, incomplete extraction and separation, and difficulty in determining the correct position of stratification, so as to achieve sufficient mass transfer between phases and ensure no Emulsifying and reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

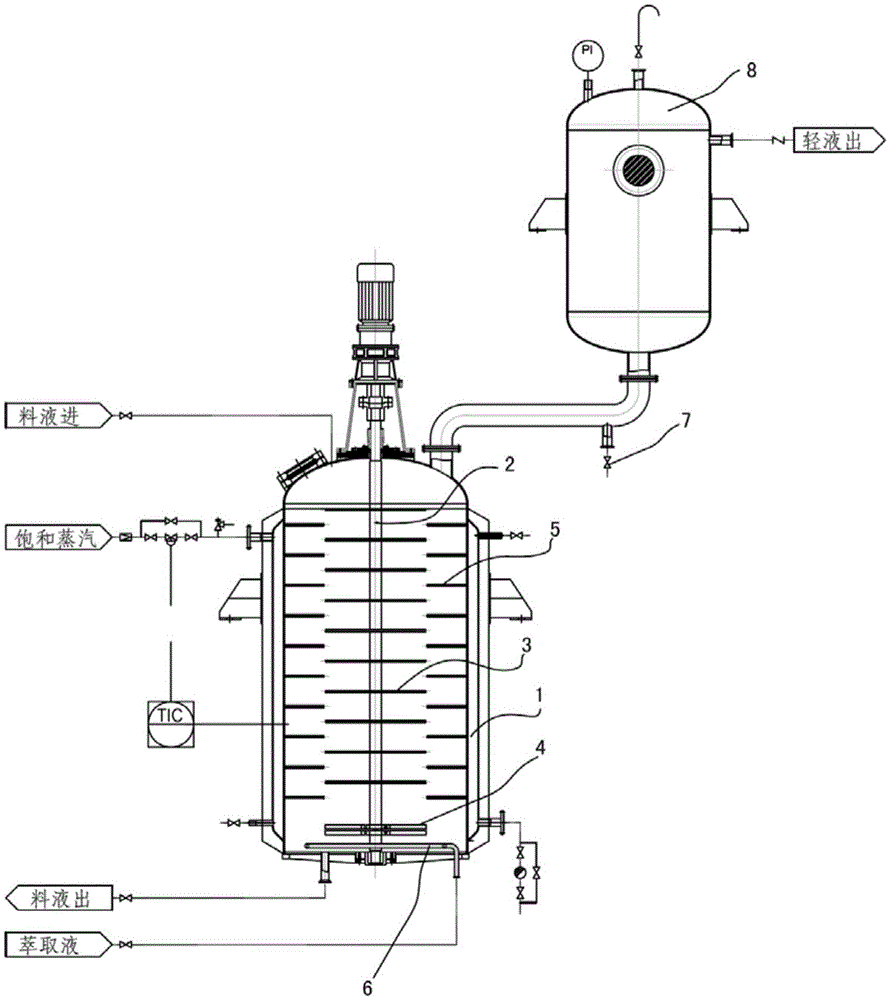

[0020] See figure 1 The extraction and extraction dual-purpose integrated machine of this embodiment includes: an extraction tank 1, a stirring shaft 2 arranged on the central axis of the extraction tank 1 and equipped with a paddle 4 at the bottom, and inside the extraction tank 1 And a plurality of stirring rings 3 axially distributed on the stirring shaft 2, a plurality of static rings 5 arranged on the inner wall of the extraction tank 1 and distributed with each stirring ring 3; the extraction tank 1 The top of the extraction tank 1 is provided with a heavy liquid inlet for inputting heavy liquid and a light phase outlet for outputting light phase feed liquid, and the bottom of the extraction tank 1 is provided with a light liquid inlet for inputting light liquid and a heavy phase for outputting heavy phase Outlet; a clarification tank 8 is provided above the extraction tank 1, the light phase outlet of the extraction tank 1 is connected to the bottom of the clarificati...

Embodiment 2

[0026] The working method of the above-mentioned extracting and extracting dual-purpose integrated machine includes:

[0027] Input the heavy liquid into the extraction tank 1 through the heavy liquid inlet on the top of the extraction tank 1, observe the liquid level through the glass sight glass on the top of the extraction tank 1, and stop the feed liquid input when the liquid level reaches the preset height ;

[0028] Slowly start the stirring shaft 2 and start stirring;

[0029] Slowly heat to keep the feed liquid in the extraction tank 1 at a preset temperature (the temperature is determined by the mass transfer temperature of the active ingredient to be extracted or extracted in the corresponding extract or extract, refer to the relevant technical manual or pass selected by multiple trials);

[0030] Evenly enter the light phase into the extraction tank 1 from the liquid distributor at the bottom of the extraction tank 1. During the stirring process, the phases realiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com