An integrated process of ecological dredging and sludge solidification and disposal

A sludge and ecological technology, applied in the direction of dewatering/drying/concentrating sludge treatment, etc., can solve the problems of solidification, inability to use directly, dispersing the compression pressure of filter belts, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific embodiments of the present invention will be described below in conjunction with the drawings.

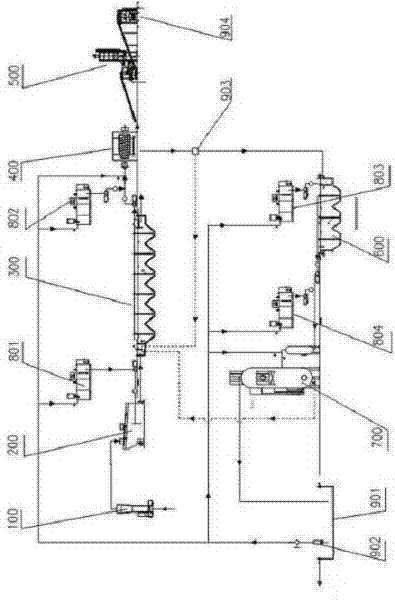

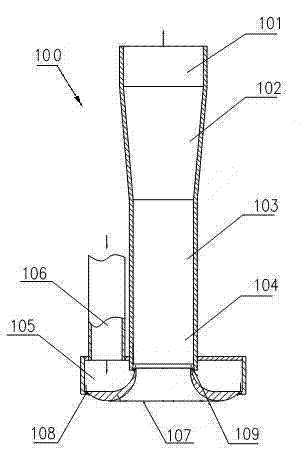

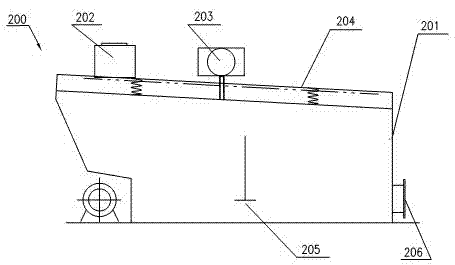

[0036] Such as figure 1 As shown, the sludge dehydration solidification and sewage purification process of the present invention includes treatment equipment including a jet pump 100 connected in series with a transfer pump, a vibrating screen 200, a reduction thickening tank 300, and a centrifuge 400. There are two pipelines from the machine 400, one of which leads to the sludge solidification equipment 500 and the automobile outbound office 904 connected to it, and the other leads to the series-connected regulating tank 600, purification tower 700, and the clean water tank 901 connected to it. . Flocculant dosing equipment 801, 802, 803, 804 are respectively provided at the entrances of the reduction and concentration tank 300, the centrifuge 400, the adjustment tank 600 and the purification tower 700.

[0037] The sludge dehydration solidification and sewage puri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com