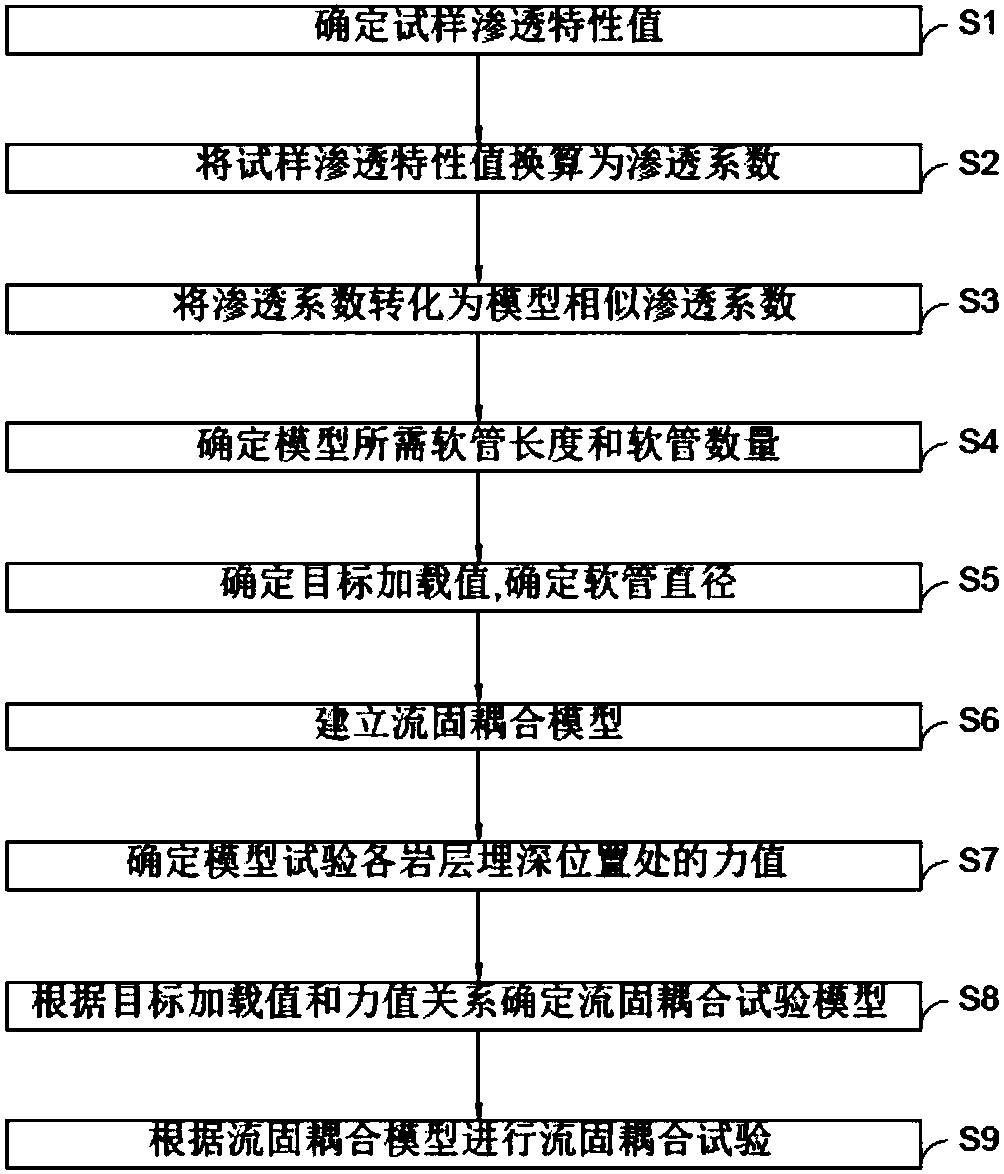

Method for building fluid-structure interaction test based on post-peak rock stress and permeability characteristic

A technology of permeability characteristics and rock stress, applied in the direction of permeability/surface area analysis, fuel oil test, material inspection products, etc., can solve problems such as conflicts of water permeability characteristics, difficulties in meeting actual production requirements, and inability of permeability characteristics to meet test requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

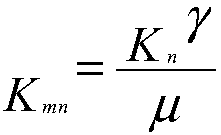

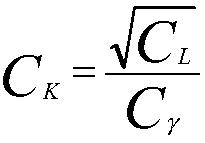

[0126] B is the length value of the buried hose; D n is the hose diameter. Further, as a specific embodiment of the method for establishing a fluid-solid coupling test based on post-peak rock stress and permeability characteristics provided by the present invention, step S8 determines the fluid-solid coupling test model according to the relationship between the target loading value P and the force value F includes:

[0127] When F≥P, the hose selected by the fluid-solid coupling test model can meet the test requirements and can be used directly;

[0128] When F≤P, the hose selected by the fluid-solid coupling test model cannot meet the test requirements. It is necessary to add a special toughened sheet pressurized hose to the upper part of the hose. The width d of the toughened sheet is the same as the diameter of the pressurized hose. D. n Similarly, the length c of the tempered sheet is:

[0129] Comparing the relationship between the target load value P and the force v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com