Modular self-adaptive regulation clamp to weld car and its regulating method

An adaptive adjustment and modularization technology, applied in auxiliary devices, manufacturing tools, welding equipment, etc., can solve problems such as inconvenient detection, and achieve the effects of saving time, great flexibility, and realizing flexible reconstruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

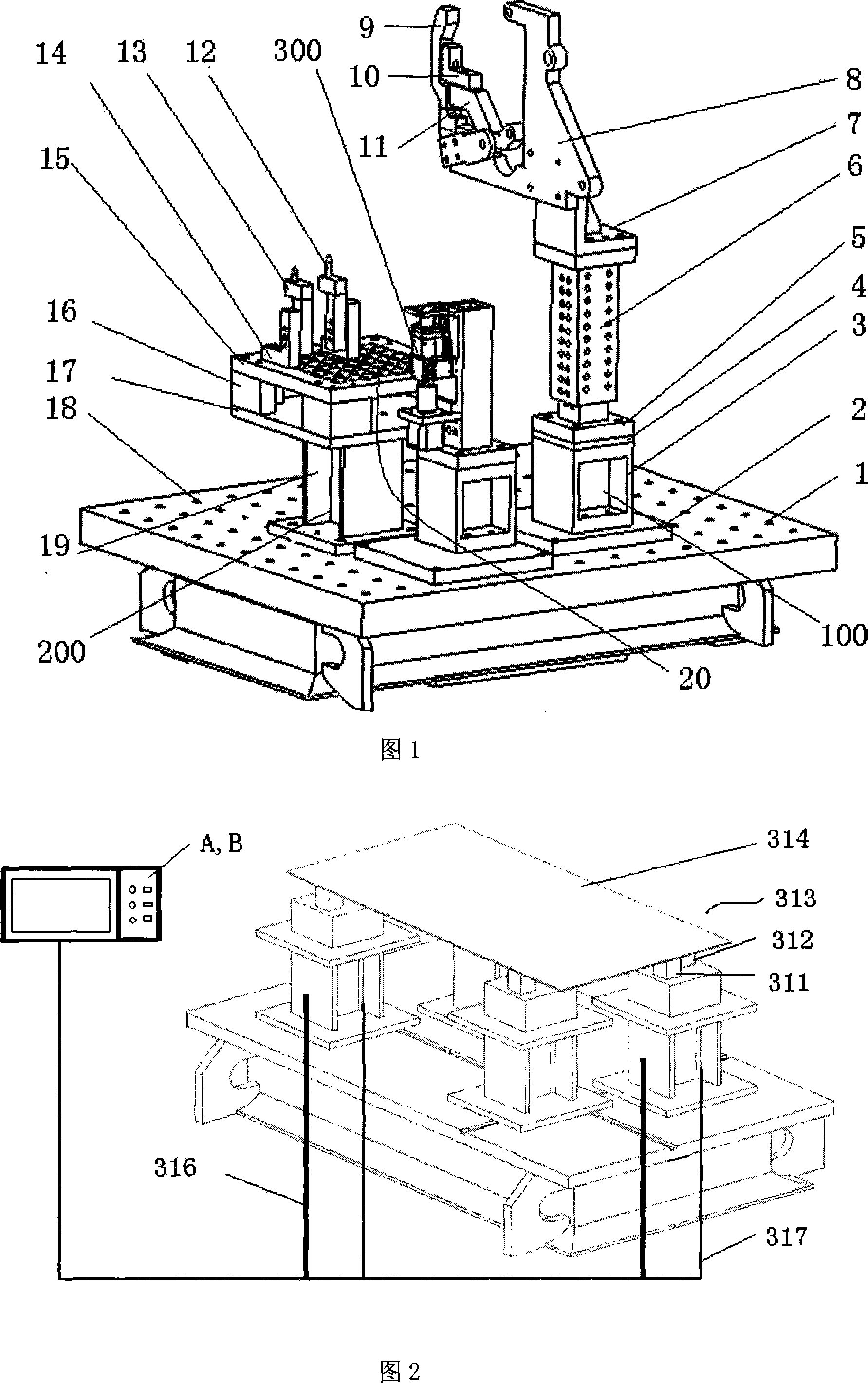

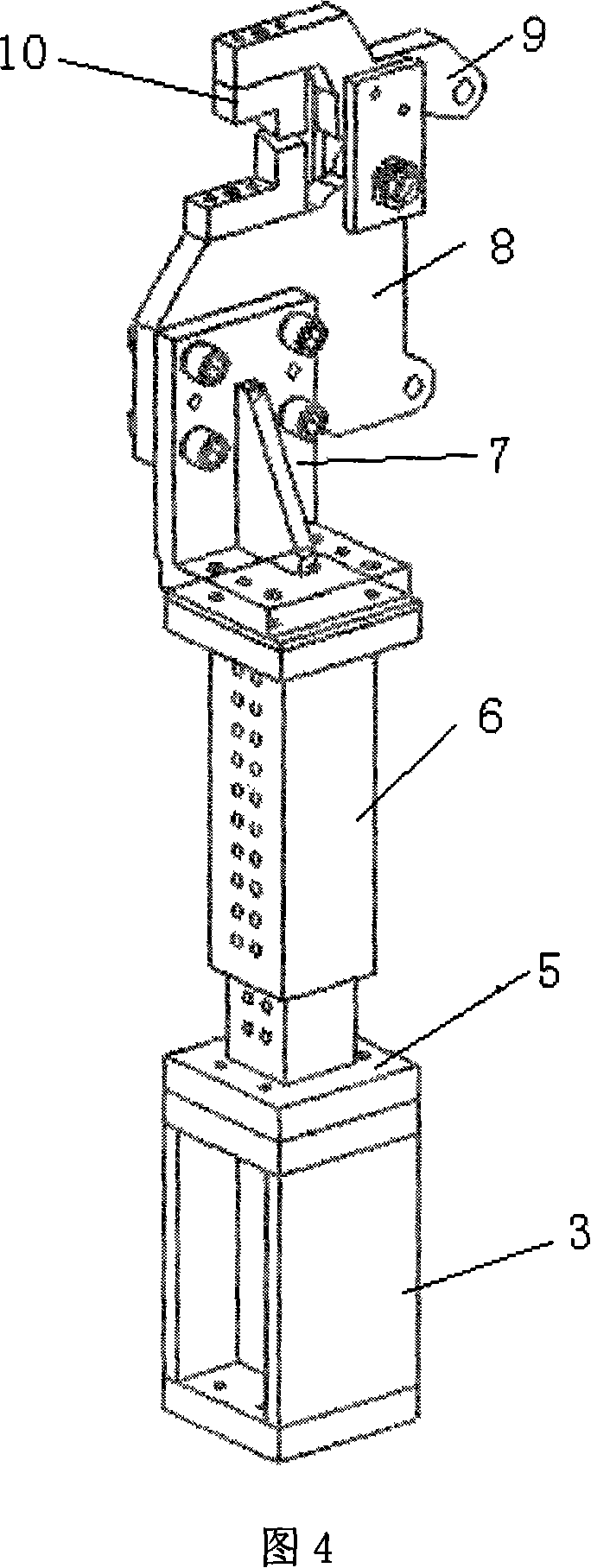

[0045] As shown in FIG. 1 , the present invention includes a base 1 , a transition plate 2 , a clamping mechanism 100 fixed on the base 1 , an independent main positioning mechanism 200 , and an adaptive adjustment and detection device 300 installed on the sleeve 6 .

[0046] As shown in FIG. 2 , the adaptive adjustment device of the present invention includes: an online real-time detection device, controllers A and B, an adaptive adjustment device 2 and an adaptive adjustment system.

[0047] The online real-time detection device is composed of a position sensor 311, a high-frequency cable 316 and a sensor controller A.

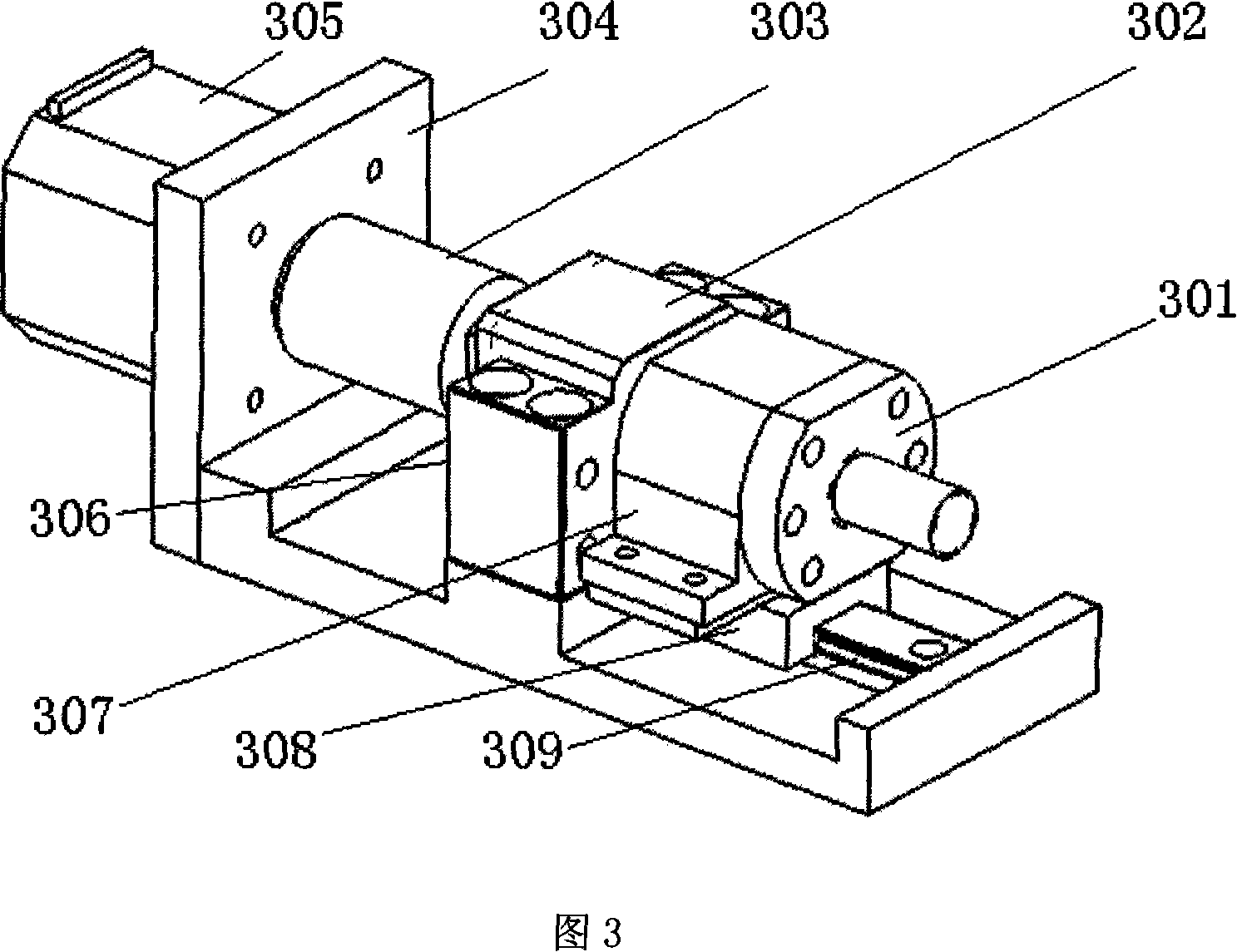

[0048]The online real-time detection and adaptive adjustment device 300 is composed of a stepper motor 305, a slider 308, a linear guide 309, a ball screw 306, a shaft coupling 303, and a push rod 301; For the quantized value to be adjusted, an instruction is issued to drive the stepping motor 305, which drives the ball screw 306 forward and reverse, so that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com