A manufacturing equipment for rows of steel fibers

A technology for manufacturing equipment and fibers, applied in the field of manufacturing equipment for rows of steel fibers, can solve the problems of unsatisfactory gluing effect, waste of raw materials, scattered steel fibers, etc., achieve better solidification effect, ensure adhesive performance and production efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

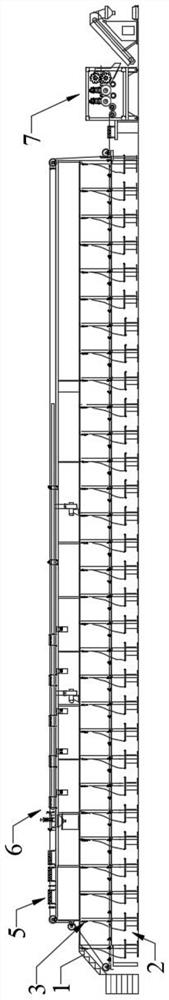

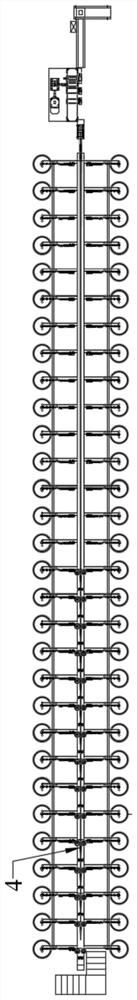

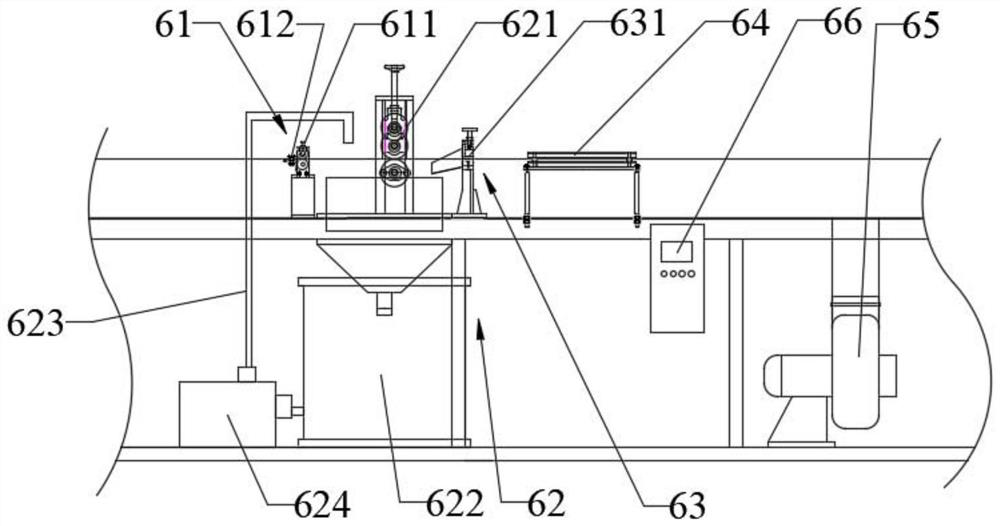

[0056] A manufacturing equipment for rows of steel fibers, comprising a bracket 1, and also includes a wire lifting device 2, a single wire straightening device 3, a paralleling device 4, a row straightening device 5, and a gluing heating device sequentially installed on the bracket. device 6 and shear forming device 7, and the gluing heating device 6 is sequentially provided with a cleaning and shaping mechanism 61, a gluing mechanism 62, a gluing mechanism 63, a heating device 64, a blower 65 and a controller along the direction in which the rows of steel wires enter 66; the cleaning and shaping mechanism 61 includes a pair of extrusion shaping rollers 611 and cleaning components 612, the extrusion shaping rollers 611 are horizontally arranged on the support 1, and there is a set between the extrusion shaping rollers 611 to facilitate forming The roll gap through which steel wires pass, the cleaning part 612 is arranged on one side of the extrusion shaping roller 611; the glu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com