A kind of aluminum oxide hollow ball modified friction material and its preparation method

A technology of aluminum oxide hollow balls and friction materials, applied in chemical instruments and methods, friction linings, mechanical equipment, etc., can solve problems such as friction materials falling off from steel backs, damage to colloidal bonding ability, and potential safety hazards in the form of locomotives. Achieve the effect of low wear rate, good heat insulation effect and excellent effect mosaic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

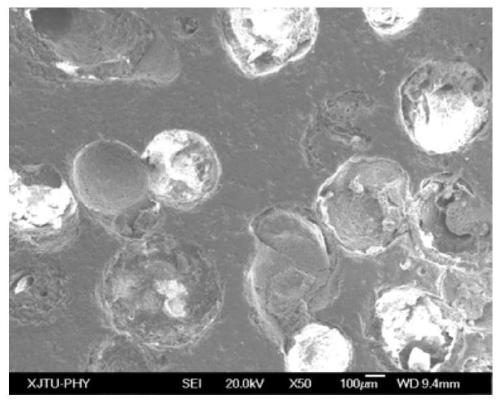

Image

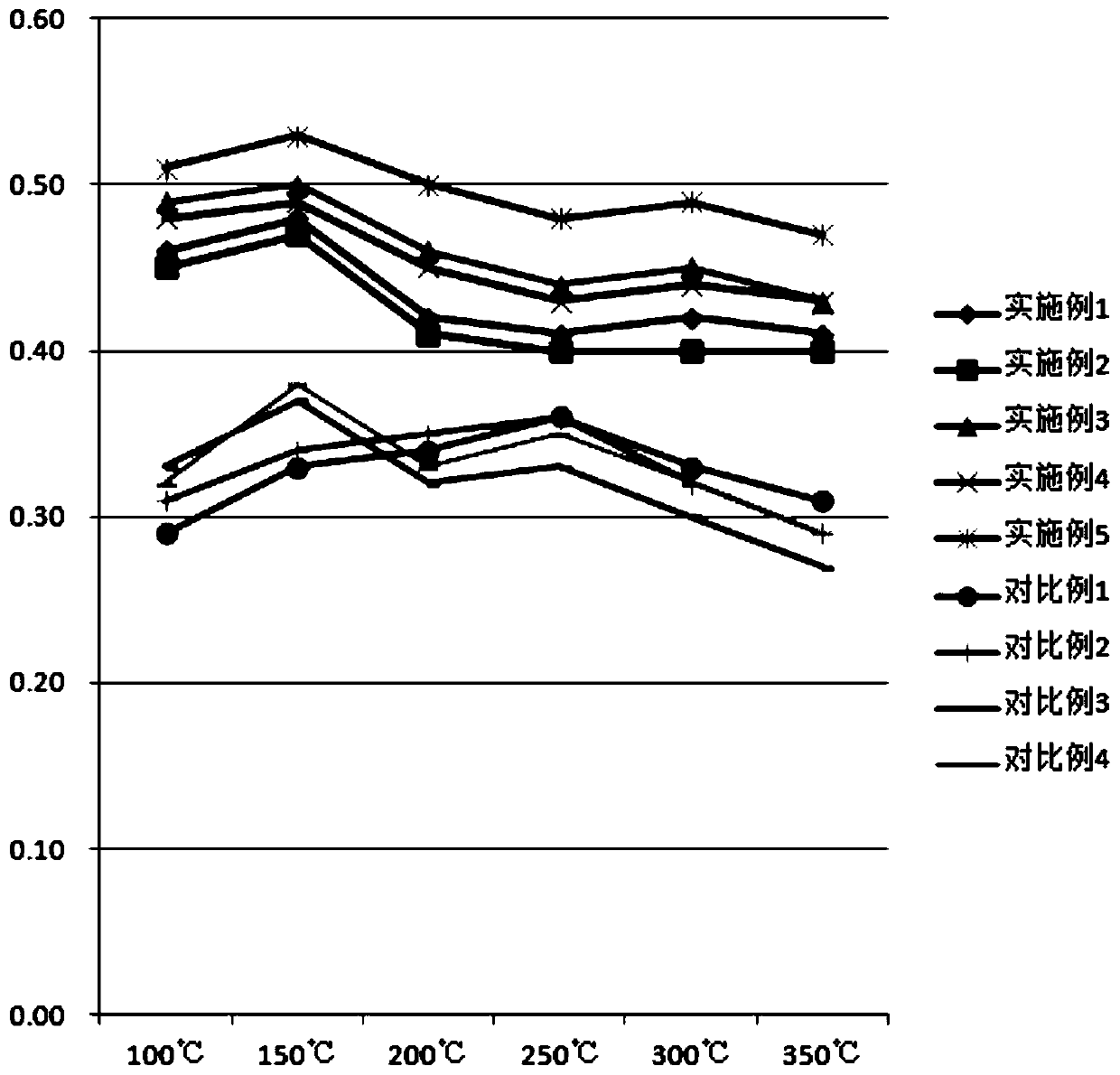

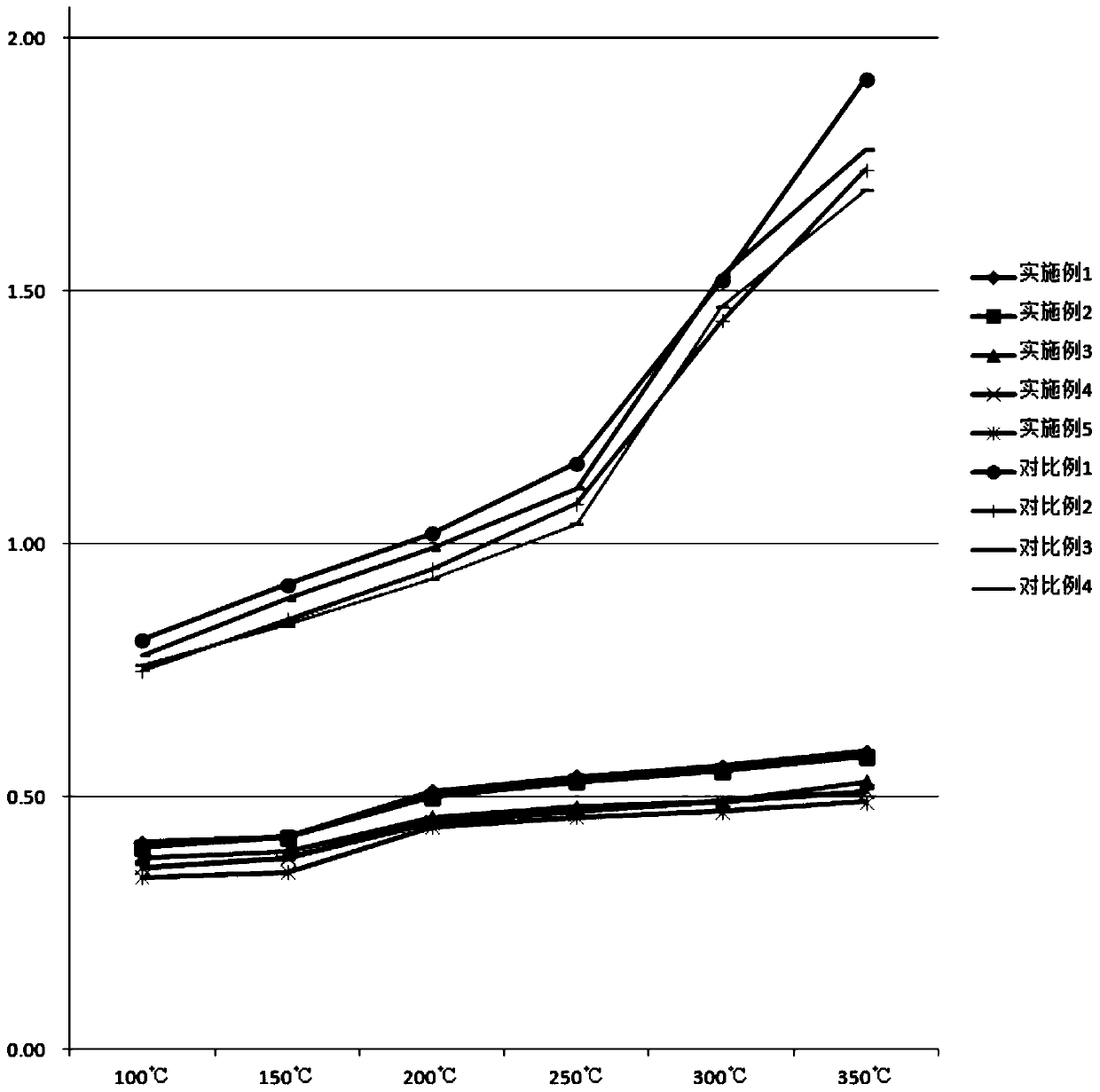

Examples

Embodiment 1

[0027] A hollow aluminum oxide ball modified friction material, comprising a base material, a wear-resistant phase and an adhesive; the base material includes the following raw materials in mass percentages: 8% phenolic resin, 4% aluminum oxide powder, and 6% aramid fiber , vermiculite 4%, calcium carbonate 4%, mica 8%, mineral fiber 6%, ferric oxide 4%, graphite powder 6%, tire powder 6%, zircon 12%, fluorite 10%, cryolite 6%, barium carbonate 10%, and lead-zinc ore 6%; the wear-resistant phase is aluminum oxide hollow spheres, and the quality of the aluminum oxide hollow spheres is 2% of the mass of the base material; the adhesive is coated on the Grinding the surface of the phase, and embedding the wear-resistant phase in the base material, the adhesive is a polyvinyl alcohol solution with a mass concentration of 5%, and the mass ratio of the aluminum oxide hollow spheres to the adhesive is 10:1.

[0028] The preparation method of the aluminum oxide hollow sphere modified f...

Embodiment 2

[0032] A hollow aluminum oxide ball modified friction material, comprising a base material, a wear-resistant phase and an adhesive; the base material includes the following raw materials in mass percentages: 10% phenolic resin, 6% aluminum oxide powder, and 3% aramid fiber , vermiculite 6%, calcium carbonate 6%, mica 10%, mineral fiber 10%, ferric oxide 4%, graphite powder 10%, tire powder 4%, zircon 8%, fluorite 7%, cryolite 4%, barium carbonate 8%, and lead-zinc ore 4%; the wear-resistant phase is aluminum oxide hollow spheres, and the quality of the aluminum oxide hollow spheres is 8% of the mass of the base material; the adhesive is coated on the wear-resistant Grinding the surface of the phase, and embedding the wear-resistant phase in the base material, the adhesive is a carboxymethyl cellulose solution with a mass concentration of 20%, and the mass ratio of the alumina hollow spheres to the adhesive is 20:1 .

[0033] The preparation method of the aluminum oxide hollow...

Embodiment 3

[0037] A hollow aluminum oxide ball modified friction material, including a base material, a wear-resistant phase and an adhesive; the base material includes the following raw materials in mass percentages: 10% phenolic resin, 6% aluminum oxide powder, and 6% aramid fiber , vermiculite 5%, calcium carbonate 5%, mica 9.6%, mineral fiber 8%, ferric oxide 4%, graphite powder 8%, tire powder 6%, zircon 10%, fluorite 6.4%, cryolite 4%, barium carbonate 8%, lead-zinc ore 4%, the mass ratio of fluorite, cryolite, barium carbonate and lead-zinc ore is 8:5:10:5;

[0038] The wear-resistant phase is alumina hollow spheres, and the mass of the alumina hollow spheres is 3% of the mass of the base material; the adhesive is coated on the surface of the wear-resistant phase, and the wear-resistant phase is embedded in the base material , the adhesive is a polyvinyl alcohol solution with a mass concentration of 5%, and the mass ratio of the aluminum oxide hollow spheres to the adhesive is 13:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com