Grinding method of high-precision beryllium semi-spherical through hole

A hemispherical through hole and grinding method technology, which is applied in the field of high-precision grinding of special materials, can solve the problems of large grinding degree of the hole, scratching the surface of the inner hole, and uneven grinding degree, so as to improve the surface roughness of the inner hole and The roundness accuracy of each section, the improvement of grinding reliability, and the effect of improving surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

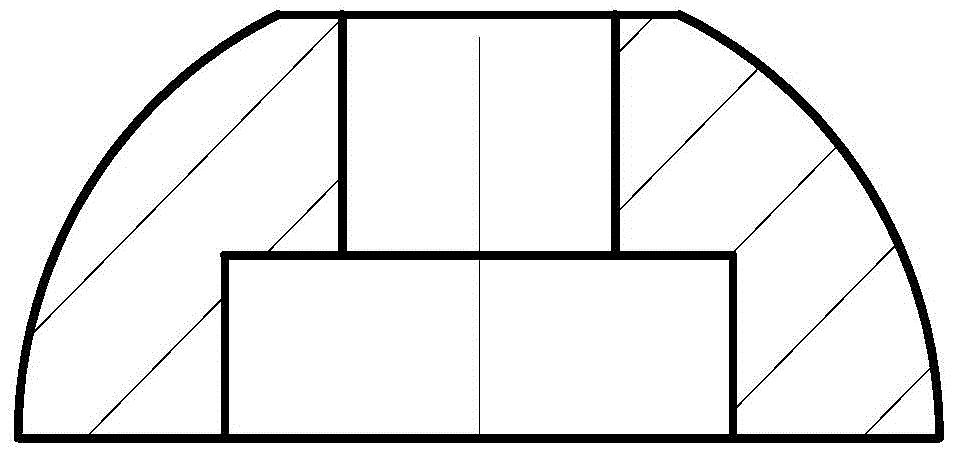

[0044] The beryllium hemisphere has a trapezoidal through hole, the diameter of the upper through hole is Φ4.5mm, and the diameter of the lower through hole is Φ8mm, and the lower part is ground for the upper through hole, such as figure 1 shown;

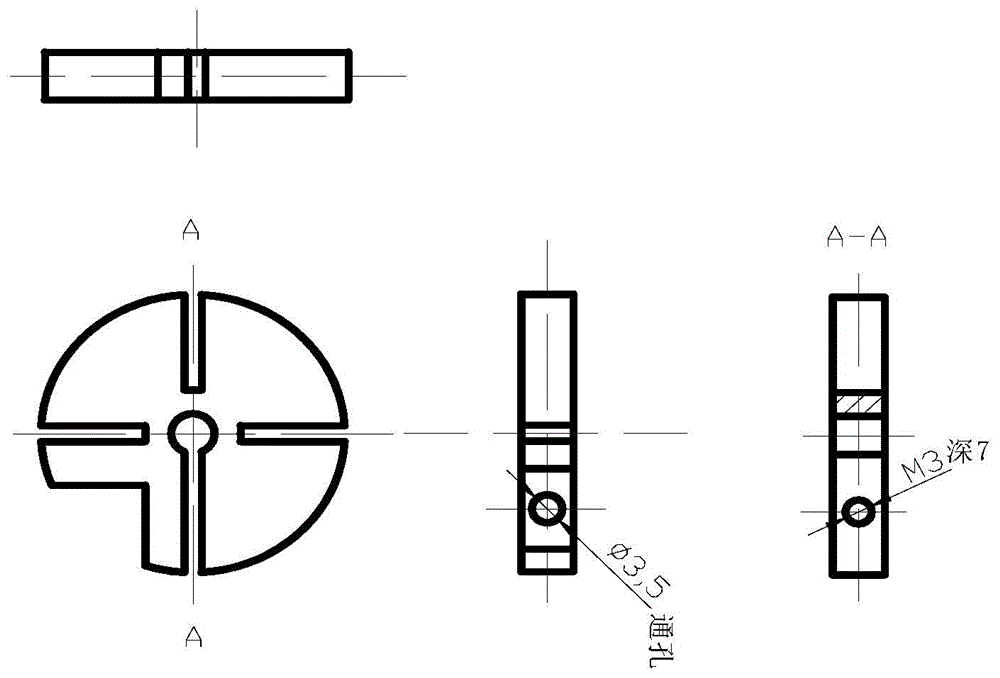

[0045] (1) Grinding rod design and training

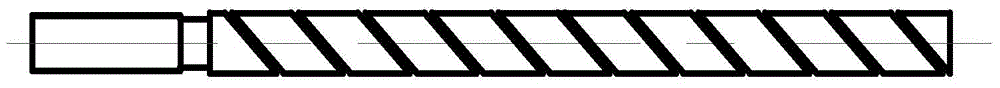

[0046] Selection and design of grinding rods. According to the material characteristics of the hemisphere, the pearlitic high phosphorus cast iron with no pores, sand holes, impurities and hard spots on the surface is selected as the grinding rod material. The schematic diagram of the grinding rod is attached image 3 shown. One end of the grinding rod is a smooth cylinder, which is convenient for the operator to hold or clamp. The main body of the grinding rod is a cylinder with an equidistant spiral sand storage tank. The diameter of the cylinder matches the hemispherical through hole, and the diameter is the hemispherical diameter. 4.505mm, the cylindricity of the finish car cyli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Cylindricity | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com