Cold-drawing finishing device and process

A cold-drawing finishing and set-up technology, which is applied to metal drawing forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems that the dimensional accuracy of inner holes cannot meet its requirements, and the loss of high-strength pipe cold-drawing molds is large. , to achieve the effect of ensuring finishing effect and quality and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

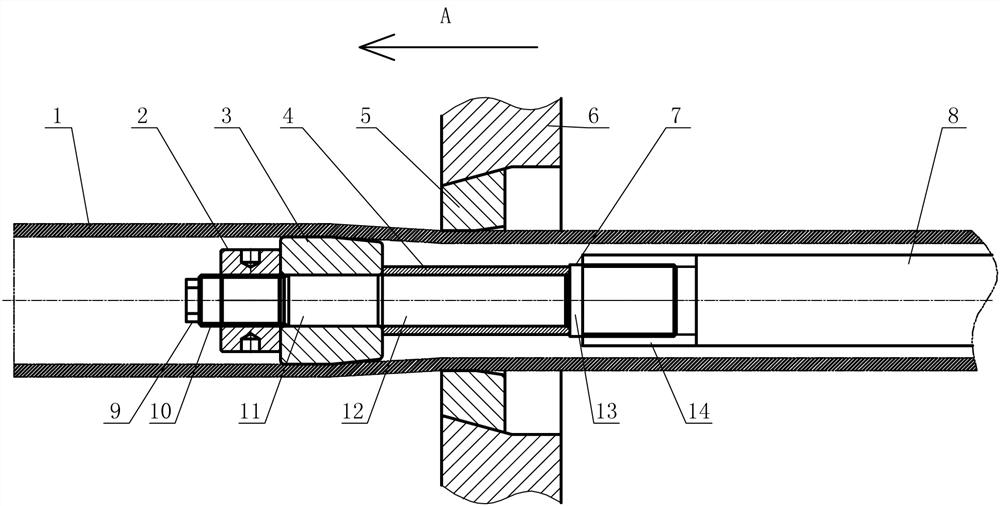

[0030] Such as figure 1 Shown, a kind of cold drawing finishing device, it comprises mold base 6, and the inside of described mold base 6 is fixedly installed with outer mold 5; Also comprises inner mold 3, and described inner mold 3 is fixedly installed on the pull bar 7, so The pull rod 7 is fixedly connected with the fixed core rod 8; the inner mold 3 and the outer mold 5 are used in pairs, and the distance between the inner mold 3 and the outer mold 5 is ≥10mm. By adopting the cold drawing and finishing device with the above structure, the products with out-of-tolerance dimensional accuracy produced in the cold drawing production process can be cold drawn and finished again to achieve the required dimensional accuracy, and then turn them into qualified products, which saves resources. , while effectively reducing costs.

[0031] Among them, in the finishing process, the relative position of the inner mold and the outer mold is very important, and the distance is ≥10mm, wh...

Embodiment 2

[0038] The cold drawing process of unqualified products is carried out with a cold drawing finishing device, including the following steps:

[0039] Step 1: Fix and install the fixed core rod 8, and pass the tube blank 1 through the fixed core rod 8;

[0040] Step 2: The tie rod 7 is fixedly connected with the installation sleeve 14 on the head of the fixed core rod 8 through the tie rod head 13;

[0041] Step 3: According to the distance requirement between the inner mold 3 and the outer mold 5, select a suitable length spacer 4 to position the inner mold 3, and fix the inner mold 3 on the tie rod 7 through the lock nut 2;

[0042] Step 4: Preliminarily pass the end of the tube blank 1 through the inner mold 3 and the outer mold 5, and fix the end of the tube blank 1 with the slider through the clamp, start the slider, and pull the tube blank 1;

[0043] Step 5: During the drawing process, the tube blank 1 is drawn successively through the direction of the outer mold 5 and t...

Embodiment 3

[0045] In this embodiment, the size of the tube blank 1 used is 220 / 198.5, the ellipticity of the inner hole is 0.6mm, the outer mold is 218, and the inner mold is 199. After cold drawing by the above-mentioned device, the inner hole ellipticity is 0.3mm, Meet the requirements;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com