Method and device for installation and correction of linear rolling guide rail of grinding machine

A technology of rolling guide and correction device, which is applied in the direction of grinding bed, grinding machine parts, grinding frame, etc., can solve the problems of damage position accuracy, low processing efficiency, long auxiliary time, etc., and achieve high correction accuracy. , Improve work efficiency, the effect of short auxiliary time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

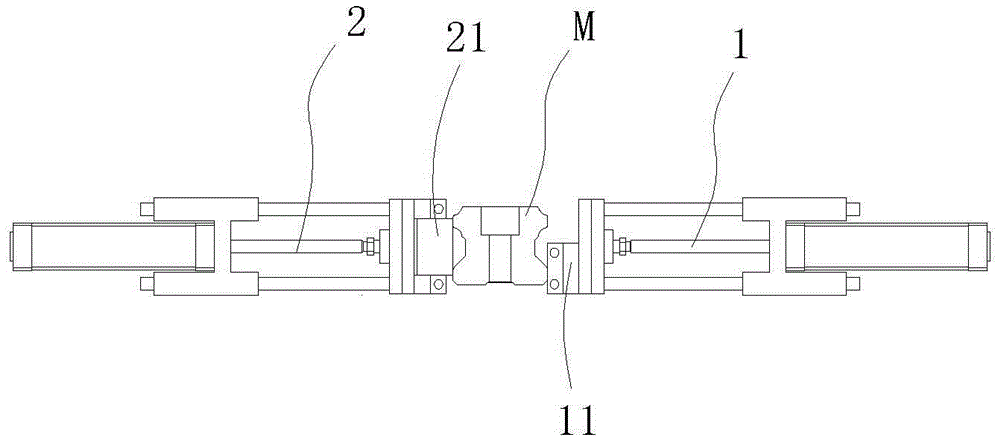

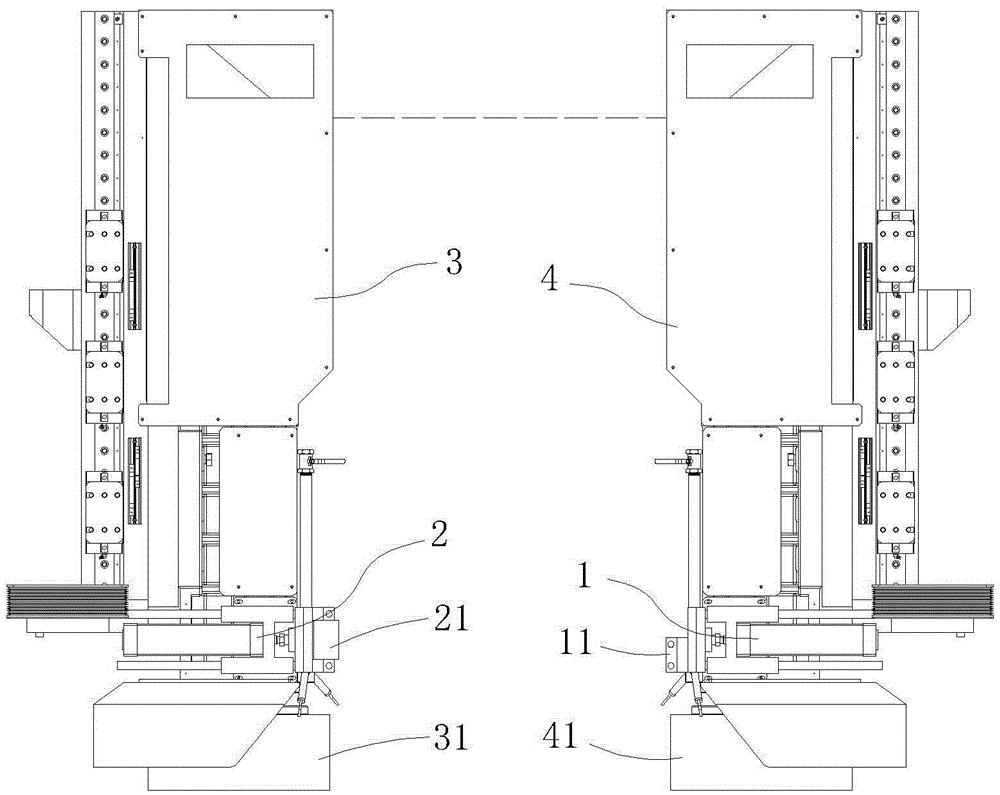

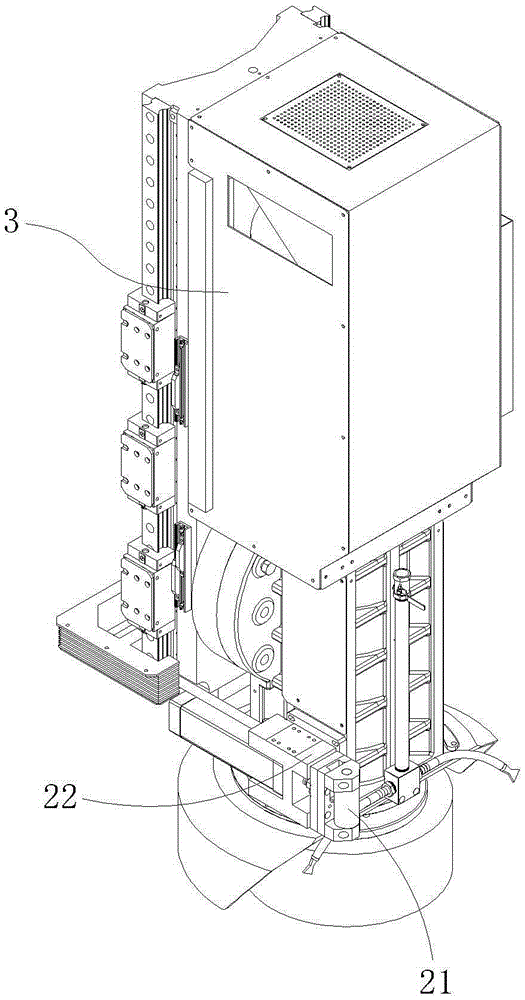

[0022] Example: see Figure 1 to Figure 4 , a method for installing and correcting linear rolling guide rails of a grinding machine, comprising the following steps:

[0023] a. Place the linear rolling guide M on the magnetic work surface of the grinding machine;

[0024] b. Move the correction device to the vicinity of the linear guide, first use the positioning block 11 connected to the reference cylinder 1 to press against the reference side of the linear guide for positioning, and then press the roller 21 of the cylinder 2 against the other side of the linear rolling guide Pressing up, the pressure set by the reference cylinder 1 is slightly larger than the pressure set by the pressing cylinder 2;

[0025] c. Start the grinder and move the correction device along the full length of the linear rolling guide with a slow moving speed. When the correction device moves, the reference position determined by the reference cylinder remains constant in the longitudinal direction o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com