Patents

Literature

64 results about "Lateral positioned" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

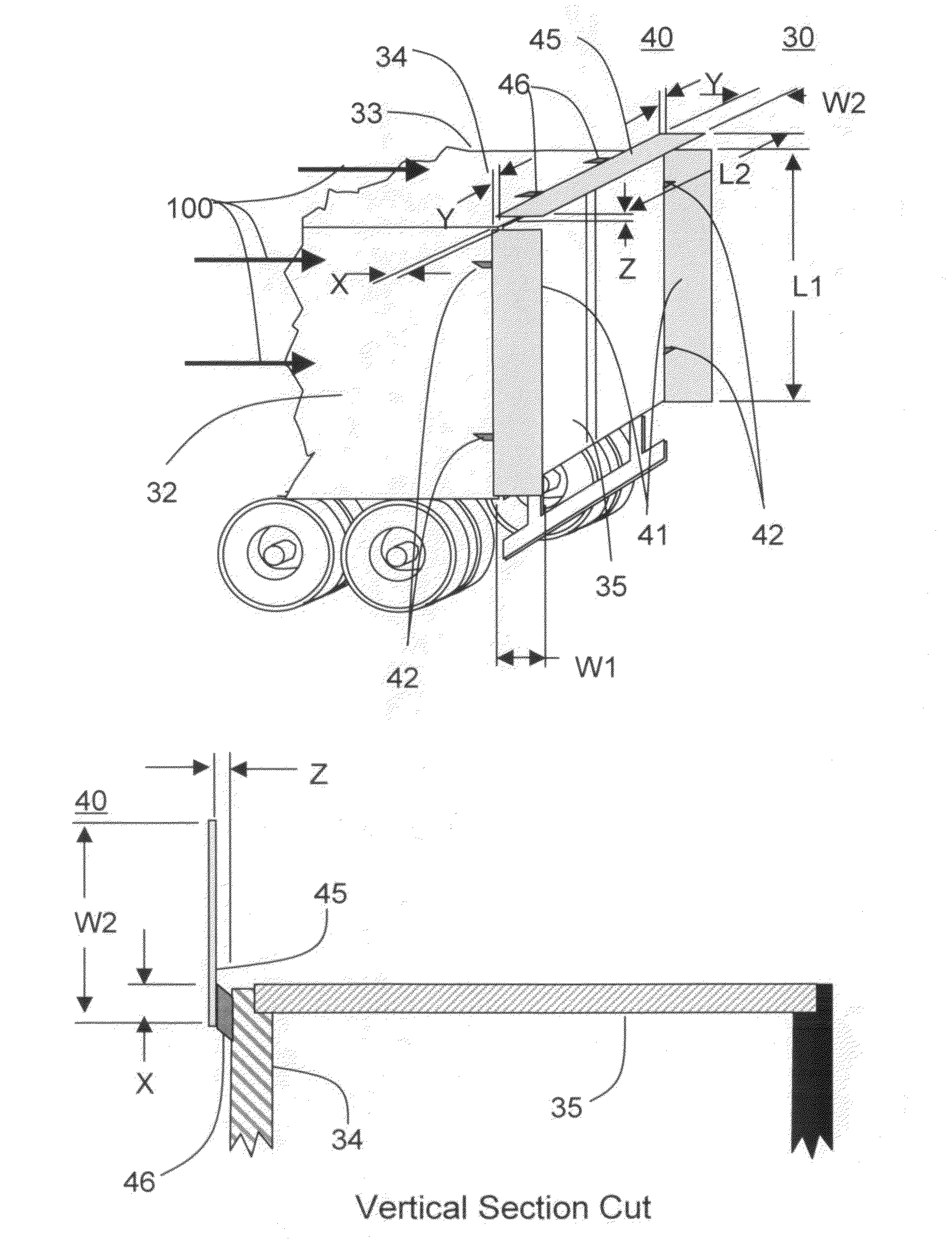

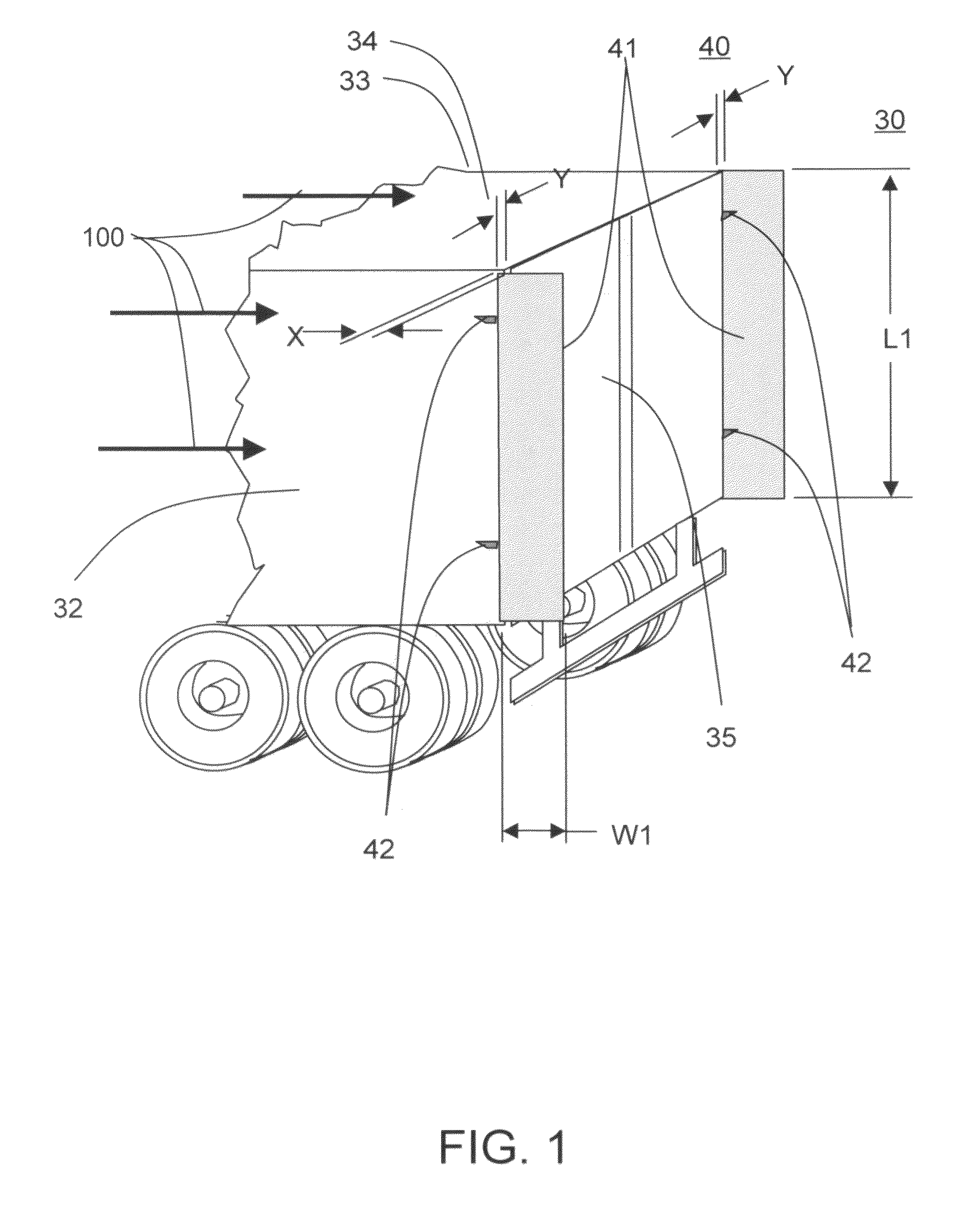

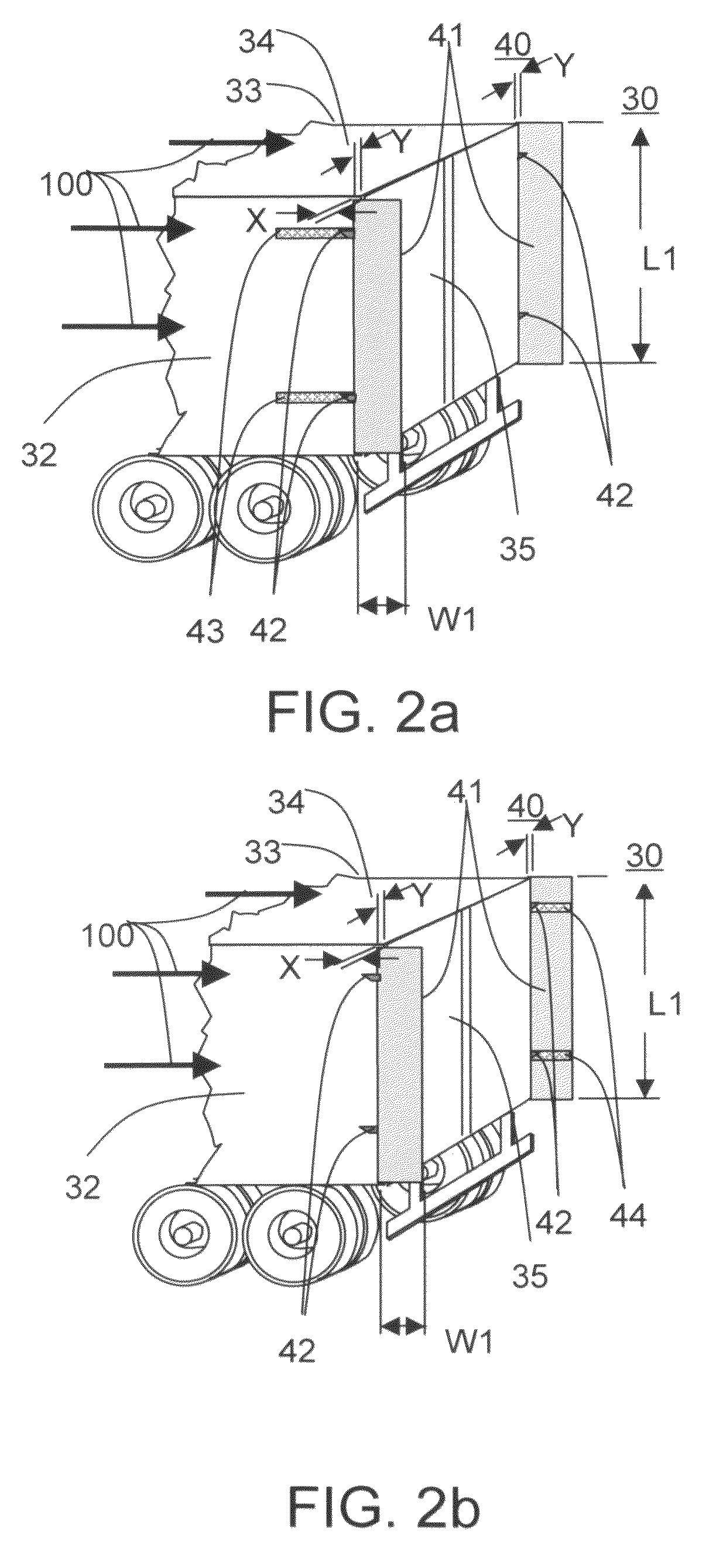

Outboard wake stabilization device and method for reducing the aerodynamic drag of ground vehicles

An improved method and device for the reduction of aerodynamic drag and for improved performance of vehicles by increasing the pressure on the base of the trailing vehicle or vehicle component by controlling the boundary layer as it exists the vehicle trailing edge. The subject invention consists of a multiple panels located near the base area of a bluff base vehicle. The flow control objectives are accomplished by positioning minimally sized panels comprising the invention in close proximity to the side and top surfaces of the vehicle, where the leading edge of each panel is positioned in close proximity to the trailing edge of the vehicle. The side panels comprising the invention are laterally positioned outboard of the side surface of the vehicle. The top panels are vertically positioned above the top surface of the vehicle.

Owner:WOOD RICHARD M

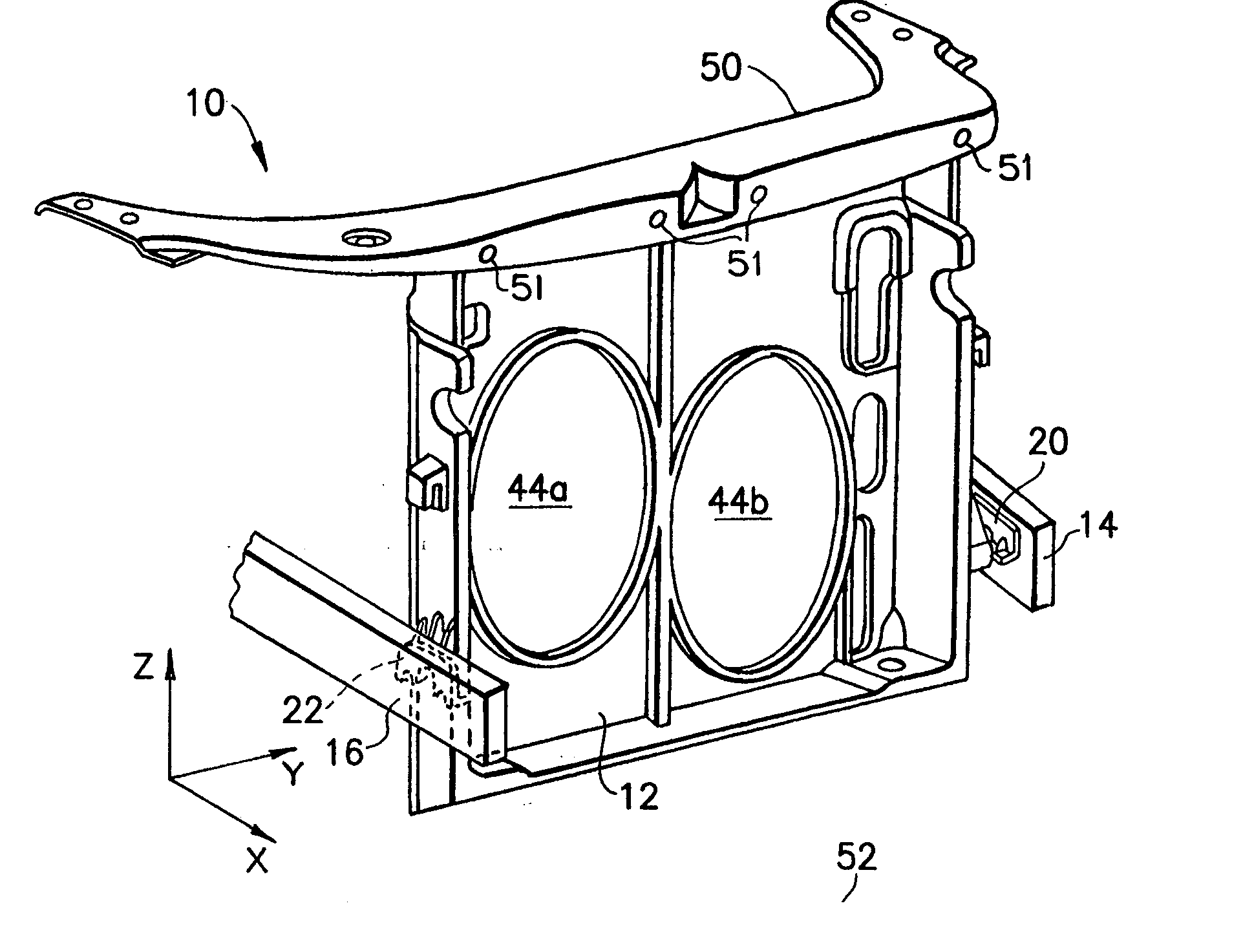

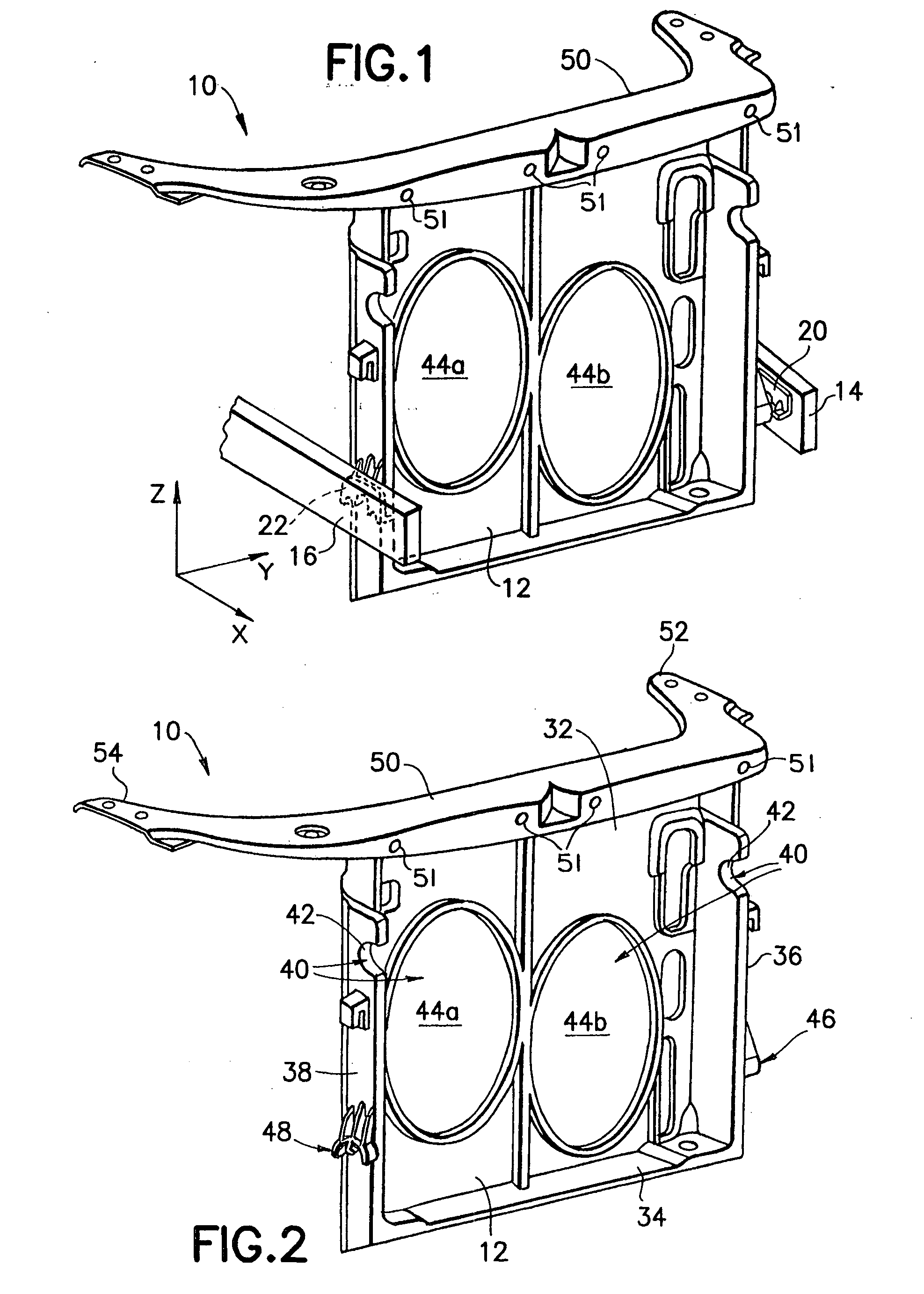

Structural carrier assembly for a motor vehicle

The structural carrier assembly is installed in a motor vehicle front or rear end. The structural carrier assembly includes one or more support brackets connected to one or more frame rails of a motor vehicle body. The structural carrier assembly further includes a carrier member having laterally positioned attachment clips. The attachment clips connect the carrier member to the support brackets. The carrier member includes one or more attachment mounts or locations for supporting accessories, such as engine accessories, of the motor vehicle. A cross frame is mounted to an upper end of the carrier member by welds or mechanical attachments. The attachment clips each include an integral fulcrum cup and locking tab typically formed on the lateral sides of the carrier member. The locking tabs engage mating openings formed in the support brackets to connect the carrier member to the frame rails.

Owner:BAYER POLYMERS LLC

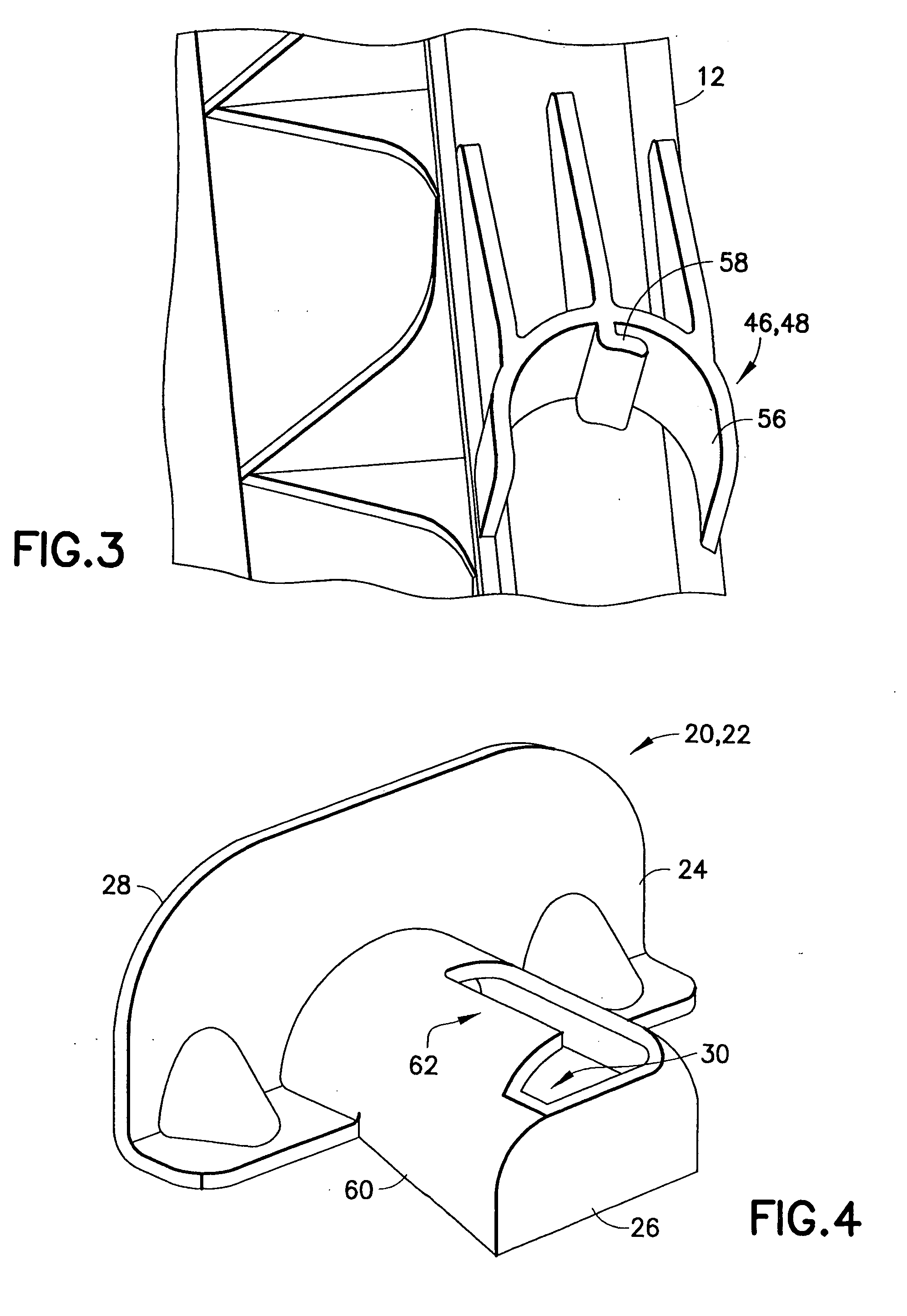

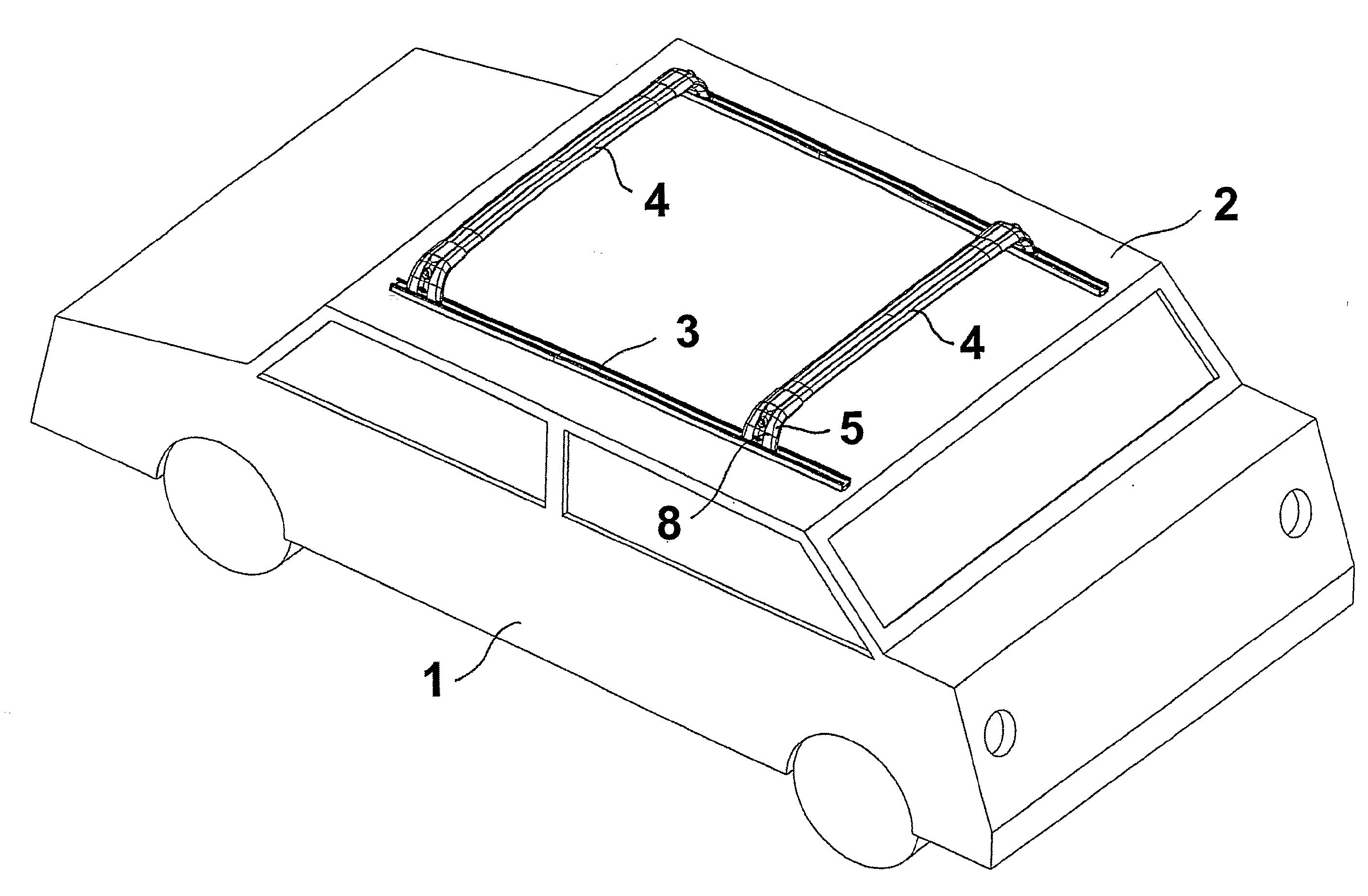

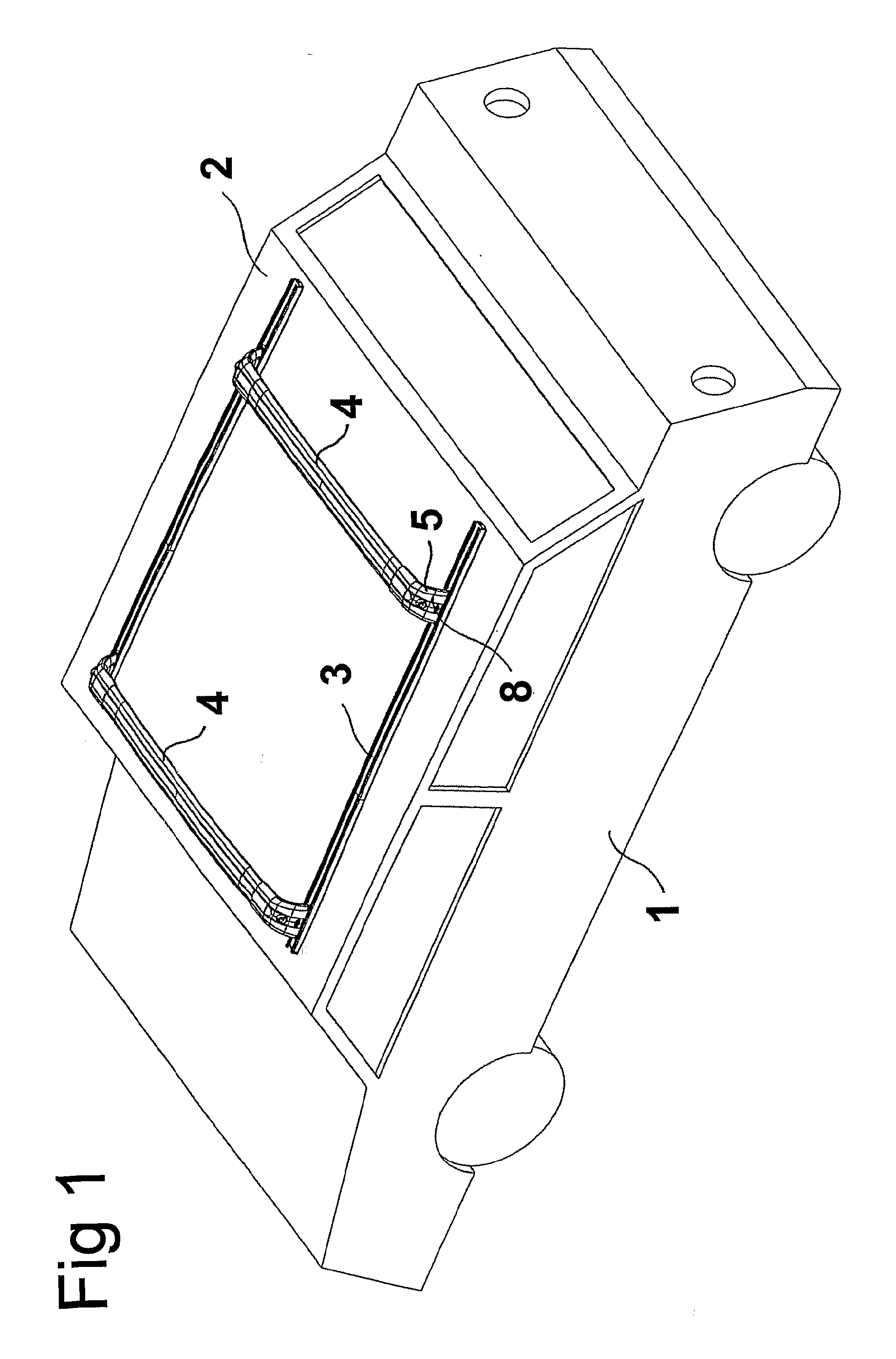

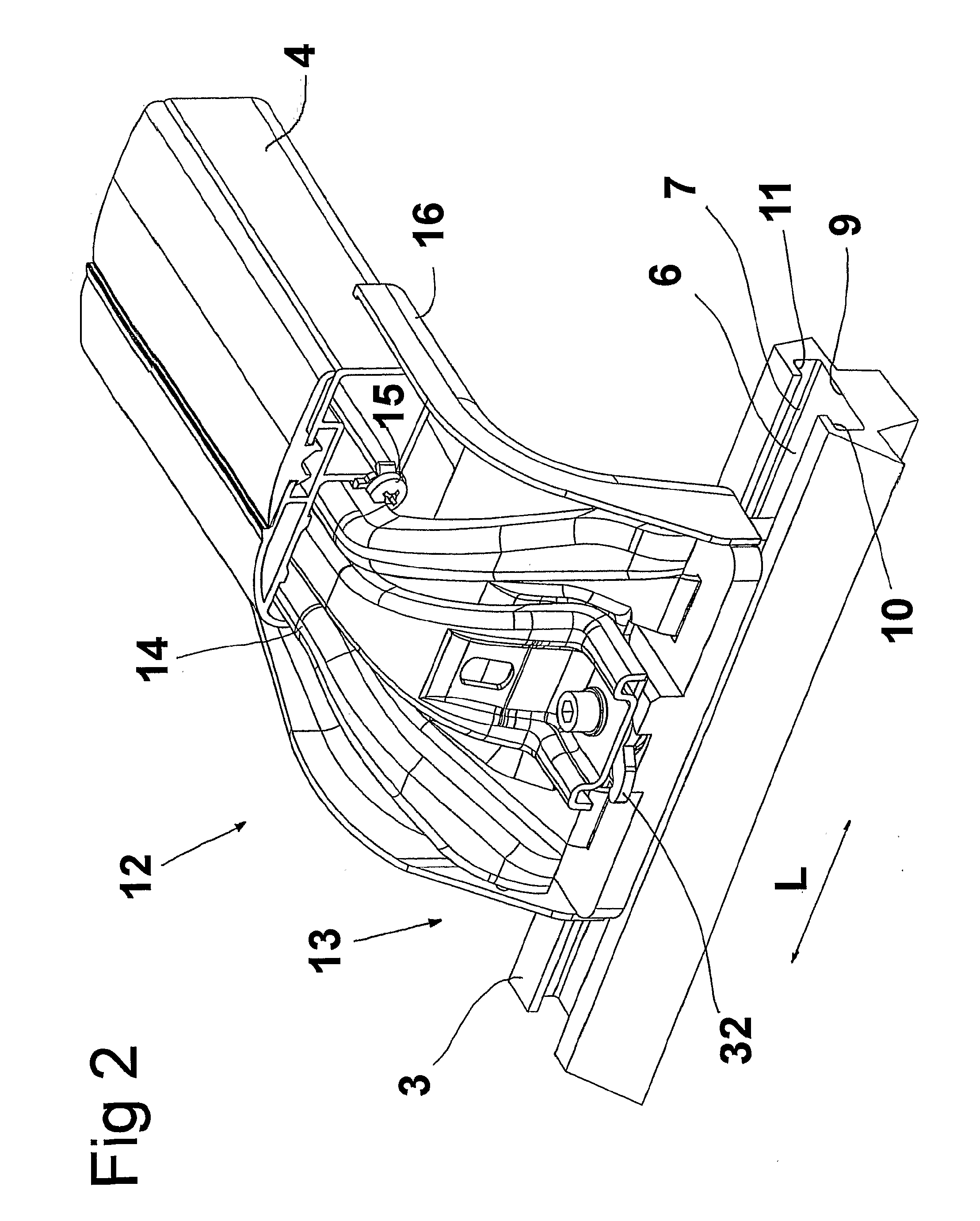

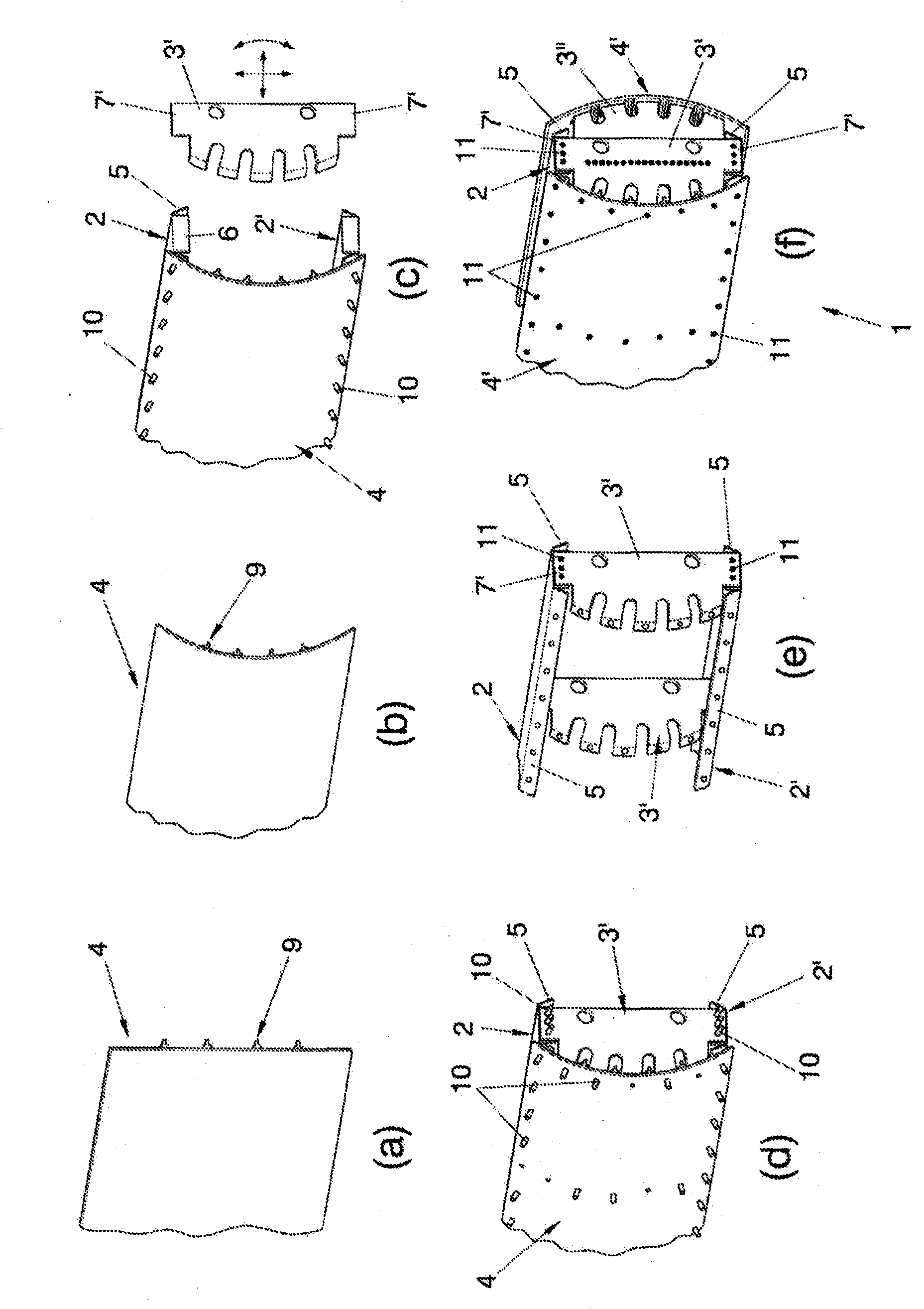

Load carrier foot

Load carrier foot (5) for connecting a load carrier bar (4) to an, at a vehicle connected, elongated rail profile (3), having in the longitudinal direction (L) of the rail an extended cavity (6), with an upwards turned opening (7), in which the width (B) of the cavity across the longitudinal direction of the rail exceeding the width (b) of the opening, whereby the cavity on each side of the opening having walls (10, 11), which are directed essentially downwards against the bottom (9) of the cavity, whereby the load carrier foot having a base part (13), which extends through the opening towards the bottom of the cavity. A fastening device (29), which by means of a clamping device (51) is moved upwards to clamping contact with the downwards directed walls (10, 11) when the base part being secured to the rail profile. A connection means (25,30) is firmly connected with the locking device (29) and turnable connected to the base part (13), and an elastic body (24) is located between the base part and the connection means, which turns the connection means and the locking device to a position in which the locking device being located transverse relative the longitudinal direction of the rail profile when the base part is mounted to the cavity, and in which position the locking device certainly will be in contact with the downwards directed walls (10, 11) when the locking device being clamped against the walls by the clamping device (51).

Owner:THULE SWEDEN AB

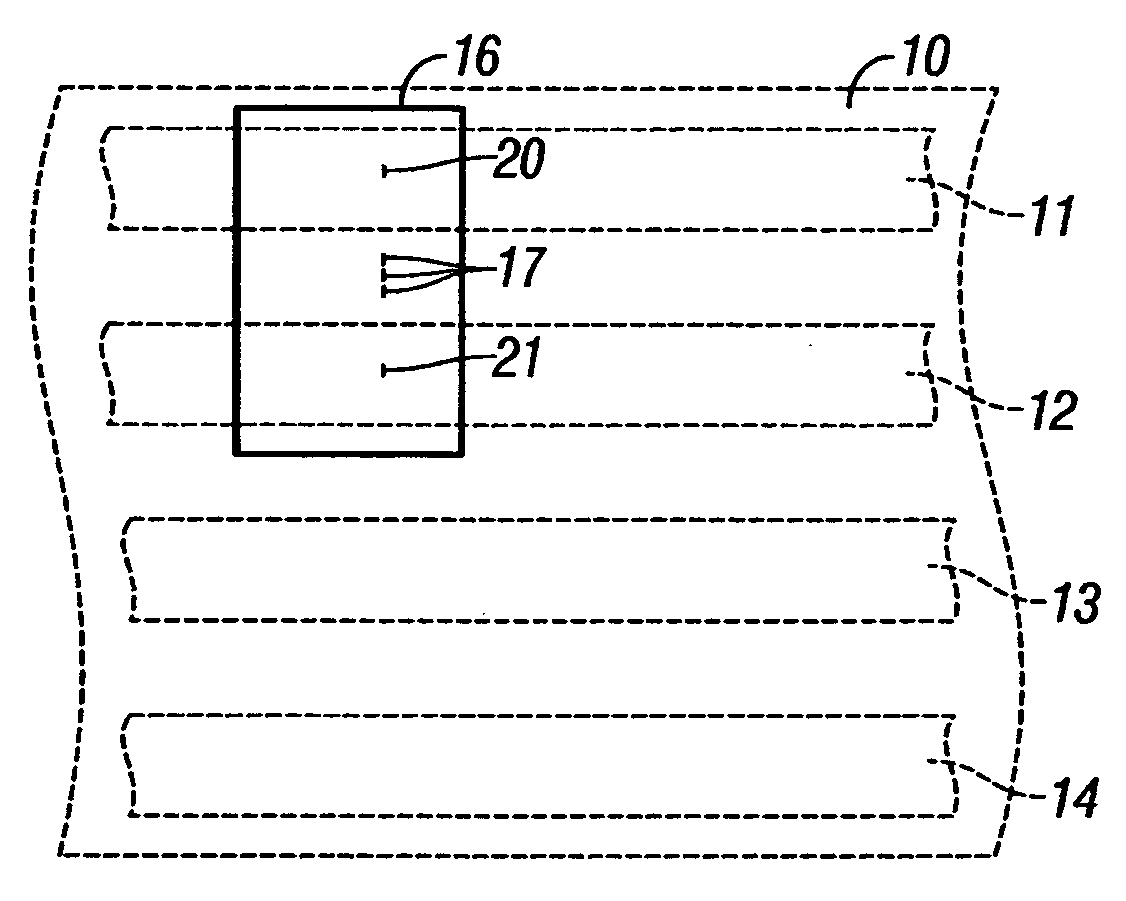

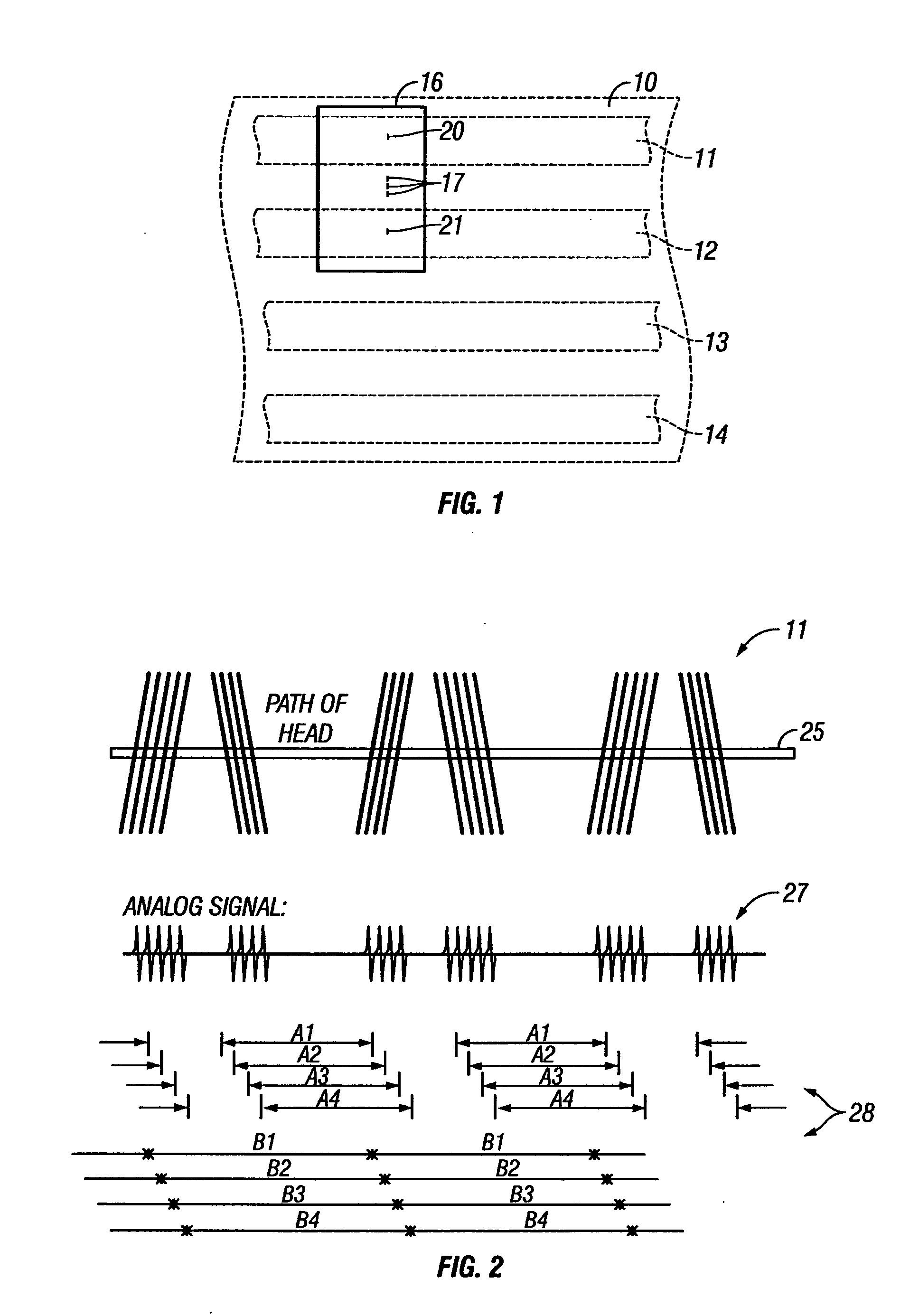

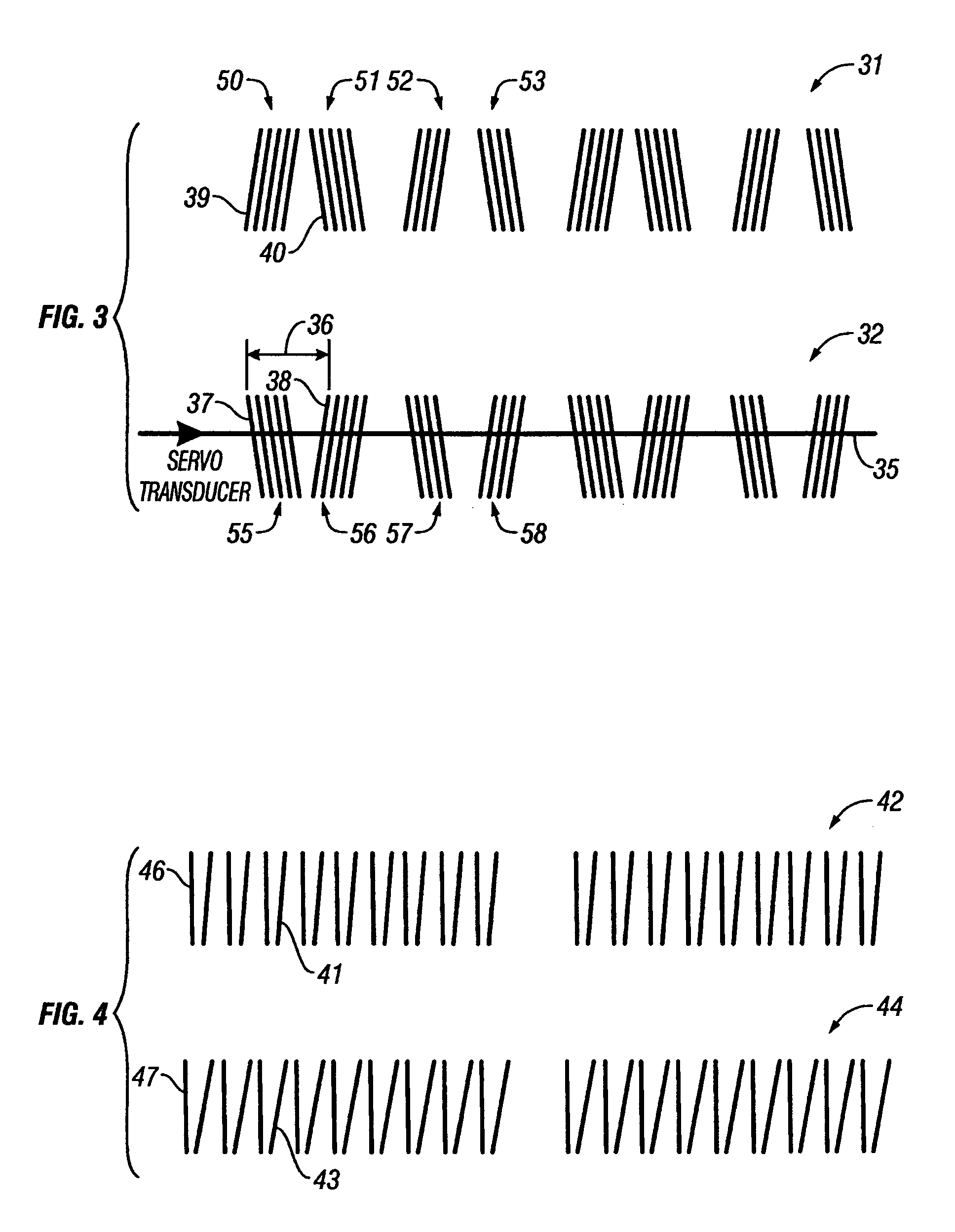

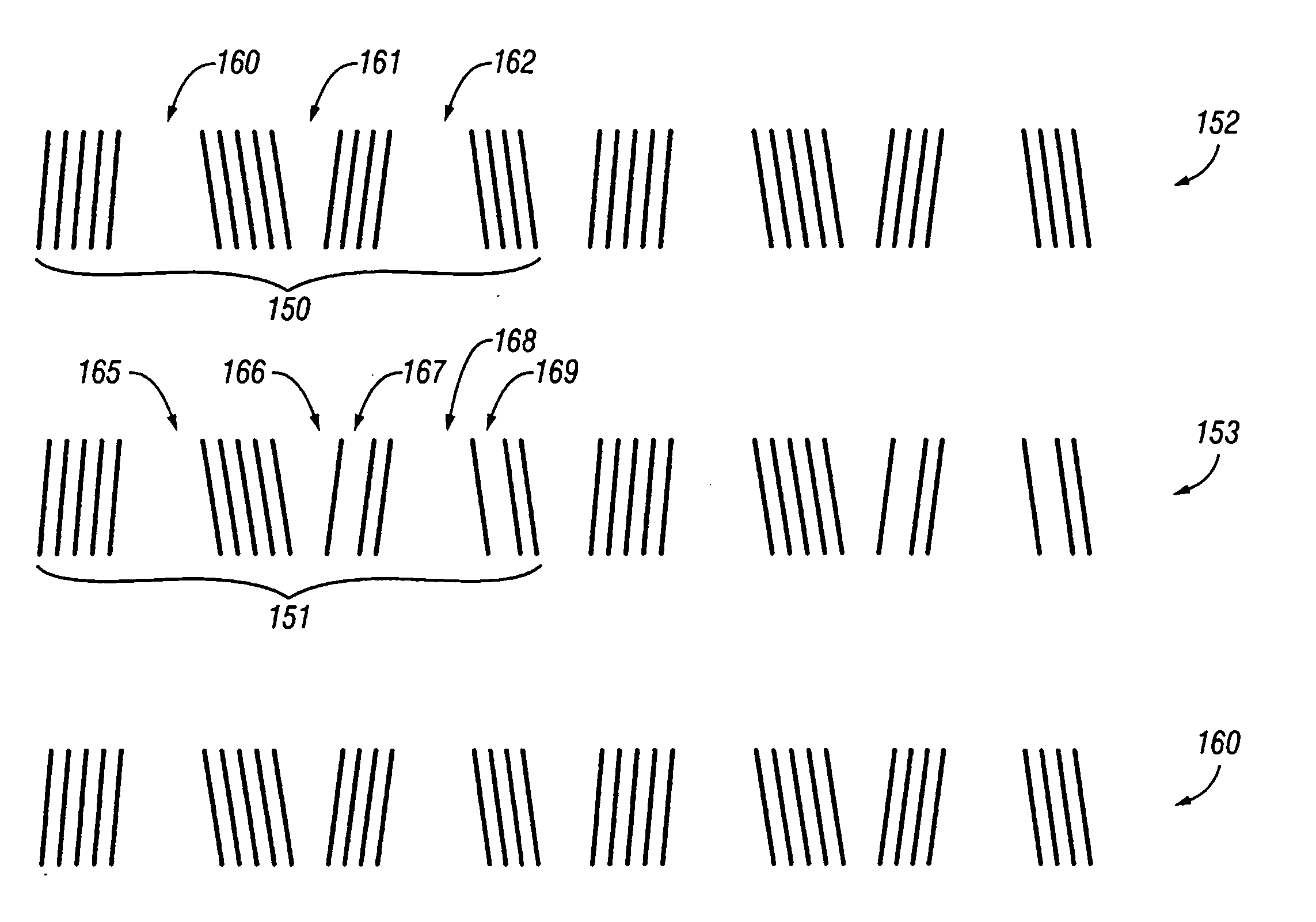

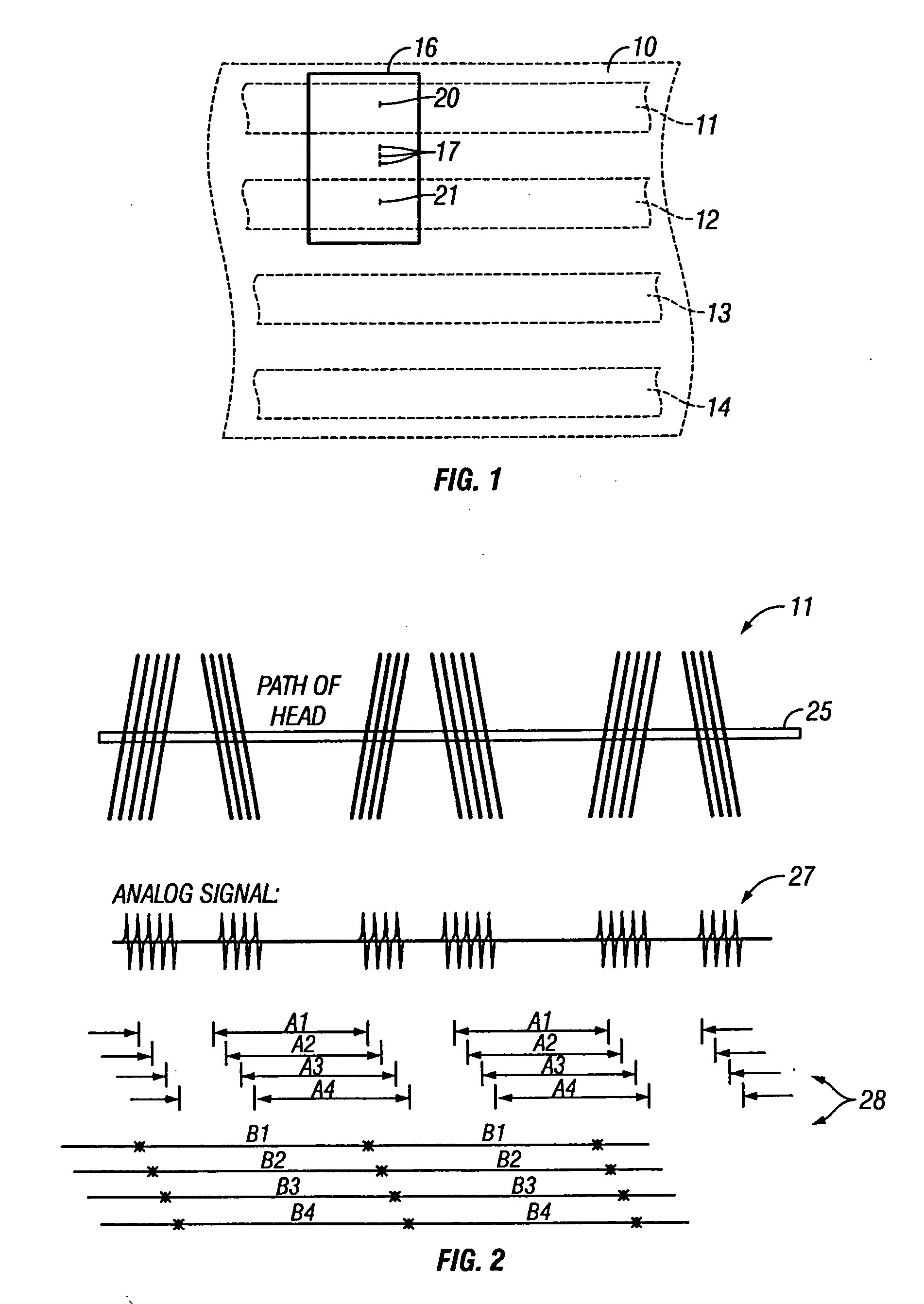

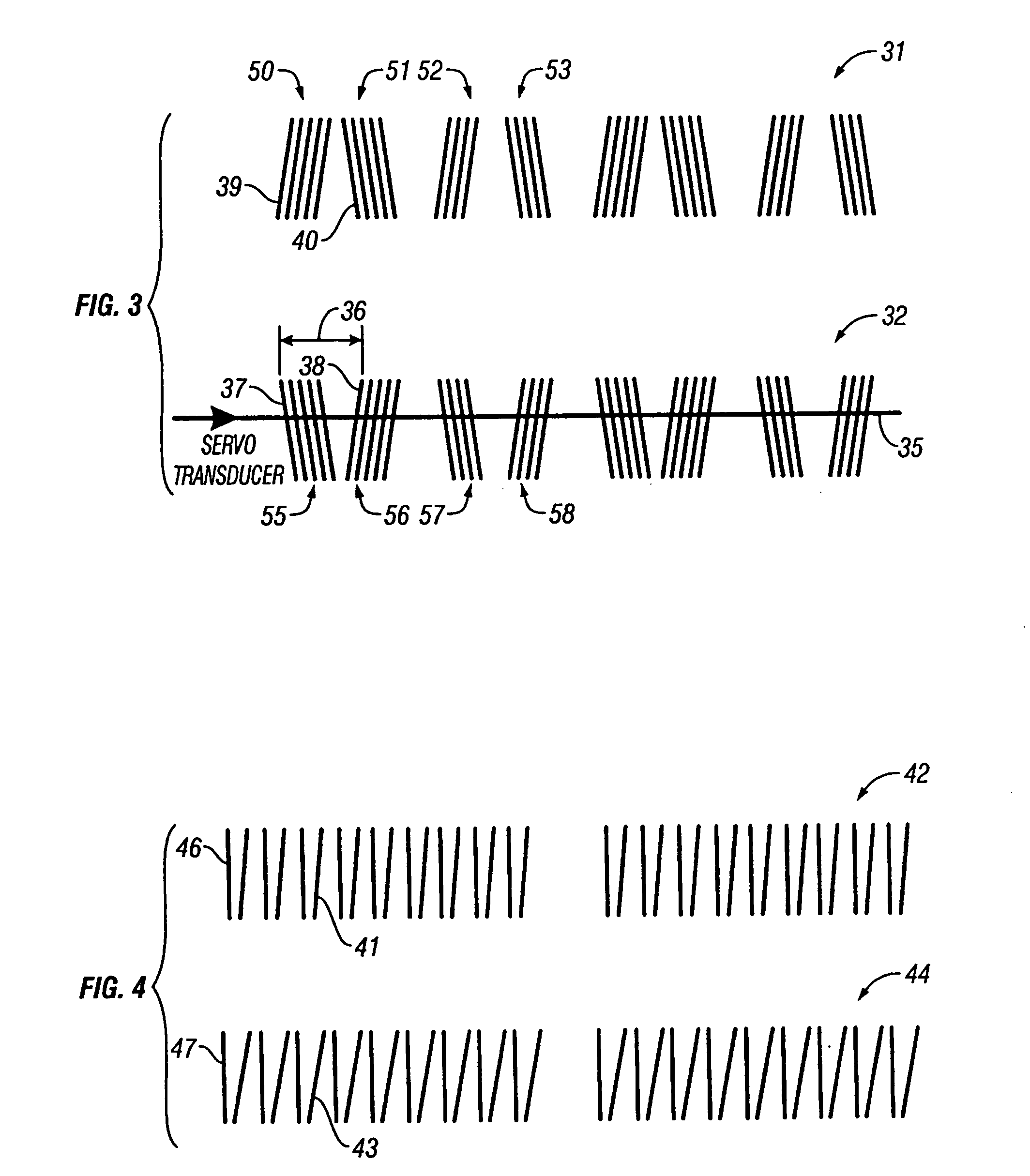

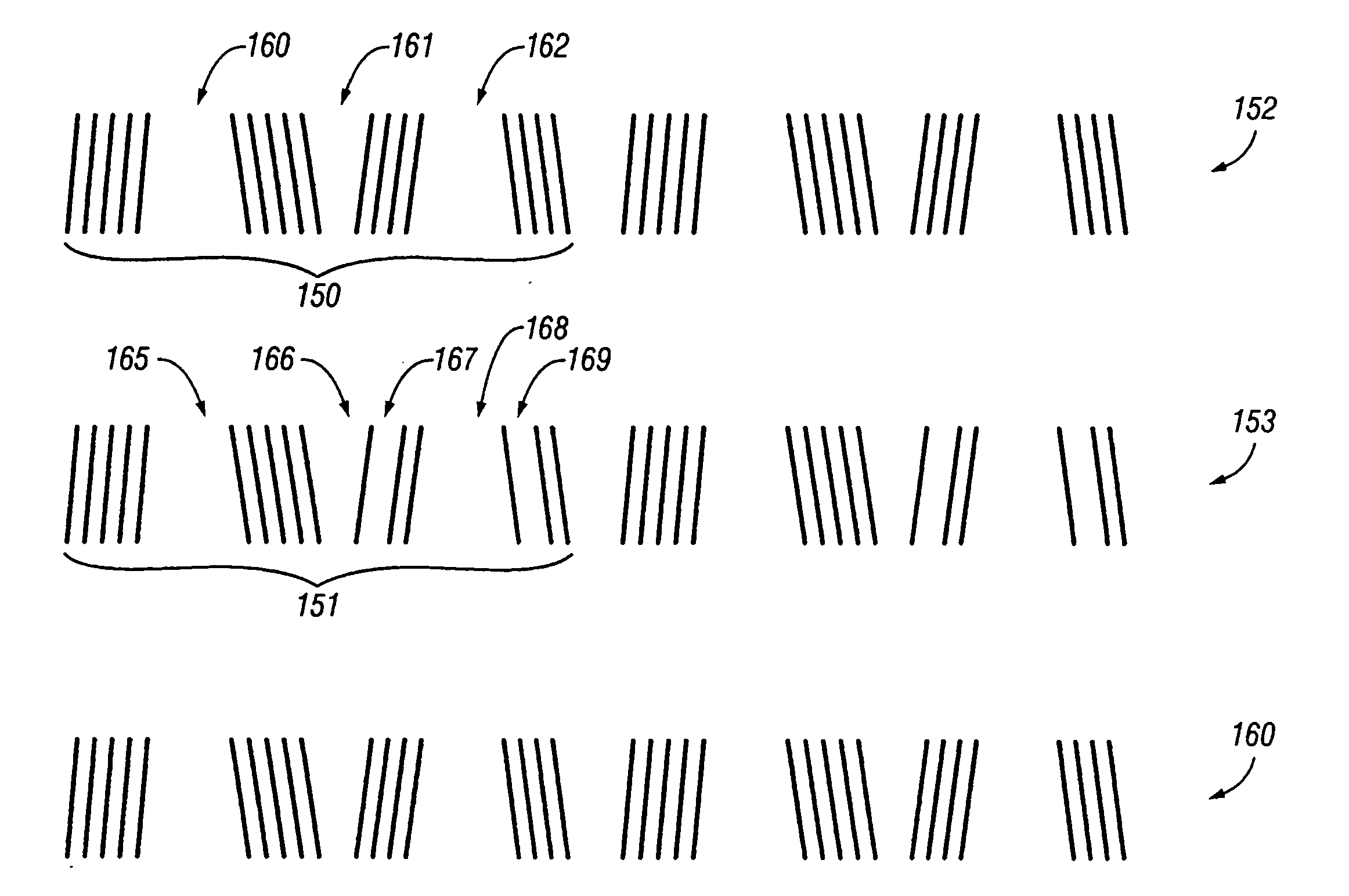

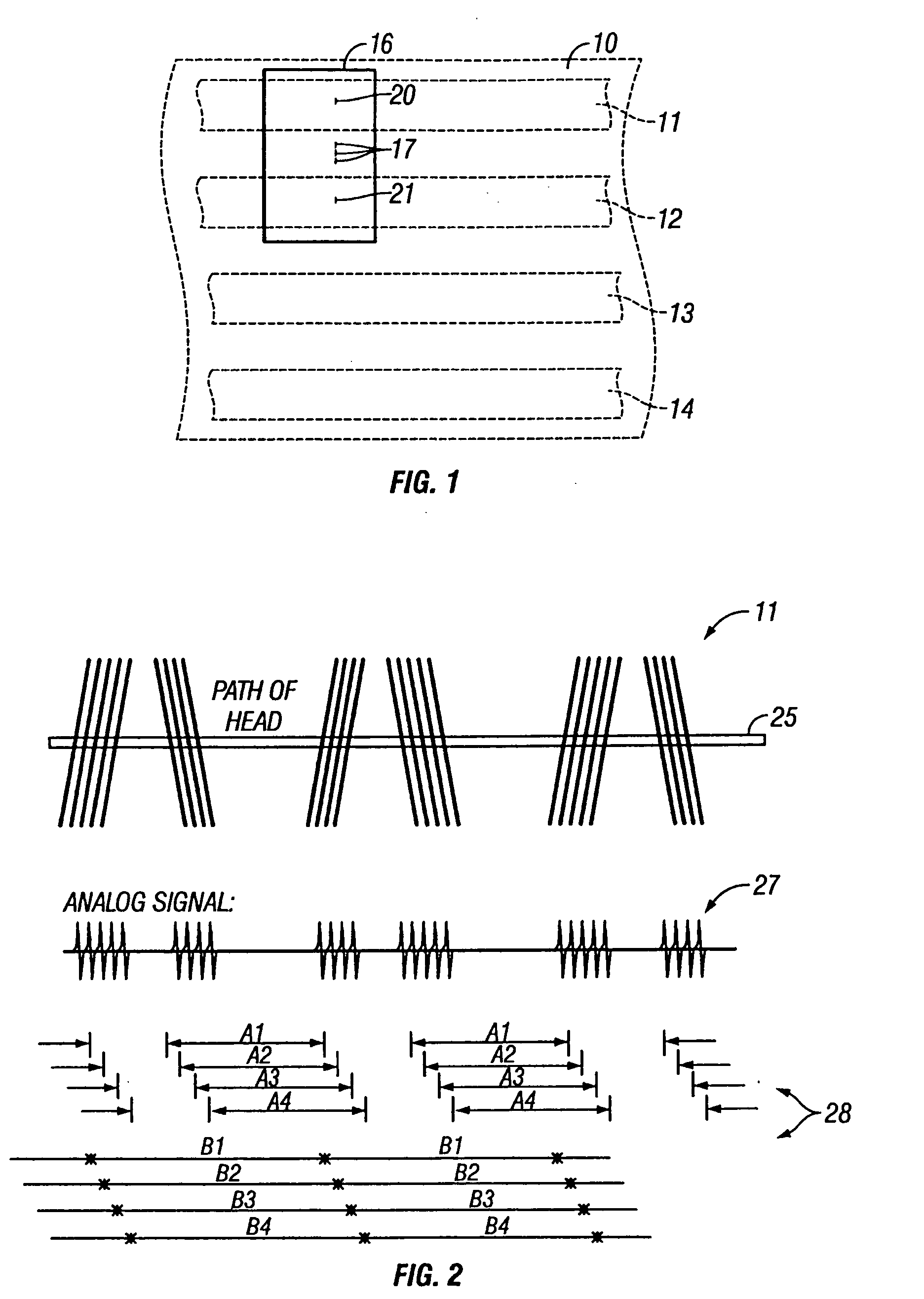

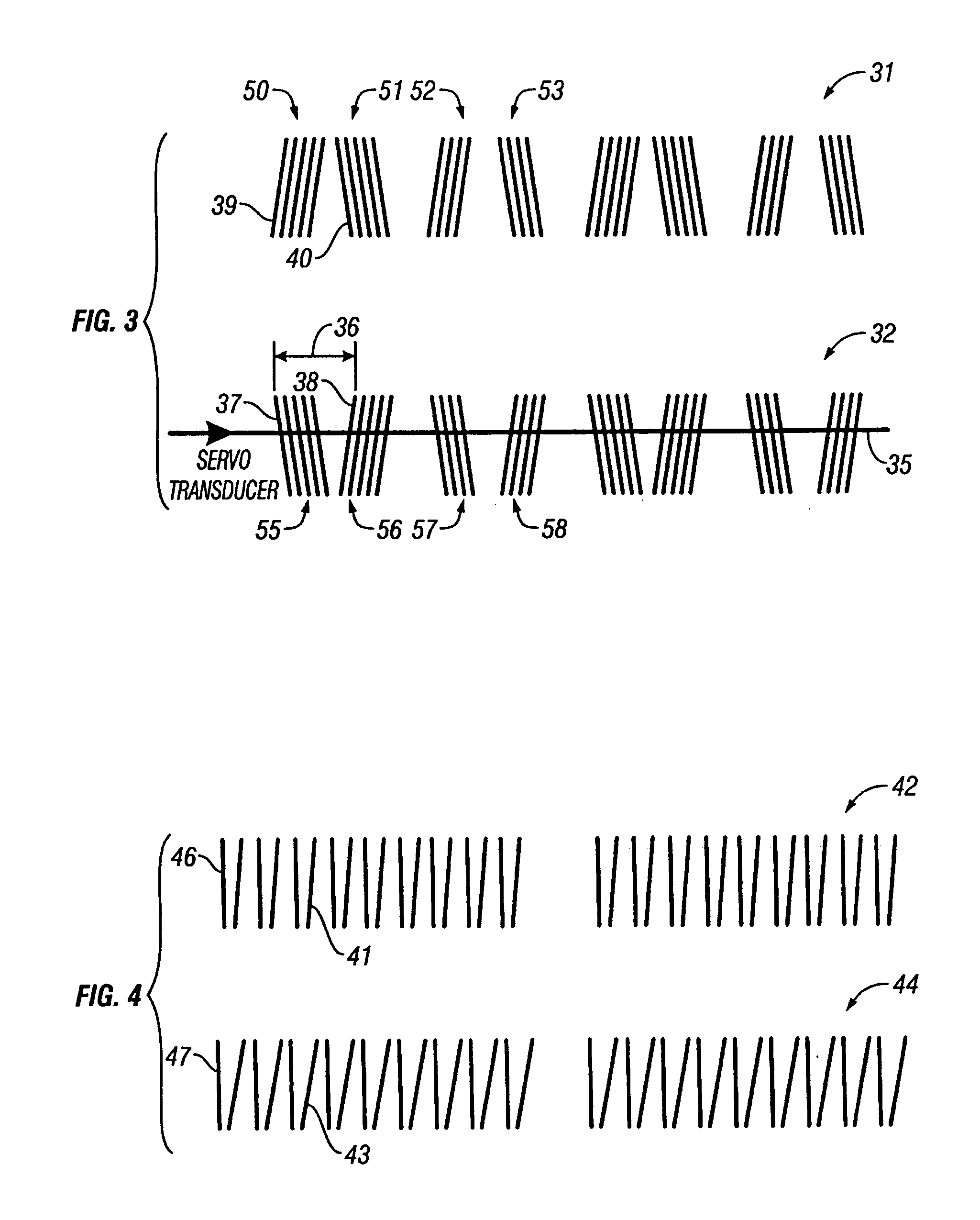

Identification of laterally positioned servo bands employing differentiating characteristics of servo patterns

InactiveUS20050030661A1Easy to adjustDriving/moving recording headsAlignment for track following on tapesLateral positionedAzimuth direction

In a tape having separate servo bands of patterns positioned laterally across the tape, the patterns of a separate servo band have at least one differentiating characteristic with respect to patterns of another of the separate servo bands. The differentiating characteristic allows identification of the separate servo bands. For example, the patterns of a separate servo band have differing azimuthal orientations of detectable transitions with respect to another servo band, such as being laterally inverted. In another, variations in the width of gaps of patterns are made with respect to another servo band. In another, variations are made in the number of the detectable transitions of patterns with respect to the patterns of another servo band.

Owner:IBM CORP

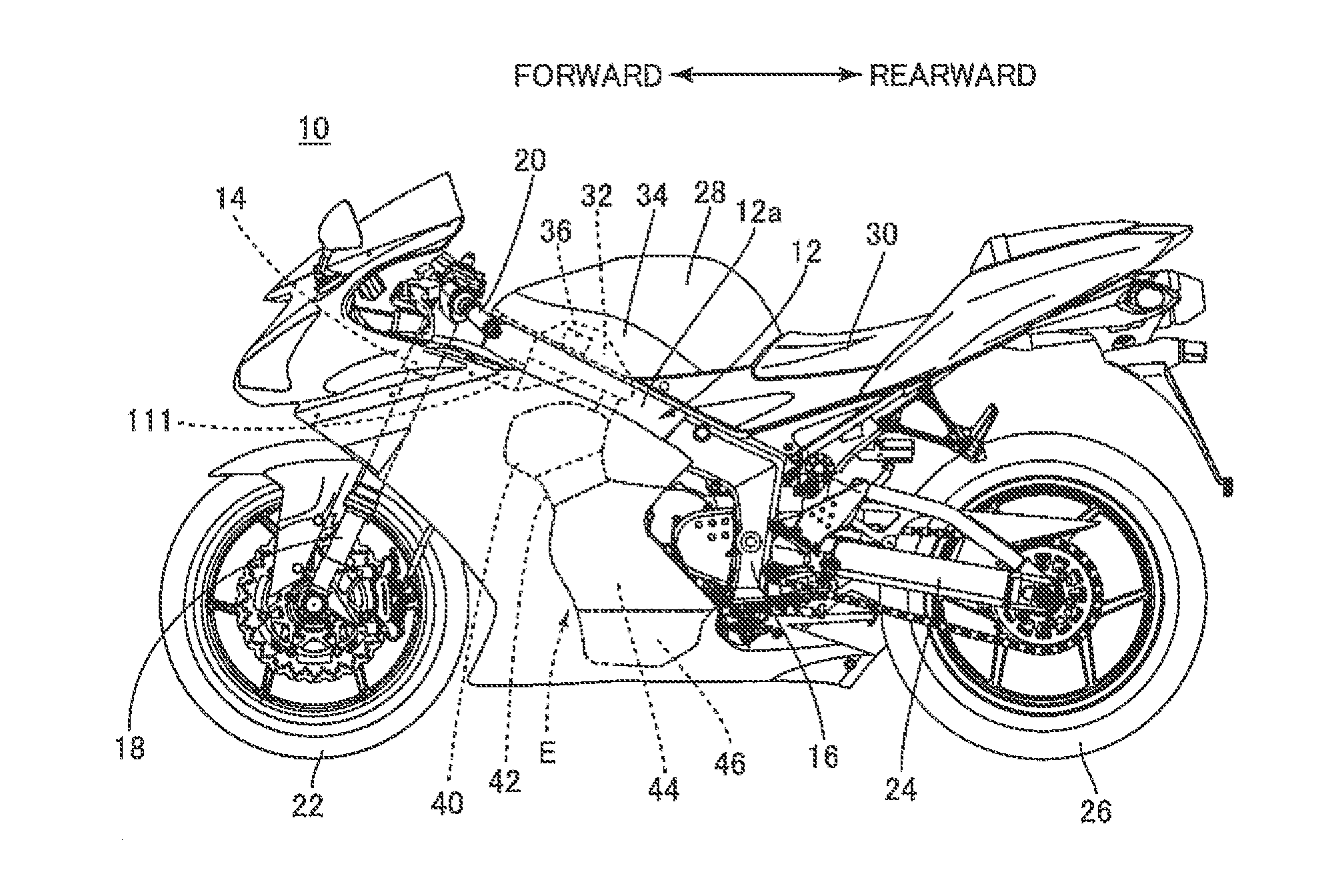

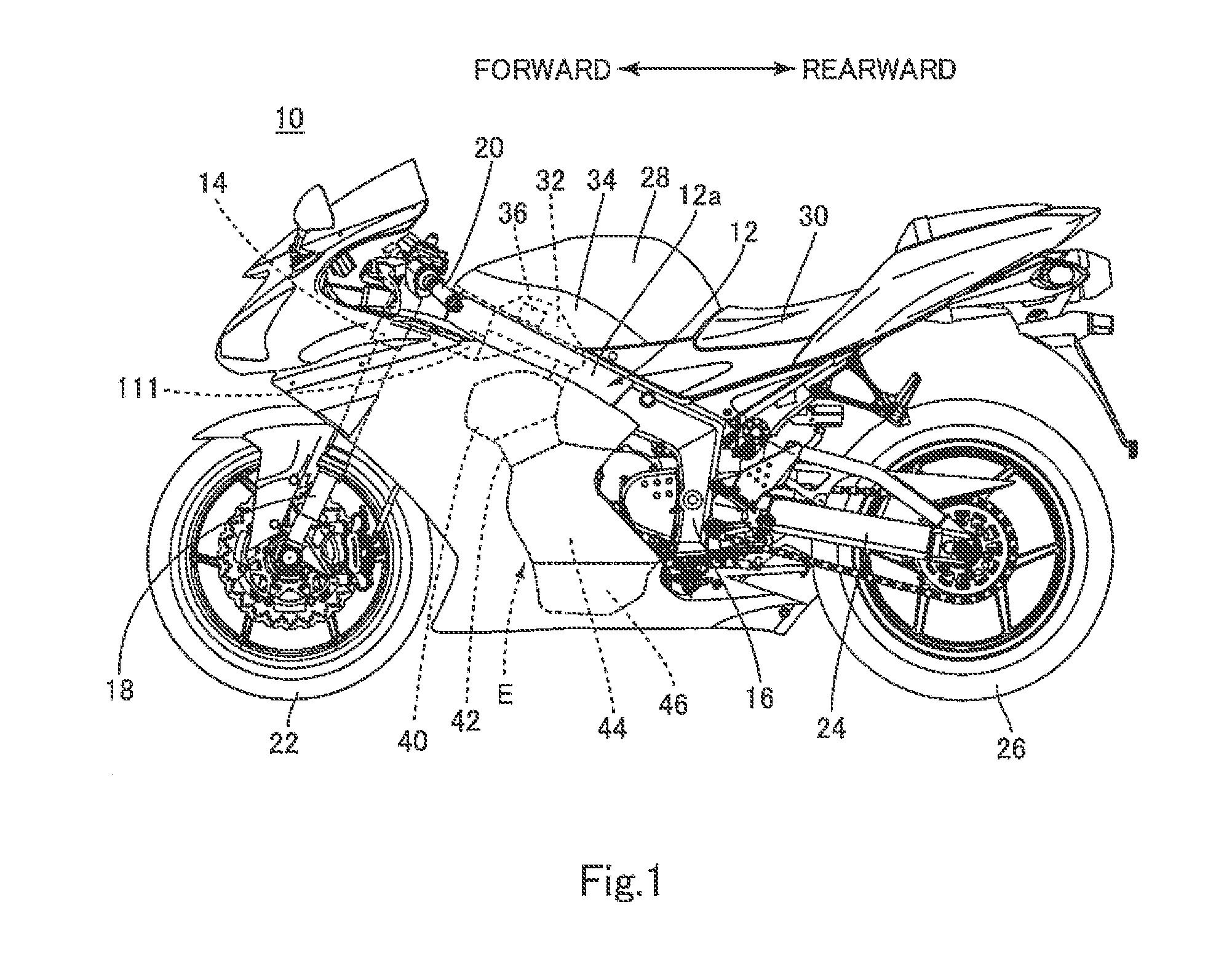

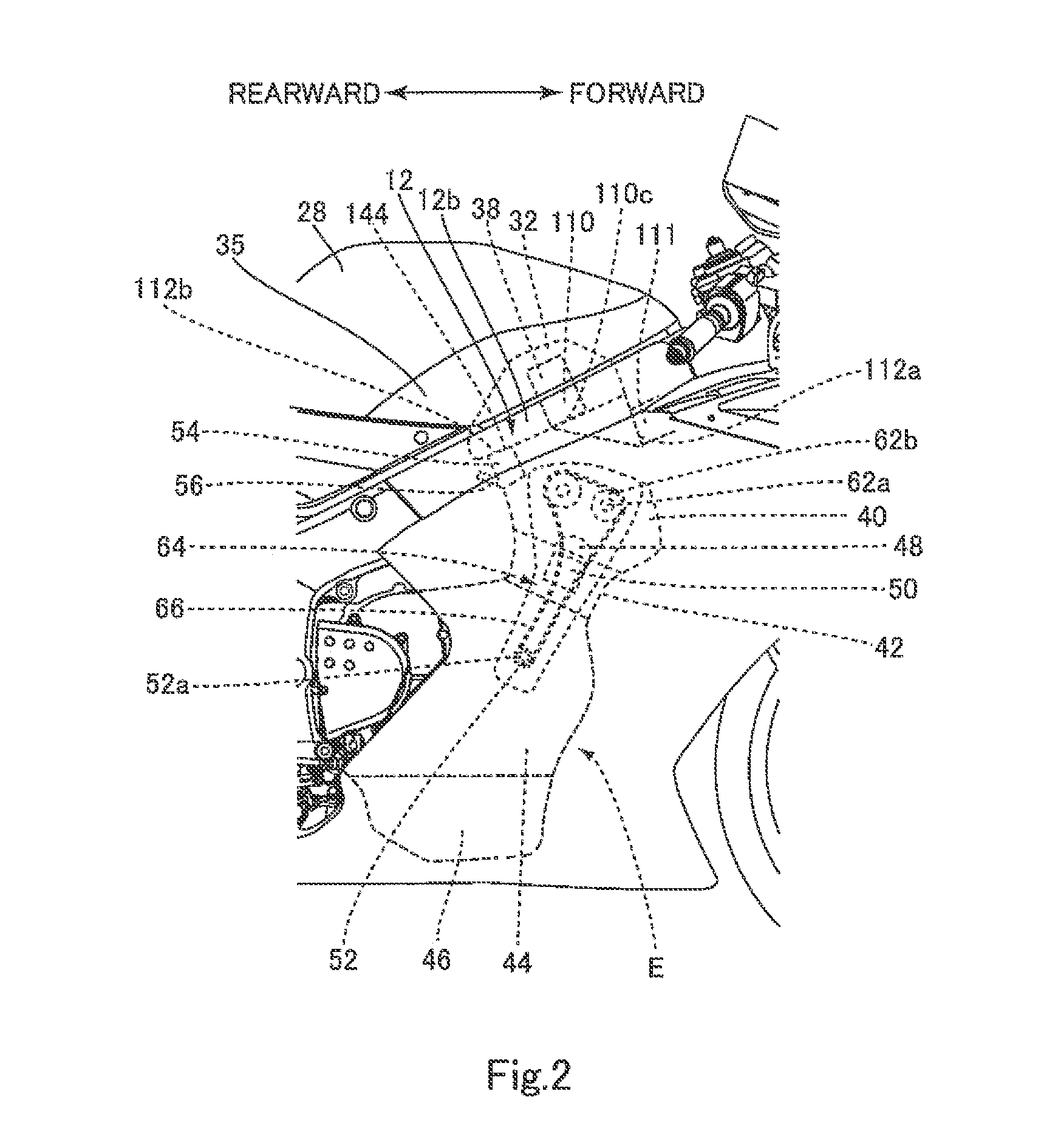

Straddle-Type Vehicle

A straddle-type vehicle includes an engine; an air cleaner including an air cleaner box forming a passage through which air is supplied to the engine and an air filter for cleaning the air flowing through the passage; and a first electric component positioned laterally relative to the air cleaner box.

Owner:KAWASAKI MOTORS LTD

Method and device for assemblying torsion box structures for an aircraft

InactiveCN102036879AImprove performanceEasy to assembleAircraft stabilisationSpars/stringersLateral positionedEngineering

Owner:AIRBUS OPERATIONS SL

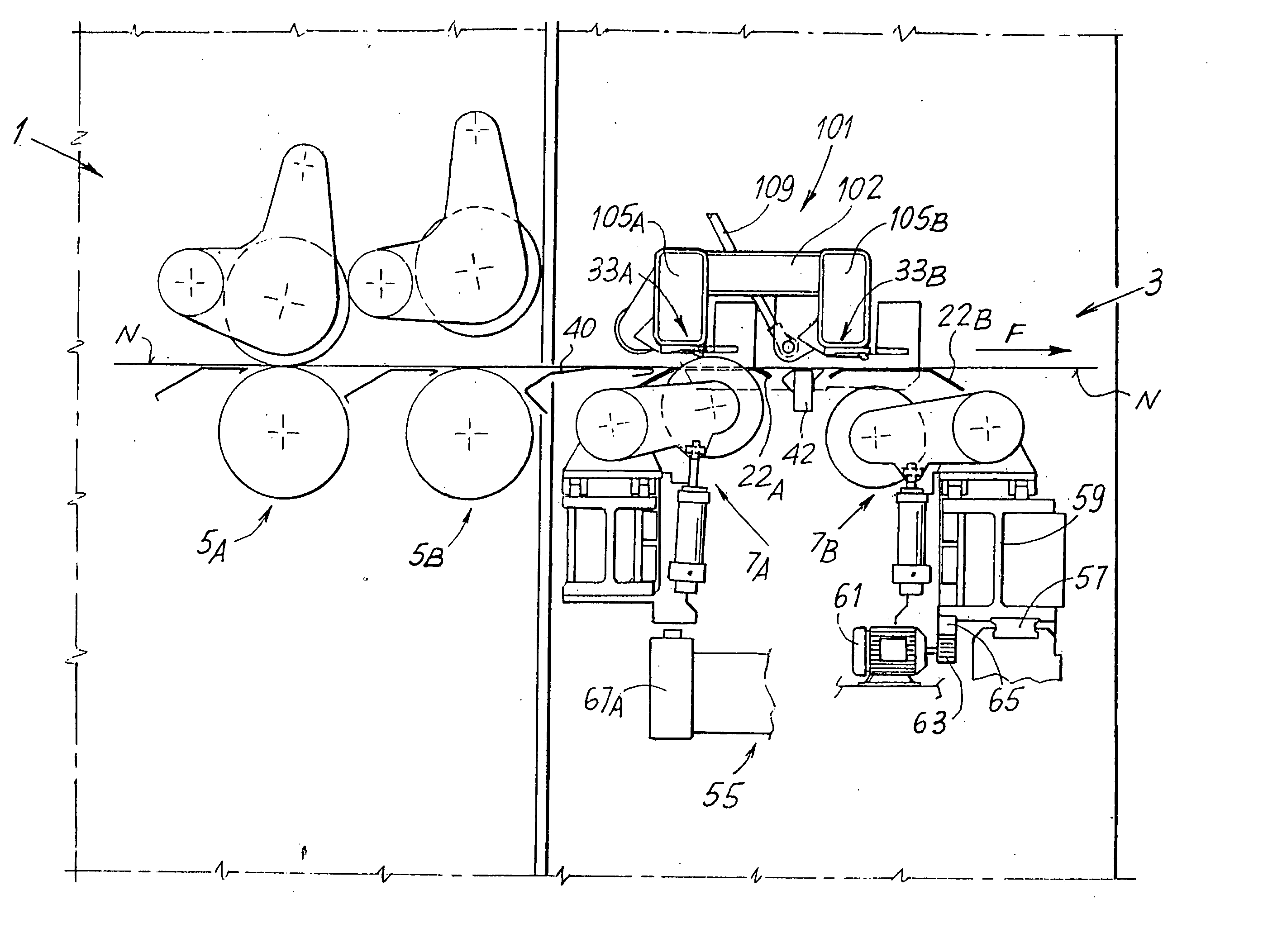

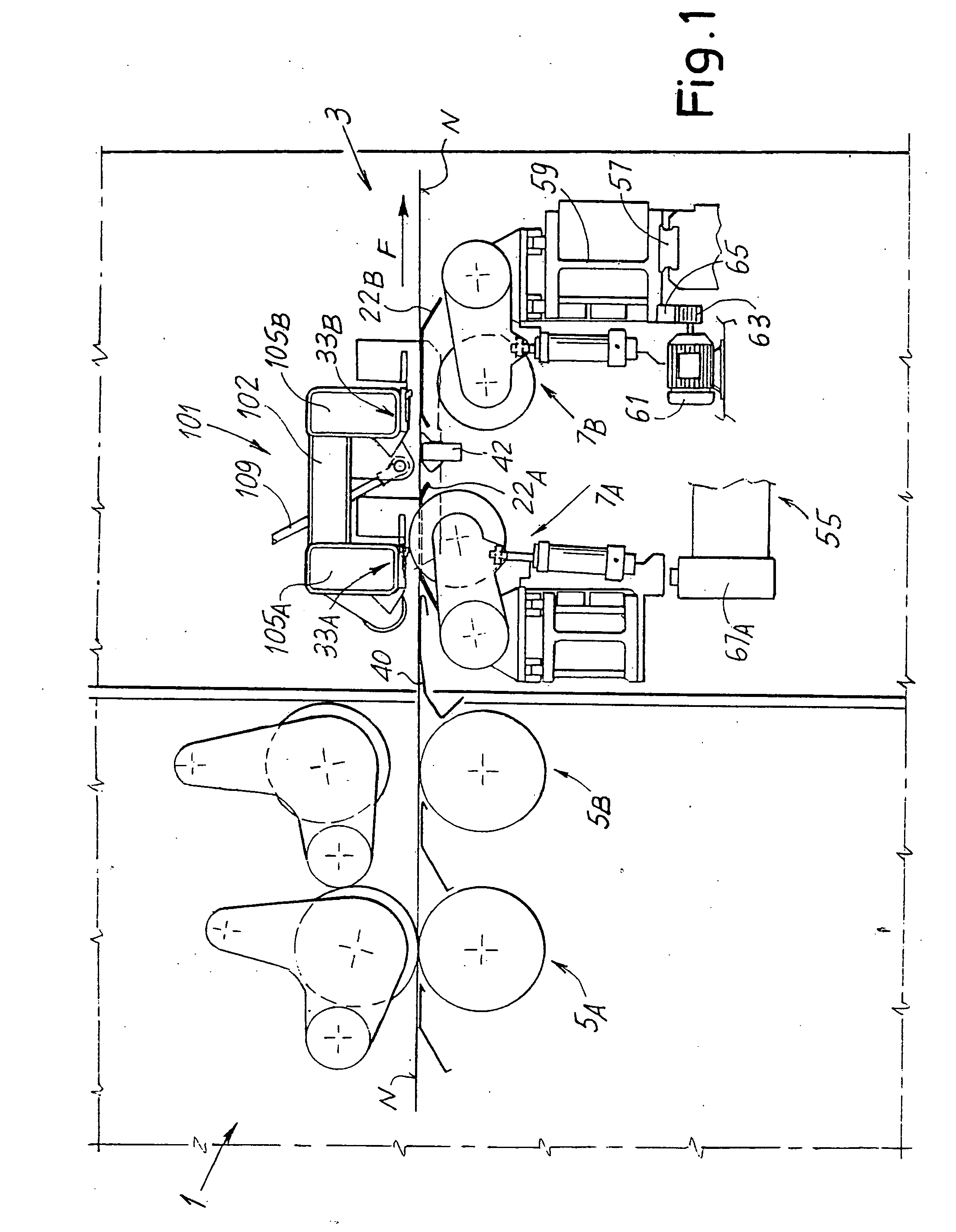

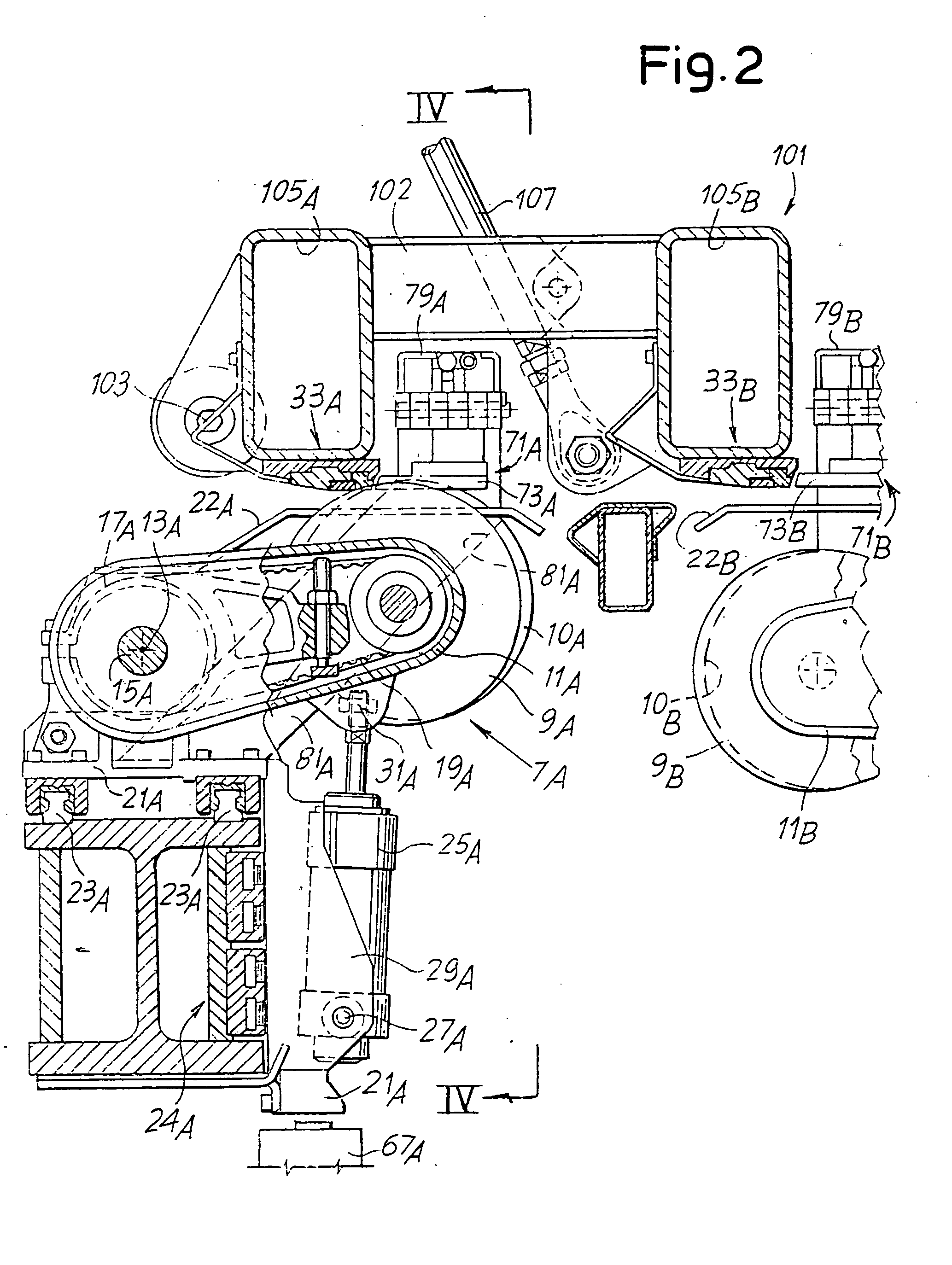

Device for longitudinal cutting of a continuous web material, such as corrugated cardboard

InactiveUS20060075864A1Simple structureEliminate needShearing machinesMetal working apparatusCardboardLateral positioned

The device comprises a path for the web material (N) and, along said path, at least one cutting unit (7A). The cutting unit comprises: a plurality of intermediate disk-shaped blades (9A) disposed on one side of the feed path of the material, which can be positioned transversely to the direction of feed and cooperating with a fixed counter-blade (33A) disposed on the opposite side of said path. Also provided are two lateral disk-shaped blades (10A) to cut the trimmings; and a member for transverse positioning of the blades. The two lateral blades each cooperate with a respective movable counter-blade (71A), separate from the fixed counter-blade, which can be positioned transversely to the direction of feed of the web material.

Owner:FOSBER

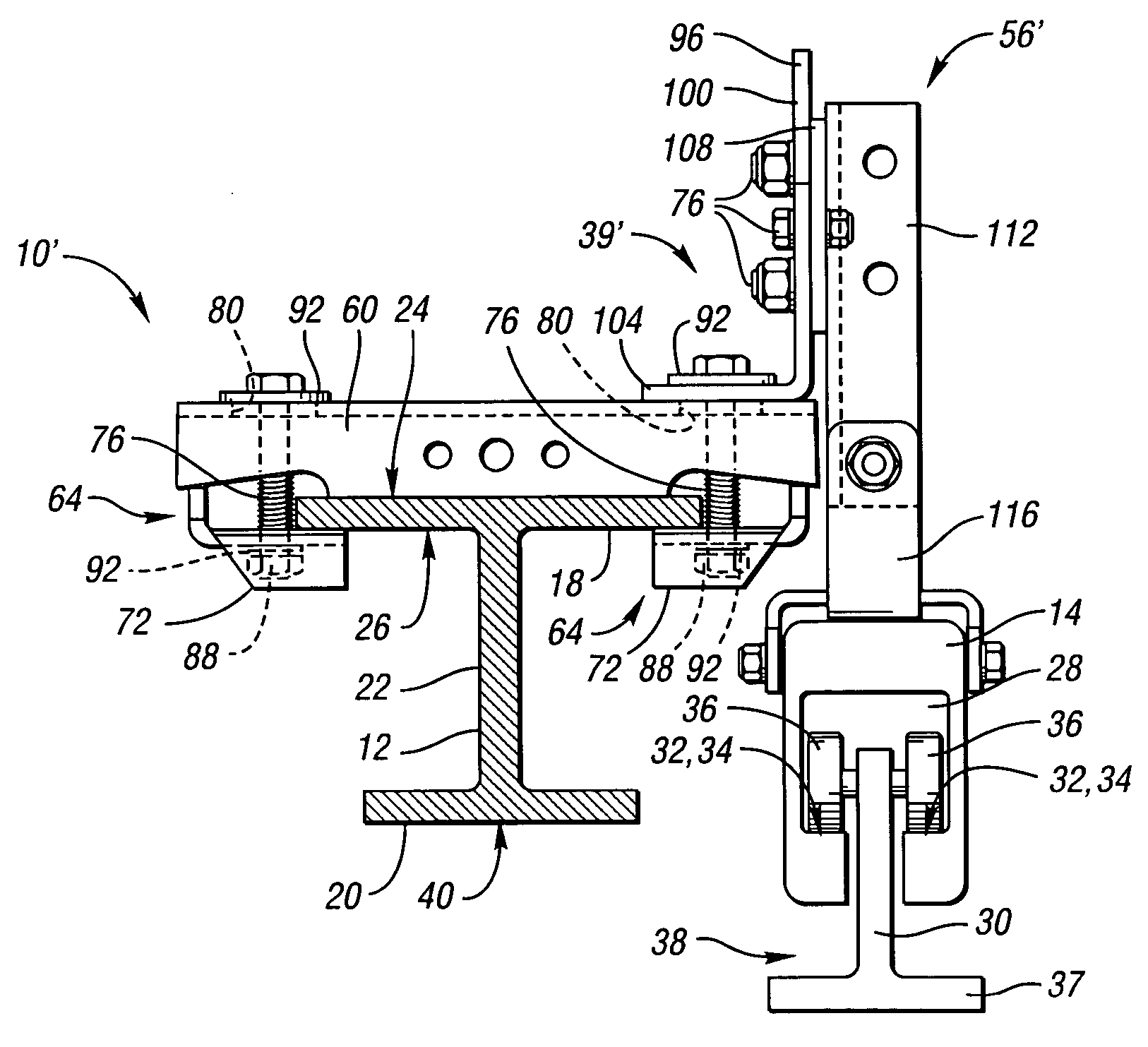

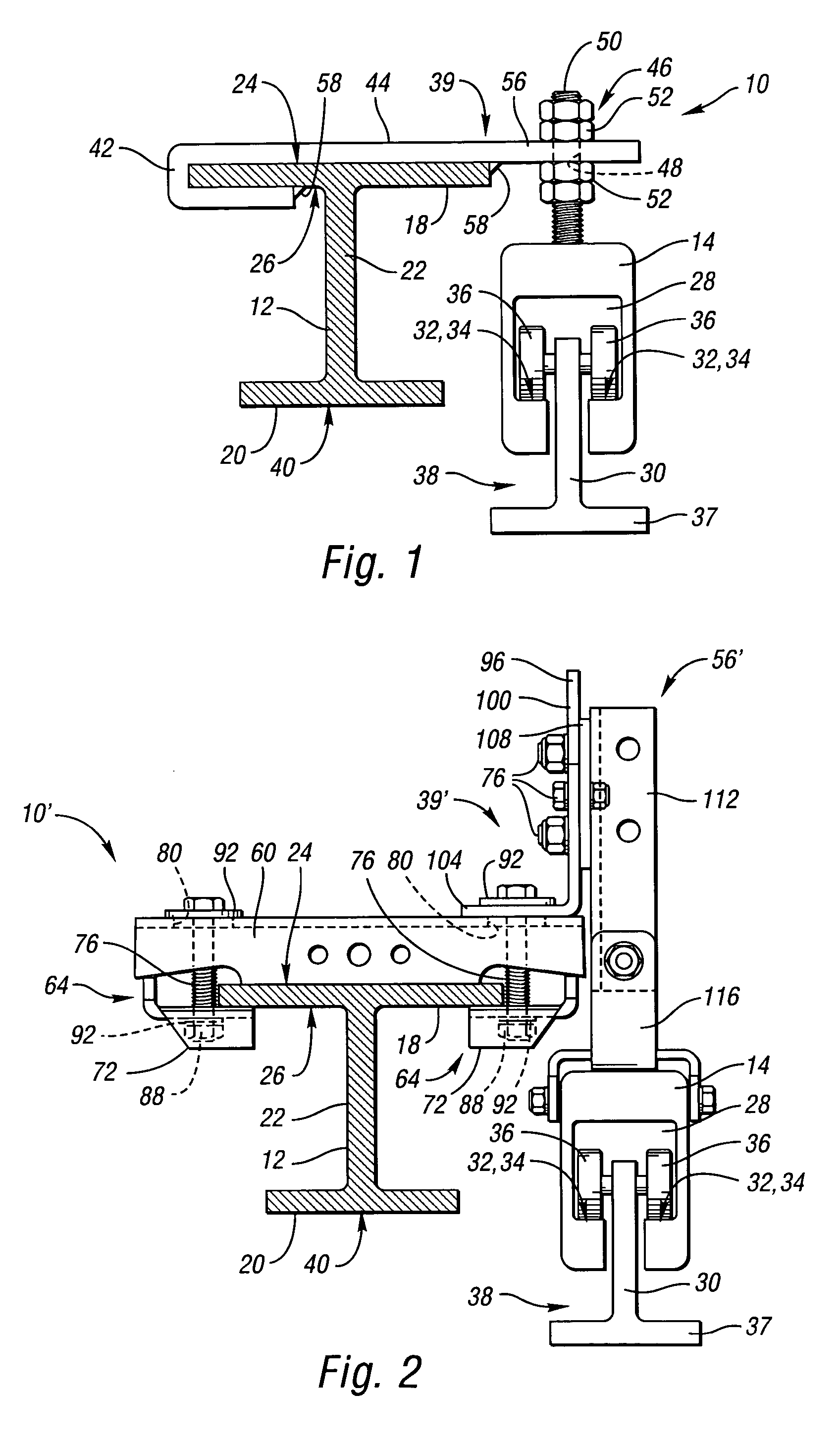

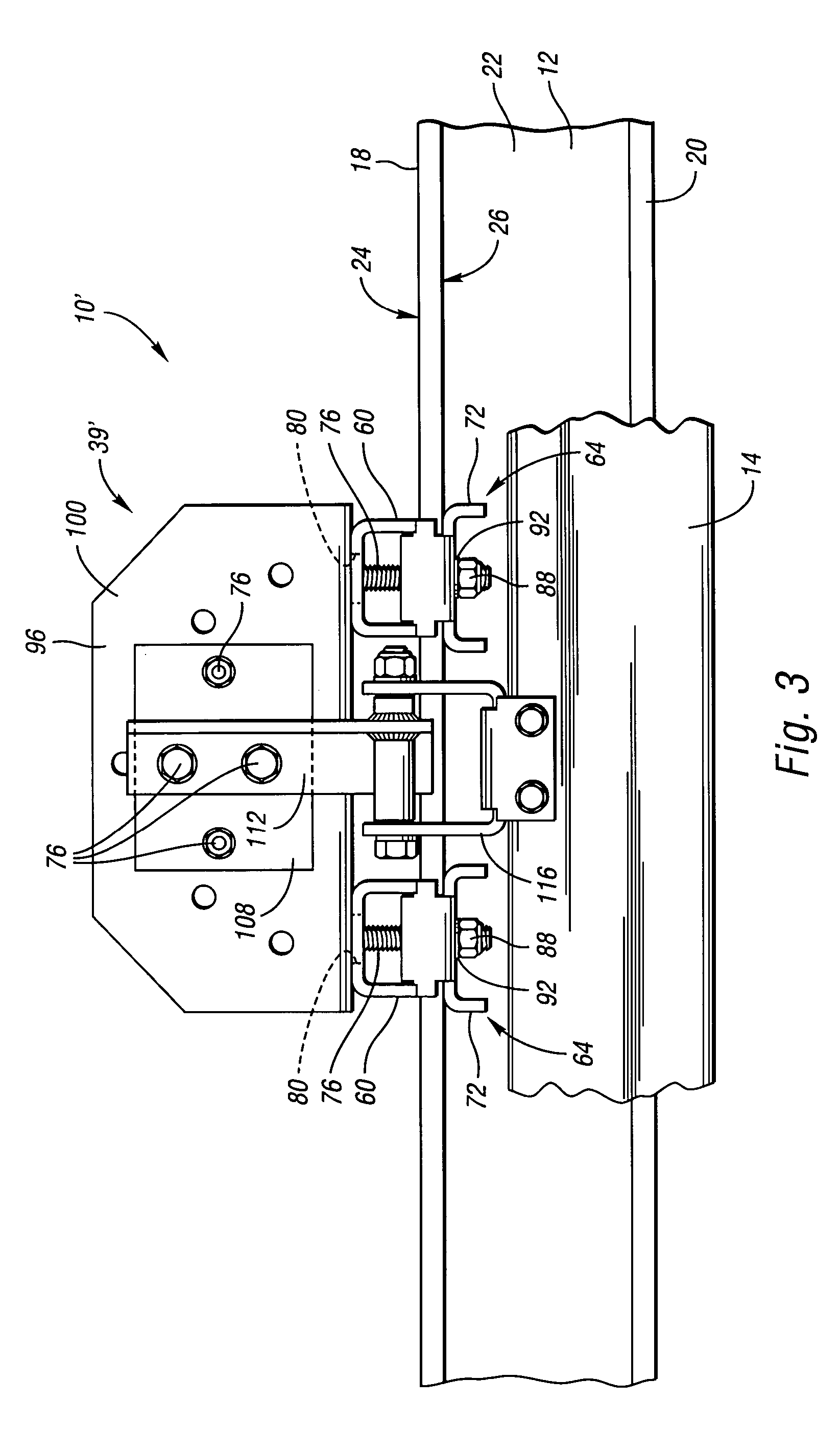

Material handling system enclosed track arrangement

InactiveUS20050028704A1Quick conversionLittle and no loss of overhead spaceConveyorsRailway tracksLateral positionedEngineering

A hanger connects an enclosed track rail to a beam such that the enclosed track rail is positioned laterally with respect to the beam. The hanger and the arrangement of the track rail with respect to the beam allows rapid conversion of a material handling system from “open roller” tracks to enclosed tracks without removal of existing tracks, without adding new structural support for the enclosed tracks, and without substantial reduction in overhead clearance. A method of retrofitting an enclosed track rail to a material handling system having an open-roller track is also provide.

Owner:GM GLOBAL TECH OPERATIONS LLC

Identification of laterally positioned servo bands employing differentiating characteristics of servo patterns

InactiveUS20050280920A1Easy to adjustAlignment for track following on tapesRecord information storageLateral positionedAzimuth direction

In a tape having separate servo bands of patterns positioned laterally across the tape, the patterns of a separate servo band have at least one differentiating characteristic with respect to patterns of another of the separate servo bands. The differentiating characteristic allows identification of the separate servo bands. For example, the patterns of a separate servo band have differing azimuthal orientations of detectable transitions with respect to another servo band, such as being laterally inverted. In another, variations in the width of gaps of patterns are made with respect to another servo band. In another, variations are made in the number of the detectable transitions of patterns with respect to the patterns of another servo band.

Owner:BUI NHAN XUAN +6

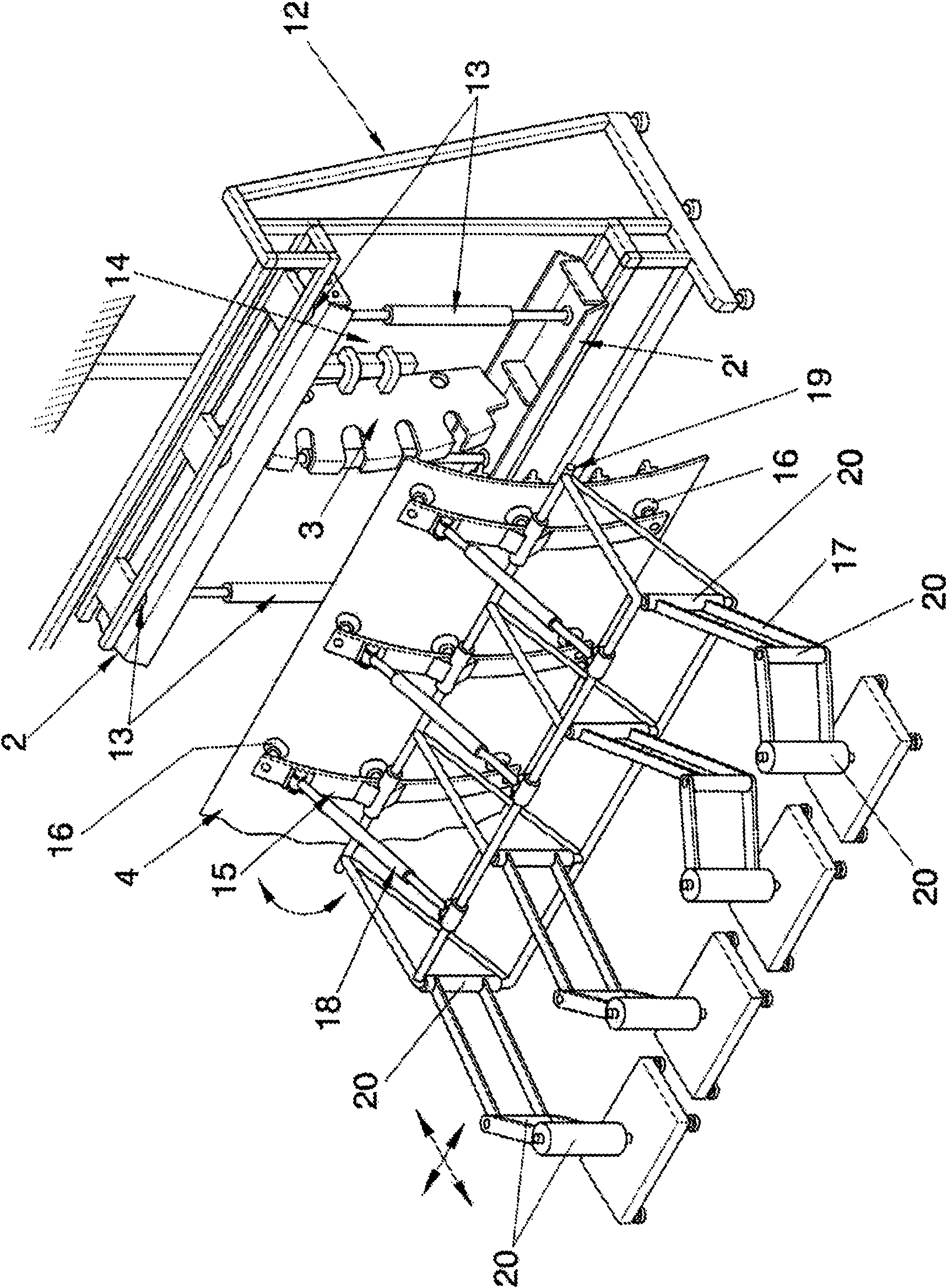

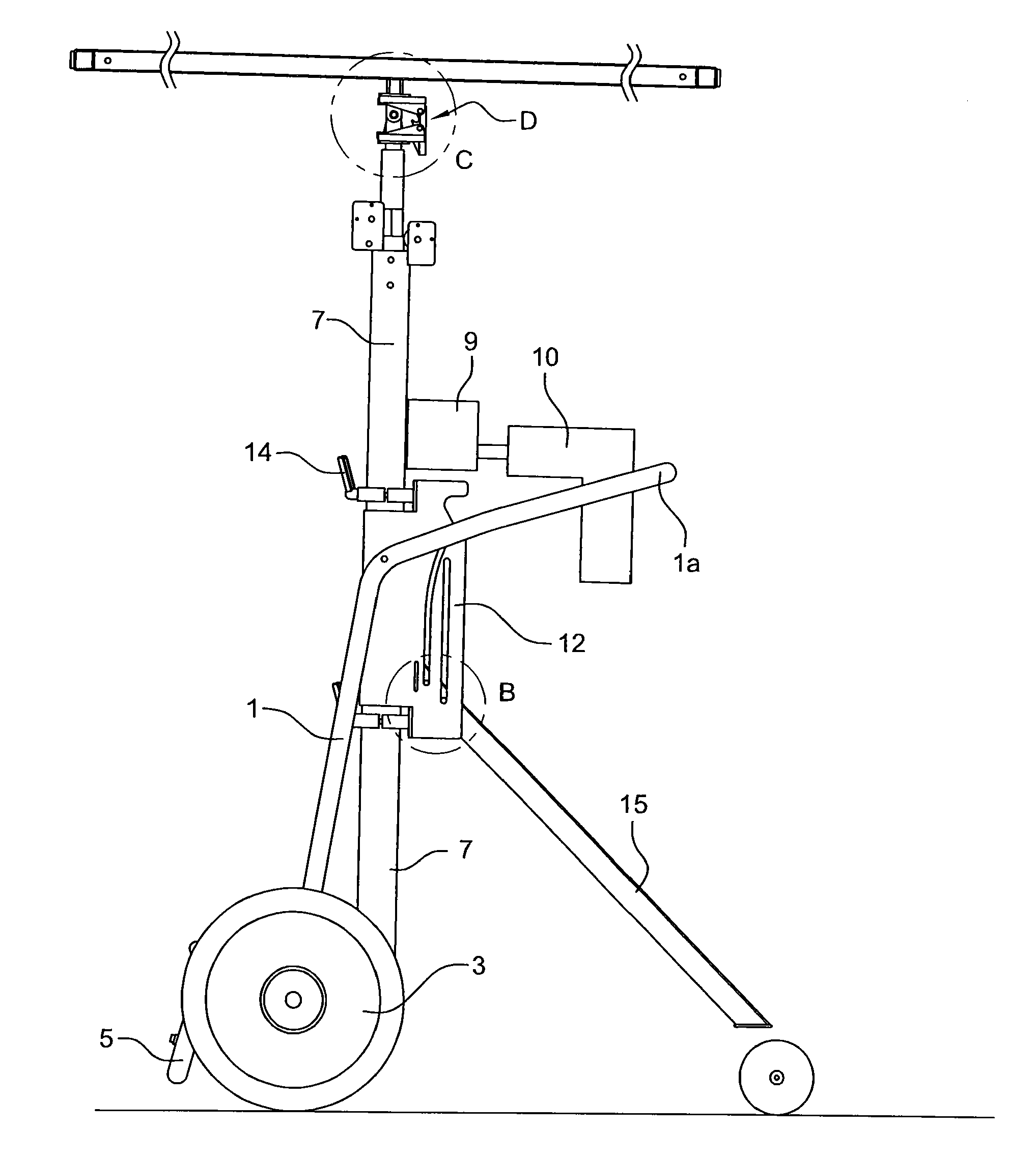

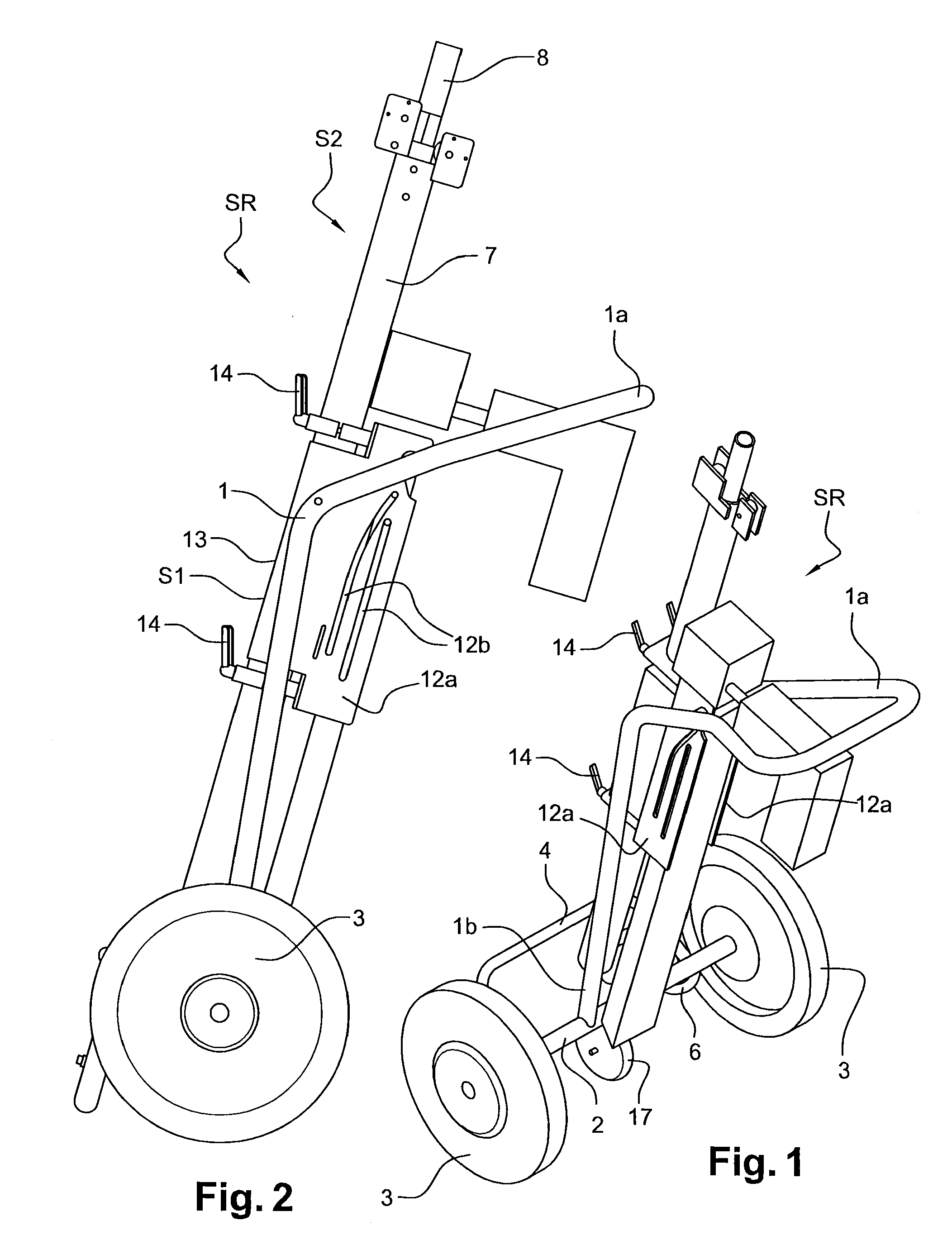

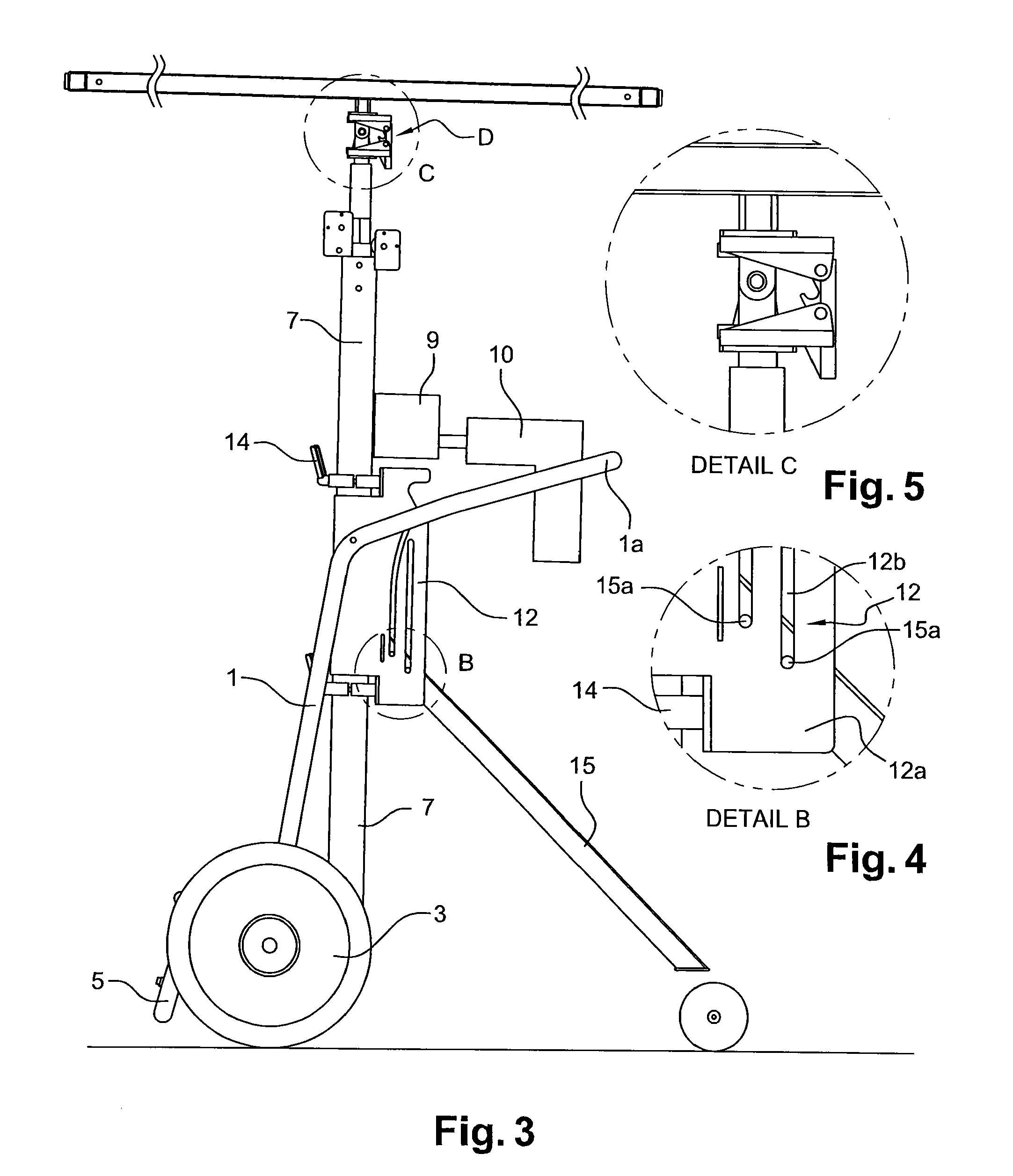

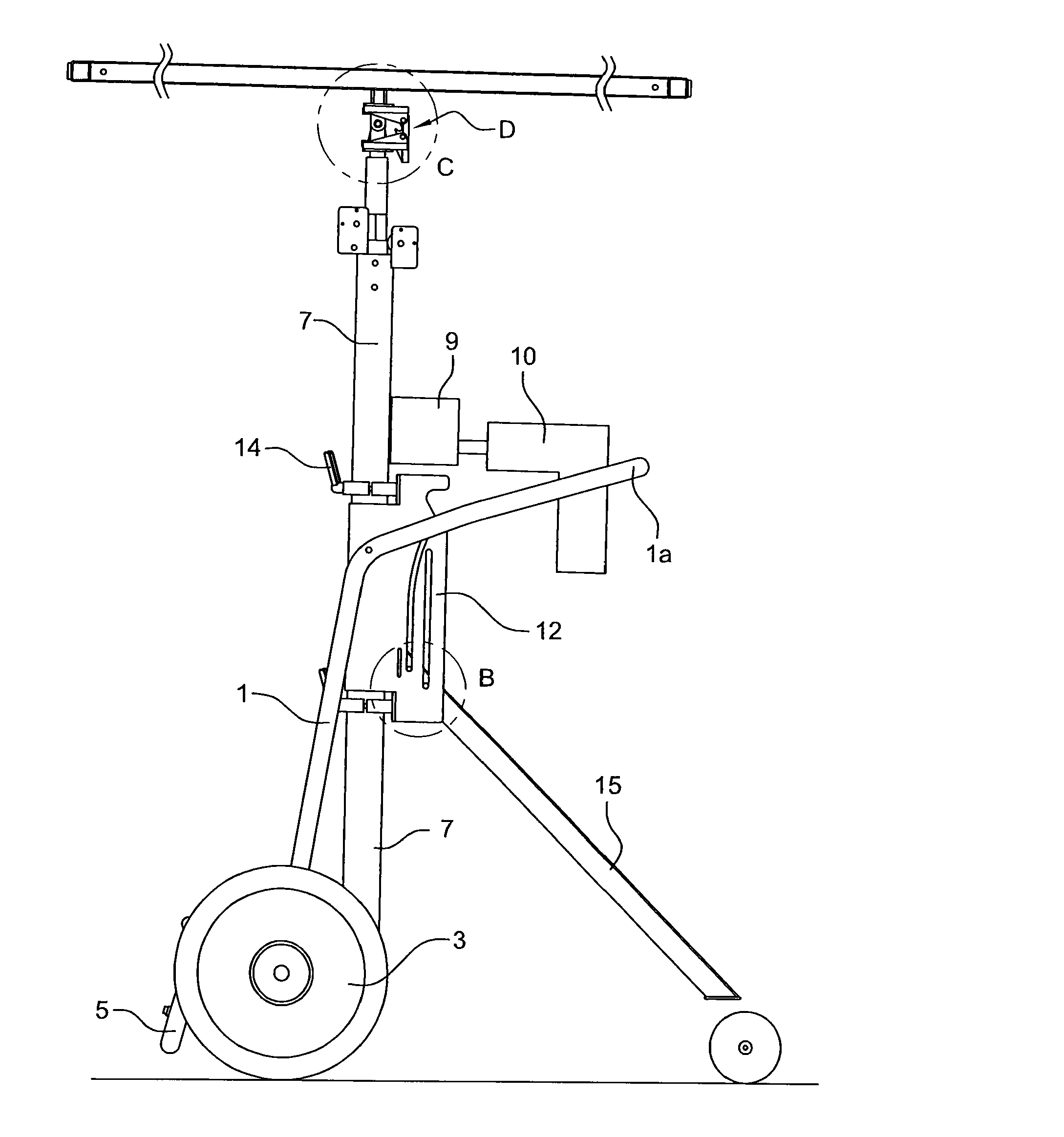

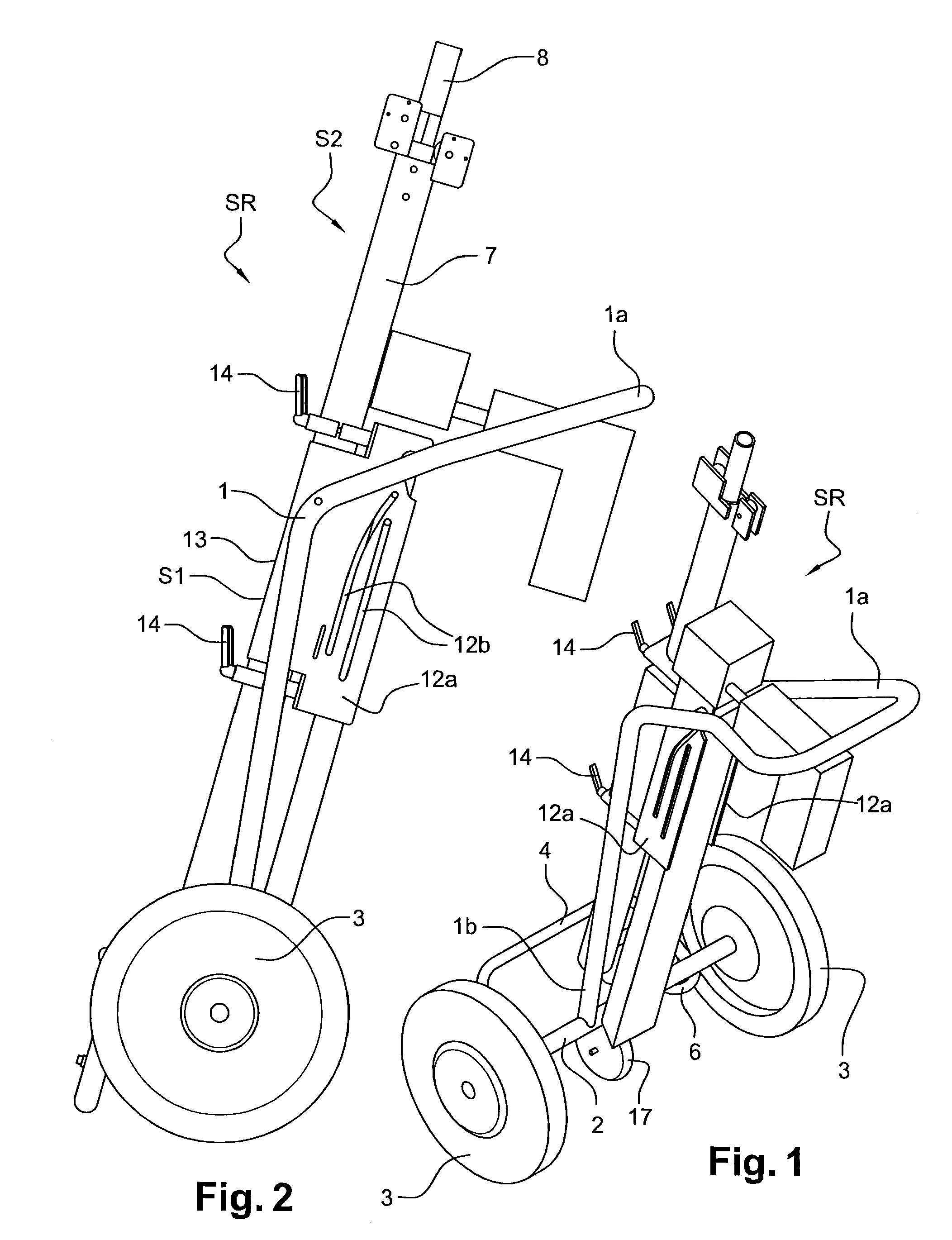

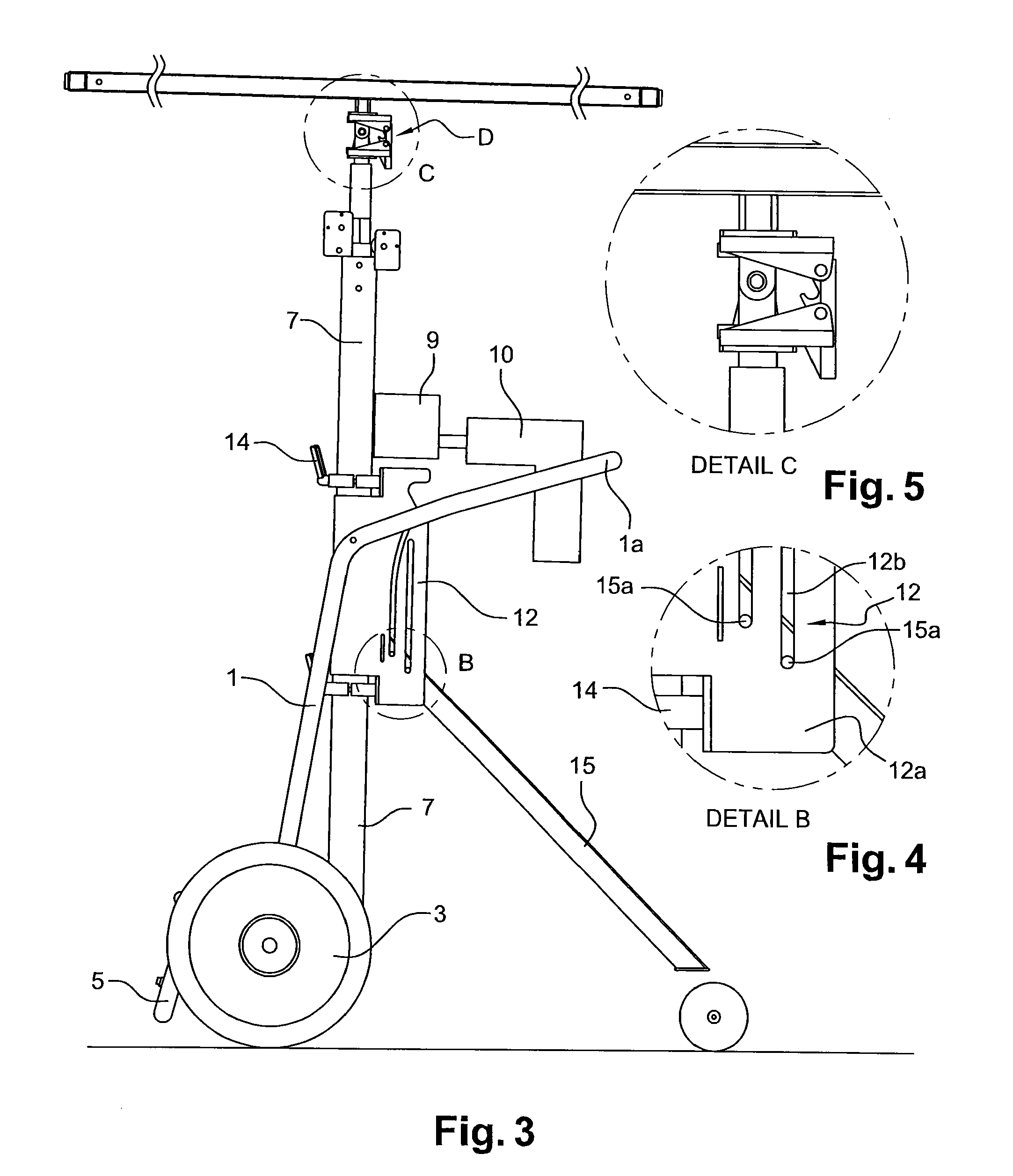

Wheeled structure for handling and fitting panels or plates

InactiveUS20130075989A1Easy to implementCarriage/perambulator accessoriesCarriage/perambulator with multiple axesLateral positionedBraced frame

The wheeled structure includes two connected sub-assemblies articulated relative to each other, with conversion capability between three wheels in a single plane for ground running operations, two main wheels for conveyance like a hand truck, or two secondary wheels for transverse positioning when fitting panels vertically. The first sub-assembly accommodates main wheels and secondary wheels and the second sub-assembly accommodates a pole, telescopic column assembly and support frame for the plates. The two sub-assemblies are rigidly connected by an assembly unit having an arm ending in a caster. The sub-assemblies, depending on their relative angular position, fulfill various vertical and horizontal panel fitting functions. The pole is mobile vertically relative to the main wheels, to the rear thereof when running on the ground, and to the fore thereof when fitting the panels vertically by lifting action on the first sub-assembly.

Owner:DEVPEMENT

Wheeled structure for handling and fitting panels or plates

Owner:DEVPEMENT

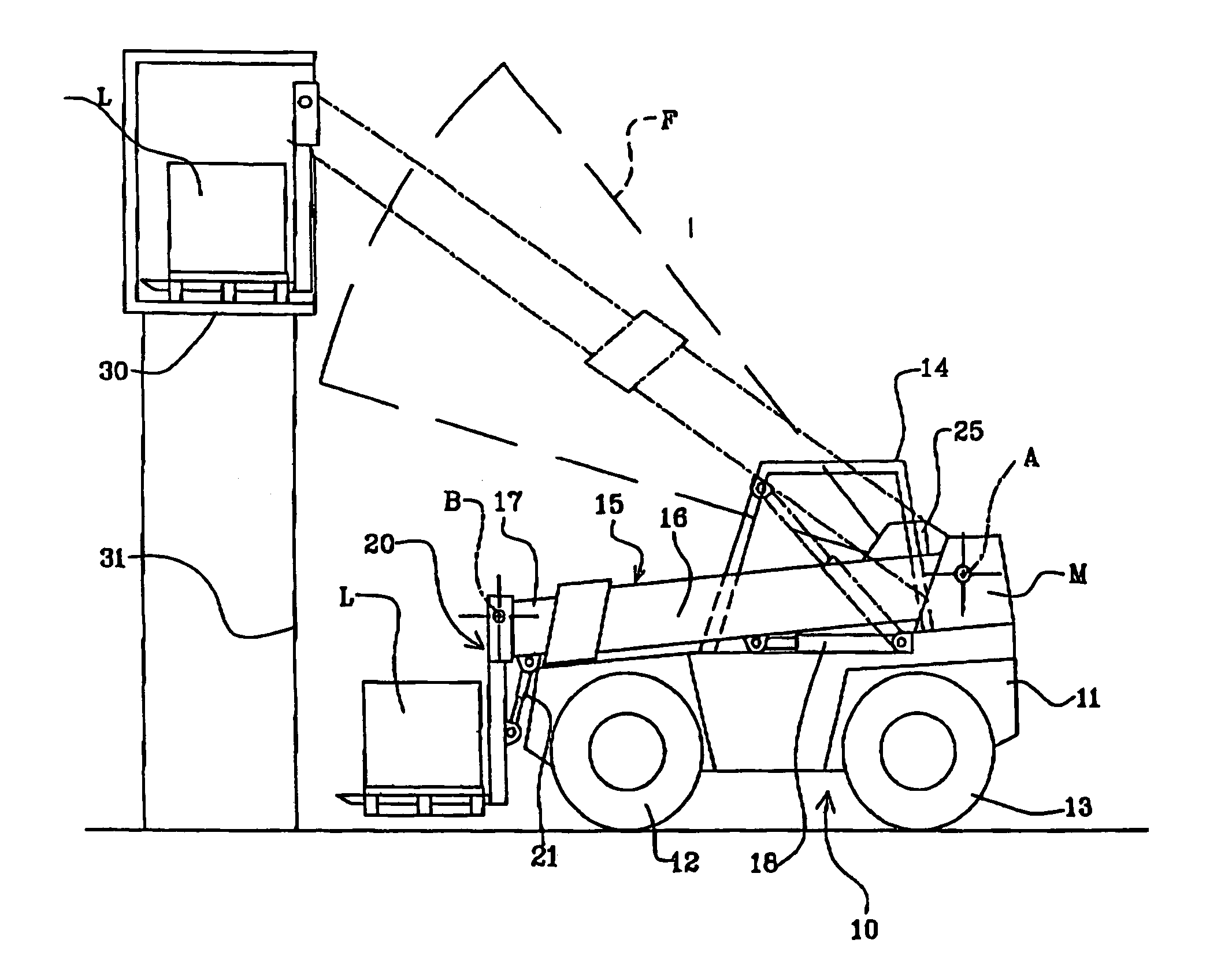

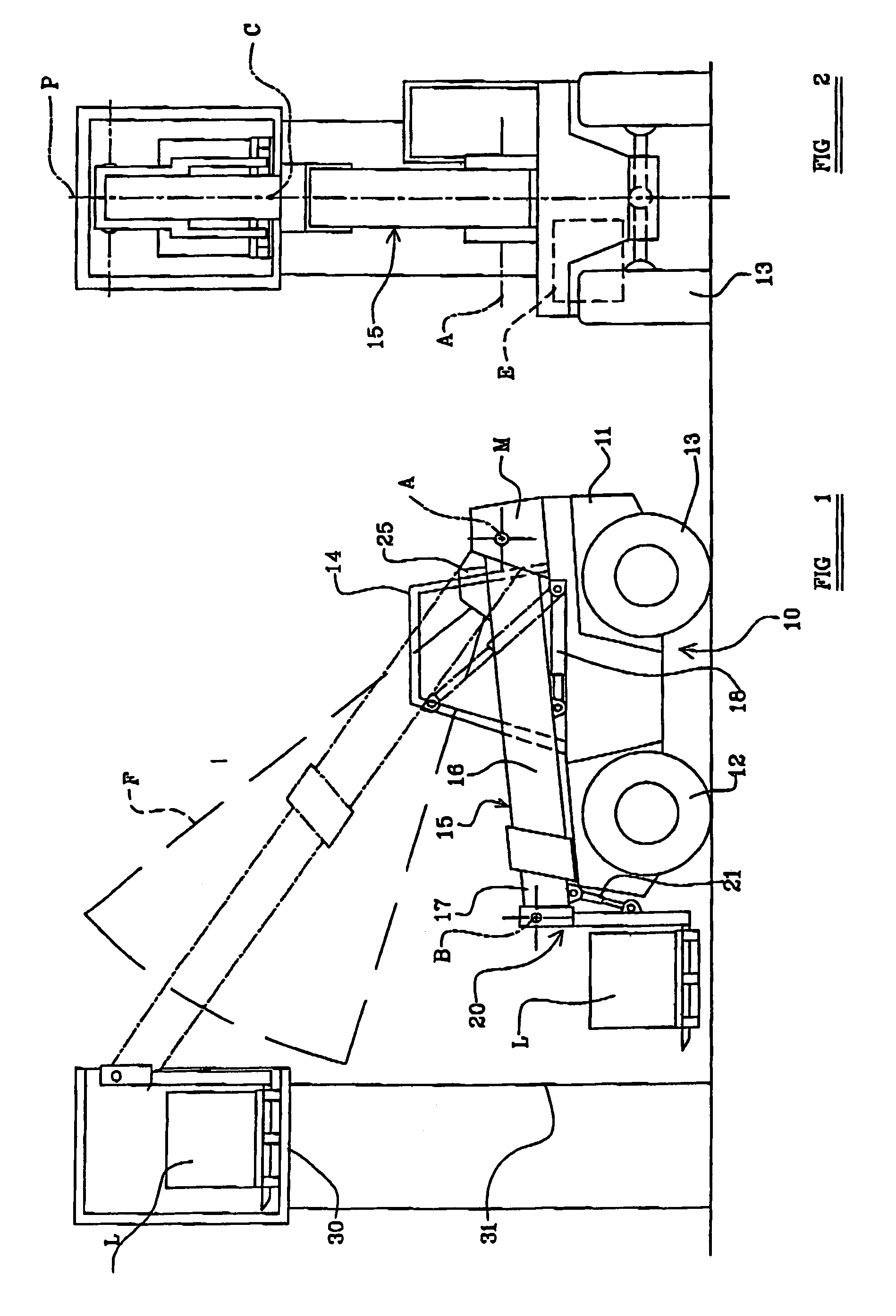

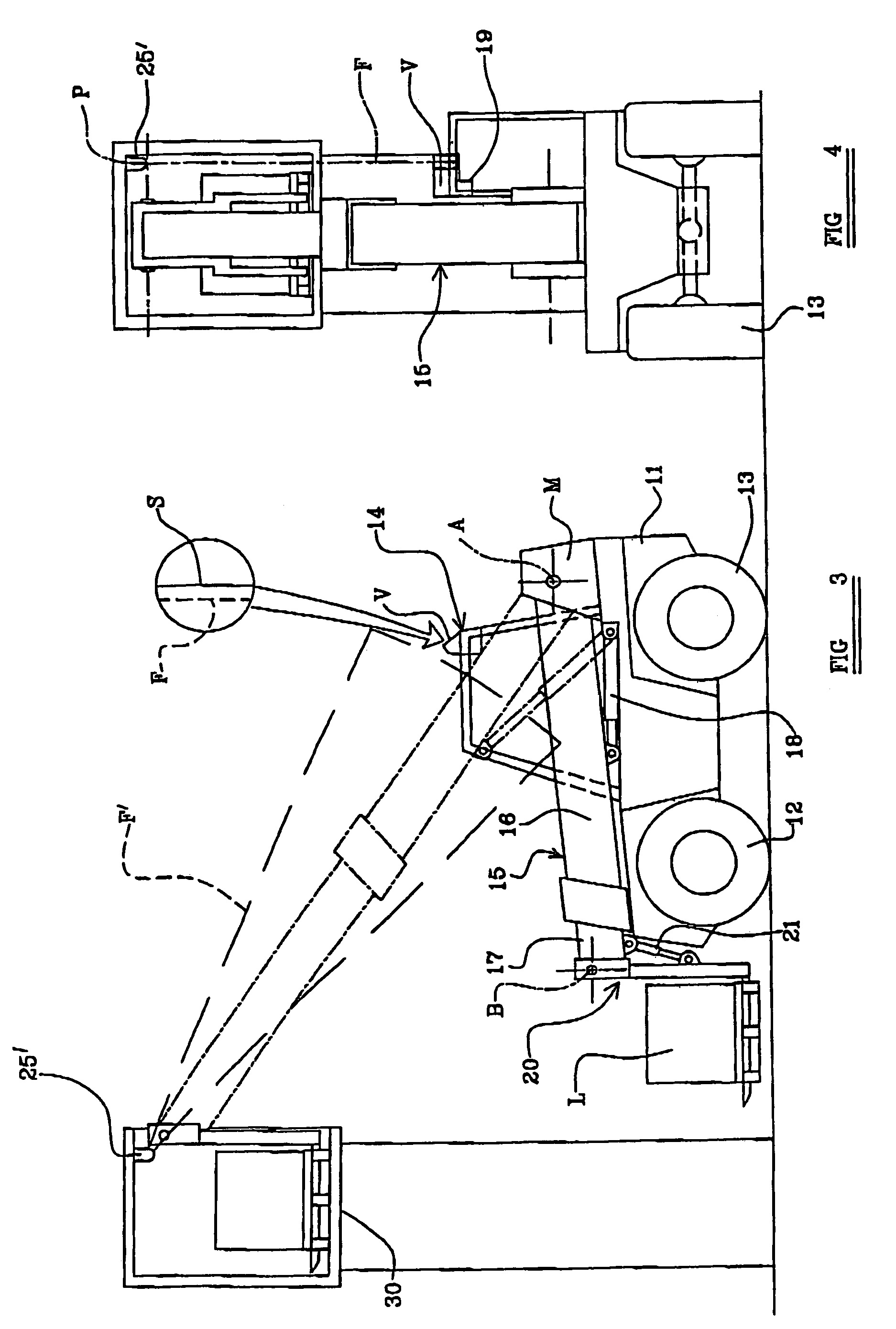

Method of handling a load

A method of handling a load at a high desired load handling position using a mobile loading machine of the kind having a loading arm connected at one end to a body of the machine for movement at least about a generally horizontal axis between a lower travelling position, and a higher load handling position, and the arm having at its outermost end a loading implement for carrying the load, the method including the steps of manoeuvring the machine with the arm in the lower travelling position generally below the load handling position, and then one of:a) directing a signal from the machine upwardly towards the load handling position in a plane in which a reference point of the loading implement is movable as the arm is raised about the generally horizontal axis, orb) directing a signal downwardly from at or adjacent the load handling position in a plane in which a reference point of the loading implement would be moveable if the arm is raised about the generally horizontal axis with the machine in a correct lateral position,to ascertain whether the machine is correctly laterally positioned, so that if the arm is lifted, the loading implement is positionable at the load handling position, manoeuvring the machine as necessary until the machine is correctly laterally positioned and then raising the loading arm to raise the loading implement towards the load delivery position.

Owner:J C BAMFORD EXCAVATORS LTD

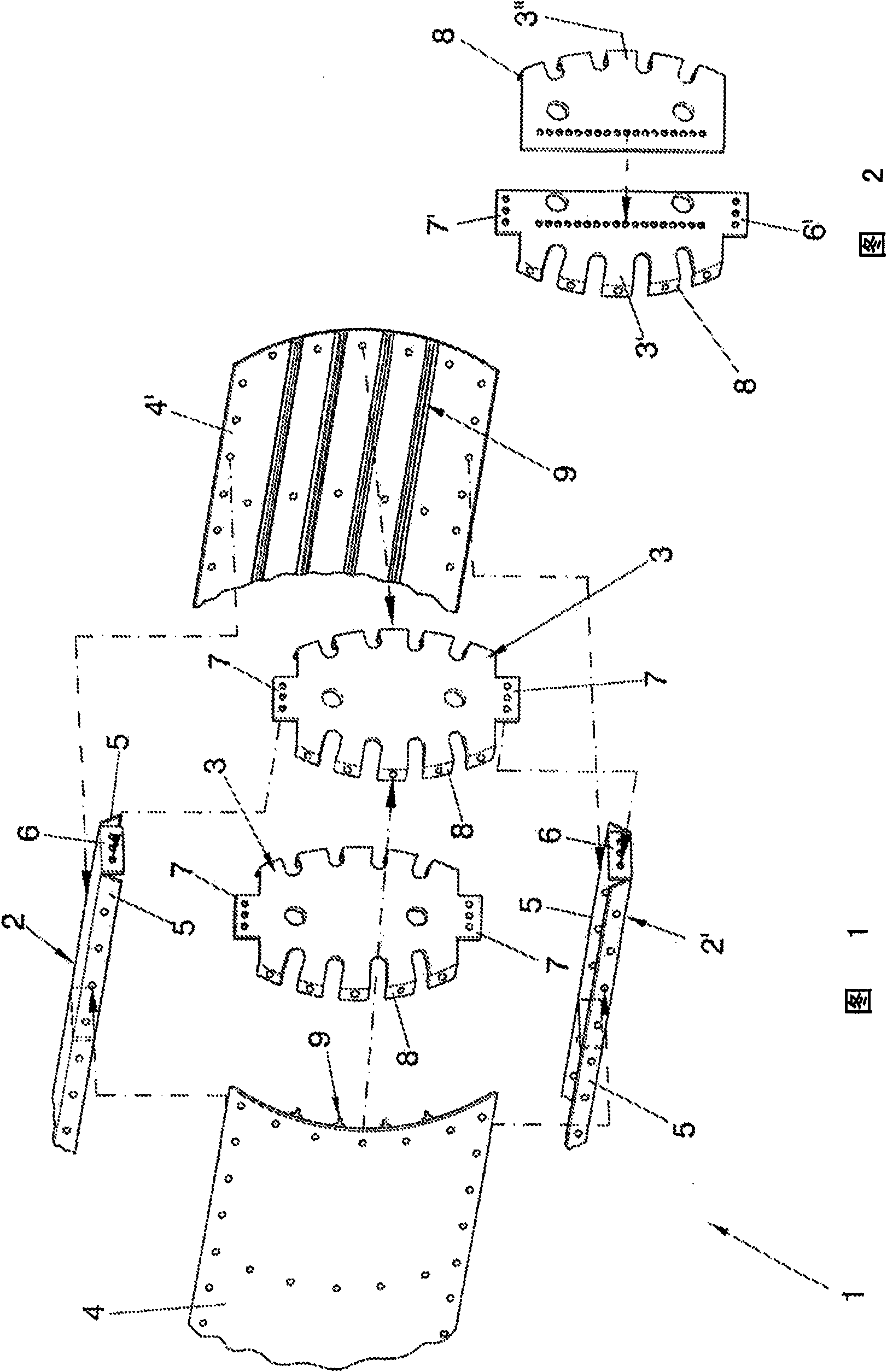

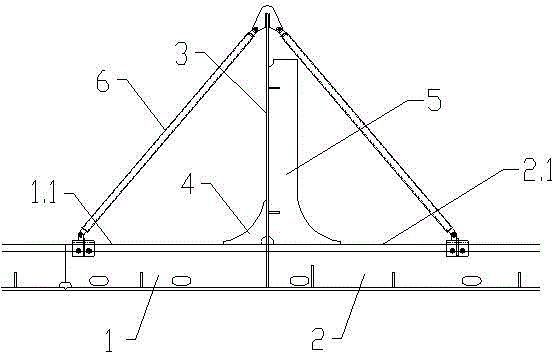

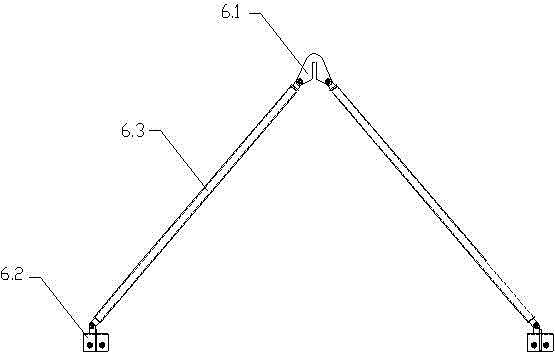

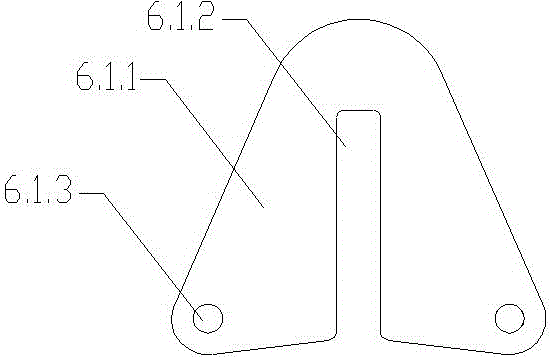

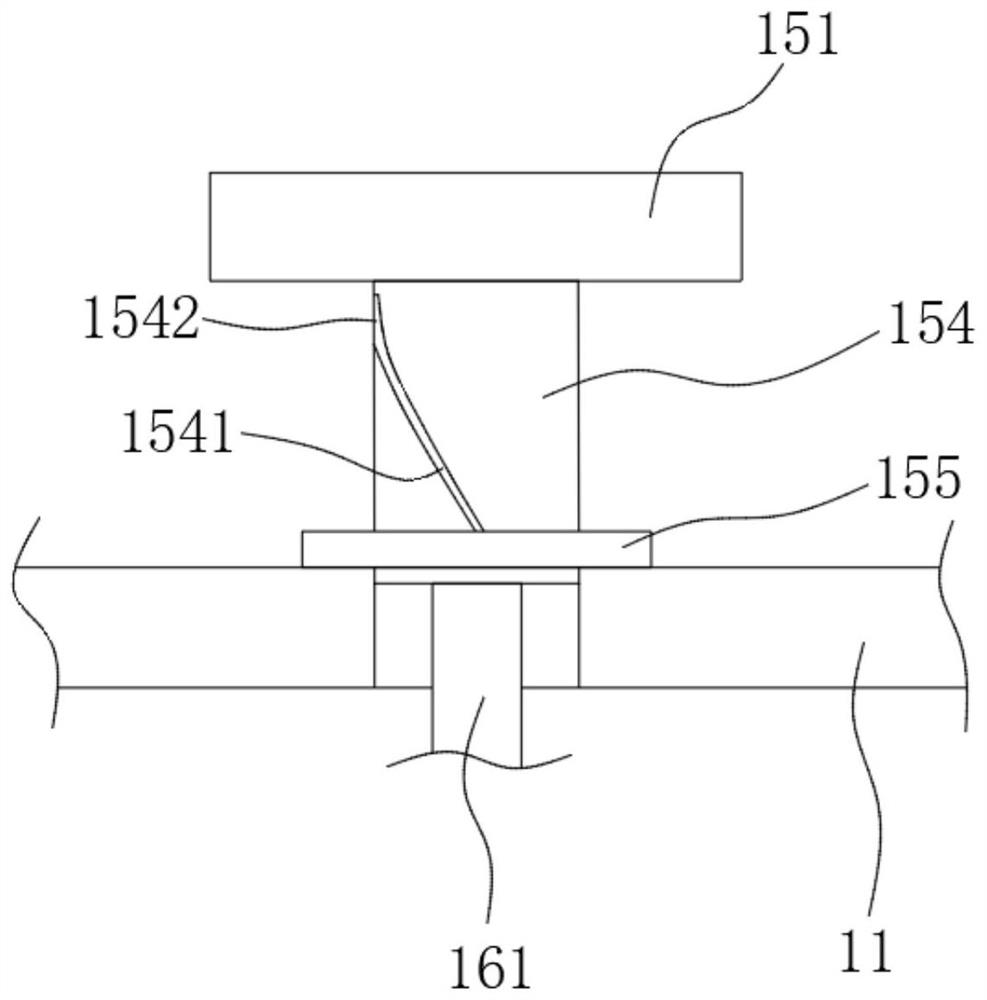

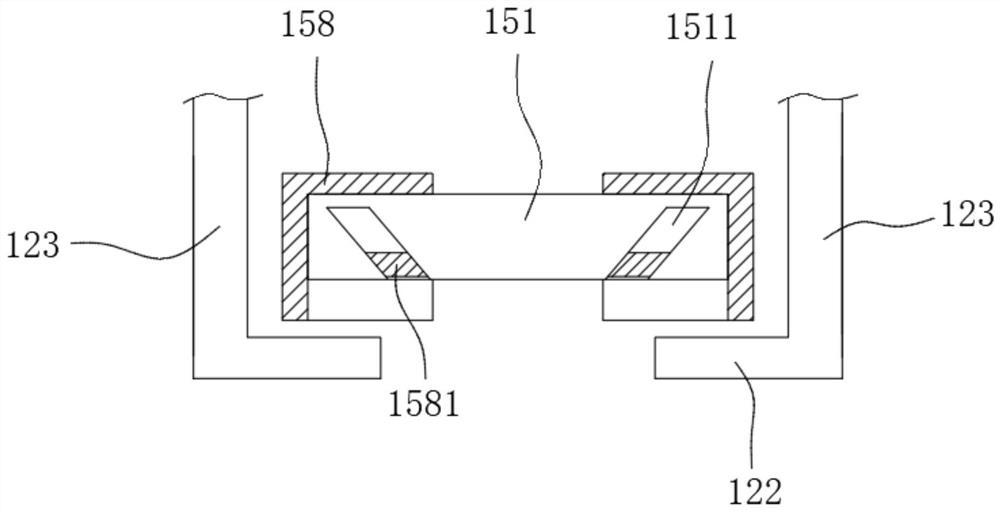

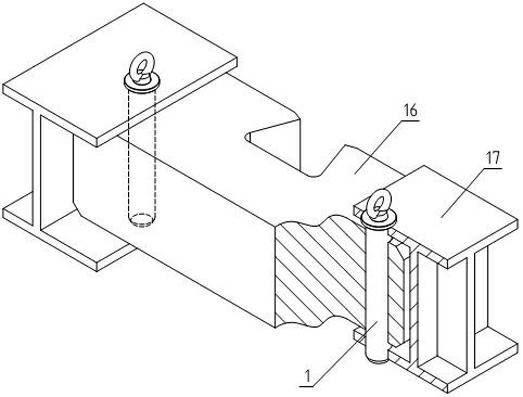

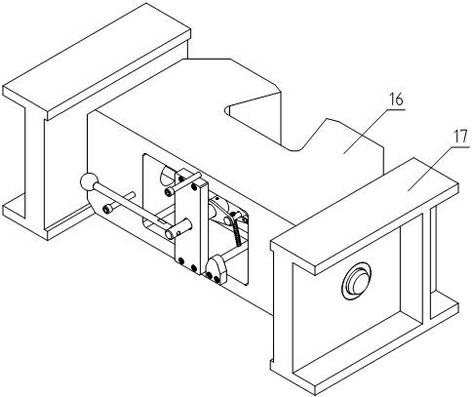

Segmented splicing method for ship hull

ActiveCN105945459AImprove splicing efficiencyImprove stitching qualityWelding/cutting auxillary devicesAuxillary welding devicesMarine engineeringSpot welding

The invention relates to a segmented splicing method for a ship hull. The segmented splicing method for the ship hull is characterized by comprising the following steps: step one, carrying out spot welding on the bottom of a ribbed plate (3), a left segment (1) and a right segment (2); step two, clamping the top of the ribbed plate (3) by using a top positioning piece (6.1) of a ribbed plate inclined strut positioning device (6), and respectively clamping two transverse positioning pieces (6.2) on a left transverse rib (1.1) of the left segment (1) and a right transverse rib (2.1) of the right segment (2); step three, transversely moving the two transverse positioning pieces (6.2) until the distances from the two transverse positioning pieces (6.2) to the bottom of the ribbed plate (3) are consistent, and locking positioning bolts (6.2.6); and step four, welding a left diagonal supporting rib (4) and a right diagonal supporting rib (5). The segmented splicing method for the ship hull has the advantages of high splicing efficiency and good splicing quality during segmented splicing of the ship hull.

Owner:江苏新扬子造船有限公司

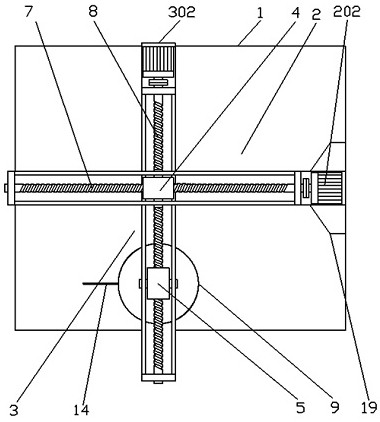

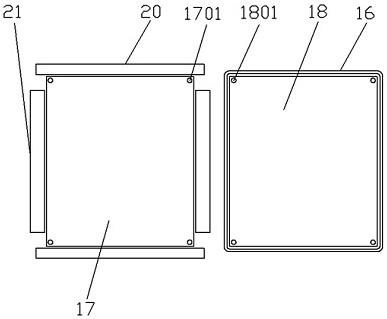

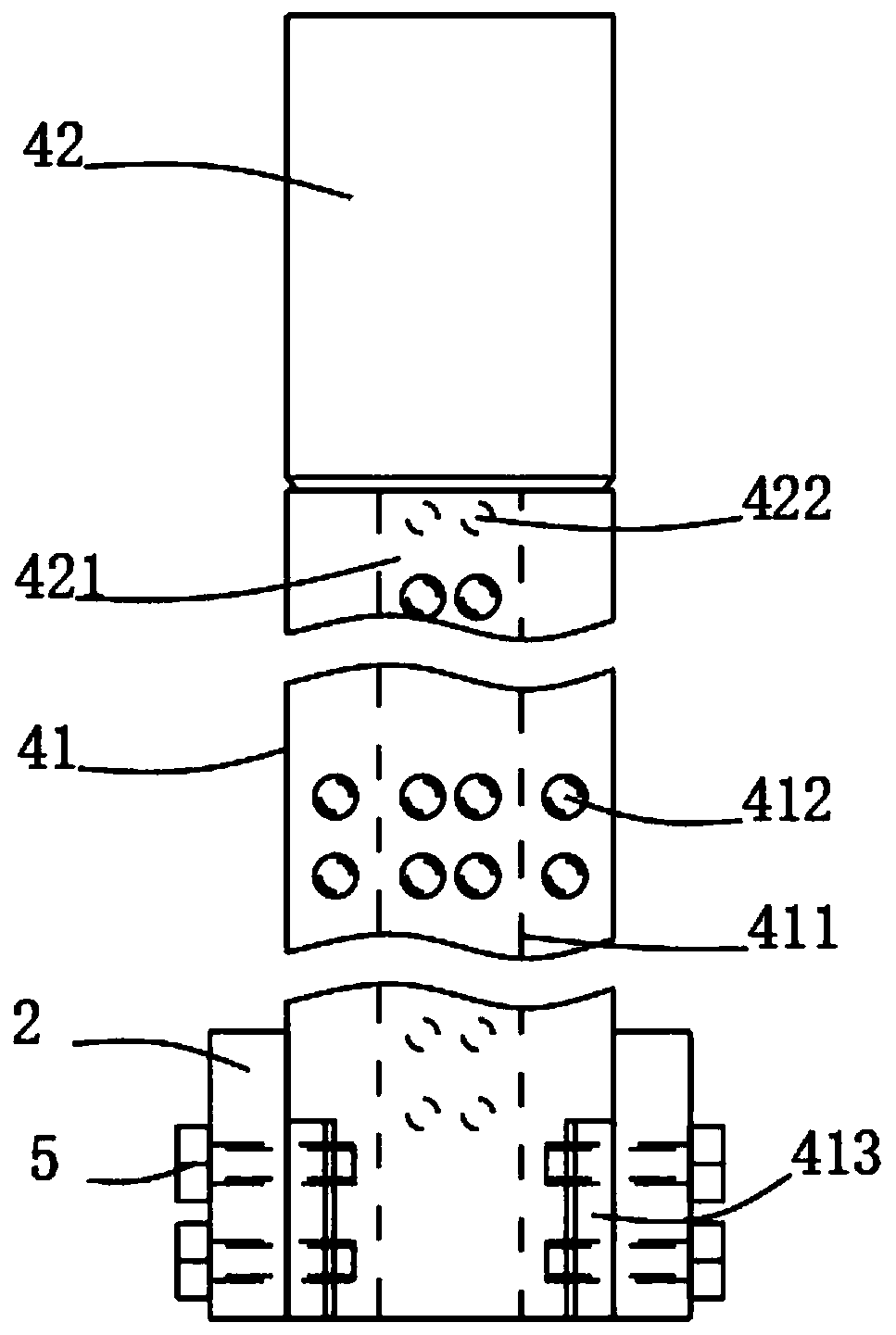

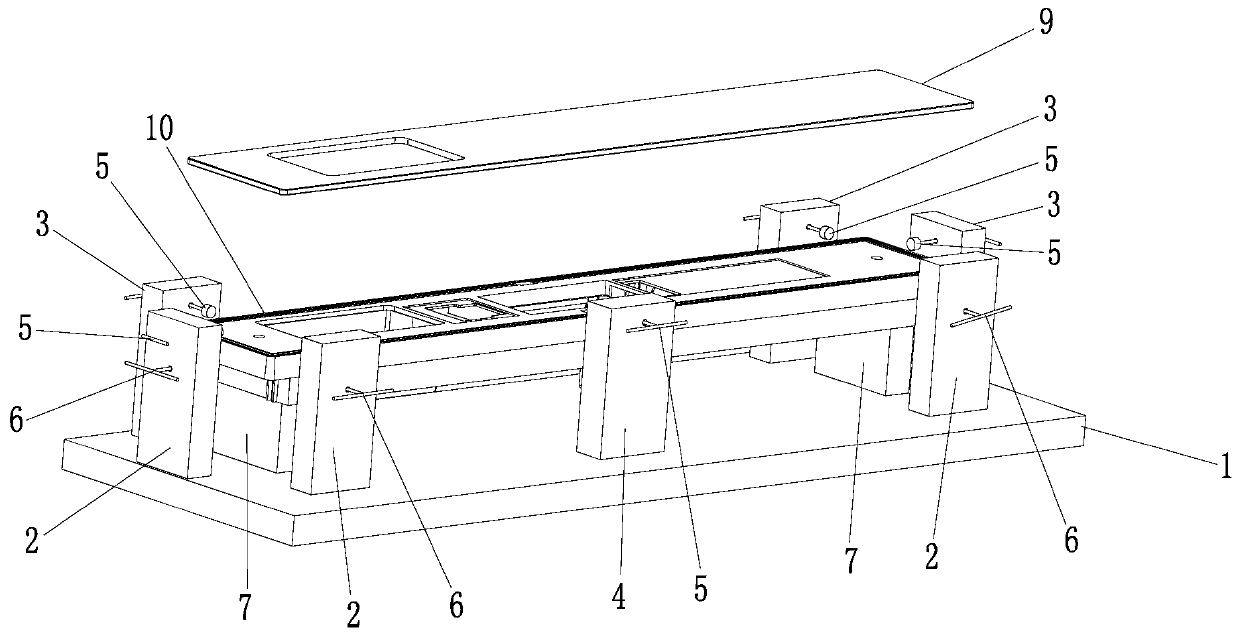

Top plate mounting device for rectangular shell

PendingCN111604678AEasy to refill and unloadReduce labor intensityMetal working apparatusLateral positionedMechanical equipment

The invention discloses a top plate mounting device for a rectangular shell, and belongs to the technical field of mechanical equipment. A transverse guide rail assembly and a longitude guide rail assembly drive a mounting plate connected at the bottom to move on a horizontal plane in multiple directions, so that a suction cup at the bottom is driven to move to the position over a top plate to clamp the top plate, and then the top plate is driven to move and be lowered to the position over the rectangular shell to be installed, so that upper and lower threaded holes of the top plate and the rectangular shell to be installed correspond to each other one by one, and a screwdriver is moved again through guide rails to move to the position above each threaded hole one by one and rotates and moves down vertically at the same time to screw a screw into the corresponding threaded hole, so that the top plate and the rectangular shell to be installed are fixedly connected; and the rectangular shell to be installed is limited and fixed by a transverse positioning plate and a longitudinal positioning plate, refilling and unloading are facilitated, an operator only needs to place the rectangular shell to be installed between the positioning plates, the labor intensity is relieved, and the product qualification rate is improved.

Owner:何佳

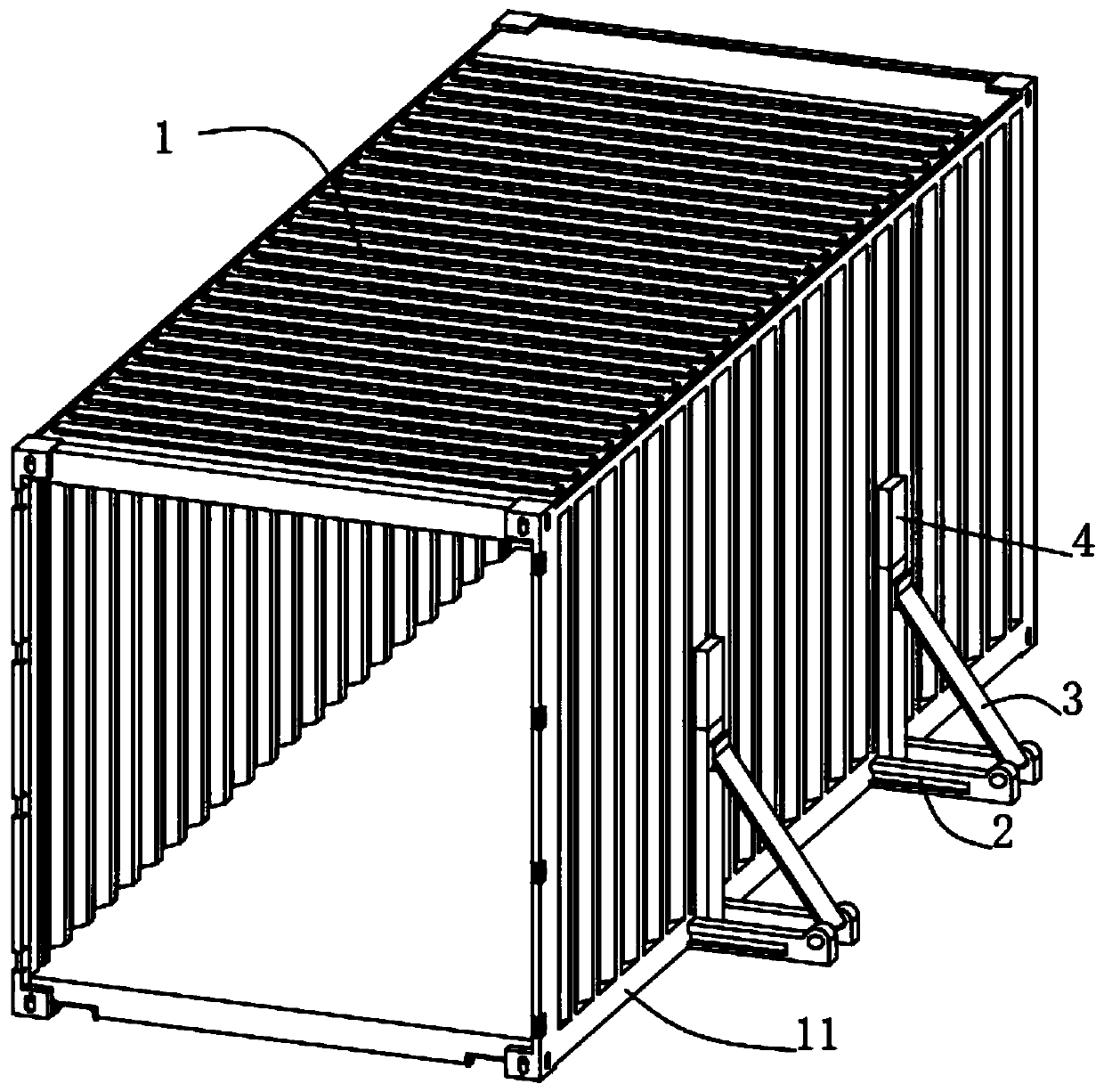

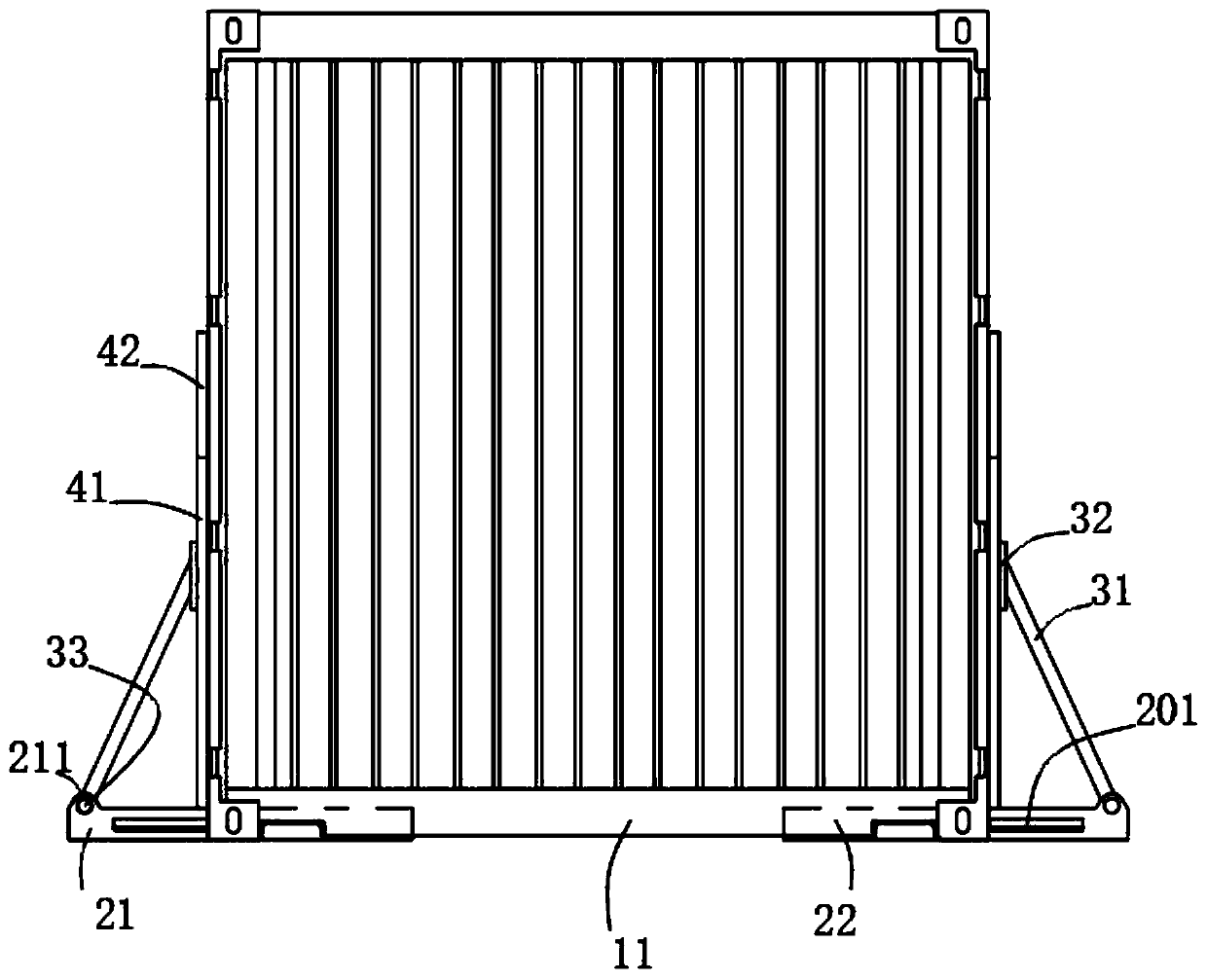

Anti-rollover container

ActiveCN110817174AIncrease the bottom edgeIncrease heightLarge containersLateral positionedFour-slide

The invention belongs to the technical field of containers, and particularly relates to an anti-rollover container. The anti-rollover container comprises a box body; at least four sliding grooves areformed in two sides of a bottom plate of the box body; a transverse positioning rod is arranged in each sliding groove; and each transverse positioning rod comprises a hinged part and a sliding part;and a positioning reference plane can be determined by arranging extractable transverse positioning rods on the side parts of the bottom plate, vertical positioning rods attached to the side wall of the box body can be arranged on the transverse positioning rods through bolts, then the vertical positioning rods are fixed through supporting inclined rods hinged at the distal ends of the transversepositioning rods, so that a triangular stable support is formed, and the pulling-out distance of the transverse positioning rods can be adjusted according to the weight of the box body, namely, a bottom edge of a triangle is increased, the heights of the vertical positioning rods can be increased, namely, a right-angle edge of the triangle is increased, the supporting range of the box body is greatly increased, and the installation process is simple and convenient.

Owner:万昇国际贸易有限公司

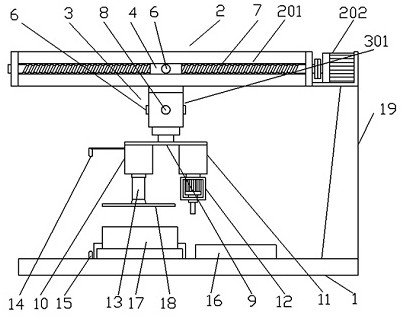

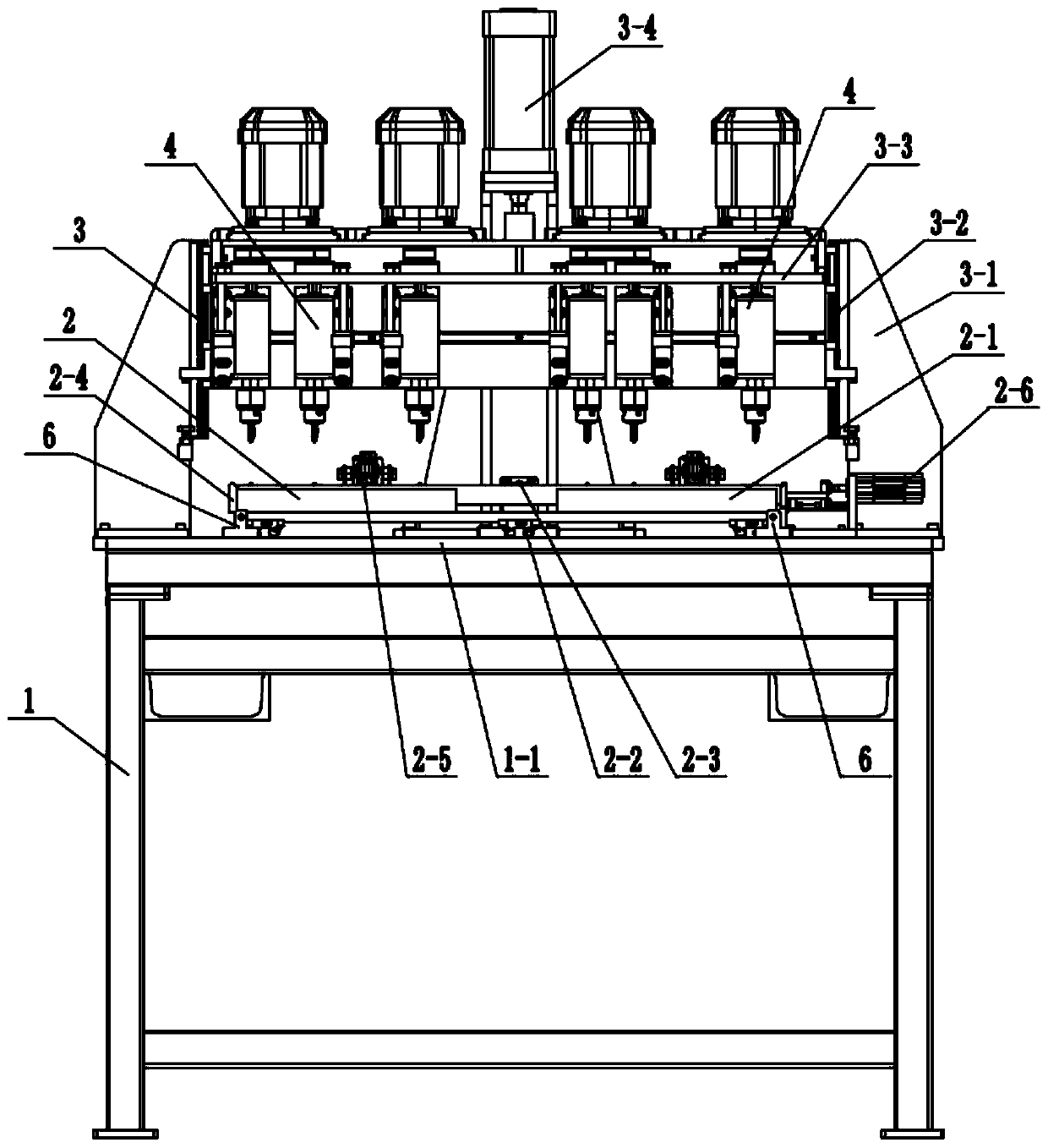

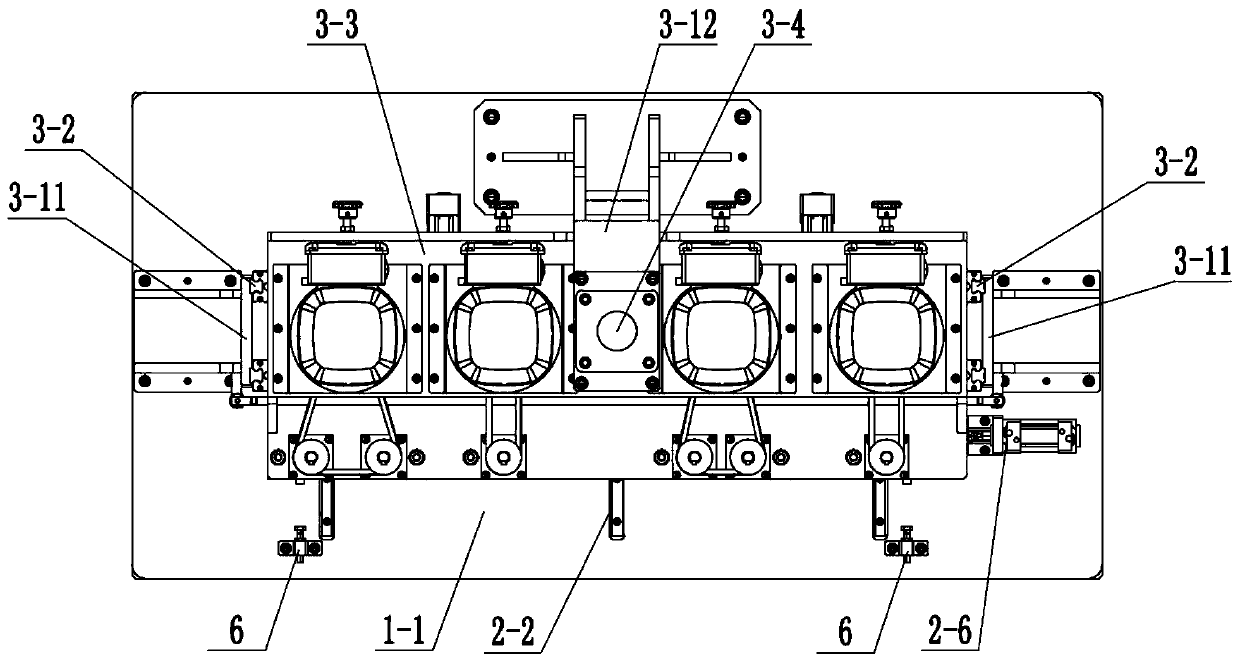

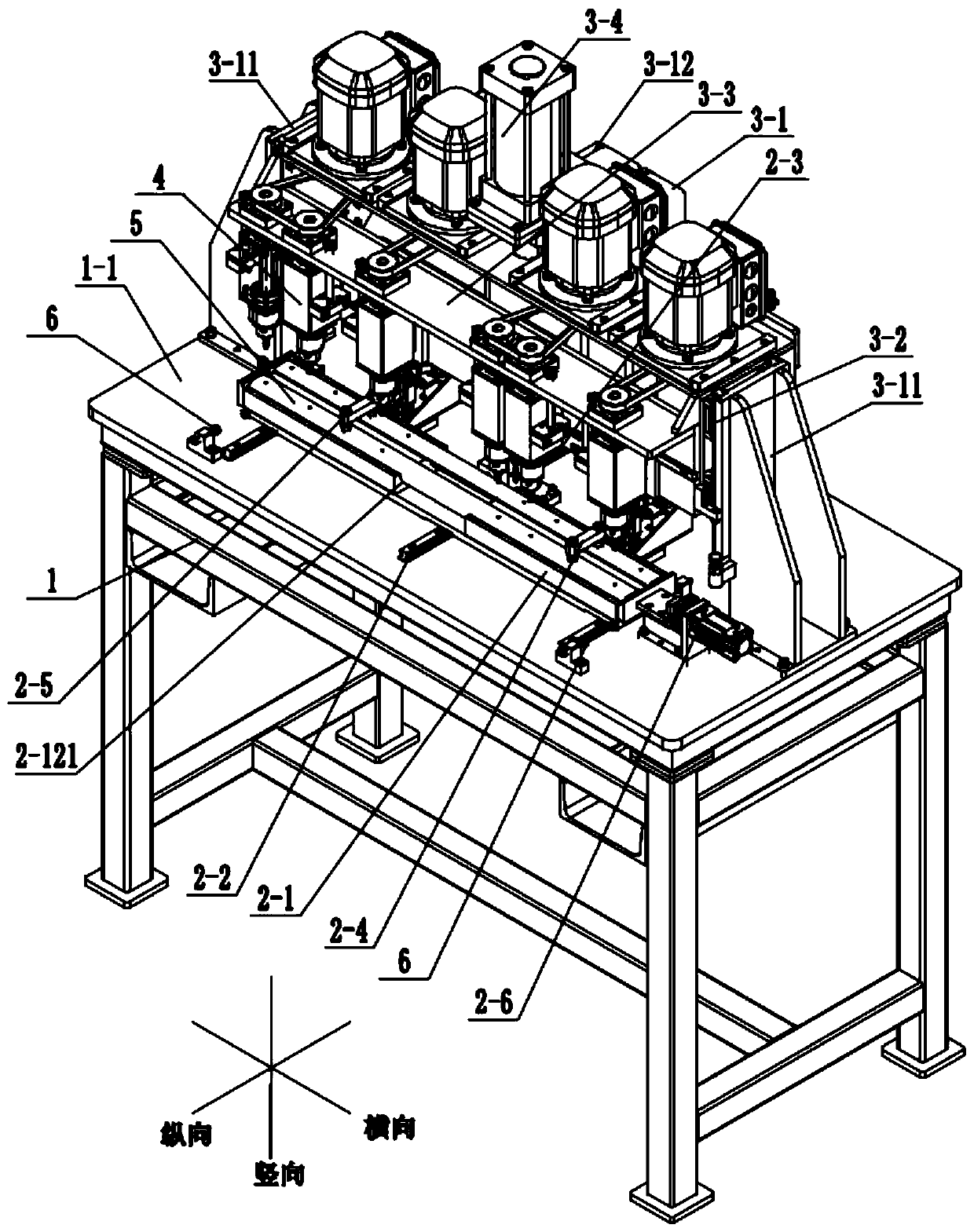

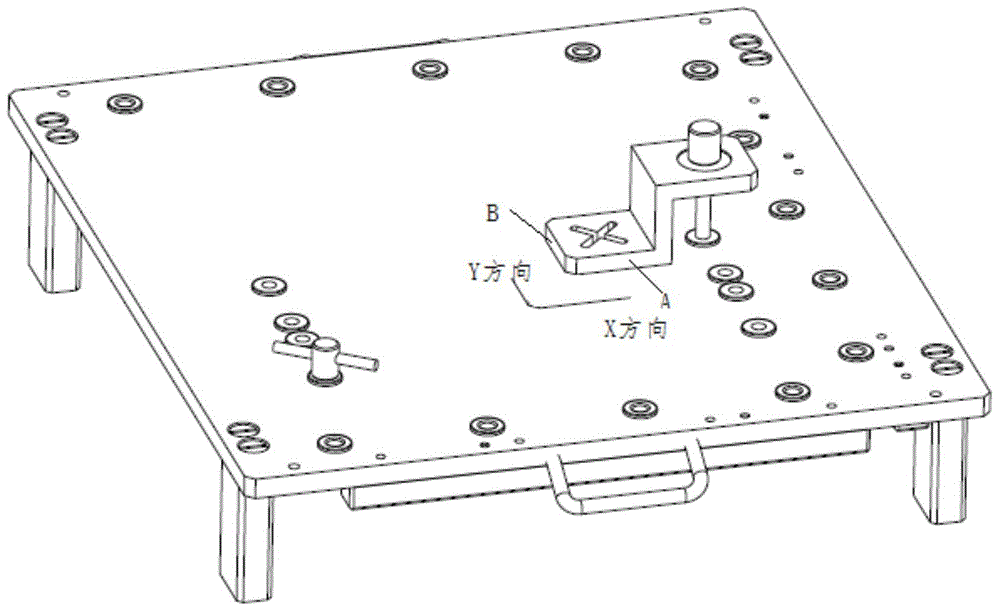

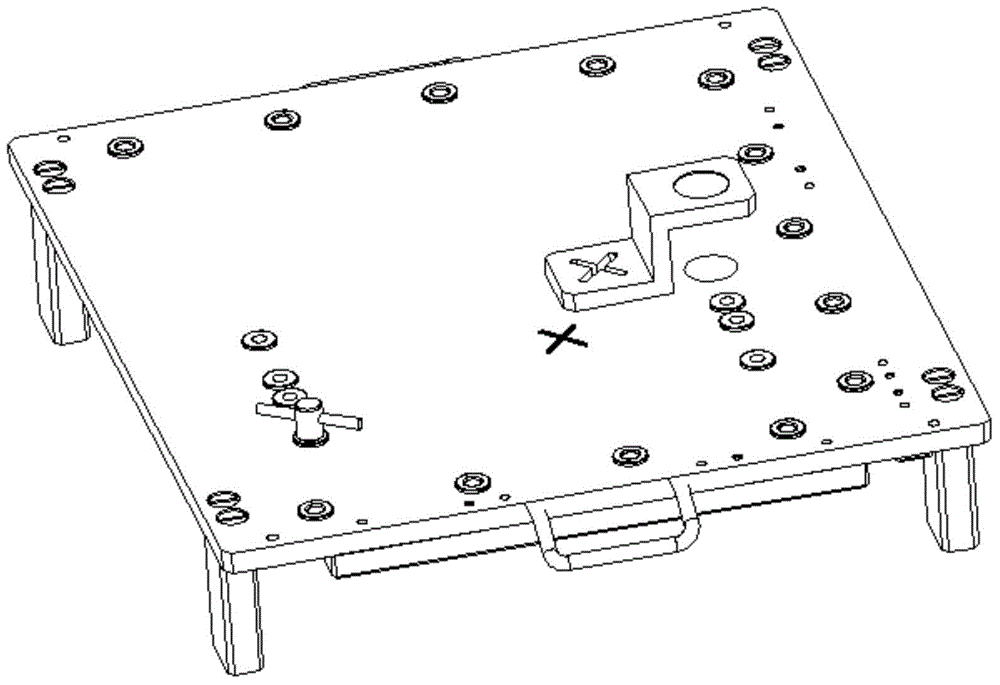

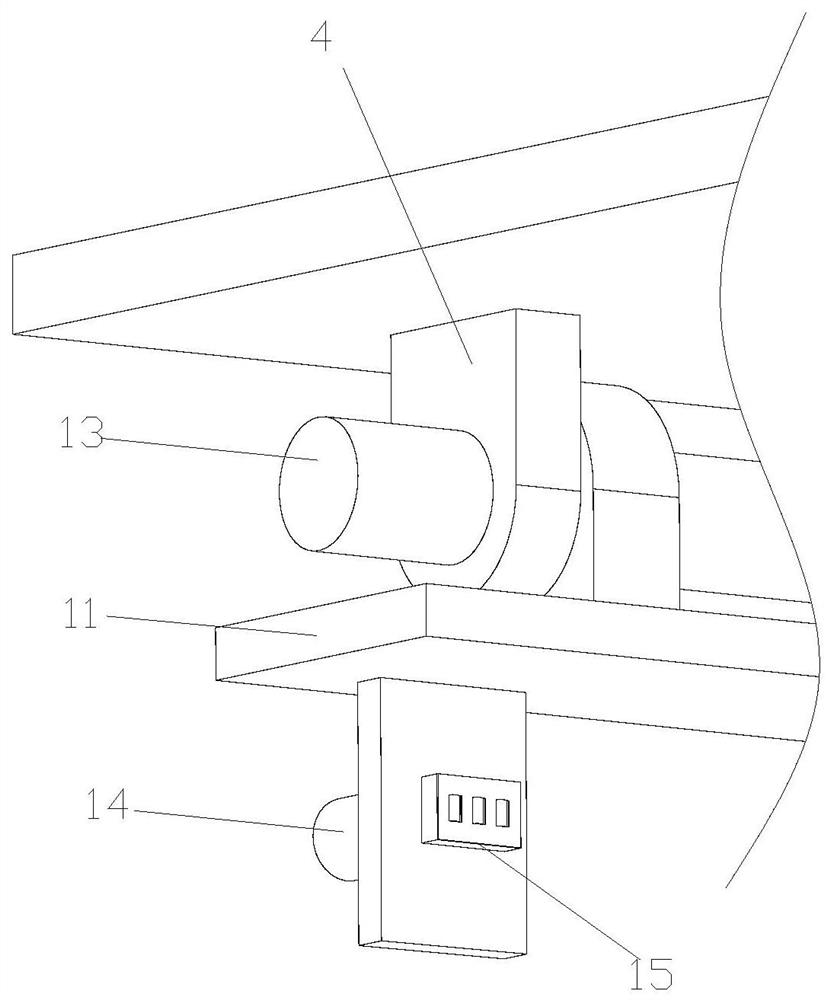

Multi-station automatic drilling equipment for aluminum alloy sections

InactiveCN111014769AIncrease productivityShort assist timePositioning apparatusMetal-working holdersLateral positionedEngineering

The invention discloses multi-station automatic drilling equipment for aluminum alloy sections. The equipment is characterized by comprising a rack (1), an aluminum alloy profile positioning clamp (2), a lifting mechanism (3) and a plurality of drilling machines (4), wherein the rack (1) is provided with a horizontal workbench (1-1), the aluminum alloy profile positioning clamp (2) comprises a positioning base (2-1), a longitudinal guide rail (2-2), a longitudinal air cylinder (2-3), a transverse positioning baffle (2-4), a first pressing mechanism (2-5) and a second pressing mechanism (2-6),the lifting mechanism (3) comprises a bracket (3-1), a vertical guide rail (3-2), a lifting seat (3-3) and a lifting driving cylinder (3-4), the drilling machines (4) are installed on the lifting base(3-3) and distributed side by side at intervals in the transverse direction. The equipment is advantaged in that multi-hole-site automatic drilling machining can be conducted on the two aluminum alloy sections, and working efficiency can be improved exponentially.

Owner:重庆新美鱼博洋铝业有限公司

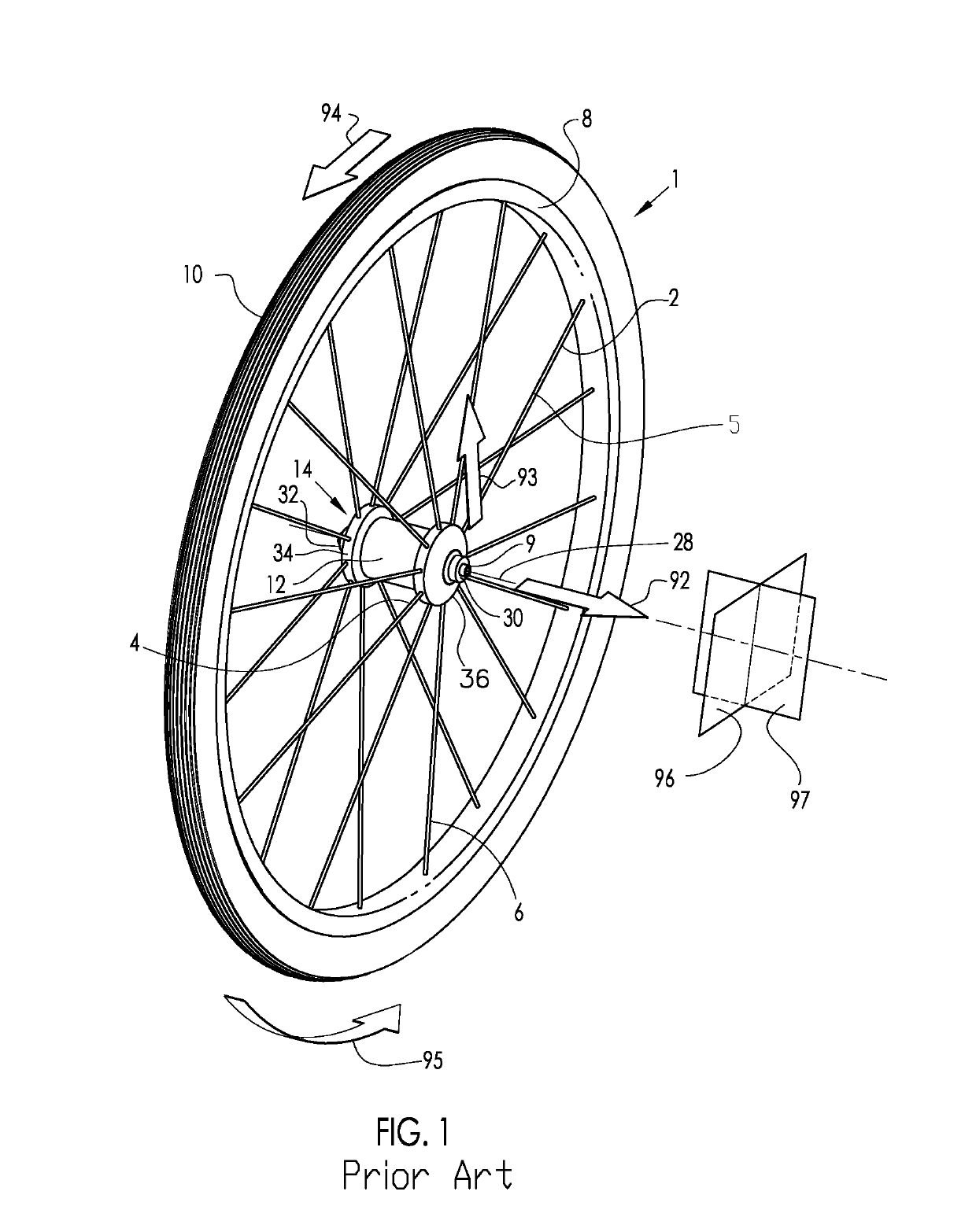

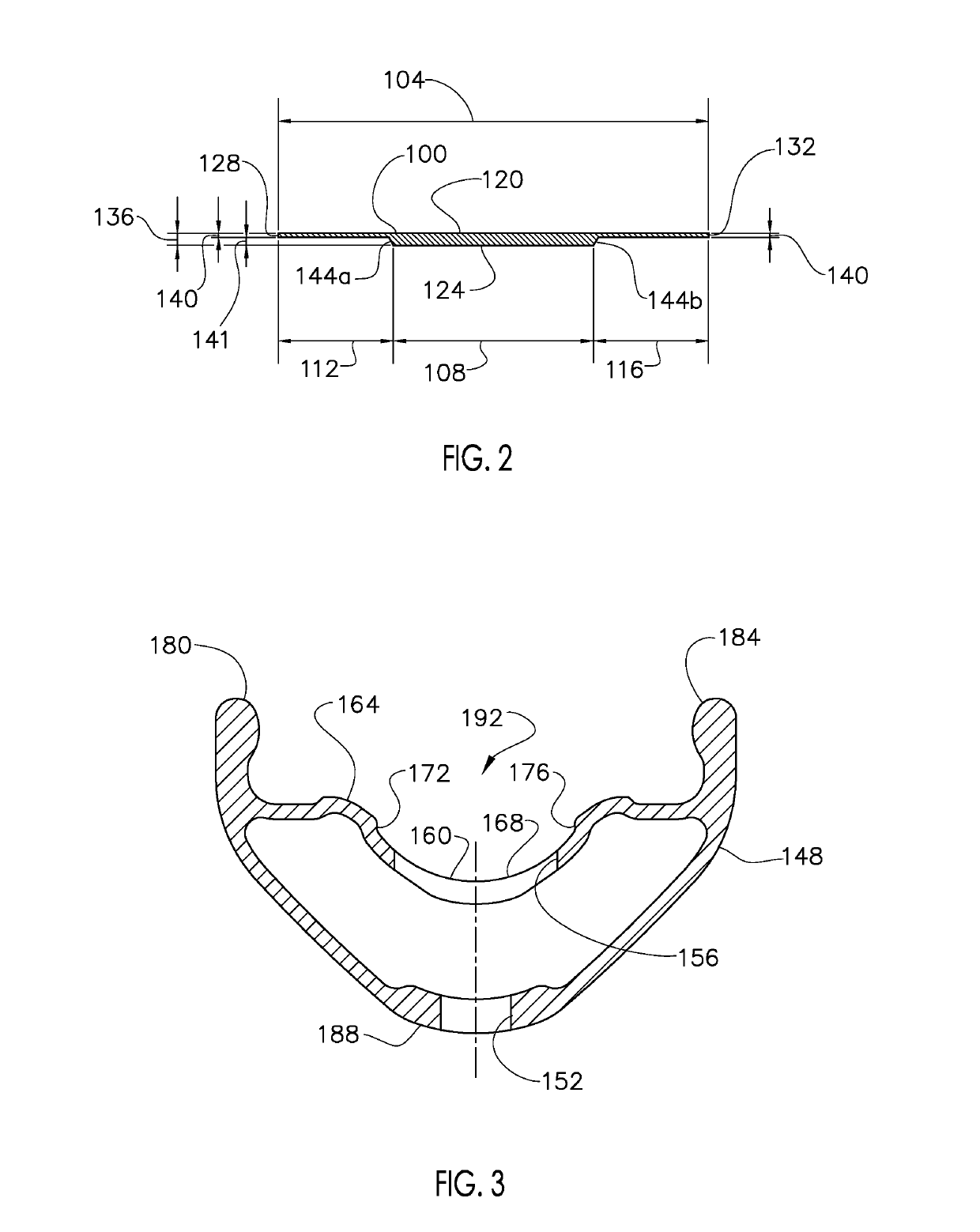

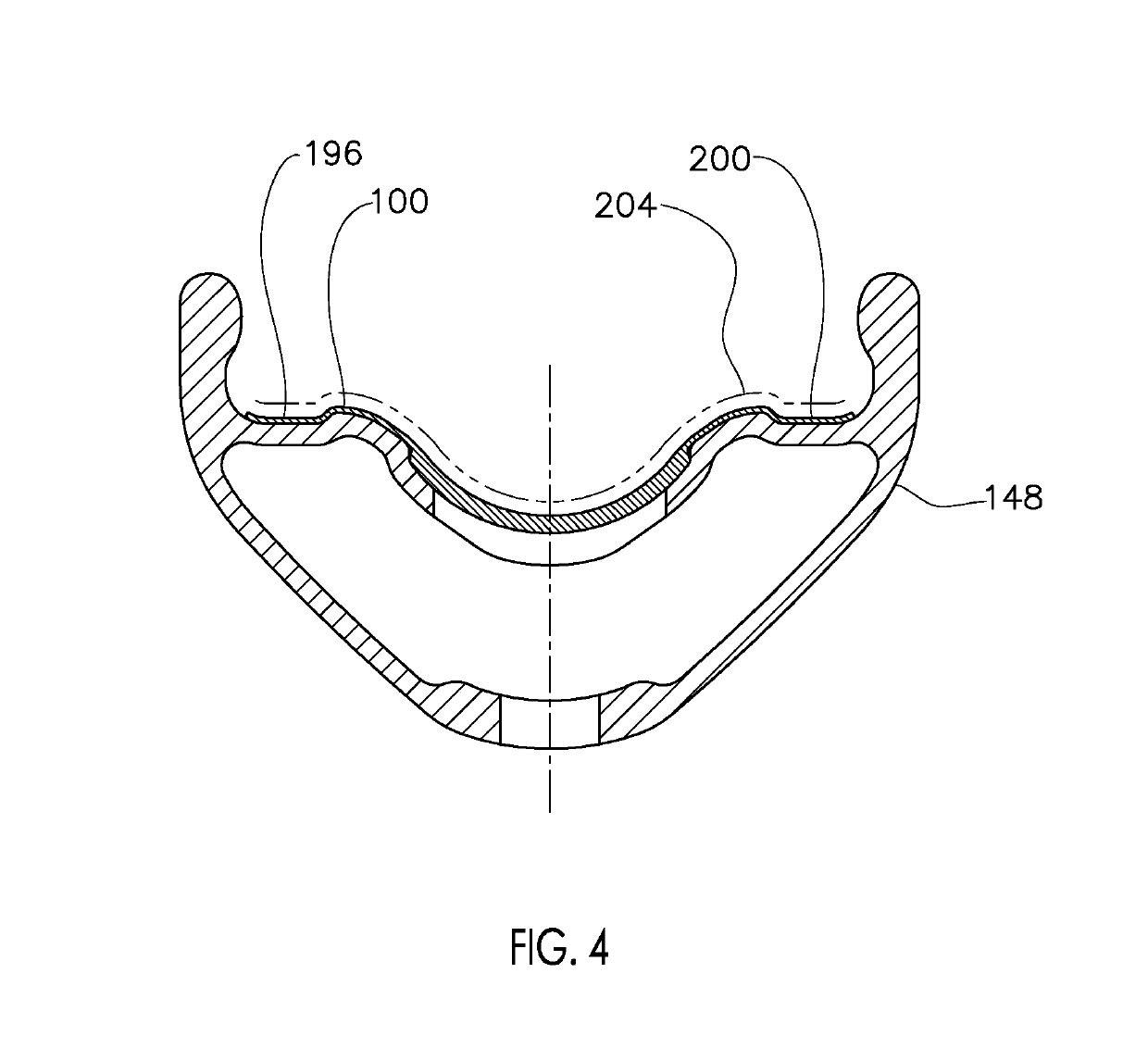

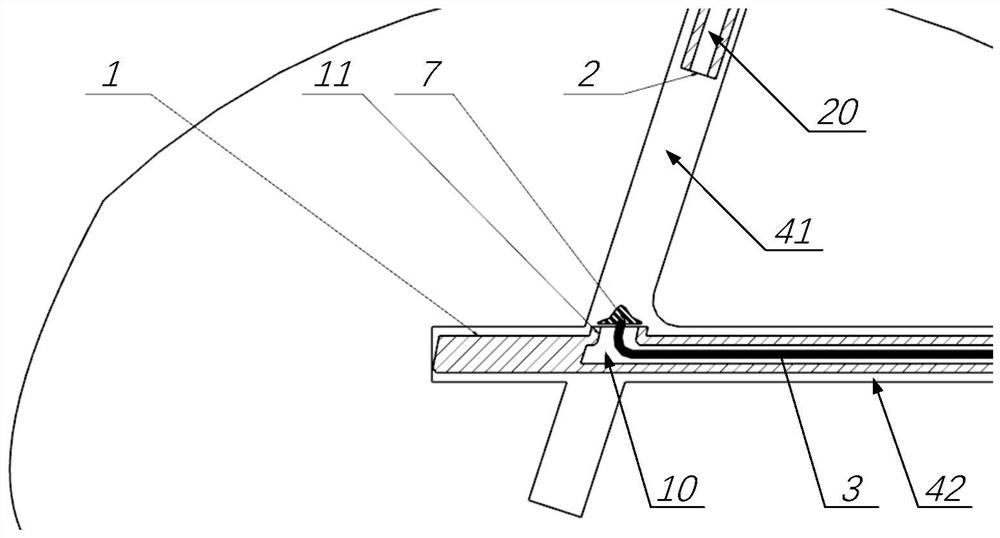

Rim with recessed channel and rim strip apparatus and system

A rim sealing strip comprising: a circumferentially elongated rim strip having a radially outwardly facing outboard surface, a radially inwardly facing inboard surface, a first lateral edge and a second lateral edge laterally spaced from the first lateral edge; where the rim strip includes an overall lateral width between the first lateral edge and the second lateral edge and a radial thickness between the outboard surface and the inboard surface; and where the radial thickness is variable across the lateral width to include a first lateral region having a first radial thickness and a second lateral region having a second radial thickness, where the first radial thickness is thicker than the second radial thickness. A rim sealing system comprising: a circumferentially elongated rim strip having a radially outwardly facing outboard surface, a radially inwardly facing inboard surface, a first lateral edge and a second lateral edge laterally spaced from the first lateral edge; a rim to receive the circumferentially elongated rim strip, where the rim includes a radially outwardly projecting first bead flange, a radially outwardly projecting second bead flange laterally spaced from the first bead flange, and a radially outwardly facing tire bed surface positioned laterally between the first bead flange and the second bead flange, and where the inboard surface of the rim strip circumscribes the tire bed surface; where the rim strip includes an overall lateral width between the first lateral edge and the second lateral edge and a radial thickness between the outboard surface and the inboard surface; and where the radial thickness is variable across the lateral width to include a first lateral region having a first radial thickness and a second lateral region having a second radial thickness, where the first radial thickness is thicker than the second radial thickness. A rim sealing strip comprising: a circumferentially elongated rim strip having a radially outwardly facing outboard surface, a radially inwardly facing inboard surface, a first lateral edge and a second lateral edge laterally spaced from the first lateral edge; where the rim strip includes an overall lateral width between the first lateral edge and the second lateral edge and a radial thickness between the outboard surface and the inboard surface; and where the rim strip includes a first lateral region and a second lateral region laterally adjoining the first lateral region; and where the material stiffness of the first lateral region has greater stiffness than the material stiffness of the second lateral region. A rim comprising: a rim, the rim comprising: a radially outwardly facing tire bed surface along a circumference of the rim; and channel laterally positioned generally in the center of the tire bed surface and along the entire circumference; where the tire bed surface includes an unsealed opening there through to communicate to the atmosphere; and where the channel has a lateral width that completely laterally overlaps the opening. A rim system comprising: a rim, the rim comprising: a tire bed surface along a circumference of the rim; a channel generally in the center of the inner surface and generally along the entire circumference; a rim strip configured to be removeably seated in the channel; and rim tape configured to adhere to the tire bed surface and the rim strip. An air barrier for a tubeless rim, the air barrier comprising: a rim strip configured to be removeably seated in a center channel located on a tire bed surface along a circumference of a tubeless rim; and rim tape configured to adhere to the inner surface and the rim strip. A rim sealing strip comprising: a circumferentially elongated rim strip having a radially outwardly facing outboard surface, a radially inwardly facing inboard surface, a first lateral edge and a second lateral edge laterally spaced from the first lateral edge; where the rim strip includes an overall lateral width between the first lateral edge and the second lateral edge and a radial thickness between the outboard surface and the inboard surface; and where the rim strip includes a first lateral region and a second lateral region laterally adjoining the first lateral region; and where at least one of: (i) the radial thickness is variable across the lateral width to include a first lateral region having a first radial thickness and a second lateral region having a second radial thickness, where the first radial thickness is thicker than the second radial thickness; and (ii) the material stiffness of the first lateral region is greater than the material stiffness of the second lateral region.

Owner:FEUCHT CHRISTIAN +4

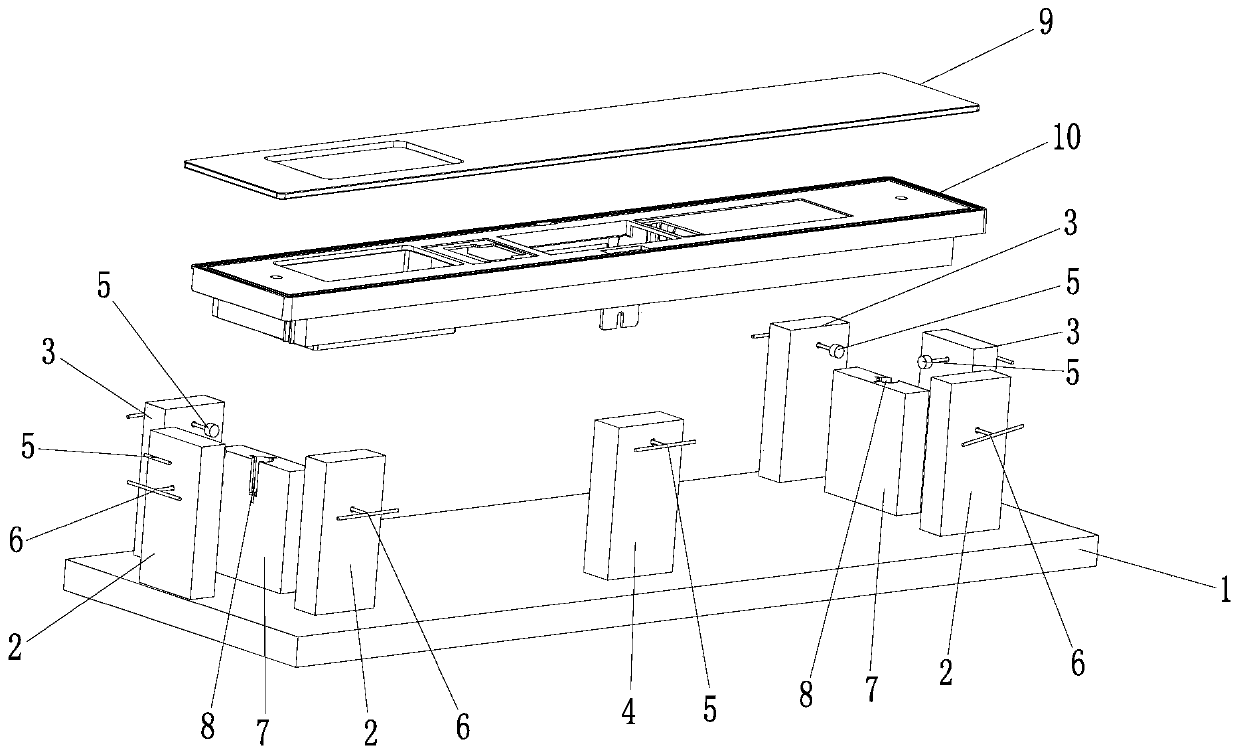

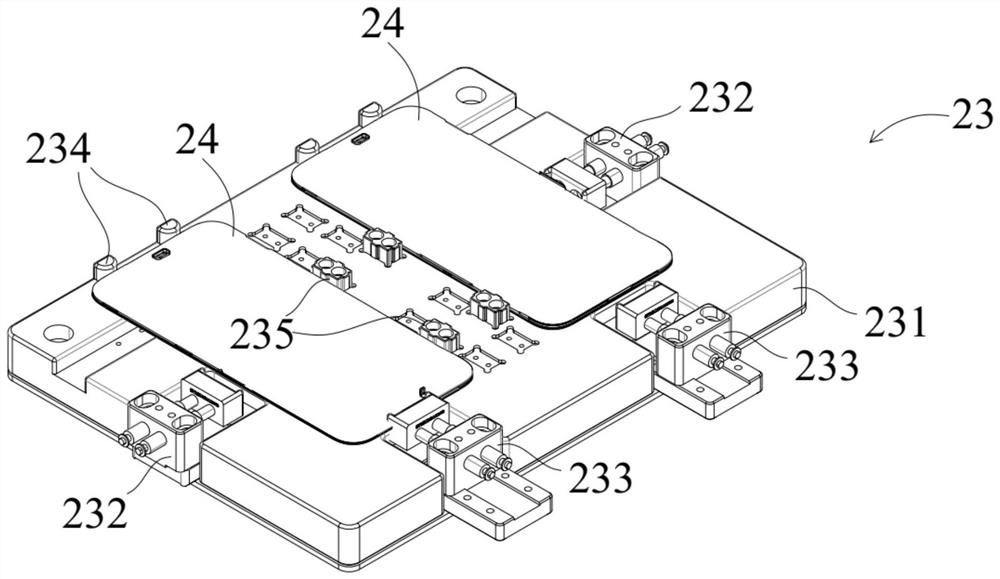

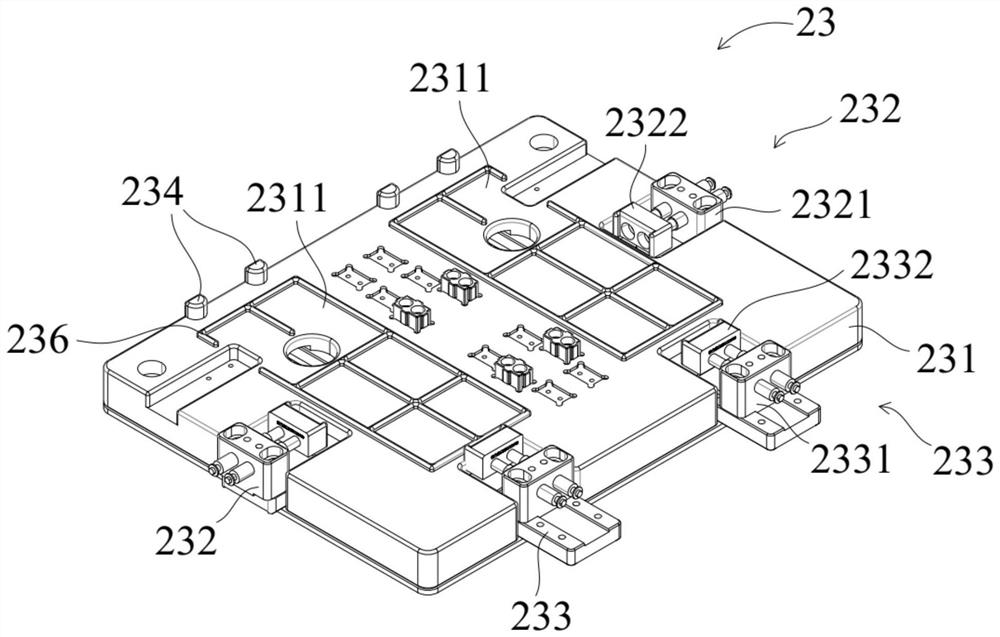

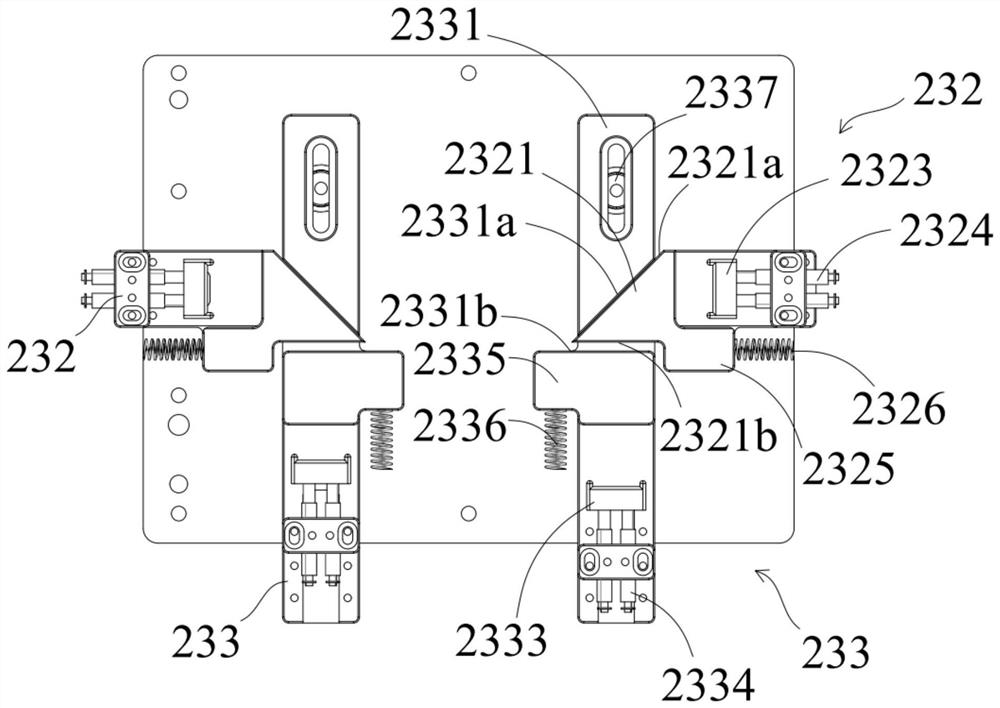

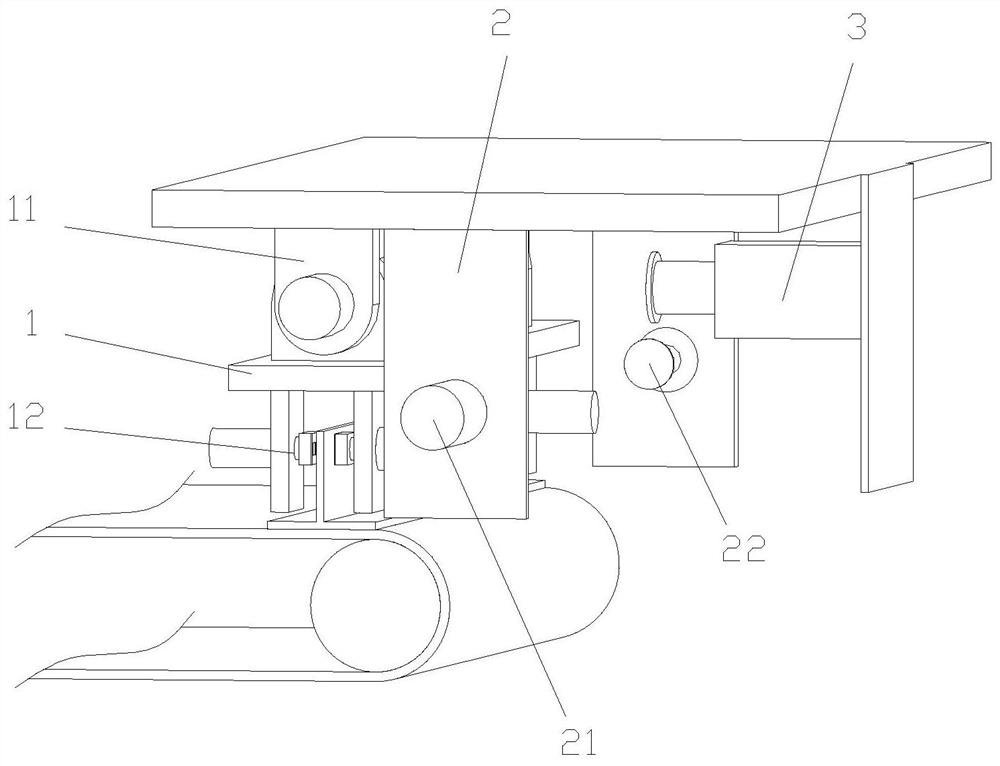

Tooling device

ActiveCN110985499AHigh positioning accuracyRepeat positioning stability is goodMaterial gluingWork holdersLateral positionedEngineering

The invention discloses a tooling device which is used for positioning and mounting workpieces. The workpieces comprise an upper workpiece (9) and a lower workpiece (10) assembled up and down in a laminating manner; the tooling device comprises a mounting bottom plate (1), a vertical positioning module and a transverse positioning module, wherein the vertical positioning module is arranged on themounting bottom plate (1) to vertically position the workpieces; the transverse positioning module is used for transversely positioning the workpieces and comprises a plurality of transverse positioning bases arranged at intervals in sequence along the warping direction of the outer contours of the workpieces; and an upper positioning pieces (5) and / or a lower positioning pieces (6) capable of moving telescopically in the transverse direction are arranged on the transverse positioning seats. The tooling device can quickly adjust the positioning standard according to actual different to-be-assembled workpieces or variation of clients' requirements, has the advantages of high positioning precision, high repeated positioning stability and high universality, and facilitates improving the assembling quality, reducing the production cost, shortening the production cycle and improving the user experience.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

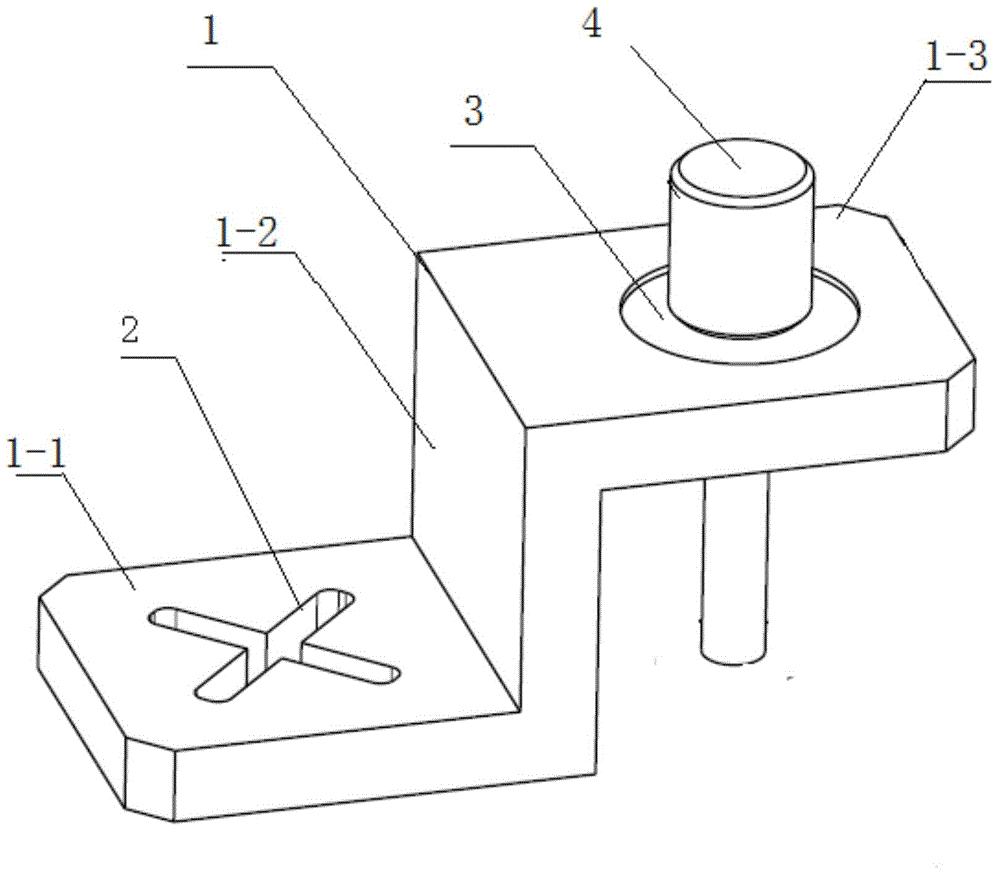

Method and device for changing hole positions of drill jig

ActiveCN105014120AShorten the timeSpecial data processing applicationsDrill jigsEngineeringDrill bushing

The invention provides a method for changing the hole positions of a drill jig. The method includes the steps that a deviation value of the position of a drill bushing hole is calculated; a transverse deviation value and a longitudinal deviation value between the position of a new drill bushing hole and the position of an old drill bushing hole are calculated; a positioning hole of a hole position transferring device is connected with the position of the old drill bushing hole through a positioning pin (4), and the directions of a transverse positioning base level and a longitudinal positioning base level of the hole position transferring device are determined according to the deviation value and the direction, determined in the step one, of the position of the drill bushing hole; and a cross-shaped groove is formed at the portion of a base plate of the hole position transferring device, 45-degree angles or 90-degree angles are formed between two through grooves of the cross-shaped groove and the transverse positioning base level and the longitudinal positioning base level of the hole position transferring device, a cross-shaped line is marked in the cross-shaped groove, an intersection point of the cross-shaped line is determined, and the positioning pin (4) is taken out from the positioning hole.

Owner:HARBIN

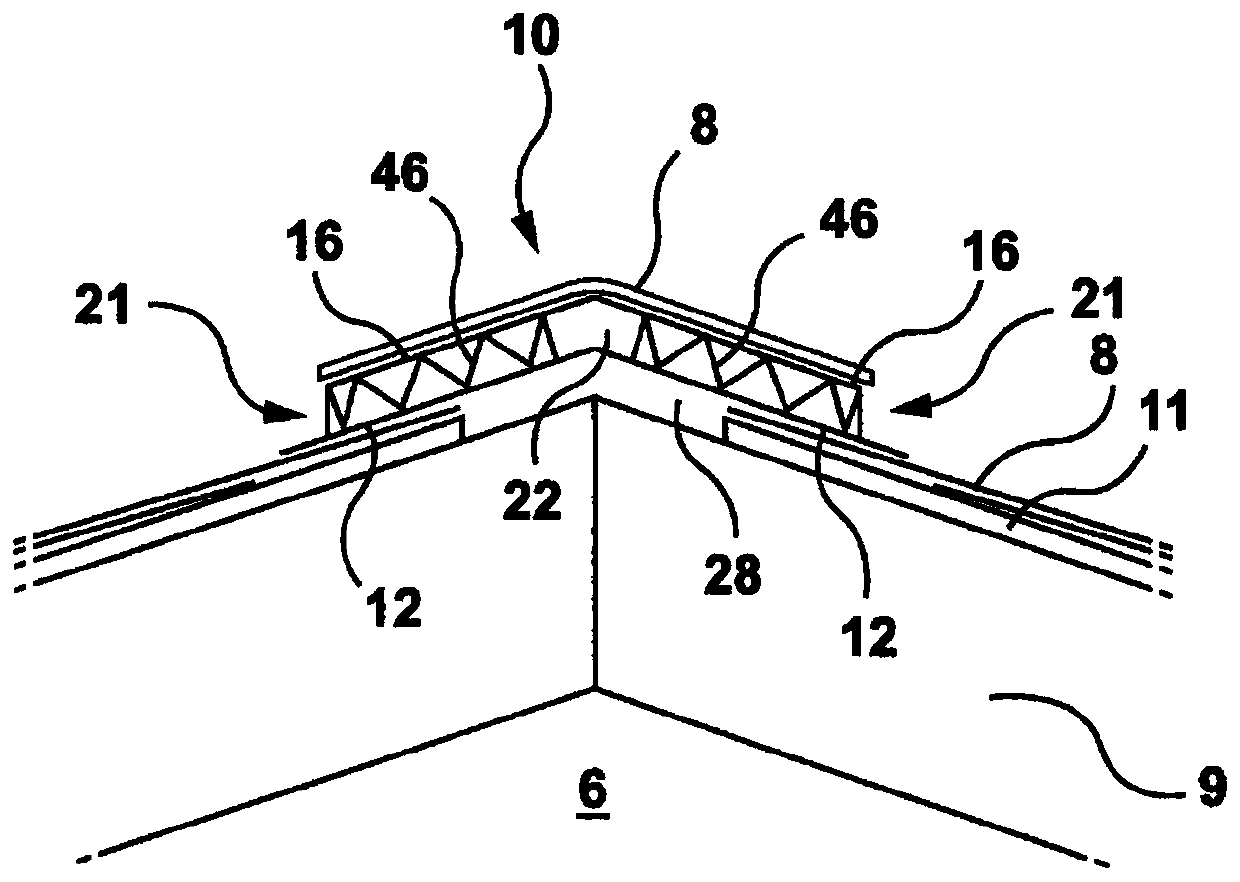

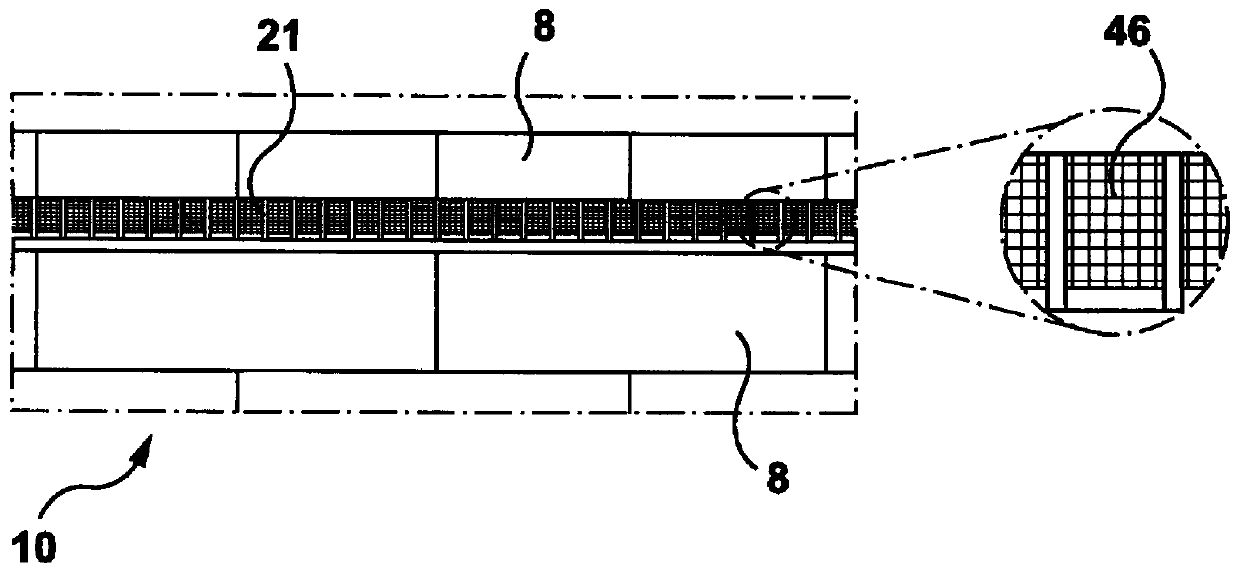

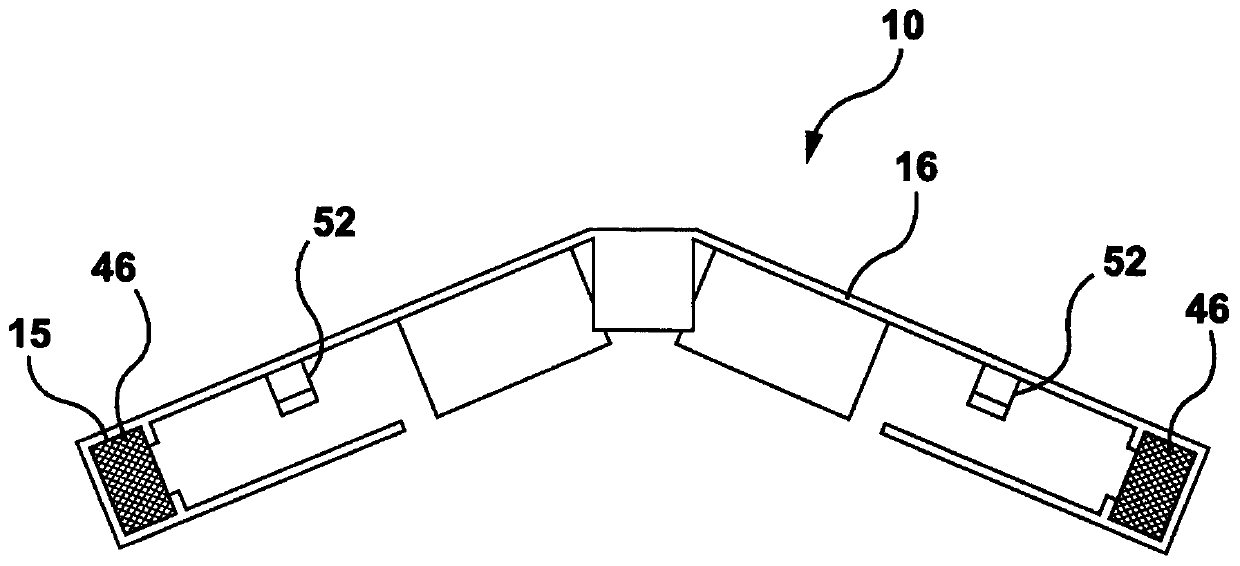

Ridge vent

InactiveCN110177979ALighting and heating apparatusSpace heating and ventilation detailsLateral positionedAcute angle

A ridge vent for ventilating a roof of a building via a hole along a roof ridge to atmosphere, the ridge vent comprising a first ridge vent panel: a flange portion for resting on the roof, the flangeportion having an opening for overlapping with the hole, the flange portion having a first flange portion positioned to one side of the opening and a second flange portion positioned to another side of the opening, such that the first flange portion and the second flange portion are at an acute angle with respect to one another; a frame portion coupled to the flange portion and having sides extending upwardly from the flange portion about the opening, the frame portion for maintaining a cap portion in a spaced apart relationship with the flange portion; the cap portion connected to the frame portion and covering over the opening; a first corrugated filter plate extending between the cap portion and the flange portion and positioned transversely between the opening and the atmosphere, the first corrugated filter plate positioned to said one side of the opening; and a second corrugated filter plate extending between the cap and the flange portion and positioned transversely between the opening and the atmosphere, the second corrugated filter plate positioned to said another side of the opening; wherein the corrugated filter plates providing for a passage of air between the atmosphereand the opening, the corrugated filter plates having a pore size sufficient for facilitating the air passage of air through the corrugated filter plates while blocking passage of atmospheric particles through the corrugated filter plates.

Owner:斯诺文科有限公司

Identification of laterally positioned servo bands employing differentiating characteristics of servo patterns

InactiveUS20050280923A1Easy to adjustDriving/moving recording headsAlignment for track following on tapesLateral positionedAzimuth direction

In a tape having separate servo bands of patterns positioned laterally across the tape, the patterns of a separate servo band have at least one differentiating characteristic with respect to patterns of another of the separate servo bands. The differentiating characteristic allows identification of the separate servo bands. For example, the patterns of a separate servo band have differing azimuthal orientations of detectable transitions with respect to another servo band, such as being laterally inverted. In another, variations in the width of gaps of patterns are made with respect to another servo band. In another, variations are made in the number of the detectable transitions of patterns with respect to the patterns of another servo band.

Owner:INT BUSINESS MASCH CORP

Positioning device for shock-proof bin safety bin base

InactiveCN111335474AConvenient for initial positioningEasy to transportBuilding constructionsProtective buildings/sheltersShock avoidanceLateral positioned

Owner:张峻华

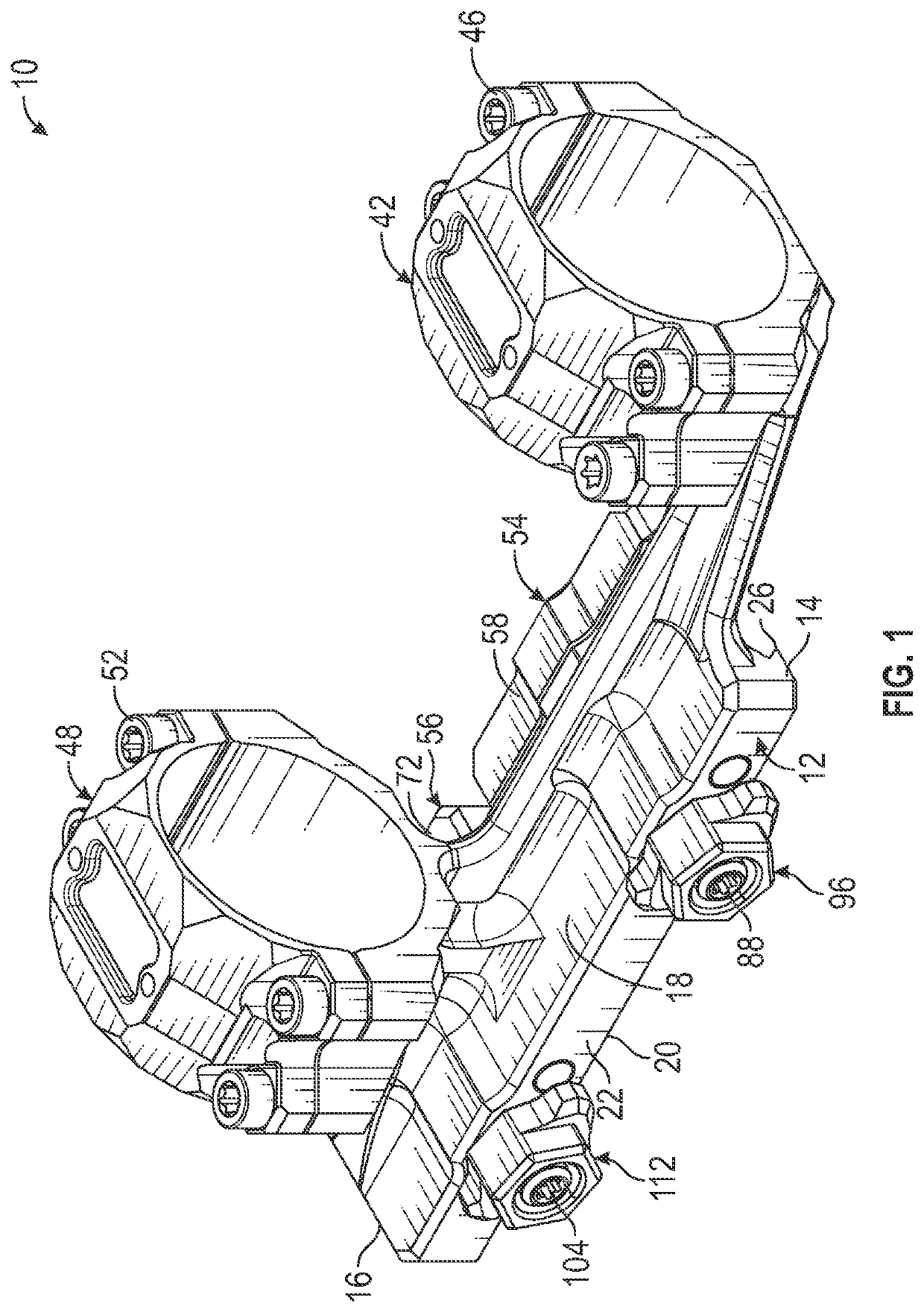

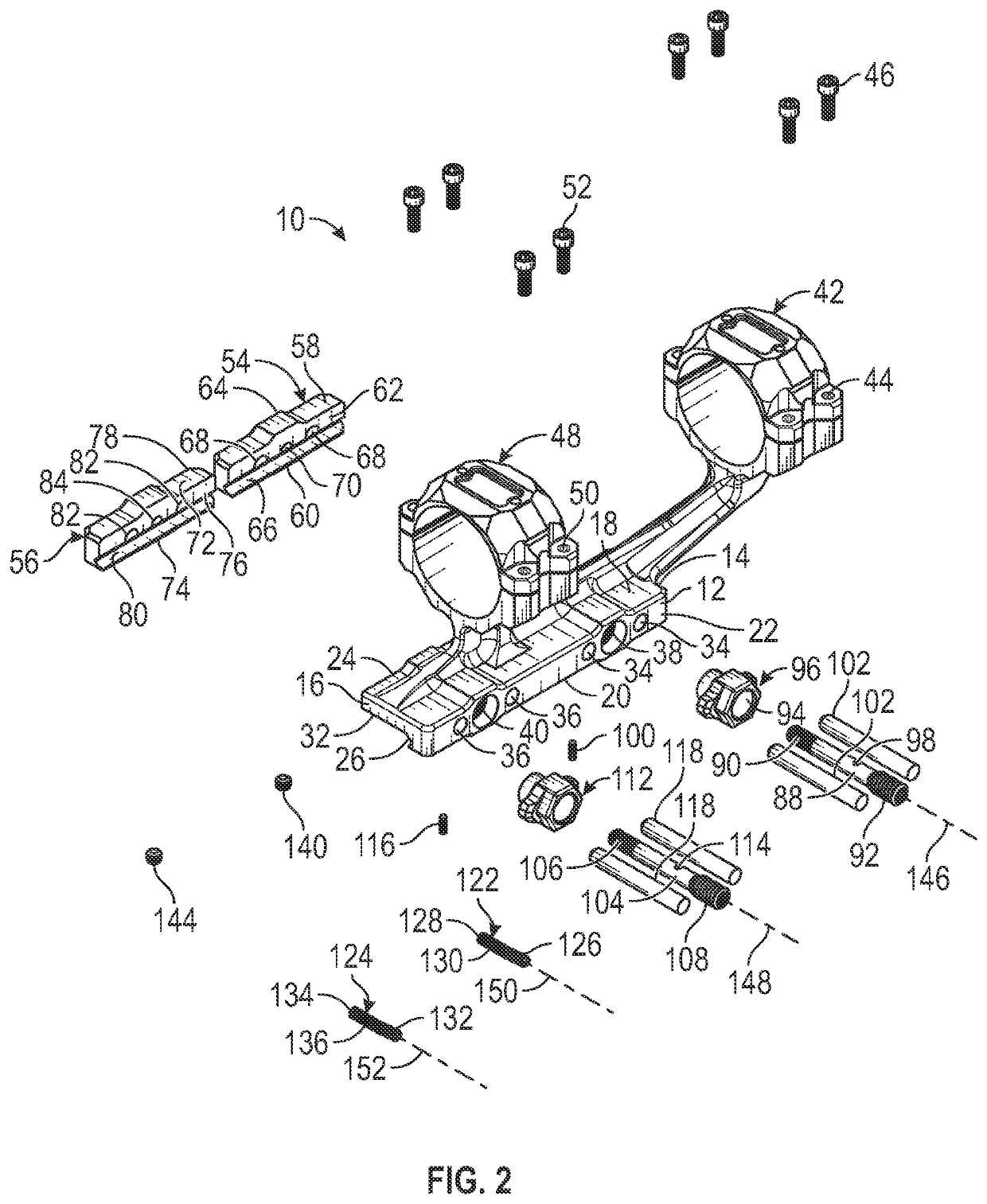

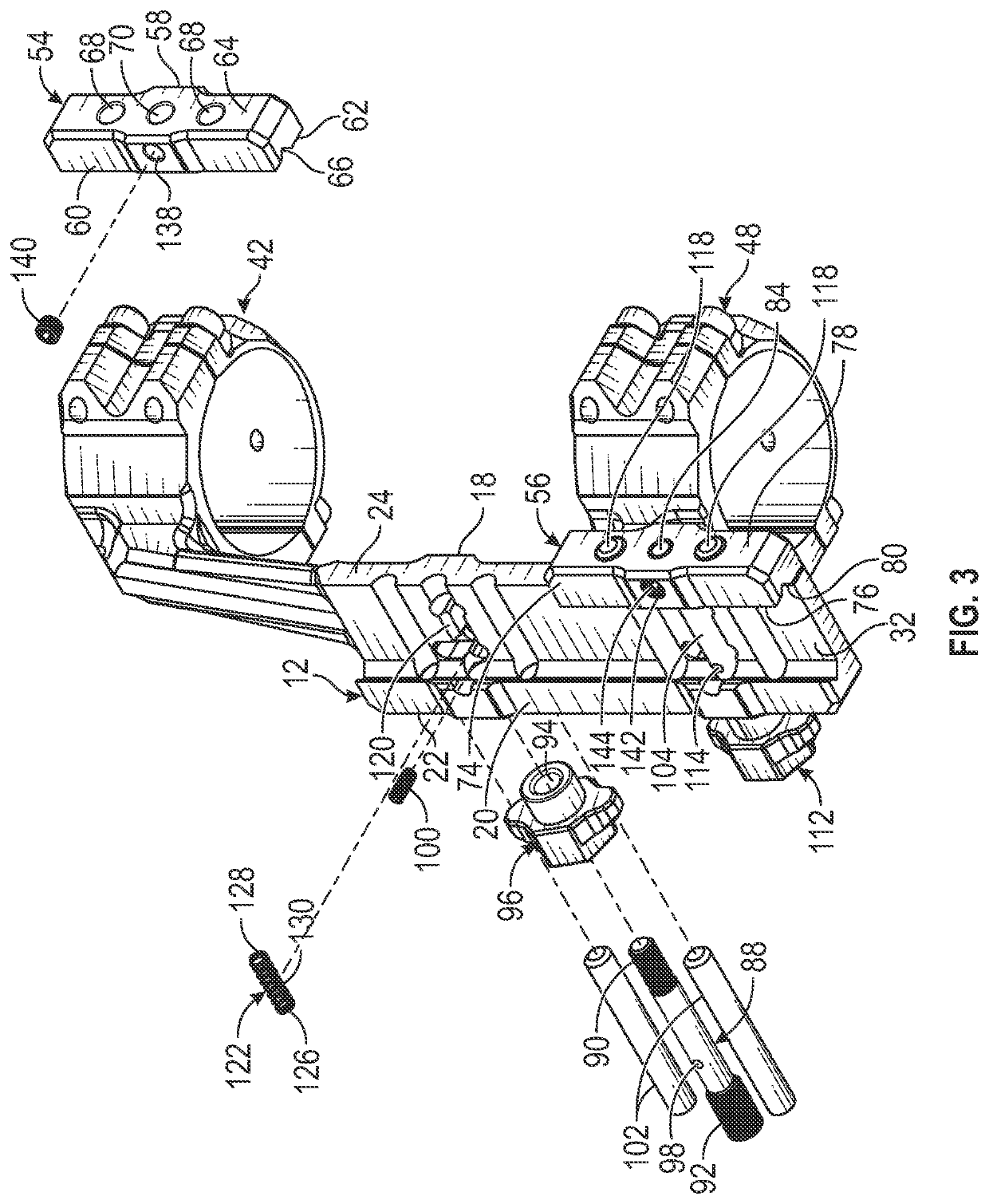

Mount for a firearm

A mount for a firearm has a body having a first clamp configured to engage a first edge of the rail, a jaw movably connected to the body and having a second clamp opposed to the first clamp and operable with the respective clamps to engage respective opposed lateral edges of the rail, a spring biasing the jaw toward the body, and at least a portion of the spring being between the clamps. There may be a pushrod connected to a first one of the body and the jaw and slidably received by the other of the body and the jaw. The spring may be laterally positioned to one side of the pushrod. The spring may be a coil spring having a spring axis offset from a pushrod axis defined by the pushrod.

Owner:ZRODELTA LLC

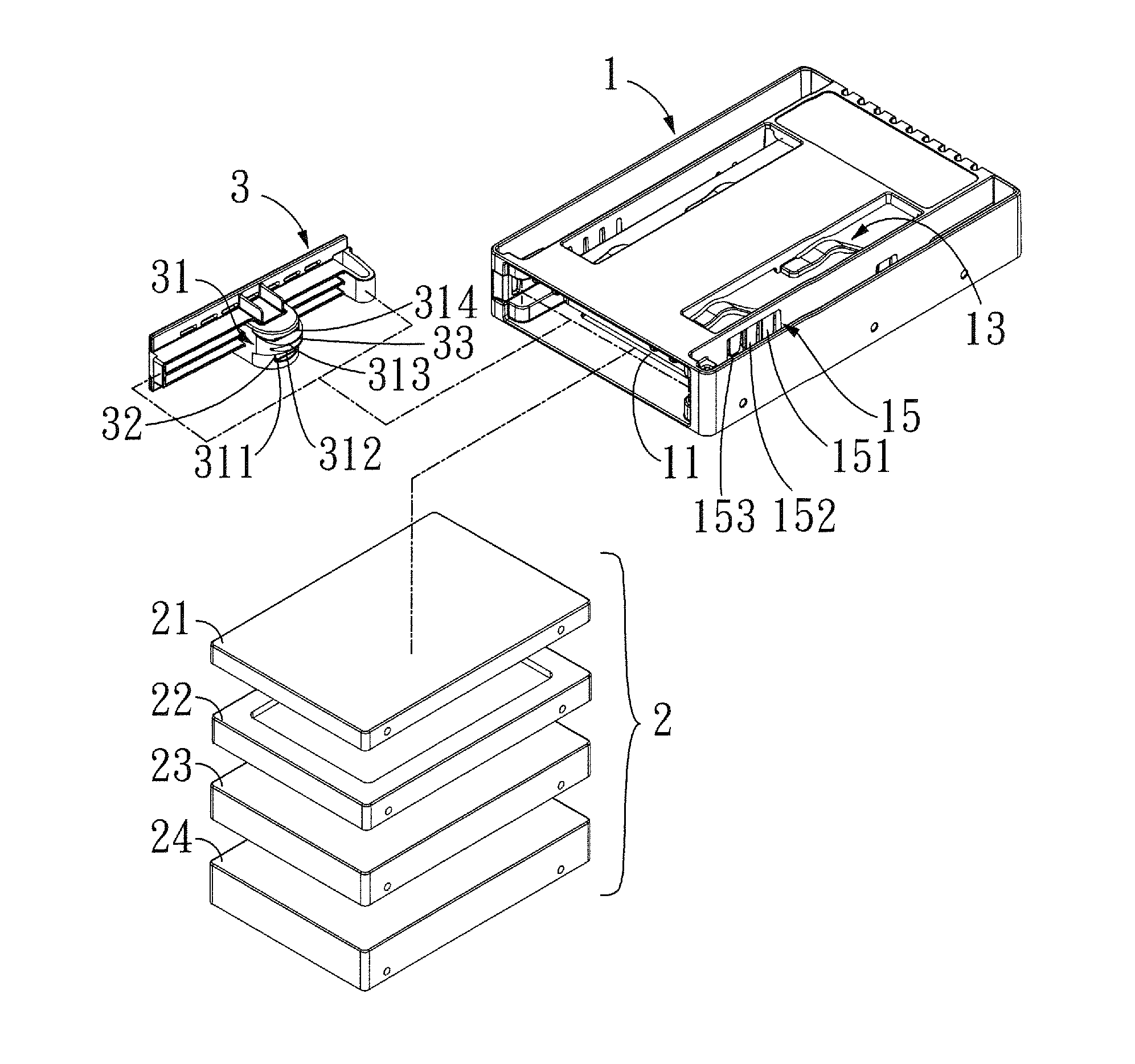

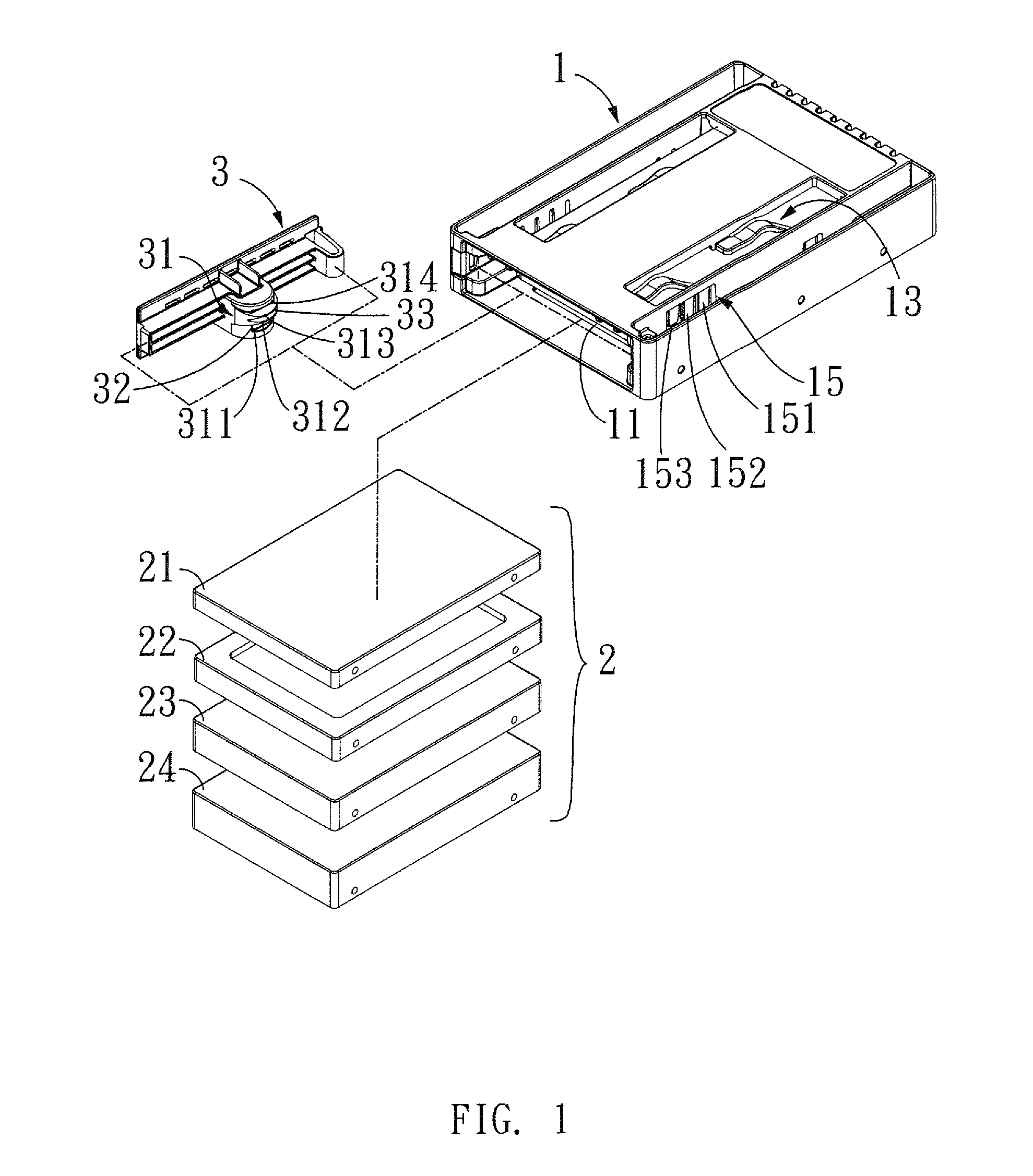

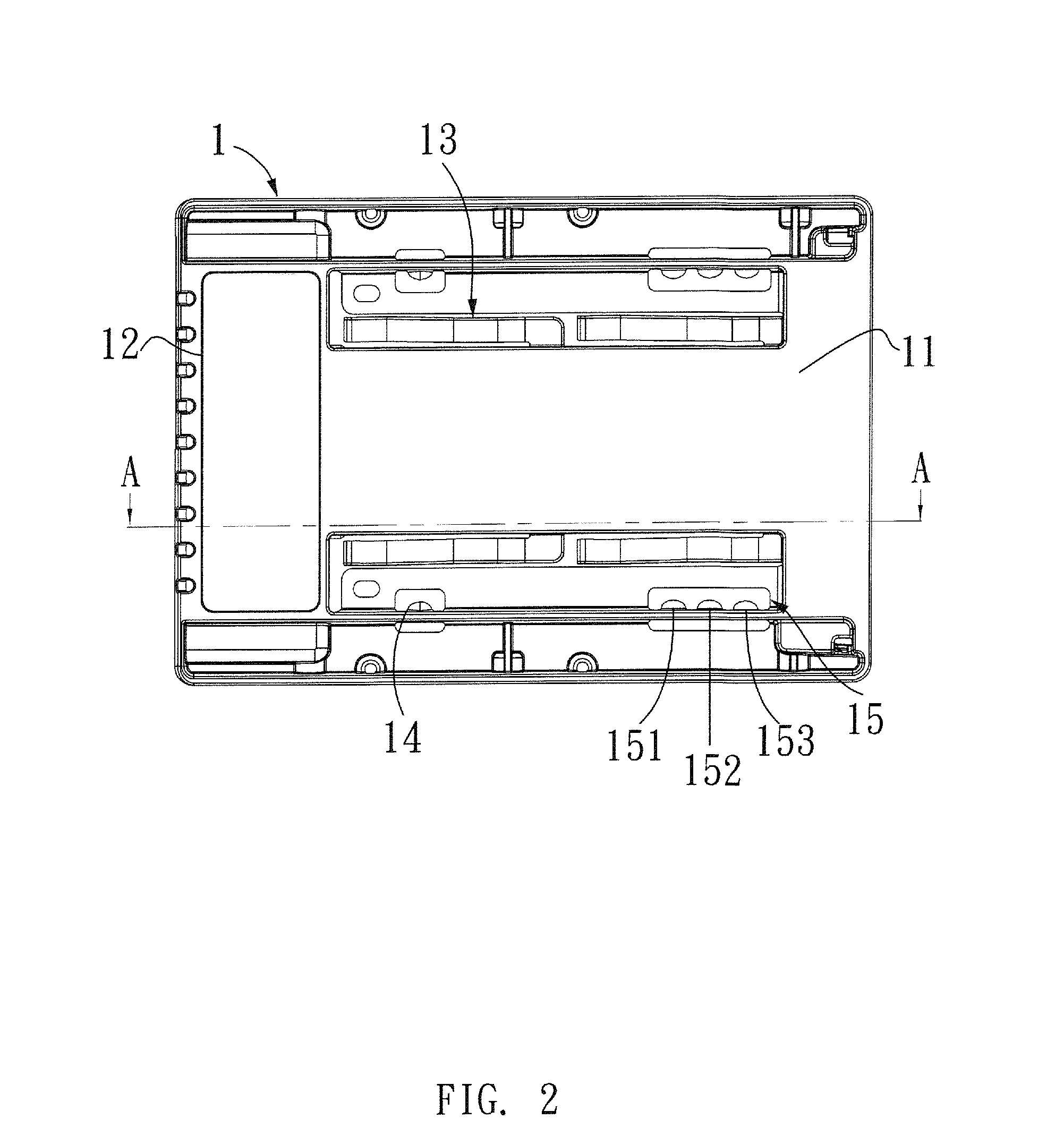

Fixing Structure Applicable To Multiple Sizes Of Storage Device

InactiveUS20160120055A1Avoid damageEasy to insertSide-by-side/stacked arrangementsCasings/cabinets/drawers detailsLateral positionedSpring force

A fixing structure applicable to multiple sizes of storage device includes an enclosure, which has an interior forming an accommodation space that receives a storage device of one of the multiple sizes to be inserted into the enclosure. The enclosure includes, in an upper portion of the interior thereof, at least one spring-biasing section, which applies a spring force to an upper surface of the storage device opposite thereto for positioning in a longitudinal direction. The enclosure includes therein positioning sections and retention sections respectively set on opposite lateral sides thereof for cooperating with lateral sides of the storage device for positioning in a lateral direction. A lid has an inside surface on which a supporting section is formed so that when the lid is mounted to and closing a front side of the enclosure, the supporting section is in engagement with the storage device to secure the storage device.

Owner:CREMAX TECH

High-stability machining clamp

ActiveCN113909956AImprove stabilityEfficient drivePositioning apparatusMetal-working holdersLateral positionedMachining

The invention provides a high-stability machining clamp. The high-stability machining clamp comprises a bottom plate, transverse positioning blocks, longitudinal positioning blocks, a clamping and fixing assembly and a driving part. The transverse positioning blocks and the longitudinal positioning blocks are fixed to the bottom plate, the transverse positioning blocks and the longitudinal positioning blocks are arranged on the outer sides of the two third wall plates, and the clamping and fixing assembly is connected with the bottom plate, located between the transverse positioning blocks, penetrates into the open groove and extends to the inner side of a workpiece. The clamping and fixing assembly comprises a vertical clamping and fixing assembly for clamping and fixing a second wall plate and a transverse clamping and fixing assembly for extruding and supporting the third wall plate; and the driving part is arranged on the side, away from the clamping and fixing assembly, of the bottom plate, penetrates through the bottom plate to be connected with the clamping and fixing assembly and is used for driving the clamping and fixing assembly to clamp or loosen the workpiece. According to the high-stability machining clamp, the driving part is used for controlling the clamping and fixing assembly to support a workpiece in the vertical direction and the transverse direction from the inner side, so that the stability is high during machining, driving is efficient, and the machining precision can be improved.

Owner:SHENZHEN JINGDIAO CNC EQUIP

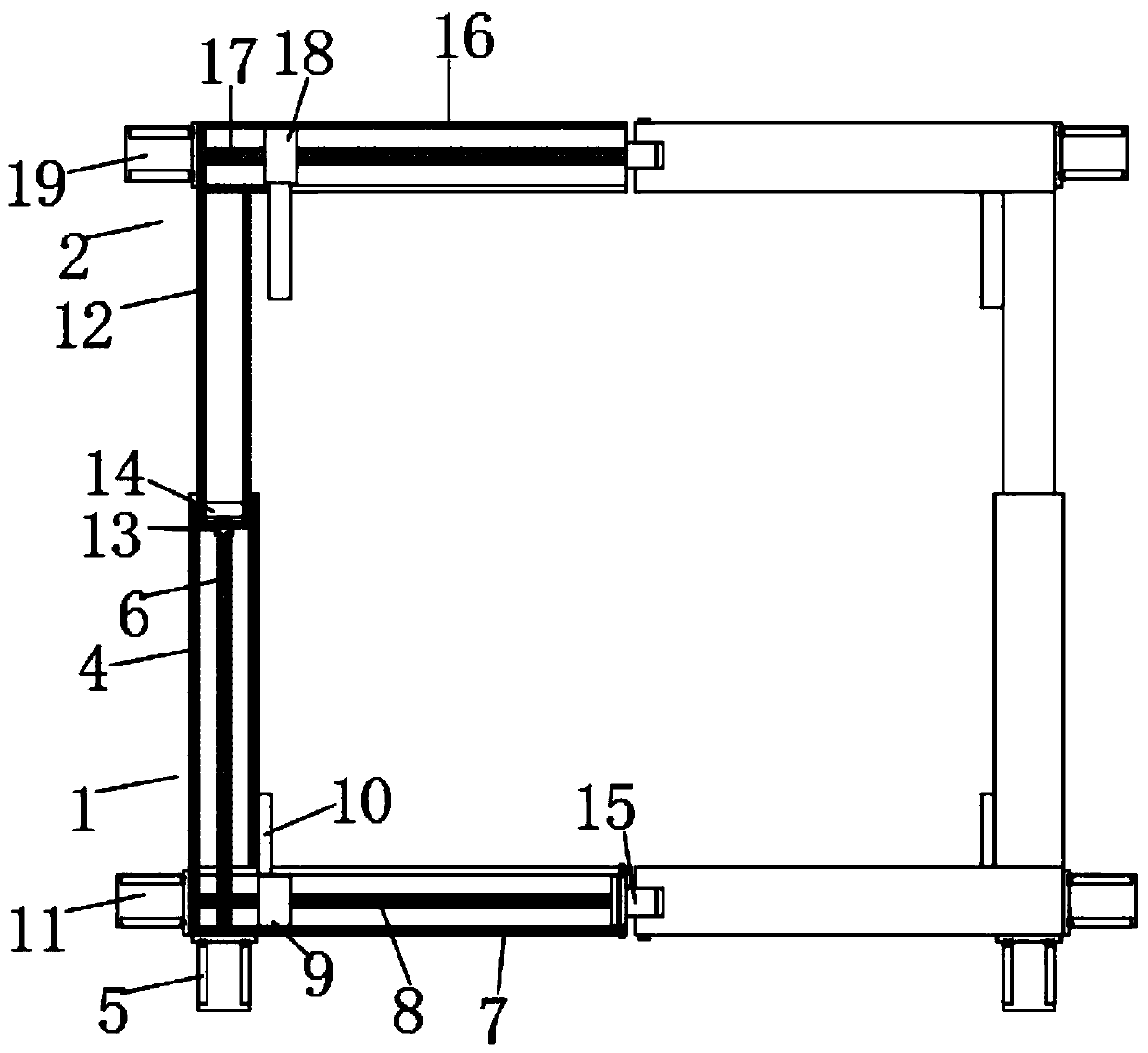

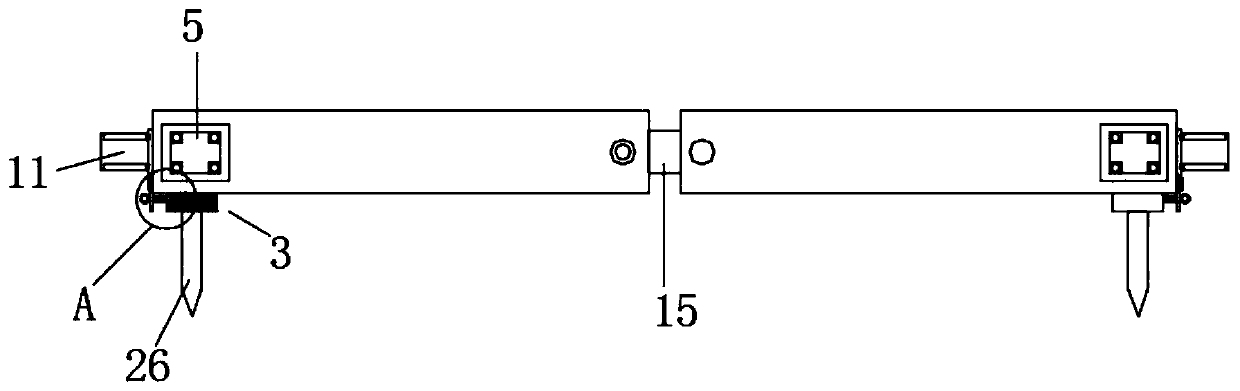

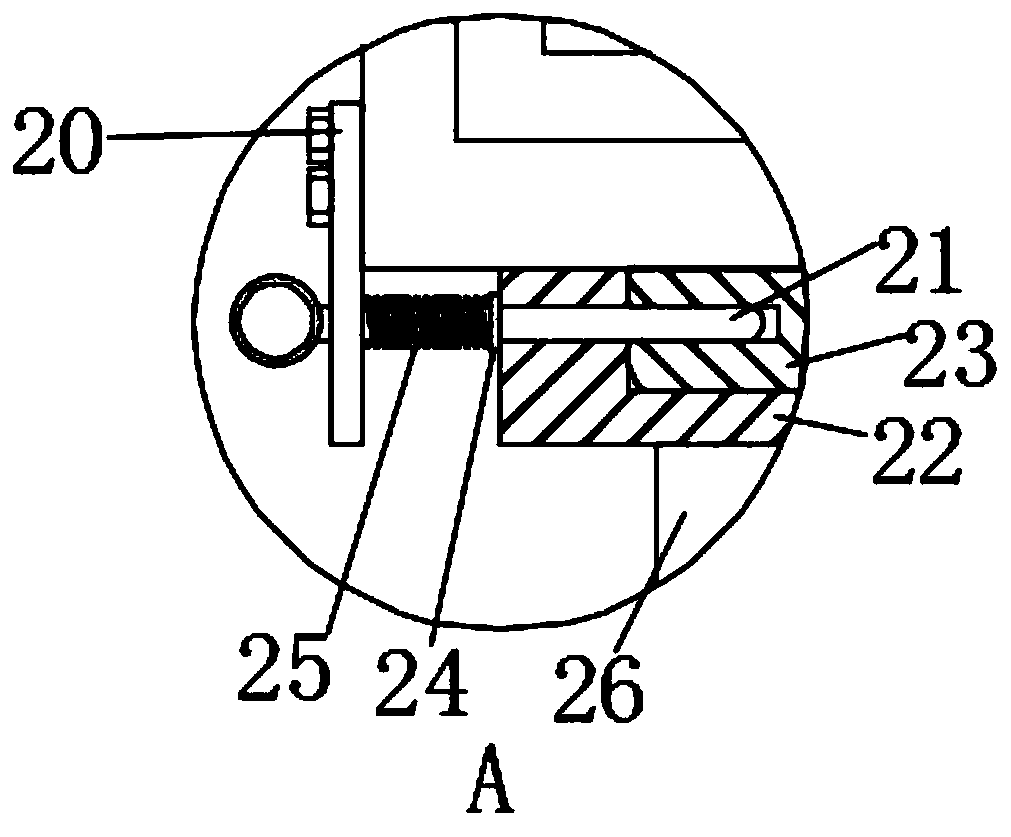

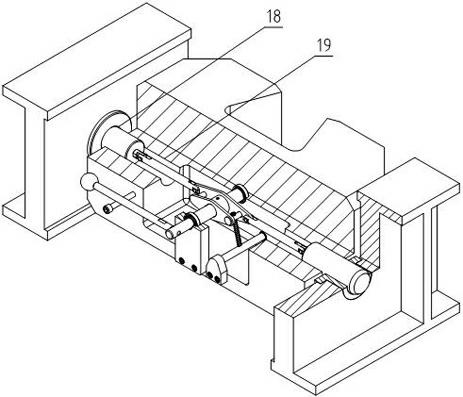

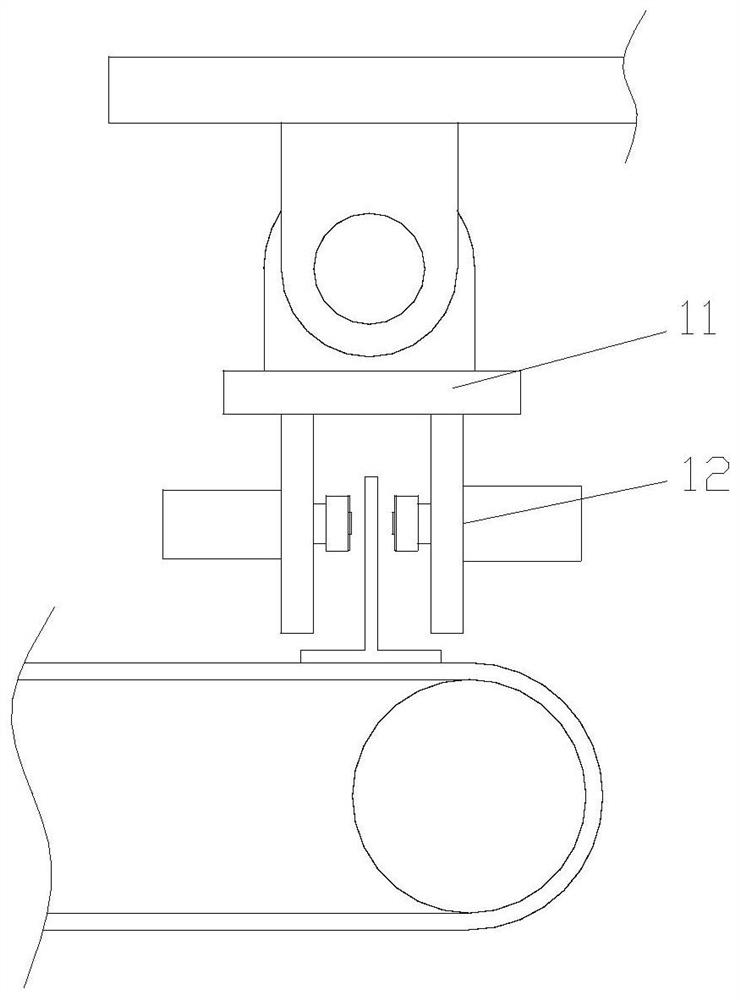

Positioning device for movable crossbeam and main unit framework of horizontal tensile tester

ActiveCN102519785ASimple structureEasy to operateStrength propertiesLateral positionedStructural engineering

The invention provides a positioning device for a movable crossbeam and a main unit framework of a horizontal tensile tester, which is safe and convenient in operation. The middle of the movable crossbeam is provided with a containing space, each of two ends of the movable crossbeam and the waist on the corresponding side of the main unit framework are respectively provided with transverse positioning holes matched mutually, the positioning holes at two ends of the movable crossbeam are communicated with the containing space, and a rotary shaft perpendicular to directions of the positioning holes is erected in the containing space. Positioning pins are inserted in the positioning holes respectively, the end of each positioning pin facing the rotary shaft is hinged with a connecting rod, and the other end of each connecting rod is hinged to a component on the rotary shaft. Besides, hinged points on the component are located on two sides of the rotary shaft respectively, and the hinged point on each side is connected with a connecting rod on the corresponding side.

Owner:JINAN SHIJIN GROUP

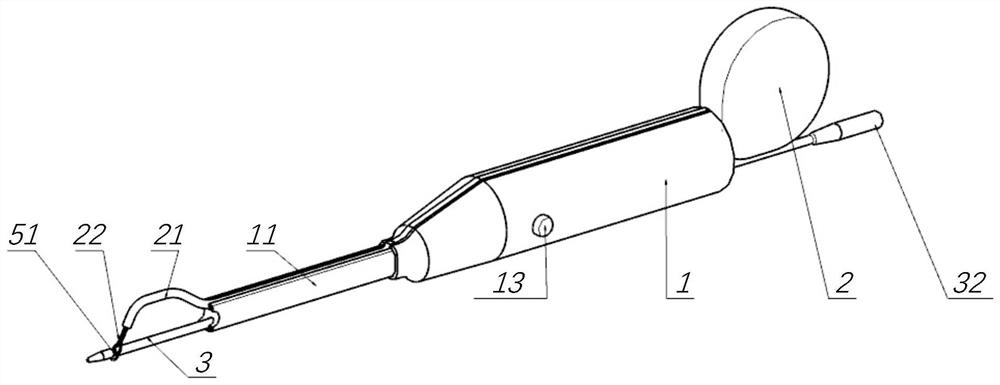

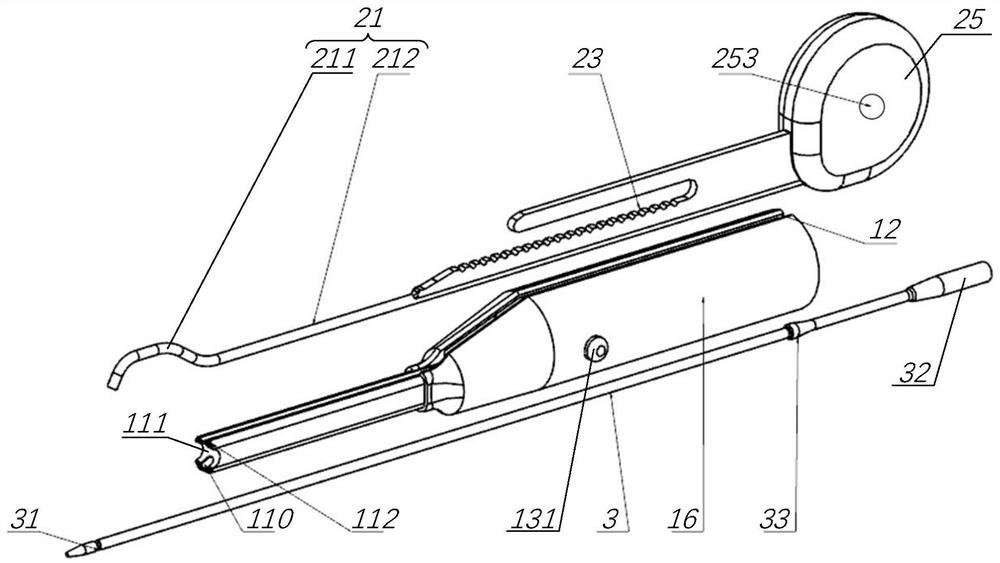

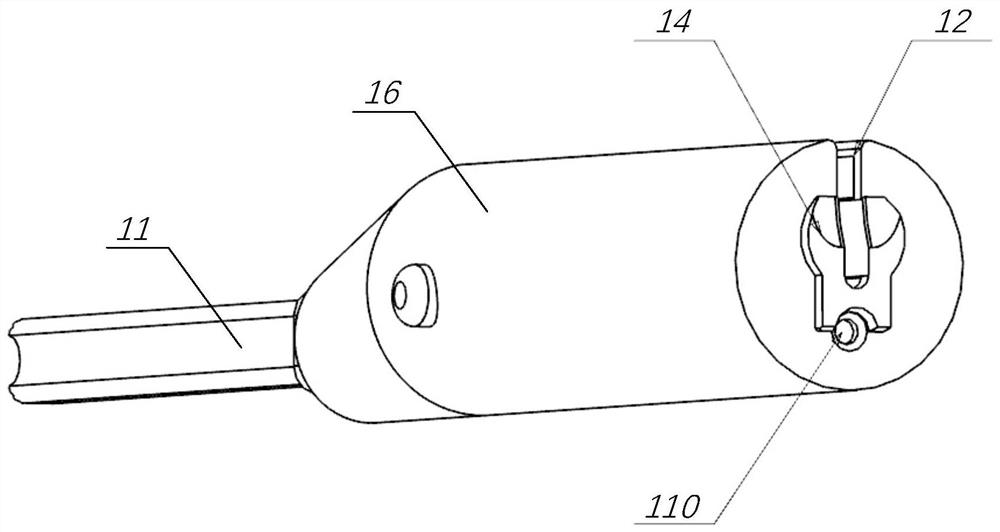

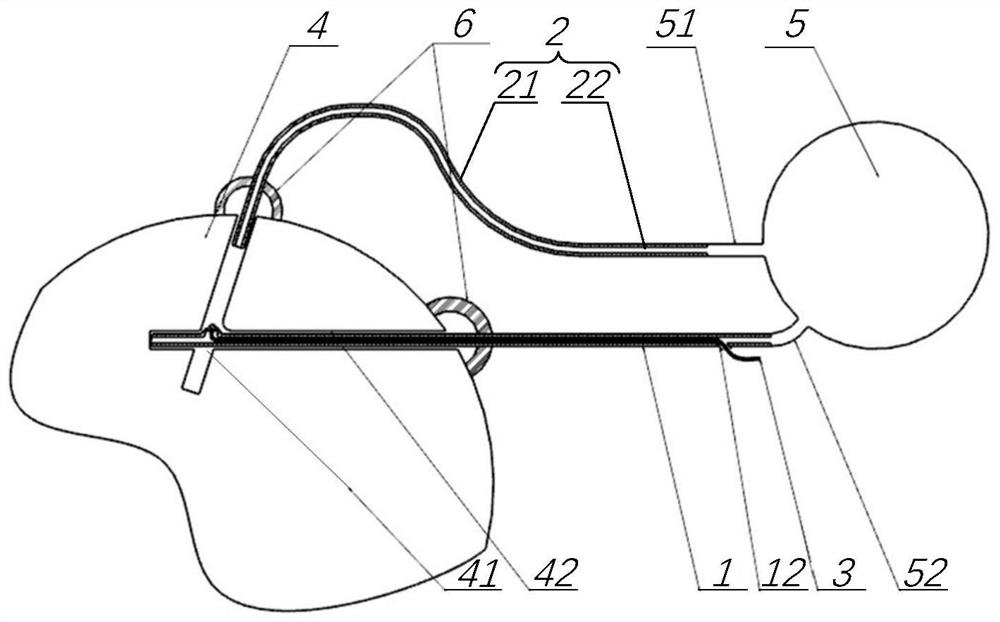

Positioner, conveyor, thread hooking rod, tunnel type thread passing system and operation method of tunnel type thread passing system

PendingCN112869803AEasy to fixAvoid the problem of not being able to hook the lineSuture equipmentsLateral positionedStructural engineering

The invention provides a positioner, a conveyor, a thread hooking rod, a tunnel type thread passing system and an operation method of the tunnel type thread passing system. The positioner comprises a transverse positioning rod and a conveyor containing part. The far end of the transverse positioning rod is used for abutting against a preset object, the transverse positioning rod is provided with a transverse channel penetrating in the axial direction of the transverse positioning rod, and the transverse channel is used for a thread hooking rod to penetrate in; the conveyor containing part is connected with the transverse positioning rod and is used for accommodating a conveyor; the extending direction of the far end of the transverse channel is used for intersecting with the extending direction of the far end of a longitudinal positioning rod, contained in the conveyor containing part, of the conveyor, so that the thread hooking rod can hook a coil or an implant contained at the far end of the longitudinal positioning rod of the conveyor after penetrating into the transverse channel. By means of the configuration, the problem that due to the fact that the transverse tunnel and the longitudinal tunnel are not crossed, thread hooking cannot be achieved is solved. The thread can penetrate through a tunnel of a predetermined object, and risks caused by falling of an anchor and the like are avoided.

Owner:SHANGHAI ARTHROPHIX MEDICAL TECH CO LTD

Secondary positioning jig

PendingCN112833830AReduce structural complexityReduce space footprintMeasurement devicesLateral positionedStructural engineering

Owner:SUZHOU RS TECH

Tunnel type thread passing device, tunnel type thread passing system and operation method of tunnel type thread passing system

PendingCN112869801AEasy to fixAvoid the risk of falling off, etc.Suture equipmentsLateral positionedEngineering

The invention provides a tunnel type thread passing device, a tunnel type thread passing system and an operation method of the tunnel type thread passing device. The tunnel type thread passing device comprises a transverse positioning rod and a longitudinal positioning rod. One part of the transverse positioning rod is used for penetrating into a transverse tunnel of a predetermined object; the transverse positioning rod is provided with a wire outlet and a transverse channel arranged in the axial direction of the transverse positioning rod. The part, located outside the transverse tunnel, of the transverse channel is used for being communicated with the positive pressure end or the outside. The thread outlet is formed in the part, penetrating into the transverse tunnel, of the transverse positioning rod, is communicated with the transverse channel and is used for allowing a thread or an implant to penetrate out of the transverse channel; the longitudinal positioning rod is provided with a longitudinal channel penetrating in the axial direction of the longitudinal positioning rod, and a part of the longitudinal positioning rod is used for penetrating into a longitudinal tunnel, intersecting with the transverse tunnel, of a preset object. The part, located outside the longitudinal tunnel, of the longitudinal channel is used for being connected with the negative pressure end, so that the far end of the longitudinal positioning rod sucks a thread or an implant penetrating out of the thread outlet through the longitudinal tunnel.

Owner:SHANGHAI ARTHROPHIX MEDICAL TECH CO LTD

A t-shaped workpiece processing positioning fixture

ActiveCN112091660BSave time in transitGuaranteed accuracyWork clamping meansPositioning apparatusLateral positionedVertical edge

The invention relates to the technical field of fixtures, in particular to a T-shaped workpiece processing and positioning fixture, comprising: a rotating clamping unit, including a rotating main body and two sets of clamping arms, the two sets of clamping arms are used to carry out the machining on both ends of the longitudinally arranged vertical sides of the T-shaped workpiece. Clamp, and drive the T-shaped workpiece to rotate around the set rotation axis parallel to the length direction of the T-shaped workpiece through the rotating body; the lateral positioning unit, including the fixed end and the extrusion end, when the rotating body rotates 30~60° and pauses the rotation, The extrusion end squeezes the T-shaped workpiece on the fixed end in the lateral direction; the processing and positioning unit performs horizontal extrusion on the side of the T-shaped workpiece that is vertically set relative to the vertical edge when the rotating body rotates 90° and pauses the rotation. Press to squeeze the T-shaped workpiece on the clamping arm to complete the positioning of the T-shaped workpiece. By means of the invention, both ends of the guide rail can be accurately positioned at the same time, so that actions such as chamfering and drilling can be performed synchronously at both ends of the guide rail with a longer length, thereby improving the compactness of the equipment and improving the production efficiency.

Owner:江苏集萃中以科技产业发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com