Ridge vent

A ventilator and roof ridge technology, which is applied in the field of roof ridge ventilators, can solve the problems of reducing the effective ventilation area, short length, and destroying the use of roof ridge ventilators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

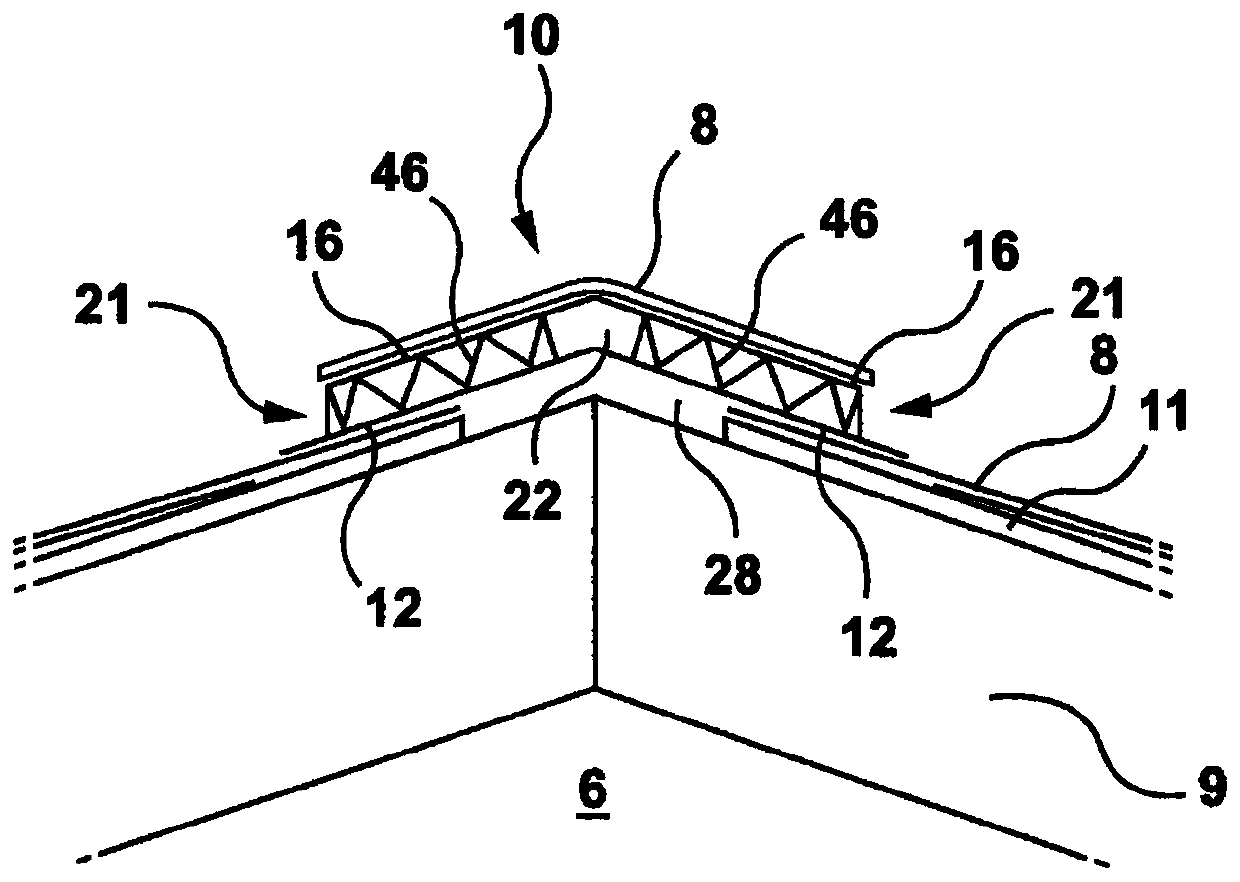

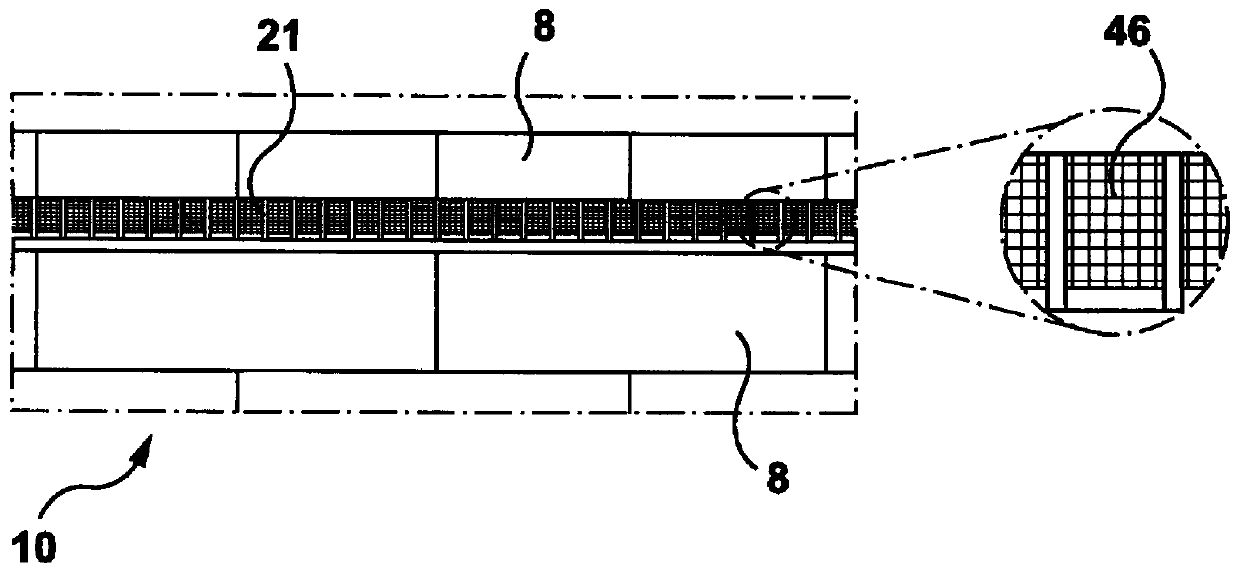

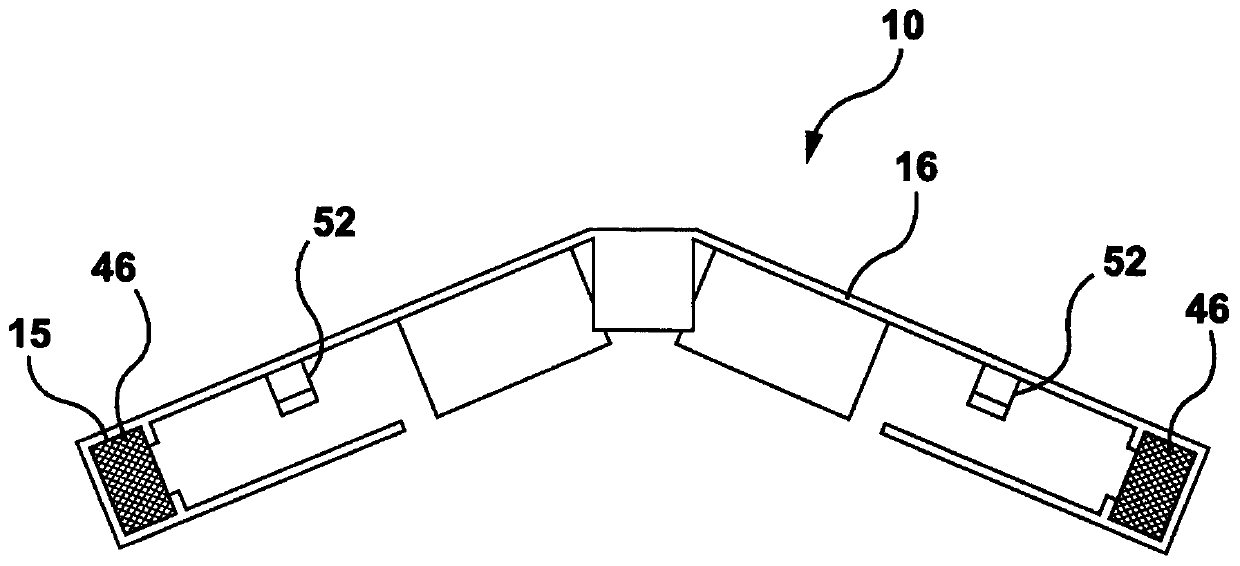

[0028] refer to figure 1 Ridge vent assembly 10 may include flanges 12 mounted along each side of roof 9, wherein flanges 12 sit atop or otherwise interweave roof panels 8. With this configuration, hot air in the attic space 6 can escape from the dwelling (i.e., the home) through the ridge vent assembly 10, especially in summer when the owner needs to cool the home and the attic space contains rather hot air. Sometimes, this provides the owner with a more energy-efficient construction and configuration. The ridge ventilator 10 for an asphalt shingle or composite roof is located above the ventilation slots 28 (ie holes) which are provided through the roof structure / roof shingle 11 along the ridge 9 .

[0029] The ridge vent assembly 10 is mounted as a series of interconnected (i.e. overlapping) angled panels 10a and 10b along the top of the roof 9 by a series of adjacent male and female joints 13a and 13b, see Figure 6 , so that the male connecting portion 13a is accommodat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com