Positioning device for movable crossbeam and main unit framework of horizontal tensile tester

A horizontal tensile test, moving beam technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as insecurity, increase equipment manufacturing costs, increase lifting equipment, etc., achieve rapid positioning and release positioning, and improve work efficiency , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

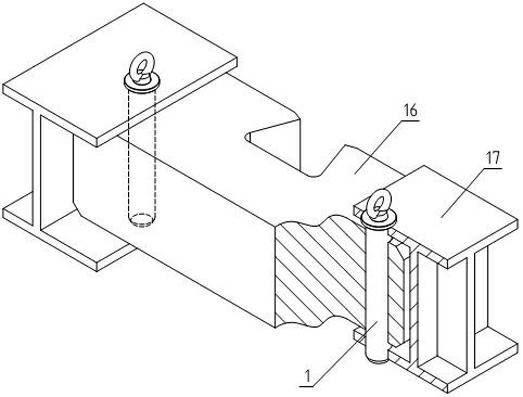

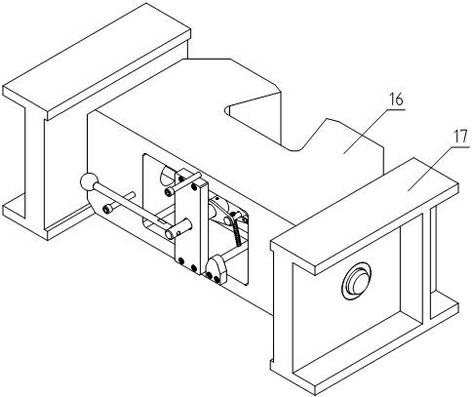

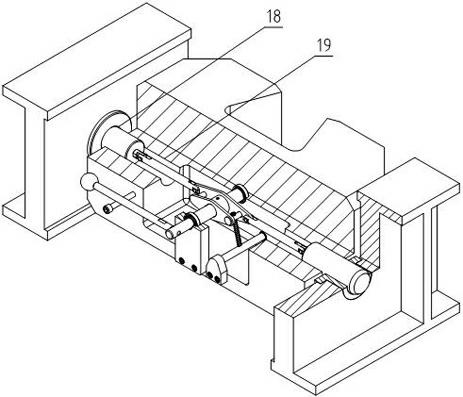

[0021] Such as Figure 2-4 As shown, a horizontal tensile testing machine is a positioning device for the moving beam and the main frame, the middle part of the moving beam 16 has accommodating space, and the two ends of the moving beam and the corresponding side waists of the main frame 17 are provided with matching horizontal positioning holes ( 18 and 19), the positioning holes at both ends of the moving beam communicate with the accommodating space, and a rotating shaft 13 perpendicular to the direction of the positioning holes is erected in the accommodating space, and positioning pins 1 are respectively accommodated in the positioning holes, and each positioning pin faces the rotating shaft One end of each connecting rod is hinged to a connecting rod 2, and the other end of each connecting rod is respectively hinged to a member 4 fixed on the rotating shaft.

[0022] In the above positioning device, one end of the rotating shaft is installed on the bearing hole inside th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com