Method and device for assemblying torsion box structures for an aircraft

A technology of aircraft structure and assembly structure, applied in aircraft assembly, aircraft control, aircraft stability, etc., can solve problems such as cumbersome adjustment operations, inaccuracy of skin aerodynamic surface, and complexity of positioning system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

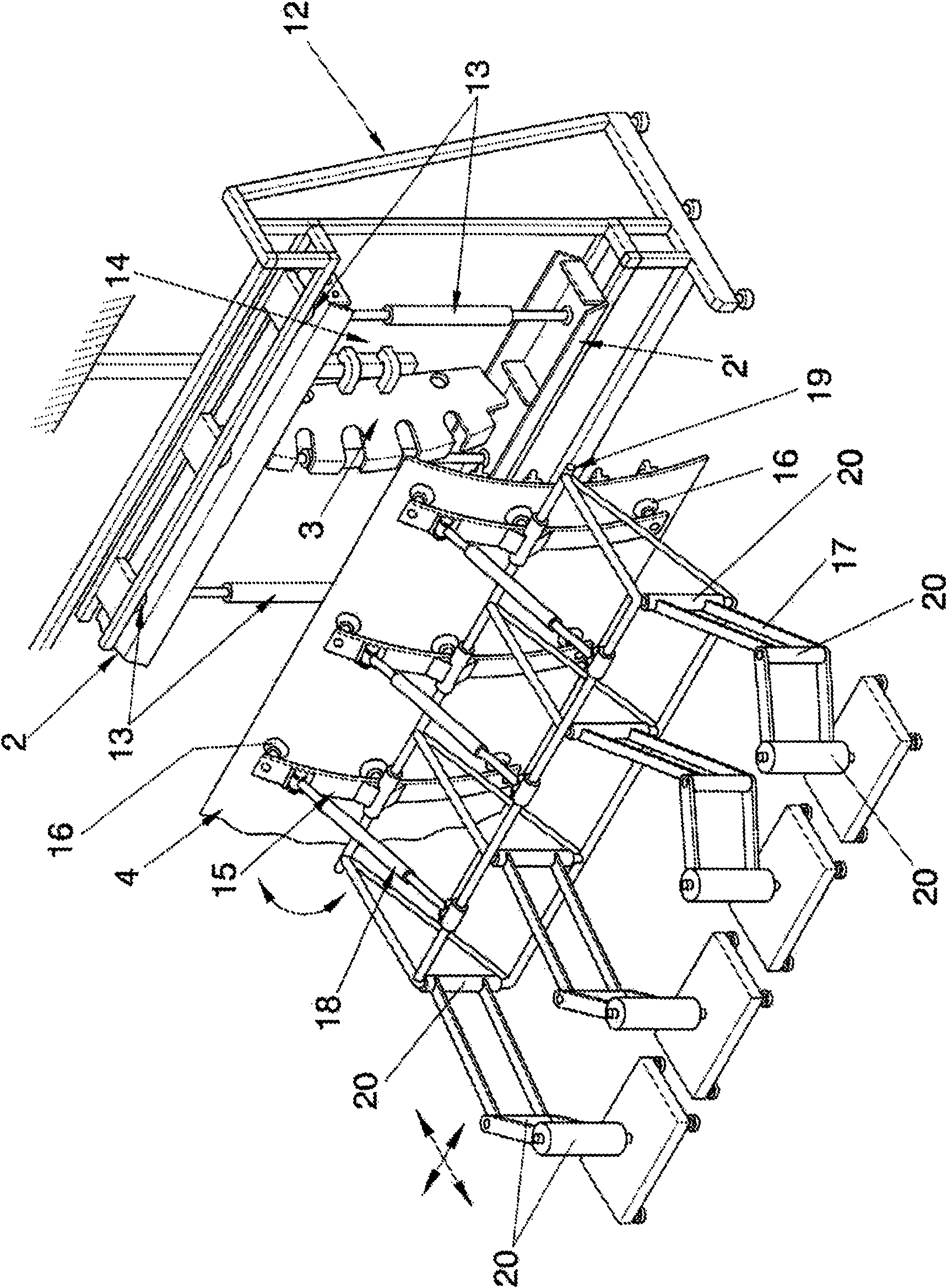

[0044] In order to better understand the purpose and function of the present invention, and not considered as a restrictive solution, the following is an introduction to the embodiments of the present invention based on the above-mentioned figures.

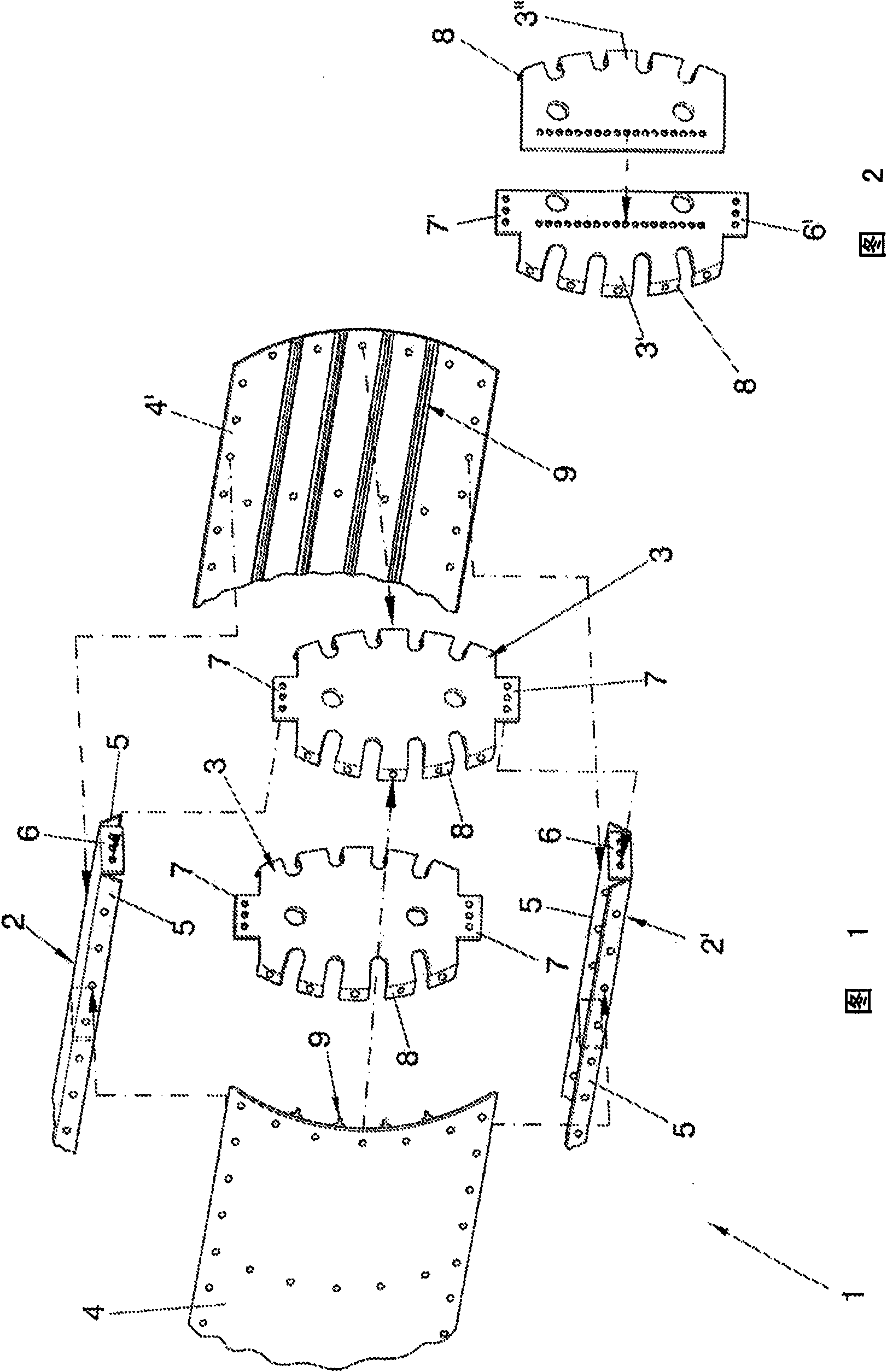

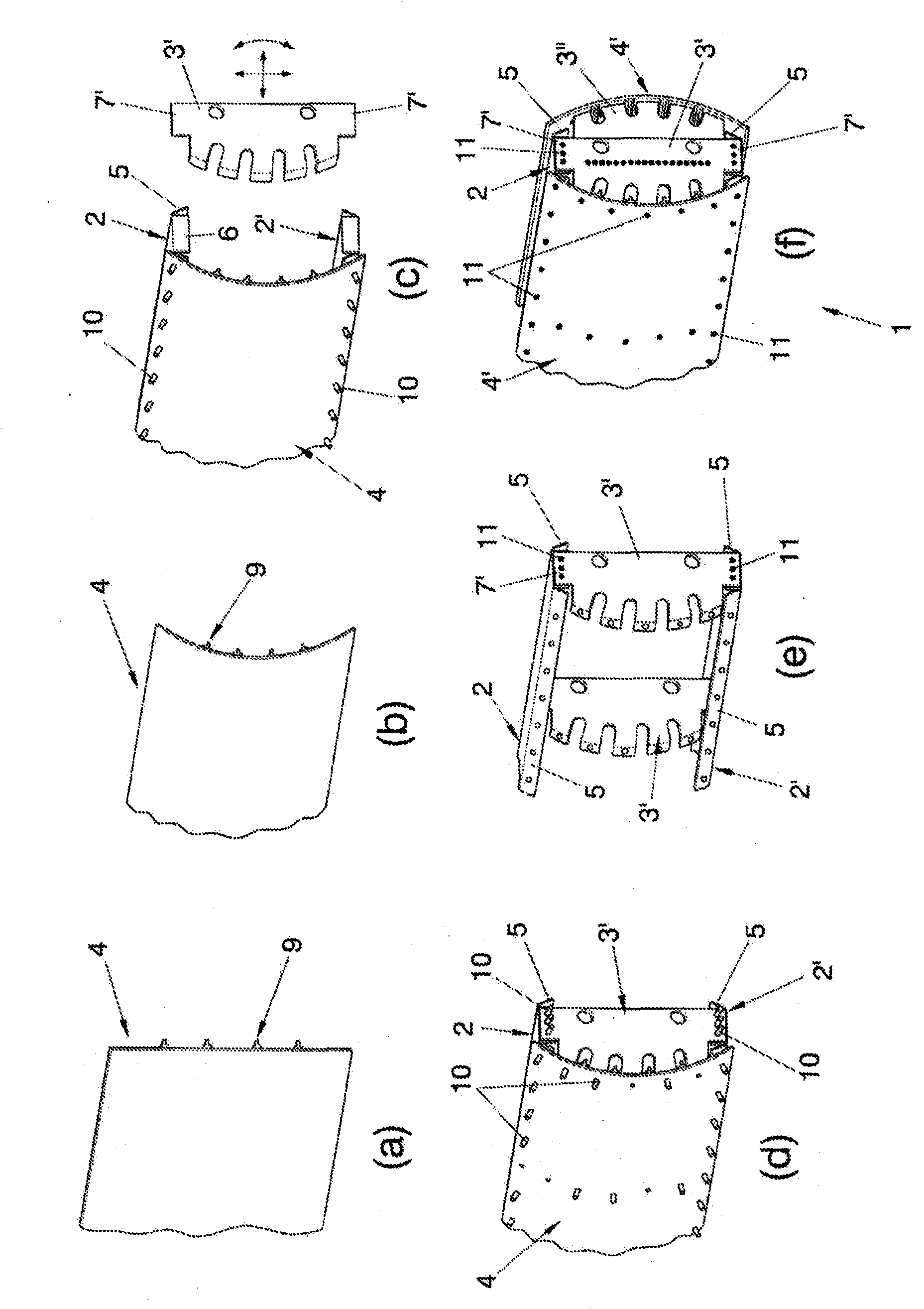

[0045] The embodiment described below relates to a method of assembling an anti-torsion box (1) for aviation use as shown in the figure, and its constituent elements to be assembled are basically as follows:

[0046] - front (2) and rear (2') stiffeners arranged longitudinally in the structure;

[0047] - a number of ribs (3) connected to the stiffeners (2, 2') and arranged transversely in the structure, each rib in this embodiment comprising a rib upper part (3') and a rib lower part (3 ");as well as

[0048] - a skin (4, 4') arranged to cover the structure around the stiffeners and ribs and connected to the stiffeners and ribs, comprising an upper skin part (4) and a lower skin part (4') (respectively the so-called upper and l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com