Segmented splicing method for ship hull

A segmented splicing and hull technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve poor splicing quality, low splicing efficiency, difficulty in grasping the verticality of the bottom plate of the rib plate and the hull segment, etc. problems, to achieve the effect of good splicing quality and high splicing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

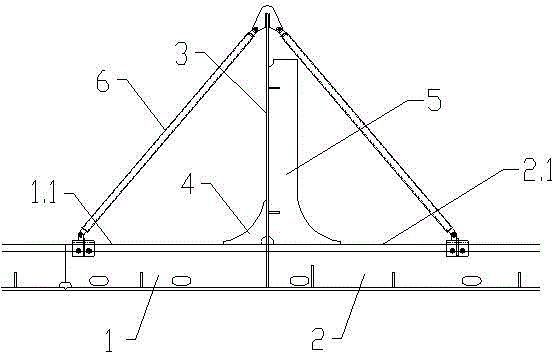

[0034] see Figure 1~Figure 9 , a hull segment splicing method related to the present invention, the hull segment splicing structure in the hull segment splicing includes two hull segments arranged left and right, and the two hull segments are respectively left segment 1 and right segment 2 A rib 3 is arranged upward between the left segment 1 and the right segment 2, and a left oblique support rib 4 is arranged between the left side of the rib 3 and the left transverse rib 1.1 on the top of the left segment 1. A right oblique support rib 5 is arranged between the right side of the rib plate 3 and the right transverse rib 2.1 on the top of the right segment 2 .

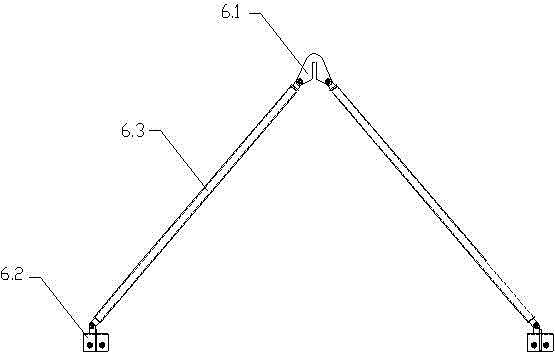

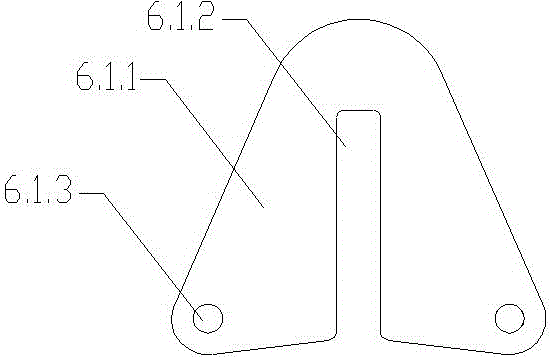

[0035] The segmented hull splicing structure also includes a rib brace positioning device 6, and the rib brace positioning device 6 includes a top positioning part 6.1, two transverse positioning parts 6.2 and two connecting pipe parts 6.3, and the two connecting pipe parts 6.3 They are respectively connected between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com