Multi-station automatic drilling equipment for aluminum alloy sections

A technology of aluminum alloy profiles and drilling equipment, which is applied in the direction of drilling/drilling equipment, metal processing equipment, boring/drilling, etc., and can solve problems such as inconsistent spacing between adjacent holes, long clamping time, and long time , to achieve the effect of ensuring position accuracy, short auxiliary time and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

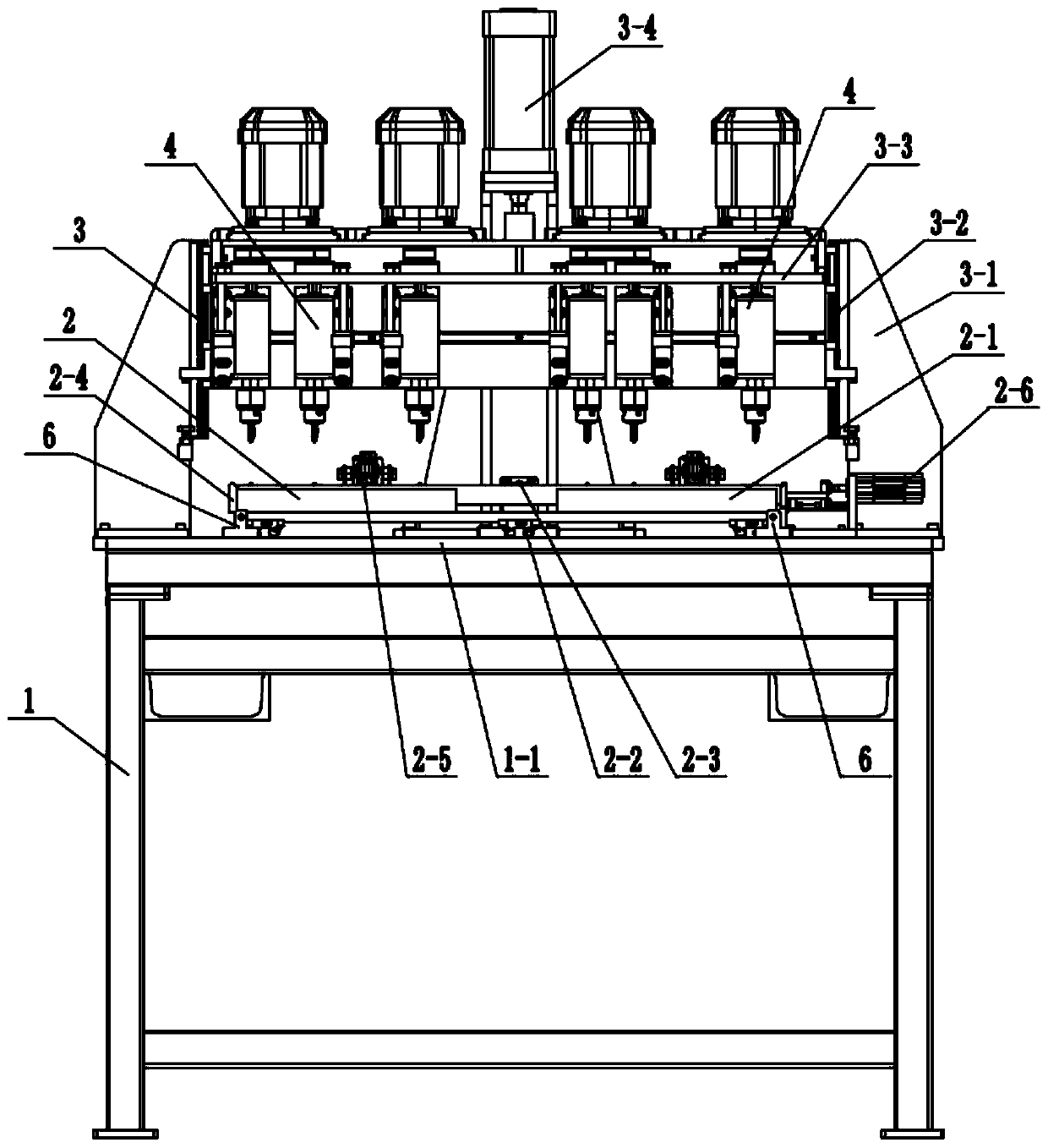

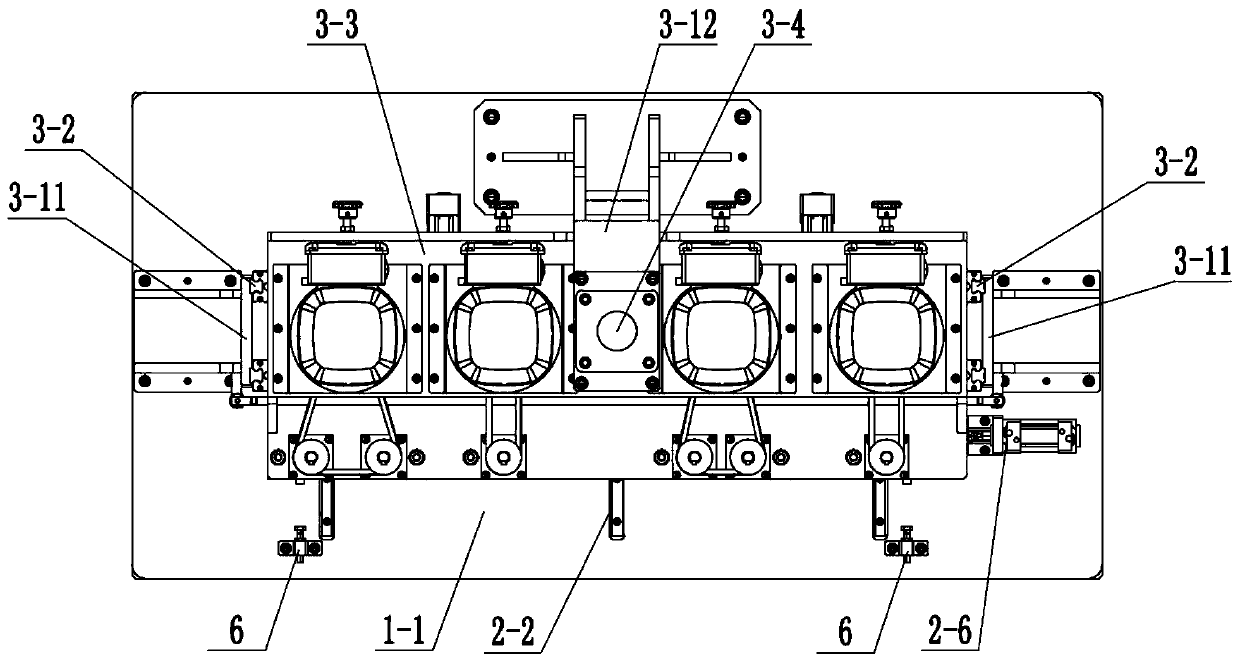

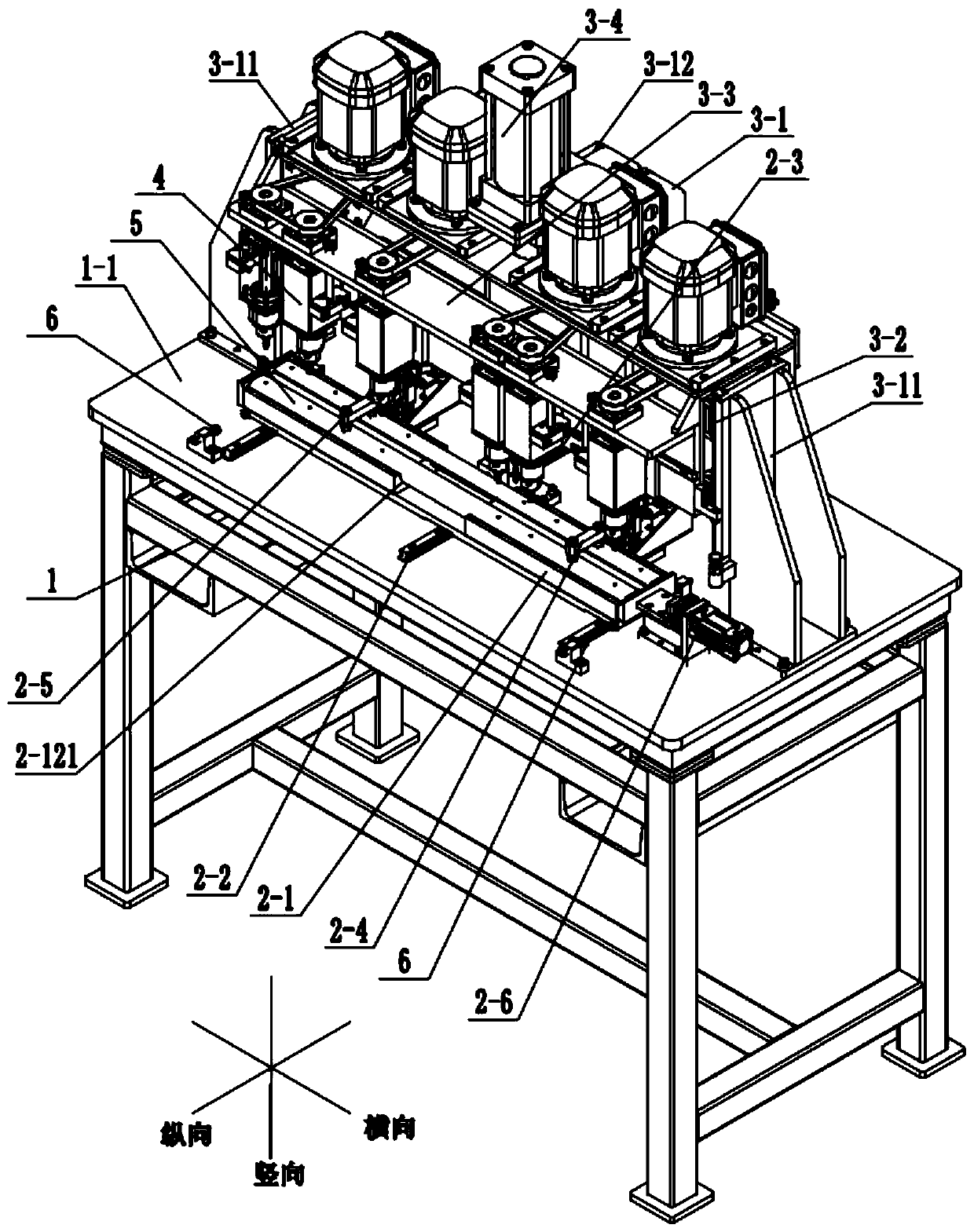

[0037] Example: see Figure 1-7 , a multi-station aluminum alloy profile automatic drilling equipment, which includes a frame 1, an aluminum alloy profile positioning fixture 2, a lifting mechanism 3 and a plurality of drilling machines 4.

[0038] Wherein, the frame 1 has a horizontal workbench 1-1.

[0039] Wherein, the aluminum alloy profile positioning fixture 2 includes a positioning seat 2-1, a longitudinal guide rail 2-2, a longitudinal cylinder 2-3, a lateral positioning baffle 2-4, a first pressing mechanism 2-5 and a second pressing mechanism Mechanism 2-6, the positioning seat 2-1 has two aluminum alloy profile positioning grooves 2-121, the groove length direction of the two aluminum alloy profile positioning grooves 2-121 is along the transverse direction and the two are arranged in parallel along the longitudinal interval, The positioning seat 2-1 is slidingly connected with the horizontal workbench 1-1 through the longitudinal guide rail 2-2; the output end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com