U+H type ventilation system

A ventilation system and air intake technology, applied in mine/tunnel ventilation, mining equipment, earthwork drilling, etc., to achieve safe handling, good transportation environment, and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

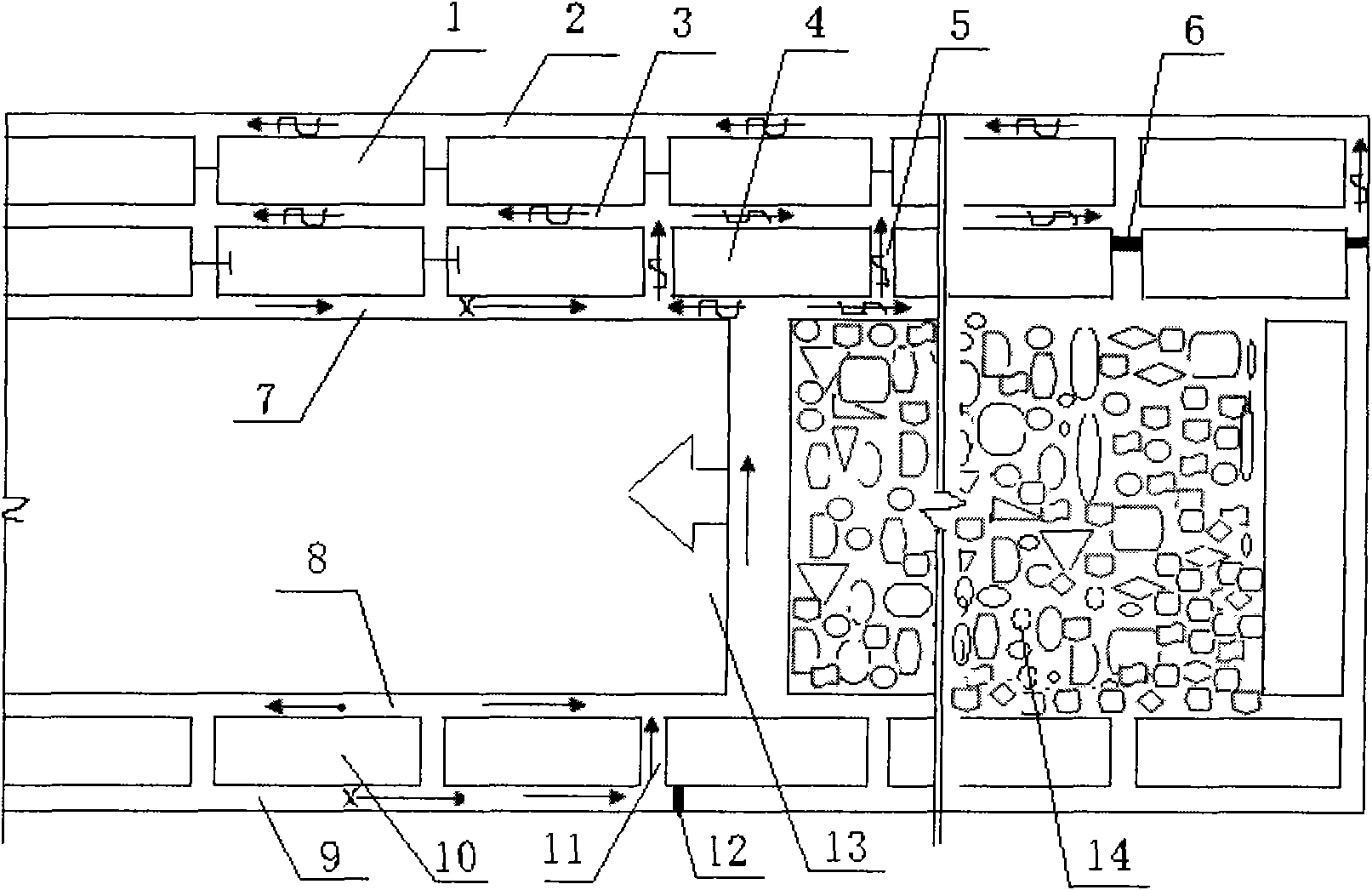

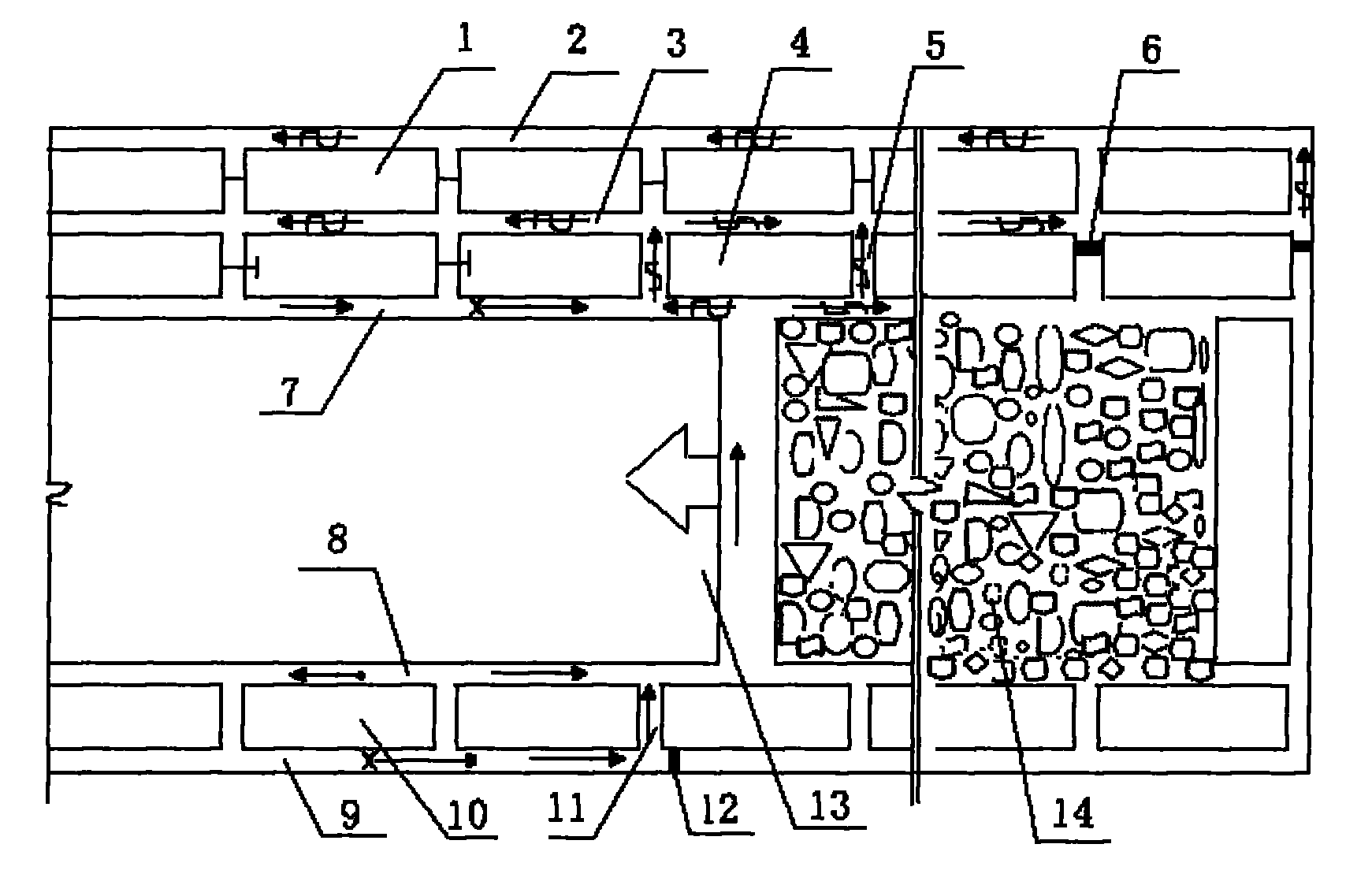

[0017] like figure 1 As shown, a U+H type ventilation system, the working face roadway is arranged with five lanes, three air inlets and two return air ventilation methods, specifically including double lanes arranged on one side of the working face 13, of which the one adjacent to the working face is The belt transportation and air intake lane 8 is responsible for the coal transportation and air intake tasks of the working face, and the other is the air intake and auxiliary transport lane 9 for the material, equipment, personnel transportation and air intake of the working face; The three lanes on the other side of face 13, from the inside to the outside, are the auxiliary transportation and air inlet lane 7 responsible for the air intake and auxiliary transportation of the working face, and the two return air lanes 3 and 2 responsible for the air return task of the working face; And the auxiliary transportation lane 9 ends at the working face 13, and connects with the belt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com