Machining Method of Drive Gear Hole System for Medium Speed Diesel Engine Frame

A technology of transmission gears and processing methods, applied in metal processing equipment, manufacturing tools, boring/drilling and other directions, can solve the problems of large accumulative errors in clamping and alignment, inability to ensure positioning dimensional accuracy, and unstable processing quality. , to achieve the effect of high work efficiency, avoiding errors and short auxiliary time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with drawings and embodiments.

[0022] The processing method of the transmission gear hole system of the medium-speed diesel engine frame includes the following steps:

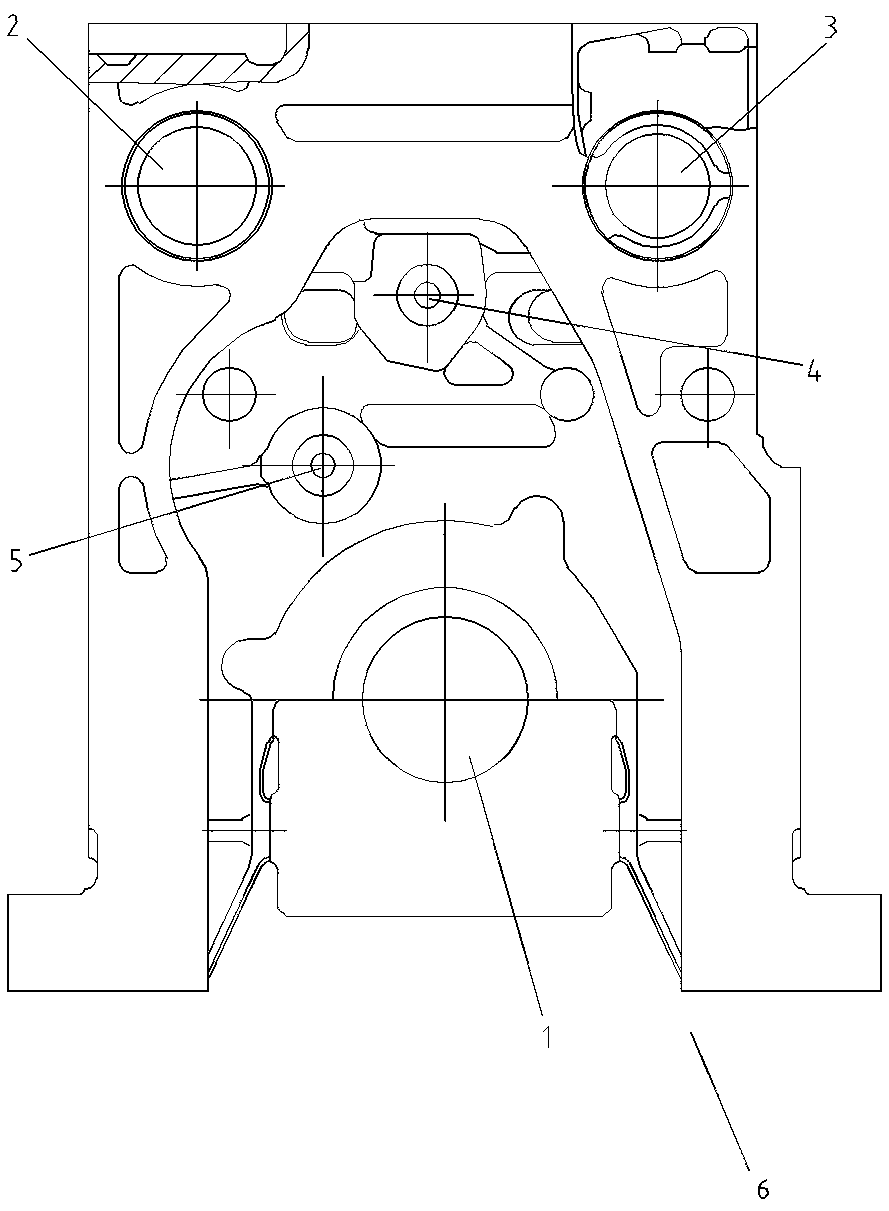

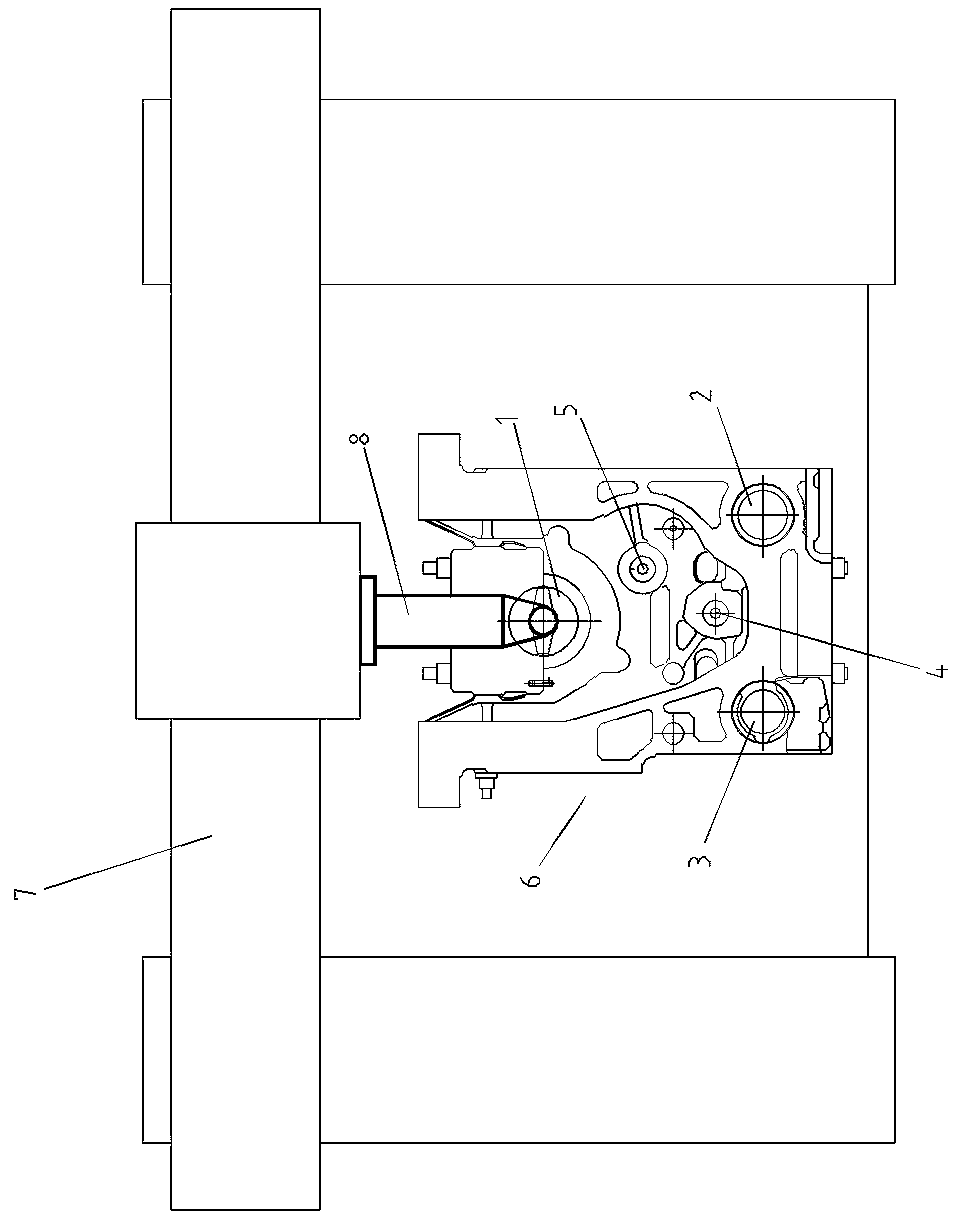

[0023] 1) Machining the main bearing hole 1: such as figure 2 As shown, put the bottom of the diesel engine frame 6 upwards, clamp and position it on the workbench of the CNC gantry boring and milling machine 7, and make the axis of the main bearing hole 1 on the frame 6 perpendicular to the axis of the machine tool spindle, and install it on the machine tool spindle The first special attachment 8 starts the machine tool, and utilizes the first special attachment 8 to process the main bearing holes 1 of each gear in turn. During processing, the axis of the first special attachment 8 coincides with the axis of the main bearing holes 1 of each gear respectively;

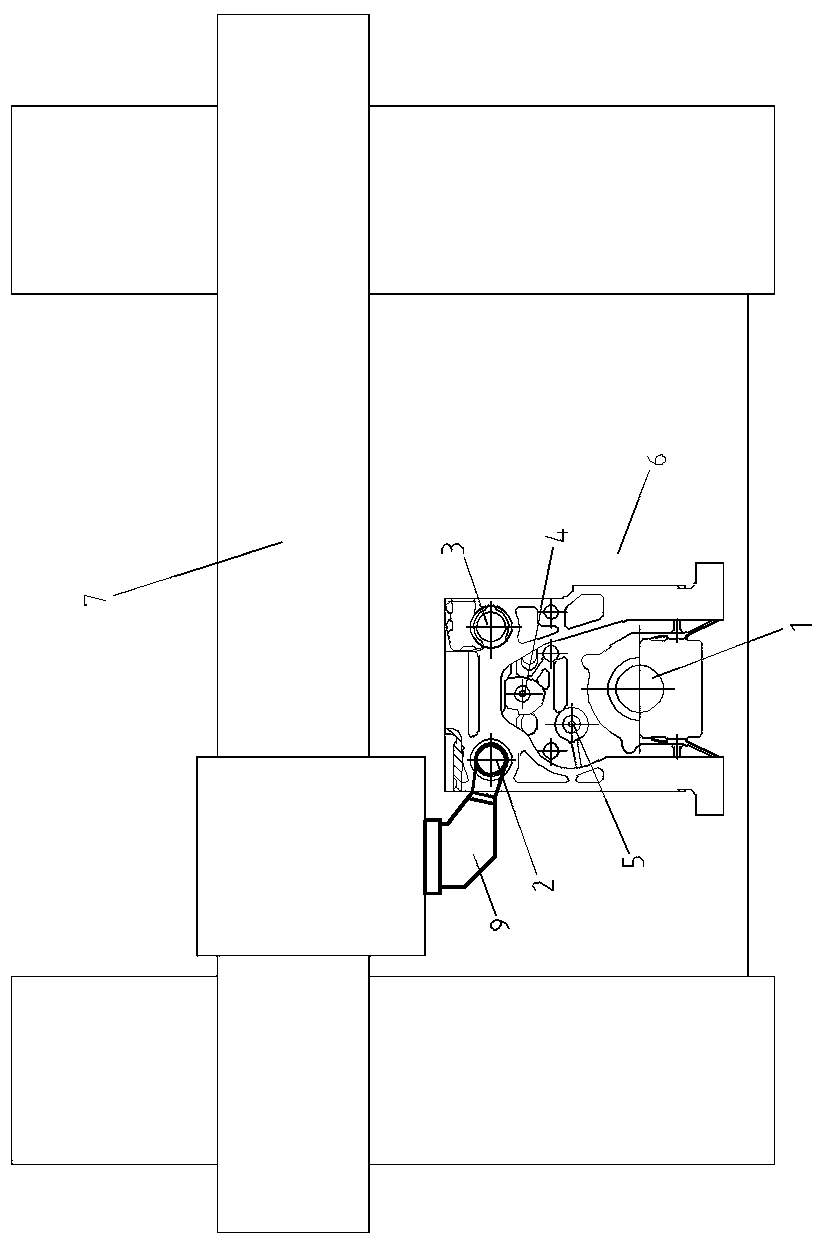

[0024] 2) Processing oil injection camshaft hole 2: such as image 3 A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com