Automatic feeding plate slot milling machine with magnetic sucking cup

A technology of automatic feeding and magnetic sucker, which is applied in the direction of milling machine equipment, milling machine equipment details, metal processing equipment, etc., can solve the problem of difficult control of the width and depth of the oil storage groove, affecting the precision of the inner hole of the shaft sleeve, and low turning efficiency, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

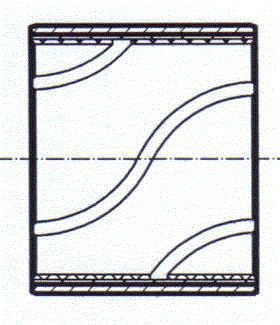

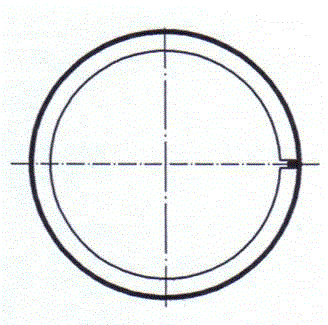

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0023] Figure 5 , Image 6 Figure 7 It is a schematic diagram of the structure of the magnetic sucker automatic feeding plate milling machine. As can be seen from the figure, it includes a frame 1, a table panel 2 is fixed on the frame 1, a slideway seat 3 is fixed at the left and right ends of the table panel 2, and two parallel parallel bars are fixed on the slideway seat 3. Circular slideways 4 of equal height, each slideway 4 is covered with a bearing seat 5, a sliding bearing 6 is fixed in the bearing seat 5, an upper plate 7 is fixed on the bearing seat 5, and a fixed upper plate 7 is fixed on the upper plate 7 Adjustment panel 8 is arranged, and plane electromagnetic chuck 9 is fixed on the adjustment panel 8, and this electromagnetic chuck 9 is identical with the electromagnetic chuck on the surface grinder, and magnetism can be pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com