Bead fabric supply frame of forming machine

A feeding frame and cloth wrapping technology, which is applied in the direction of thin material handling, transportation and packaging, and winding strips, etc., can solve the problem of long time required for manual cutting of slit wrapping cloth, affecting the operating efficiency of tire building machines, manual sticking Combined with the problems of high labor intensity, etc., the feeding process is coordinated and reliable, the adjustment is convenient, and the effect of reducing stretching is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

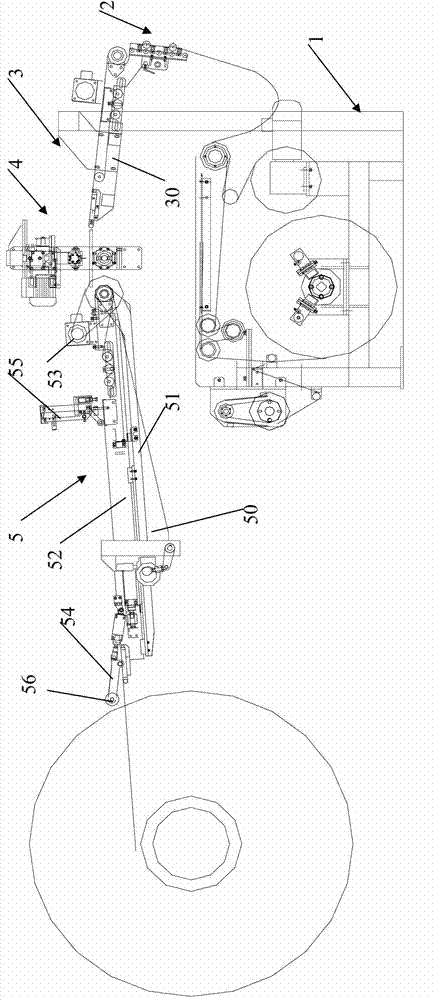

[0024] Such as figure 1 As shown, the slit cloth feeding rack of the forming machine of the present invention comprises a slit cloth guiding device 1, a rear feeding mechanical edge fixing device 2, a rear feeding conveying device 3, a cutting device 4 and a feeding conveying device arranged in sequence. Device 5, the feeding frame leveling device and the specification adjustment device; wherein, the rubber lining of the slit cloth is placed on the cloth and rolled on the I-shaped wheel for storage. When forming, the slit cloth guiding device 1 is required to remove the cloth Coil and unwind the rubber strip, which is similar to the prior art here, and will not be repeated here.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com