Vertical double-sided milling machine of gantry

A vertical, double-sided technology, applied in the field of milling machines, can solve the problems that milling machines are difficult to meet processing requirements, rarely process large-size workpieces, and cannot guarantee milling, etc. It achieves short worker assistance time, wide application range, and easy positioning and clamping Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

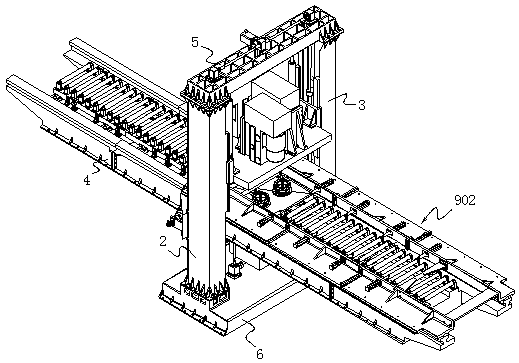

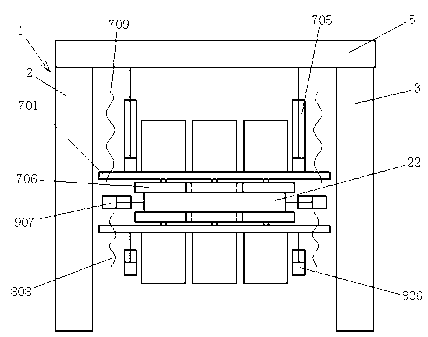

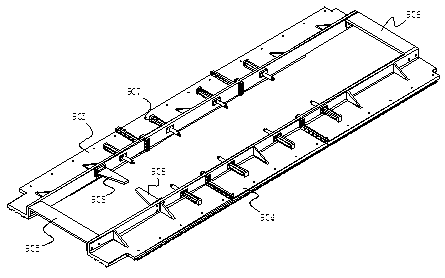

[0034] Such as figure 1 As shown, a gantry vertical double-sided milling machine includes a gantry 1 and a bed 4 fixed on the gantry 1. The bed consists of 4 sections and is fixedly connected by bolts. The first longitudinal frame 903 and the second longitudinal frame 904 is composed of three sections, and is fixedly connected by bolts. The upper and lower sides of the bed 4 are respectively provided with an upper milling mechanism 7 and a lower milling mechanism 8 for milling workpieces; The workbench 902 that is fixed on the workbench driving mechanism 9 on the gantry 1 and performs reciprocating motion. The gantry 1 is also provided with an upper milling drive mechanism that can drive the upper milling mechanism 7 to move up and down vertically and is used to support the upper milling mechanism. The upper milling support mechanism of the milling drive mechanism, the lower milling drive mechanism capable of driving the lower milling mechanism 8 to move vertically up and down...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com