Patents

Literature

60results about How to "Improve pairing accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bluetooth pairing method and system, and Bluetooth KEY

InactiveCN103701503AImprove convenienceImprove pairing accuracyNear-field transmissionGraphicsComputer network

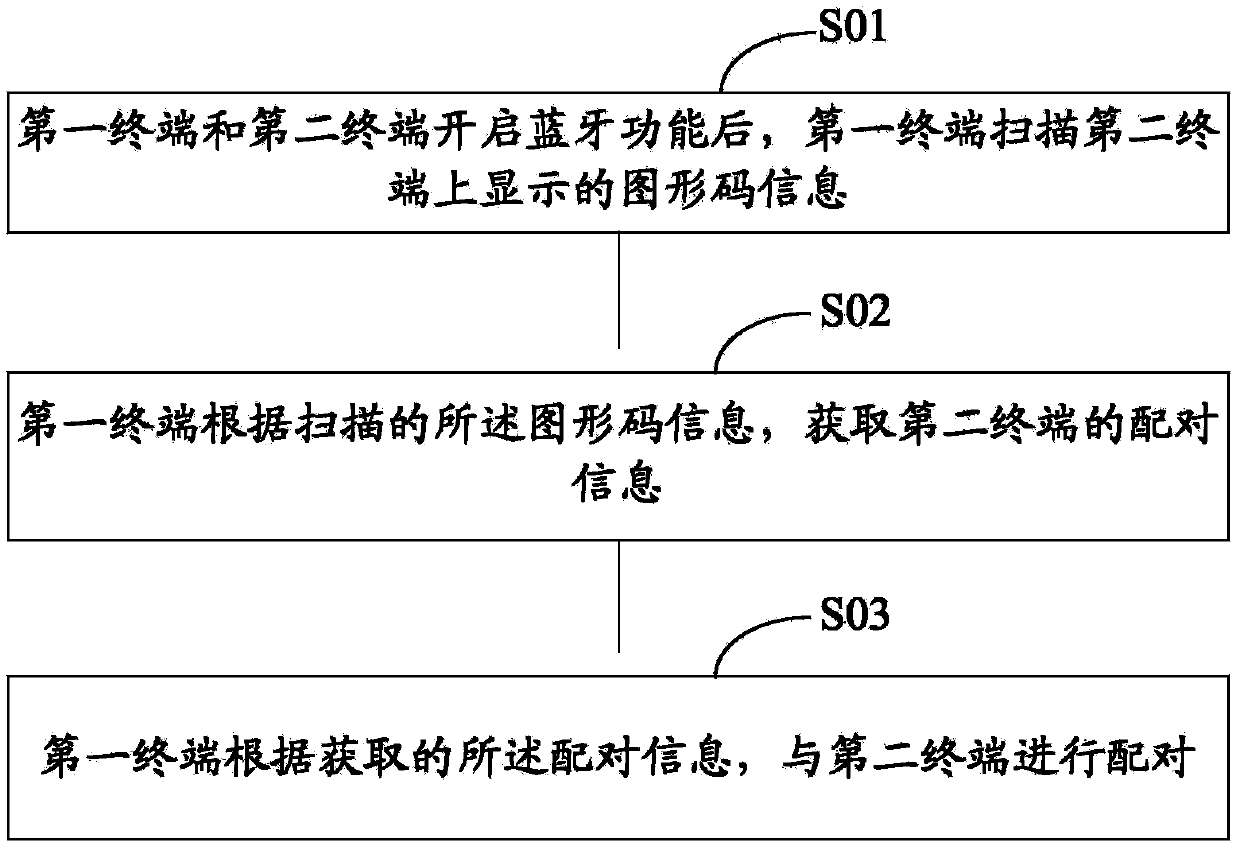

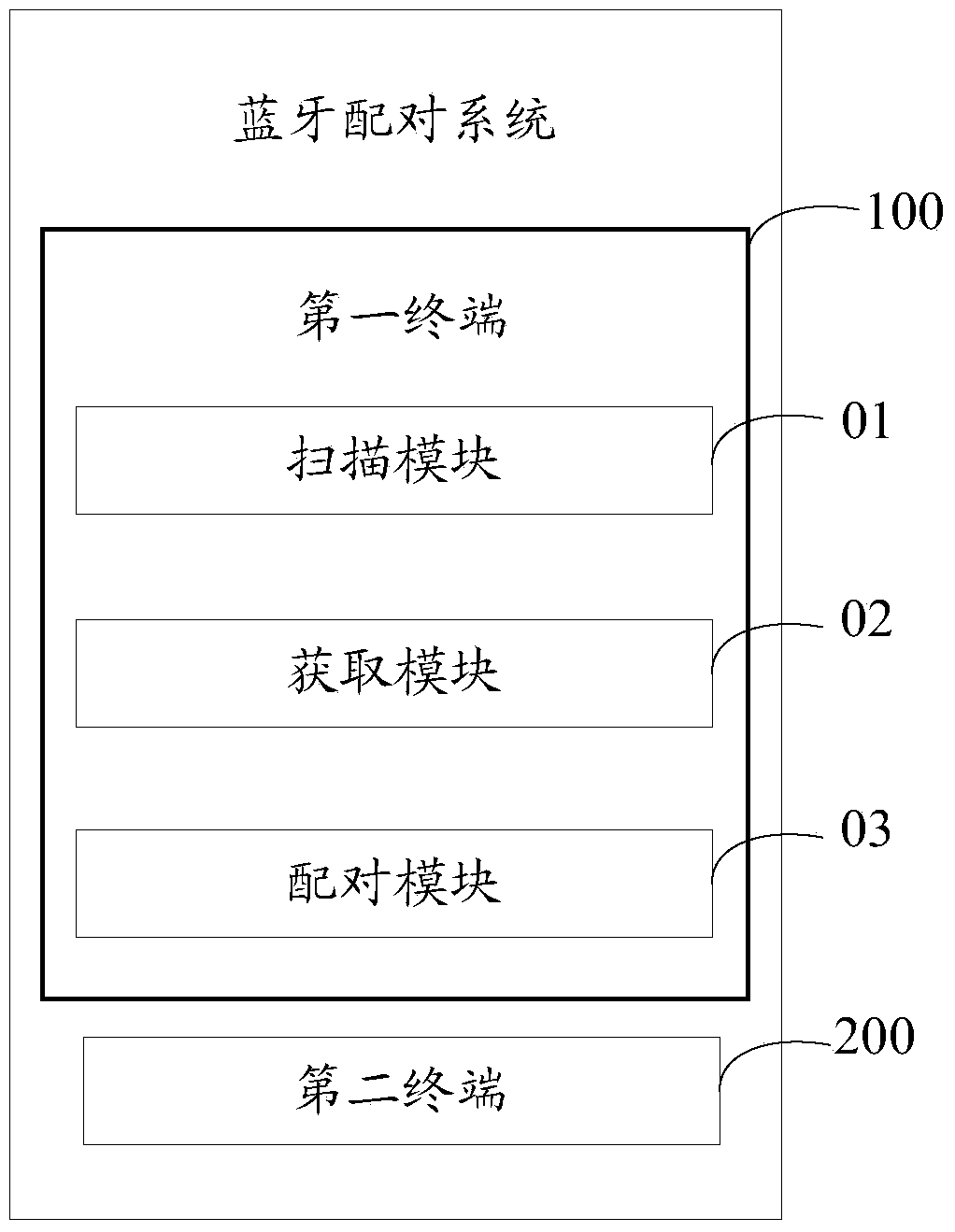

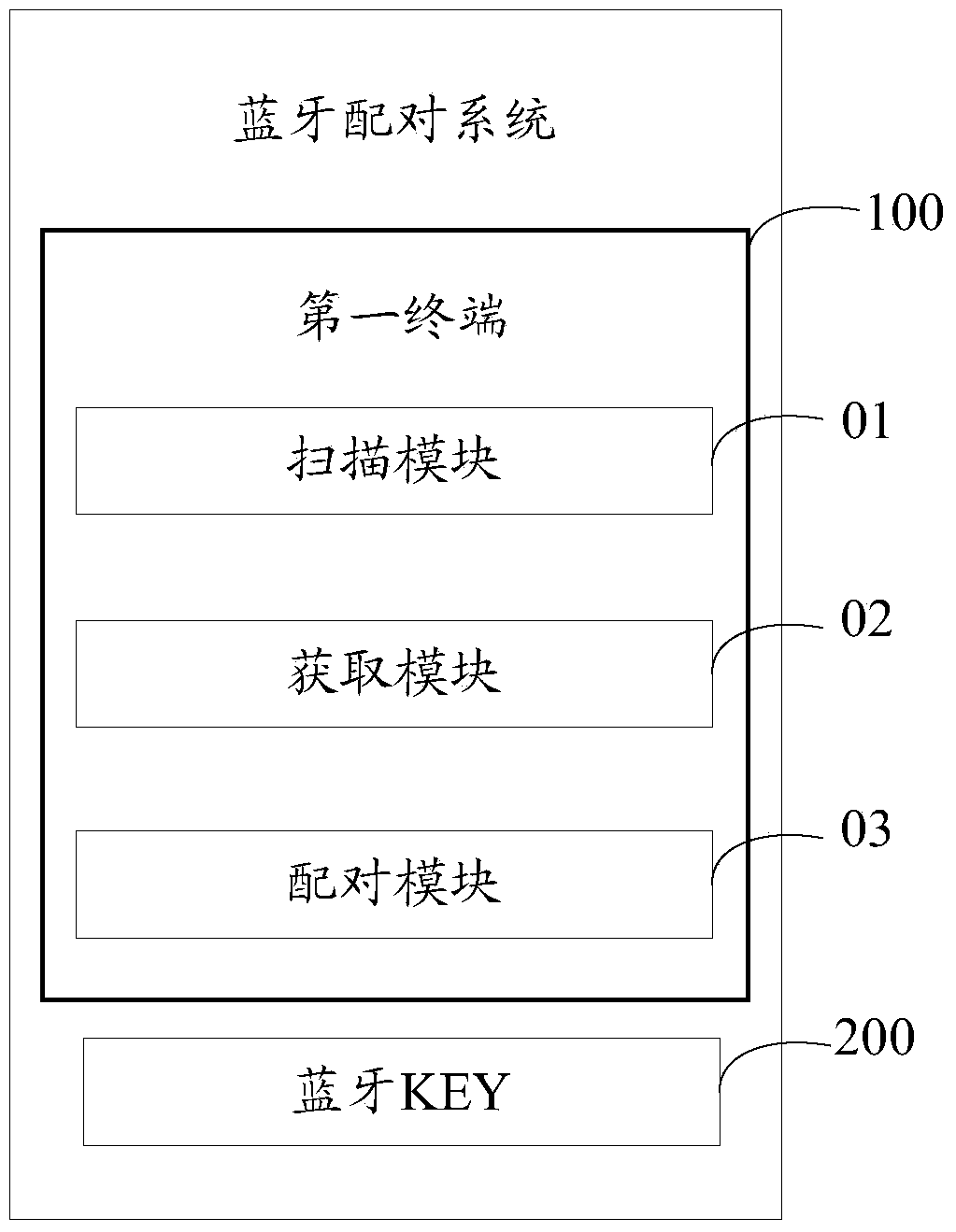

The invention discloses a Bluetooth pairing method and system. In the embodiment of the invention, the method comprises the following steps that a first terminal and a second terminal start Bluetooth functions, and the first terminal scans graphic code information displayed on the second terminal; the first terminal acquires the pairing information of the second terminal according to the scanned graphic code information; the first terminal is paired with the second terminal according to the acquired pairing information. The embodiment of the invention further discloses a Bluetooth KEY. The embodiment of the invention has the beneficial effect of high pairing accuracy; meanwhile, convenience in pairing each terminal with the Bluetooth KEY is enhanced.

Owner:SHENZHEN EXCELSECU DATA TECH

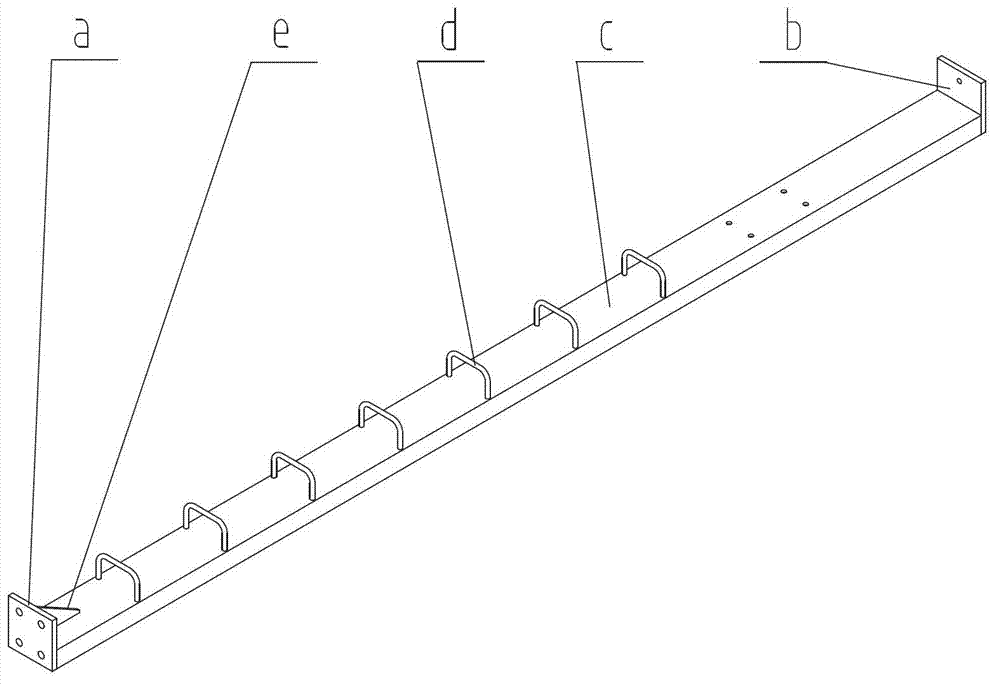

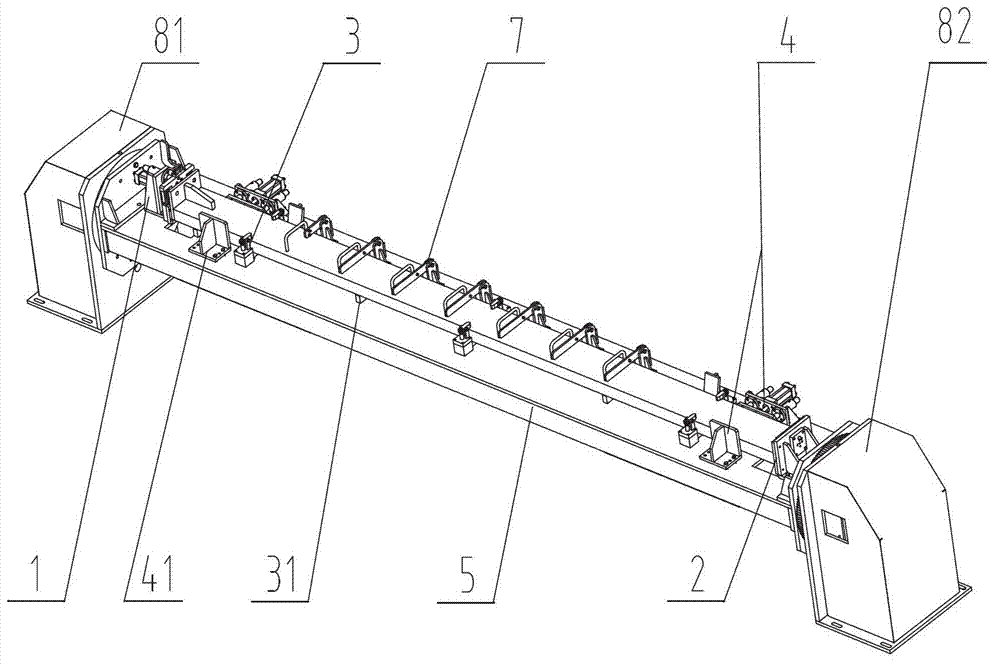

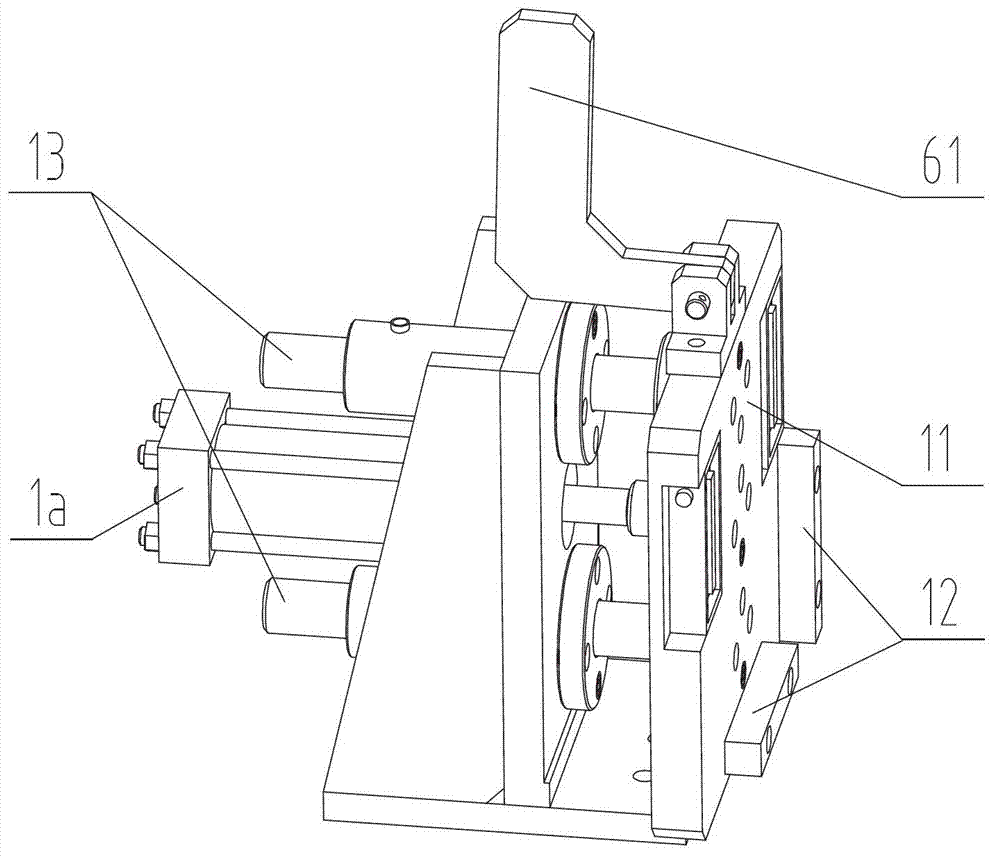

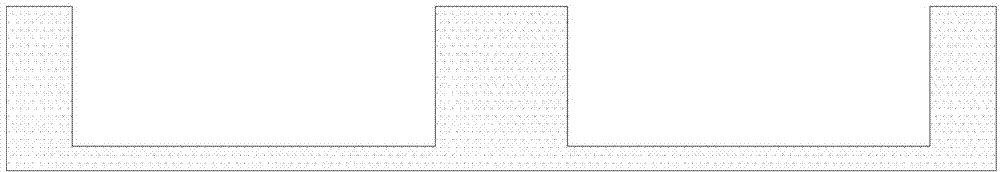

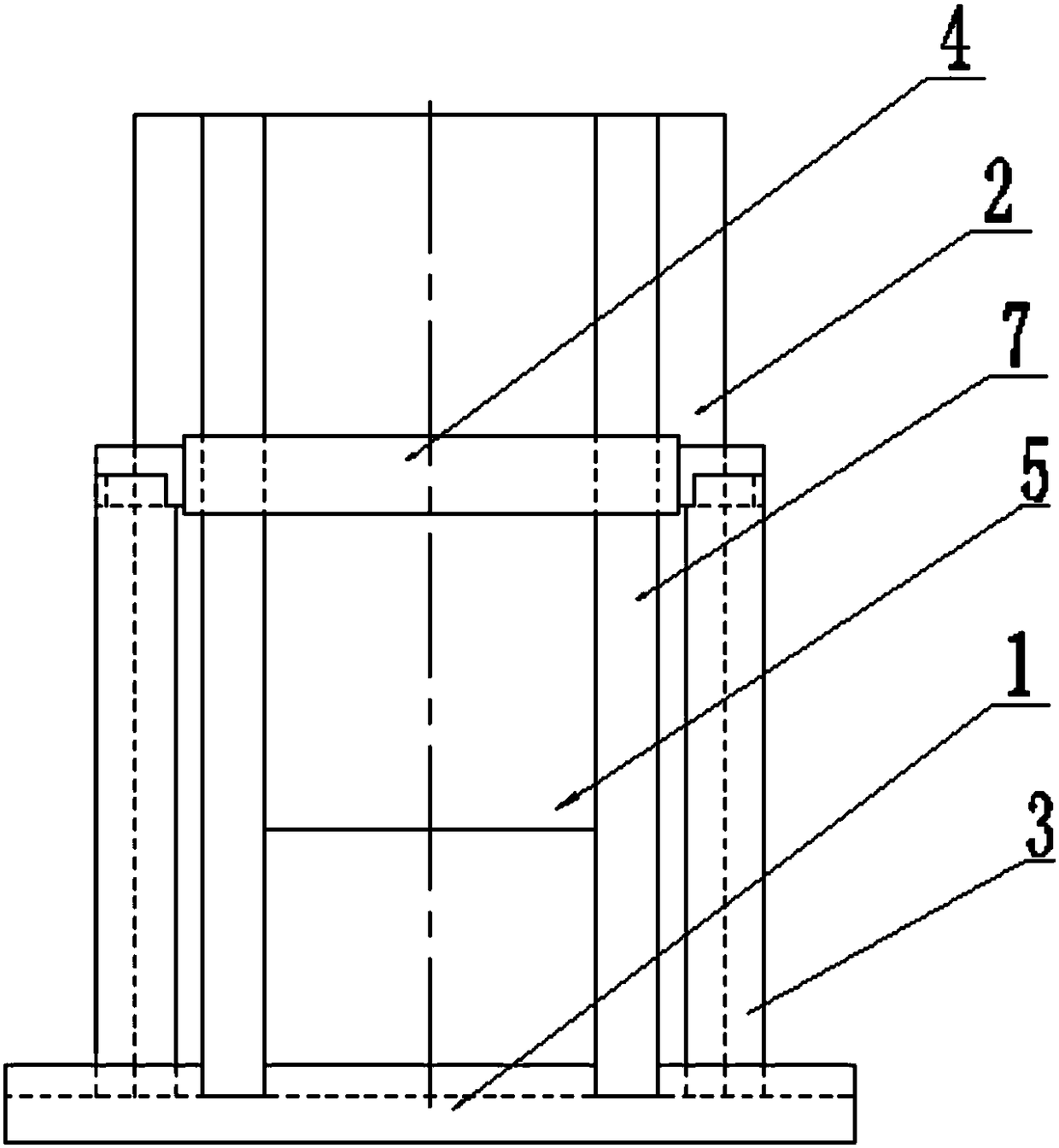

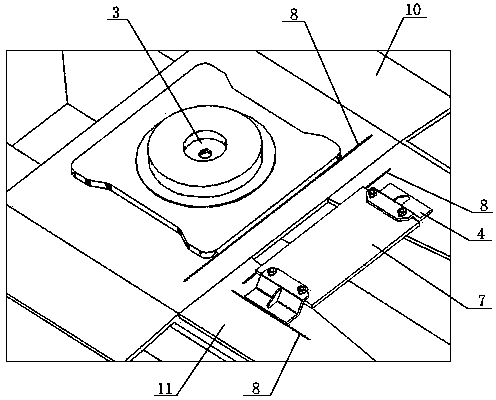

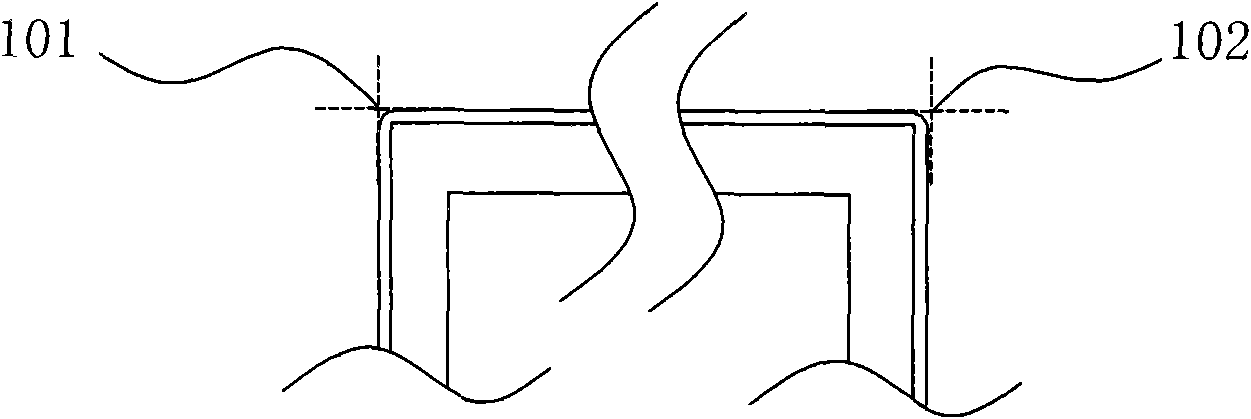

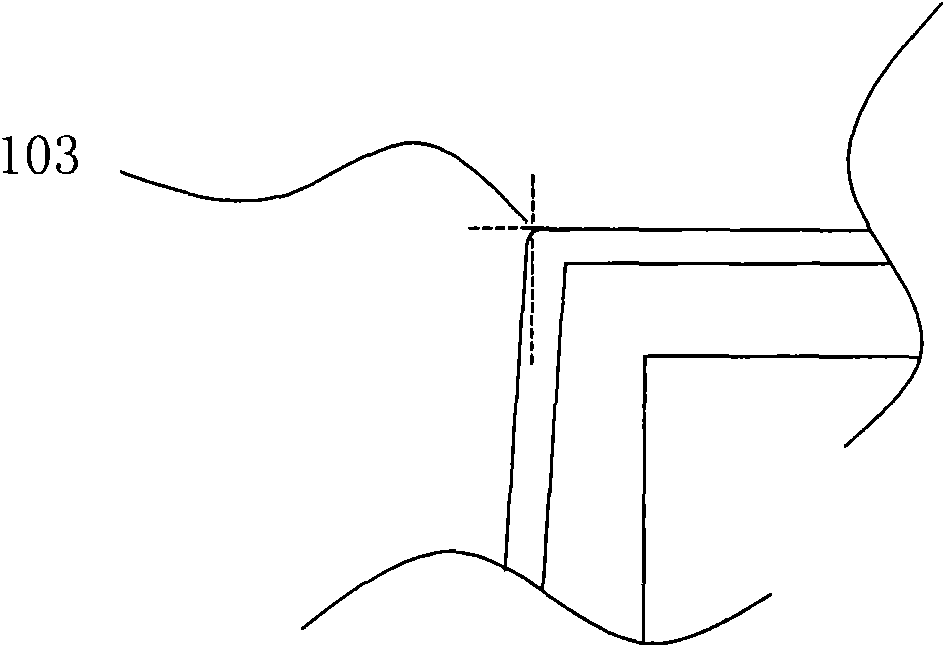

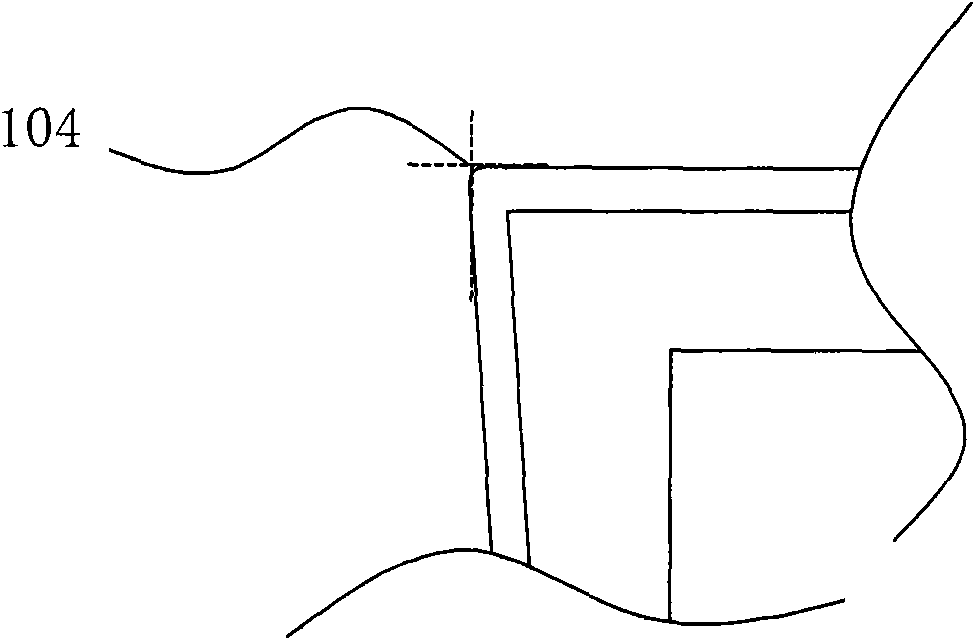

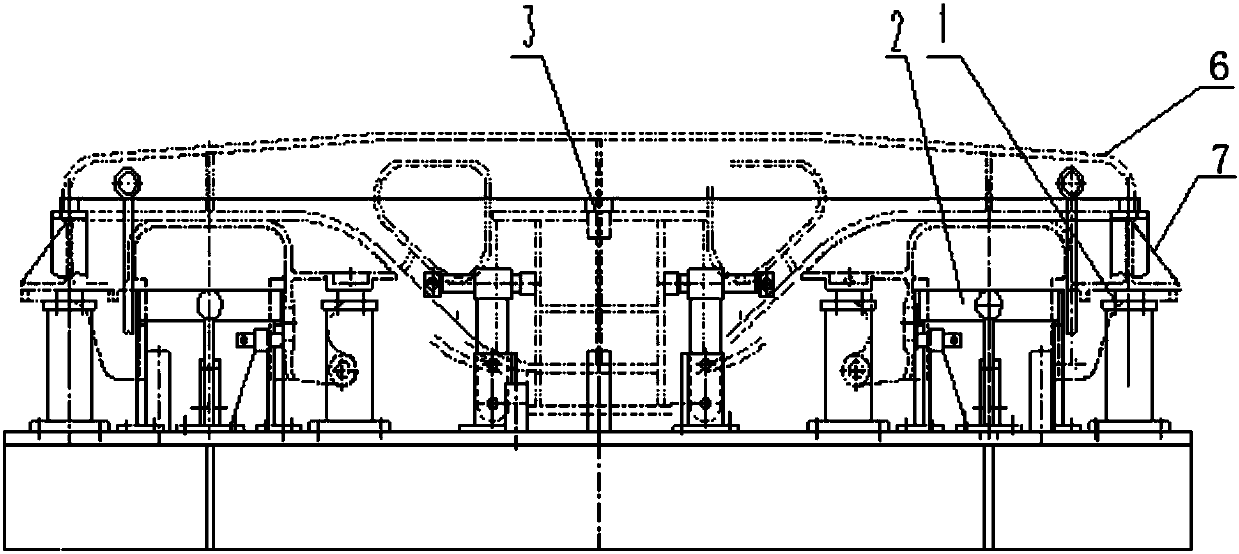

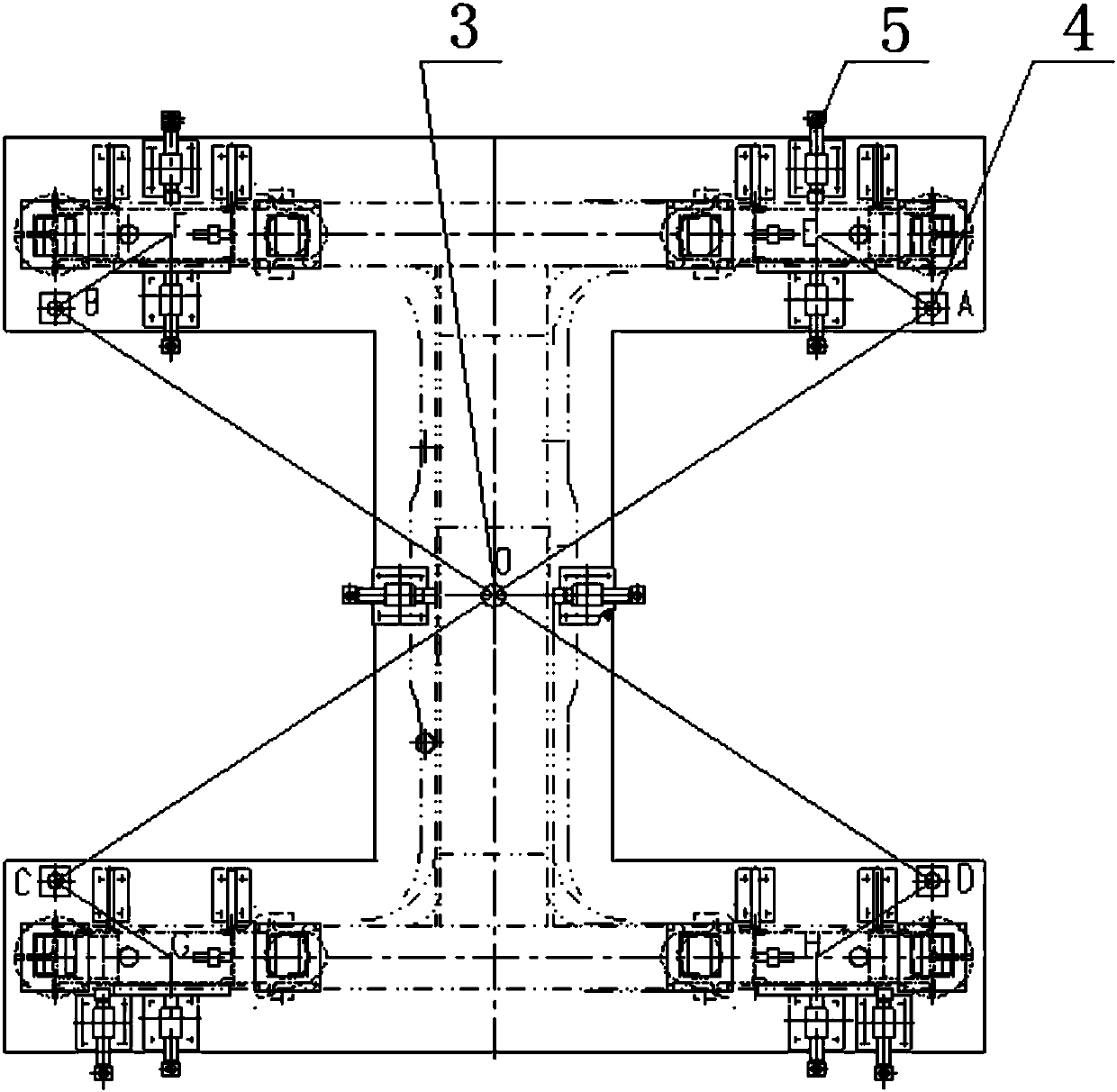

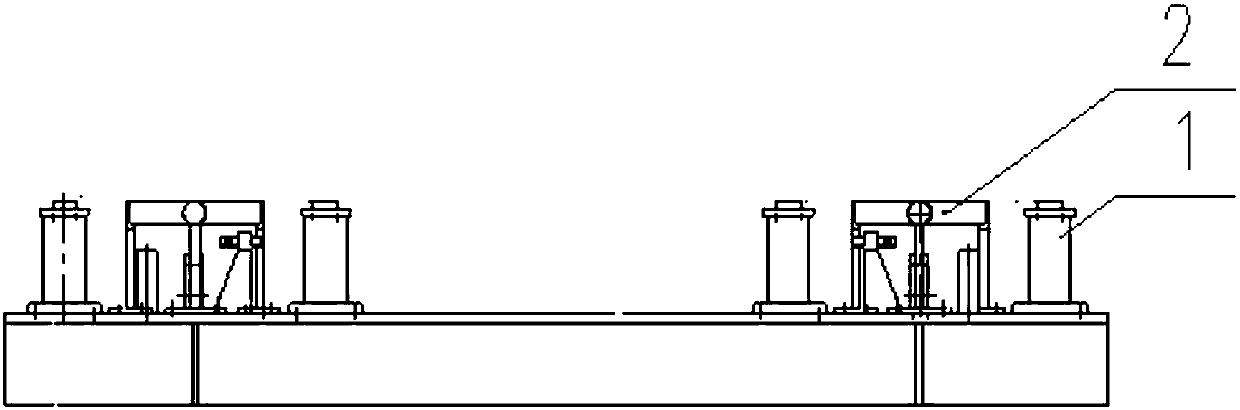

Standing column assembly welding tool

InactiveCN102825408AFast demouldingReduce labor intensityWelding/cutting auxillary devicesAuxillary welding devicesEngineering

The invention provides a standing column assembly welding tool for welding a standing column of a mixing plant. The standing column assembly welding tool comprises a left and right limit mechanism, an up and down limit mechanism and side limit mechanisms. The left and right limit mechanism comprises a first end and a second end. A first connecting plate of the standing column is limited at the first end. A second connecting plate of the standing column is limited at the second end. The up and down limit mechanism is used for limiting fluctuation of a standing column body. The side limit mechanisms are disposed on sides of the standing column body and are used for limiting the forward and backward motions of the standing column body. By the aid of the limit mechanisms, all parts of the standing column can be limited. The standing column assembly welding tool has the advantages of high work efficiency, low labor intensity, high assembly precision.

Owner:SANY HEAVY IND CO LTD (CN)

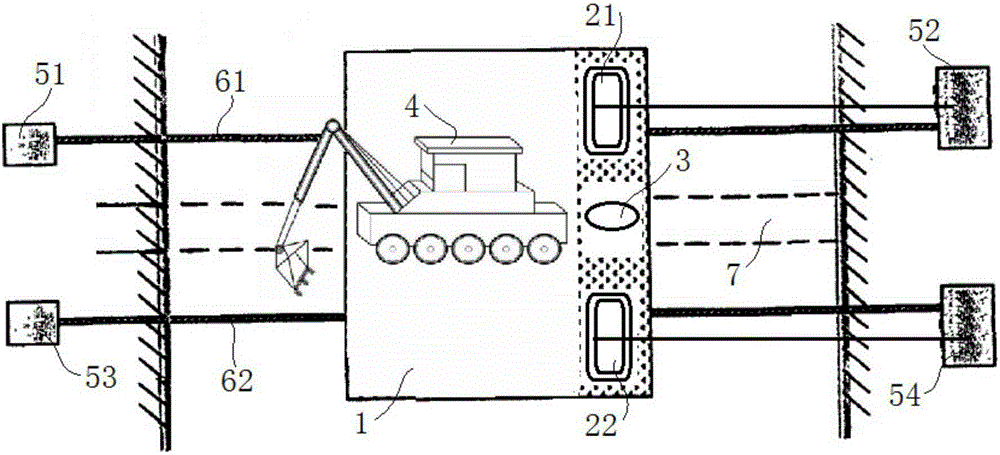

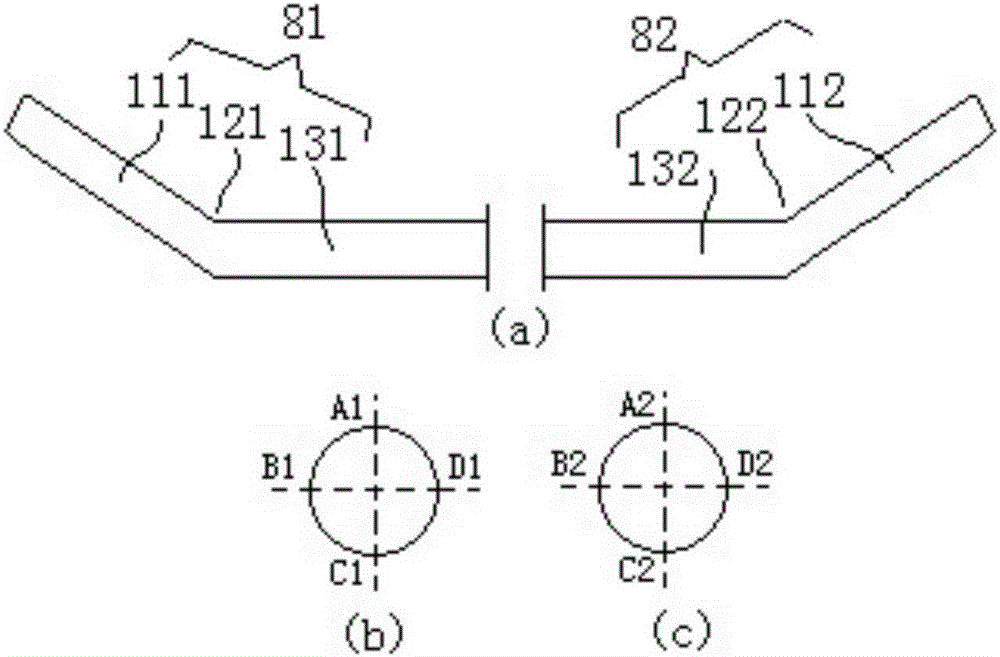

Sunken pipe assembling method for making pipeline pass through river

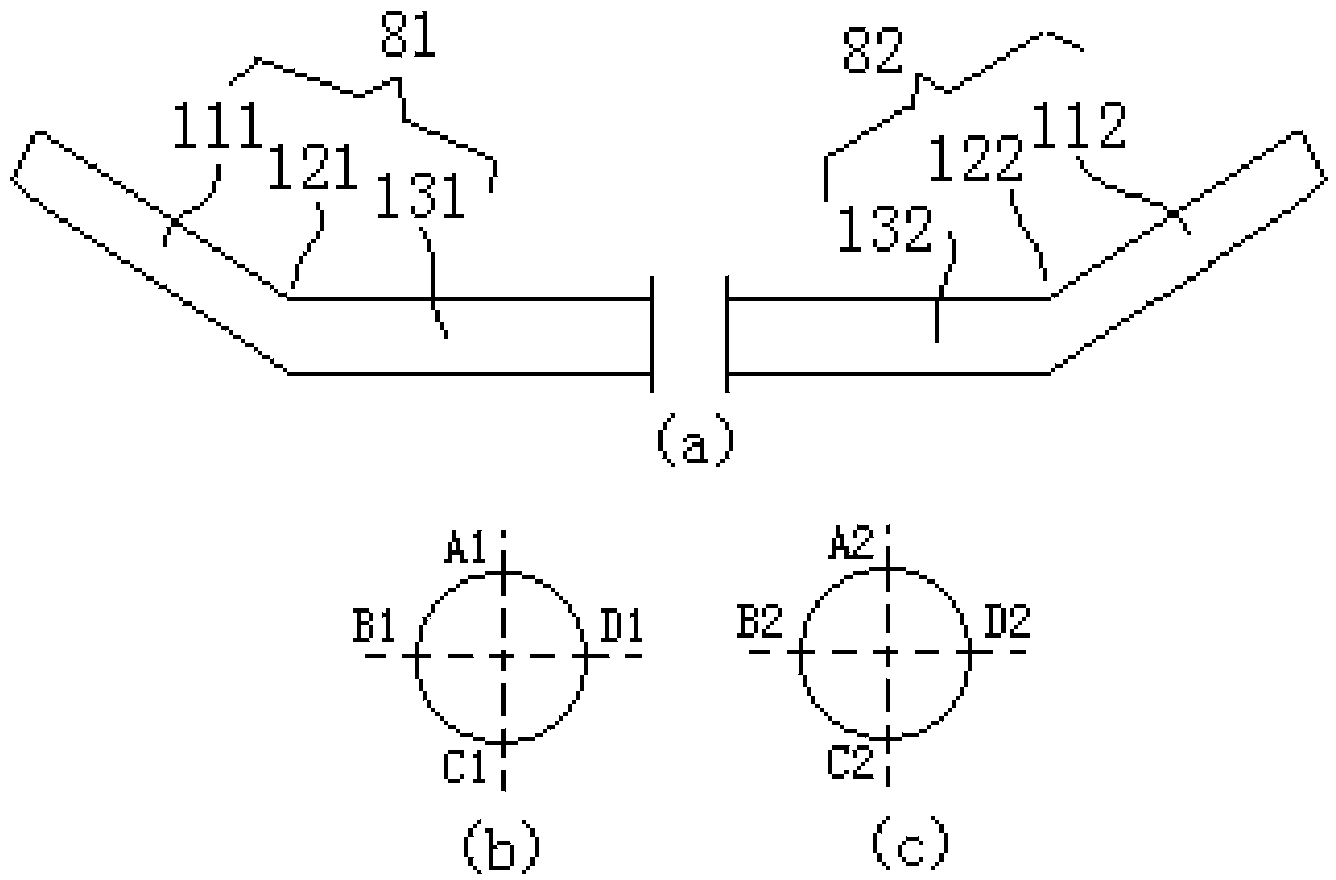

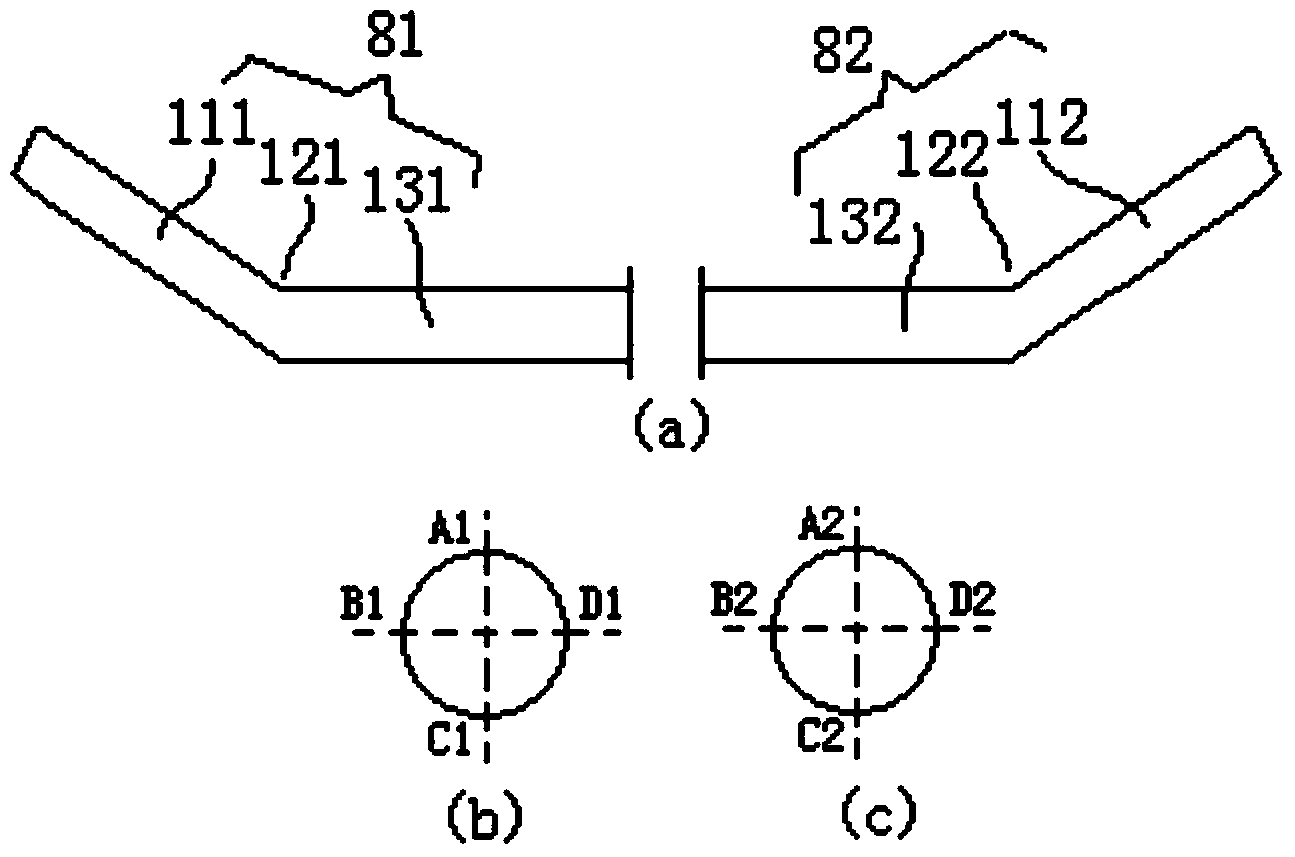

ActiveCN103912722AImprove pairing accuracySinking smoothlyPipe laying and repairEngineeringAssembly line

The invention discloses a sunken pipe assembling method for making a pipeline pass through a river, and belongs to the technical field of underwater pipeline laying. The method includes the steps that first, pipes are arranged for the pipeline, the assembly procedure includes the pre-assembly process and the pontoon assembly process, the first pre-assembly pipeline and the second pre-assembly pipeline are assembled beside the bank of the river, position point information is marked on the end face of each pre-assembly pipeline, and a first river bed straight pipe segment and a second river bed straight pipe segment are assembled on a platform of a pontoon; second, pipe sinking is performed for the pipeline, the overall pipeline sinking technology is adopted in the pipeline sinking process, a first buoy is tied to a first elbow segment on the pipeline, a second buoy is tied to a second elbow segment, and by controlling a first valve, a second valve, the first buoy and the second buoy always in the center line of a pipe ditch, it is guaranteed that the pipeline accurately sinks into the pipe ditch. With the method, the whole pipeline can be accurately controlled to sink into the assigned pipe ditch, and the control accuracy is high.

Owner:CHINA NAT CHEM ENG THIRD CONSTR

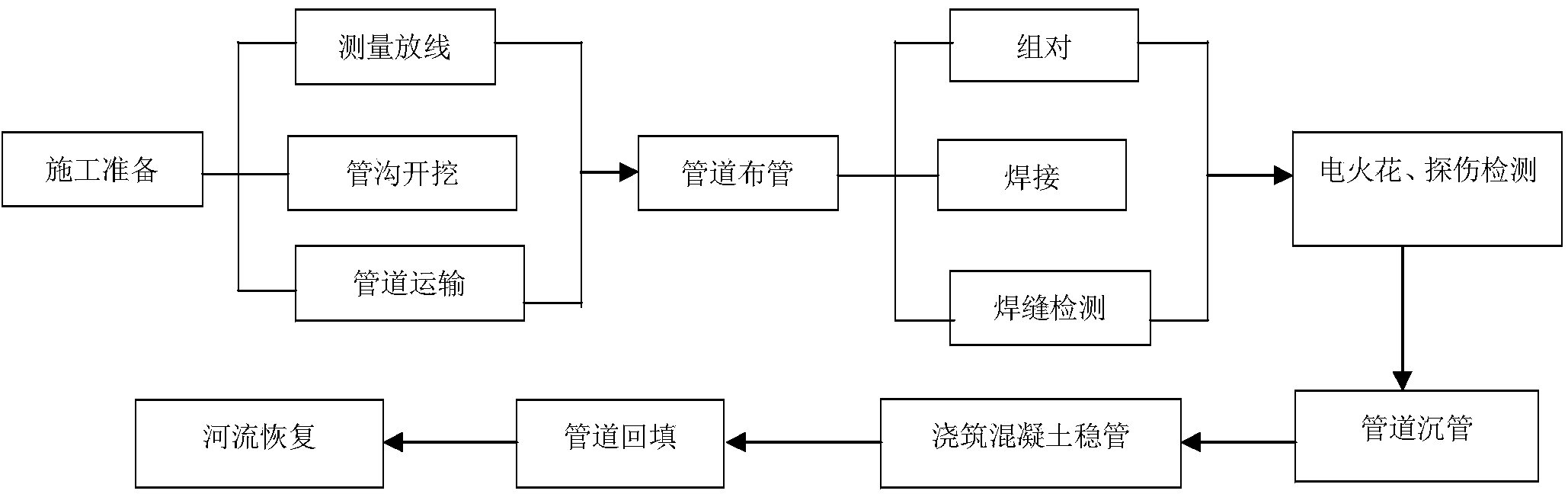

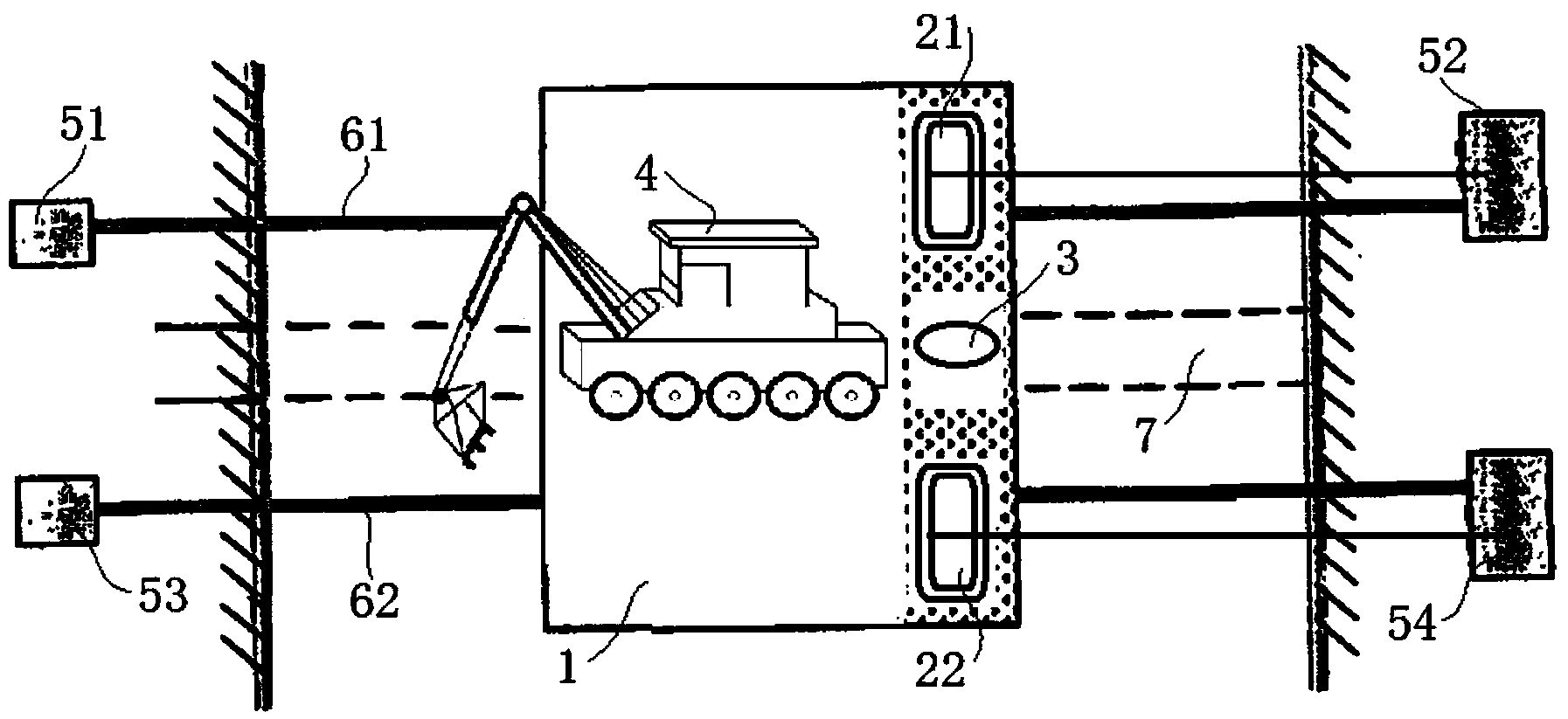

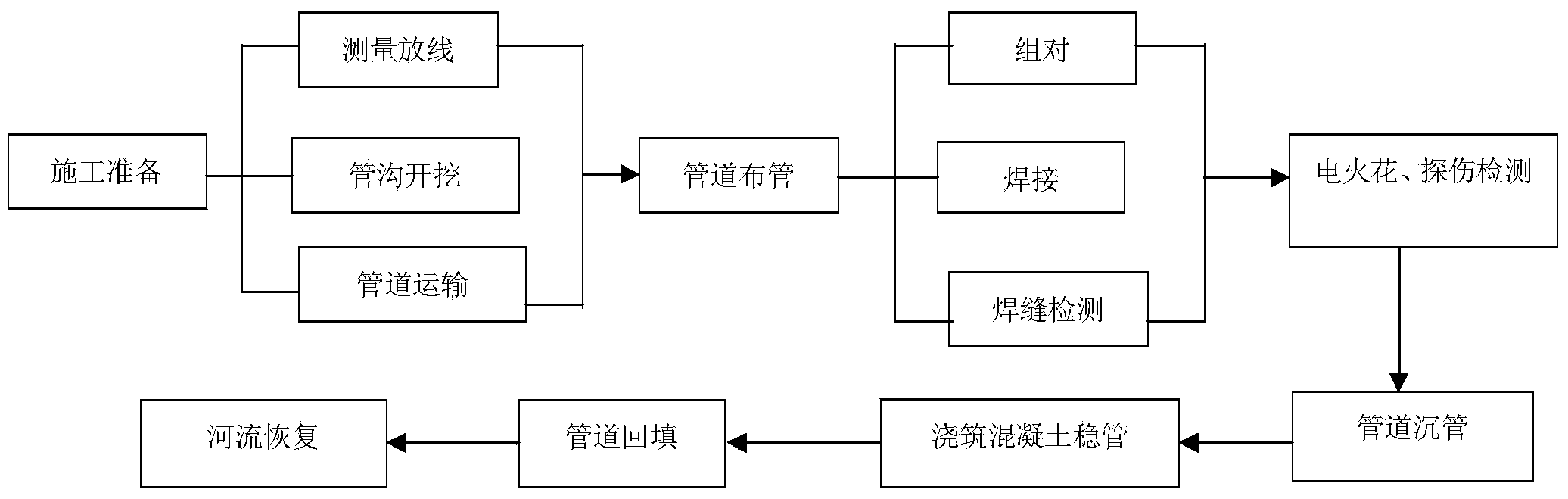

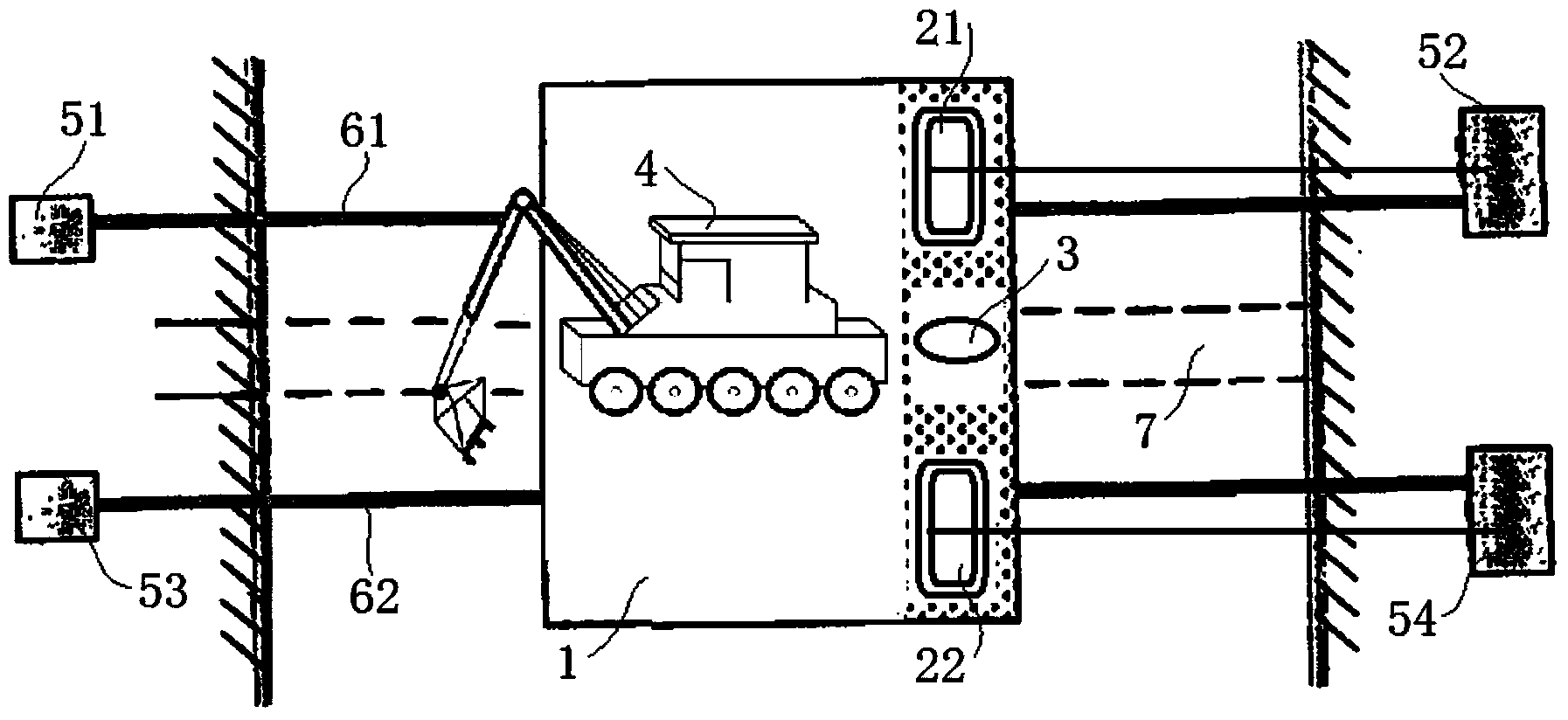

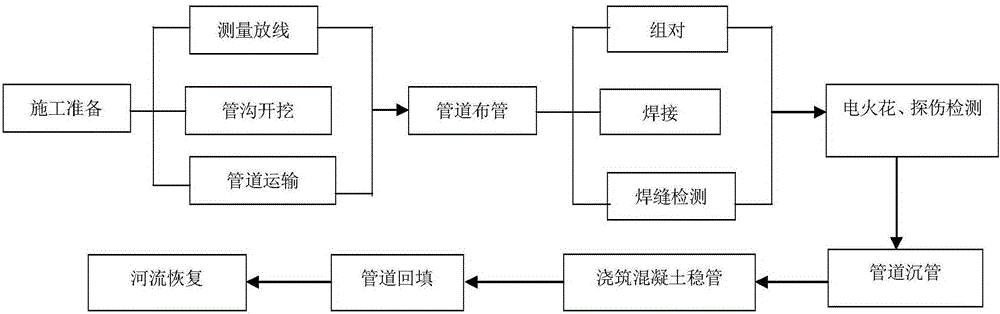

Underwater grooving and pipe sinking river traversing construction method

ActiveCN103912721AImprove pairing accuracyGuarantee smooth constructionWater resource protectionPipe laying and repairEngineeringFluvial

The invention discloses an underwater grooving and pipe sinking river traversing construction method, and belongs to the field of underwater pipeline laying technologies. The underwater grooving and pipe sinking river traversing construction method includes steps of preparing for construction; arranging pipes of pipelines, performing preliminary assembling procedures and photon assembling procedures in assembling procedures for arranging the pipes of the pipelines, particularly, preliminarily assembling the first pipelines to be preliminarily assembled and the second pipelines to be preliminarily assembled on river banks, marking location point information on the end surfaces of the pipelines, and assembling straight pipe sections of first river beds and straight pipe sections of second river beds on platforms of photons; sinking the pipes of the pipelines, implementing an integral pipeline sinking technology in procedures for sinking the pipes of the pipelines, tying first buoys at first elbow sections on the pipelines, tying second buoys on second elbow sections on the pipelines, and controlling first valves, second valves, the first buoys and the second buoys to always keep the first valves, the second valves, the first buoys and the second buoys on the center lines of pipe trenches so as to guarantee that the pipelines are accurately sunken in the pipe trenches; pouring concrete and stabilizing the pipes; refilling the pipelines and restoring rivers. The underwater grooving and pipe sinking river traversing construction method has the advantage that the integral pipelines can be accurately and stably sunken in the specified pipe trenches under the control of the underwater grooving and pipe sinking river traversing construction method.

Owner:CHINA NAT CHEM ENG THIRD CONSTR

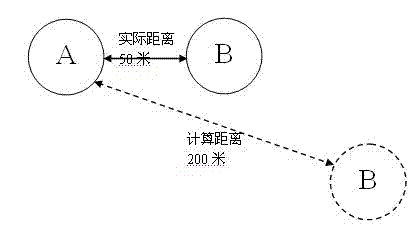

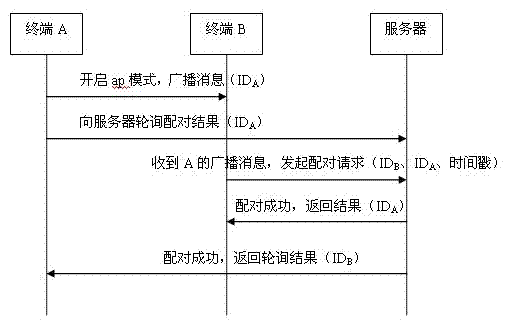

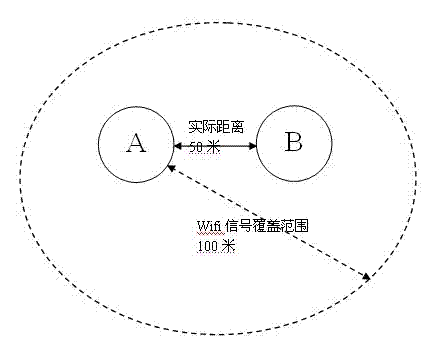

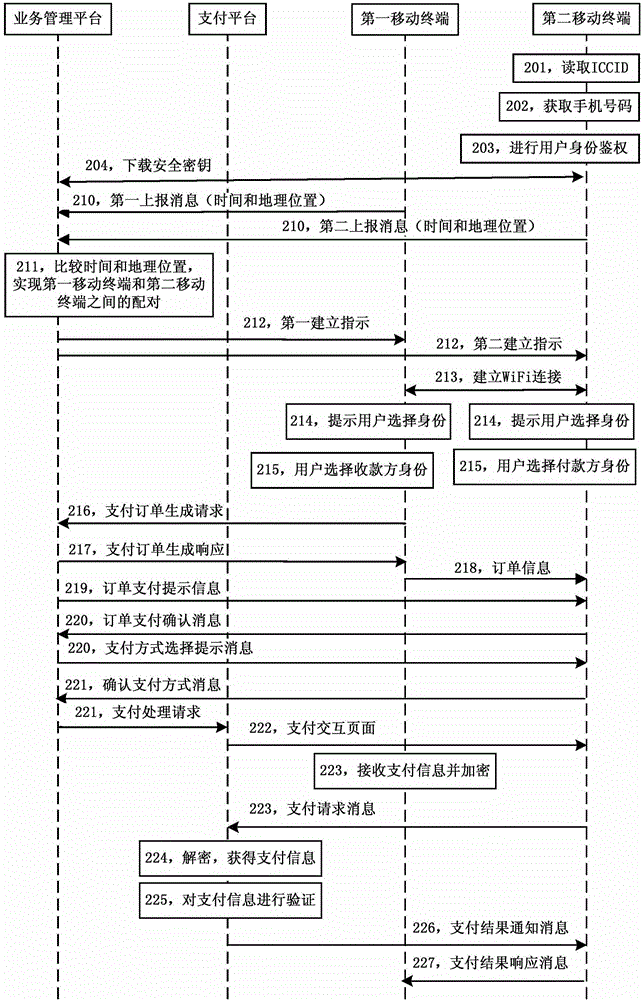

Short-distance pairing method of wifi (wireless fidelity) mobile terminal

InactiveCN102791014AImprove pairing accuracySave pairing timeAssess restrictionConnection managementShortest distancePairing

The invention discloses a short-distance pairing method of a wifi (wireless fidelity) mobile terminal, which has the advantages that the pairing precision is high, the time is short, and the LBS (location based service) dependence is avoided. The method comprises the following processes that a mobile terminal A periodically makes broadcast, and the broadcast message contains the unique identification ID of the mobile terminal A; a mobile terminal B starts the scanning mode of a wifi module, if the mobile terminal B is in the wireless signal coverage range of the terminal A, whether the pairing requirement is met or not is judged, and if the pairing requirement is met, the terminal B sends out requests to a service for realizing the pairing with the terminal A; the server receives the pairing request sent by the terminal B and returns the pairing results to the terminal B according to the pairing relationship, and the terminal B builds the pairing relationship with the terminal A according to the results; and the terminal A periodically polls the server, the server checks the successful pairing list according to the ID, and if the list contains ID, the terminal A builds the pairing relationship with the terminal B according to returned results.

Owner:ARCHERMIND TECH NANJING

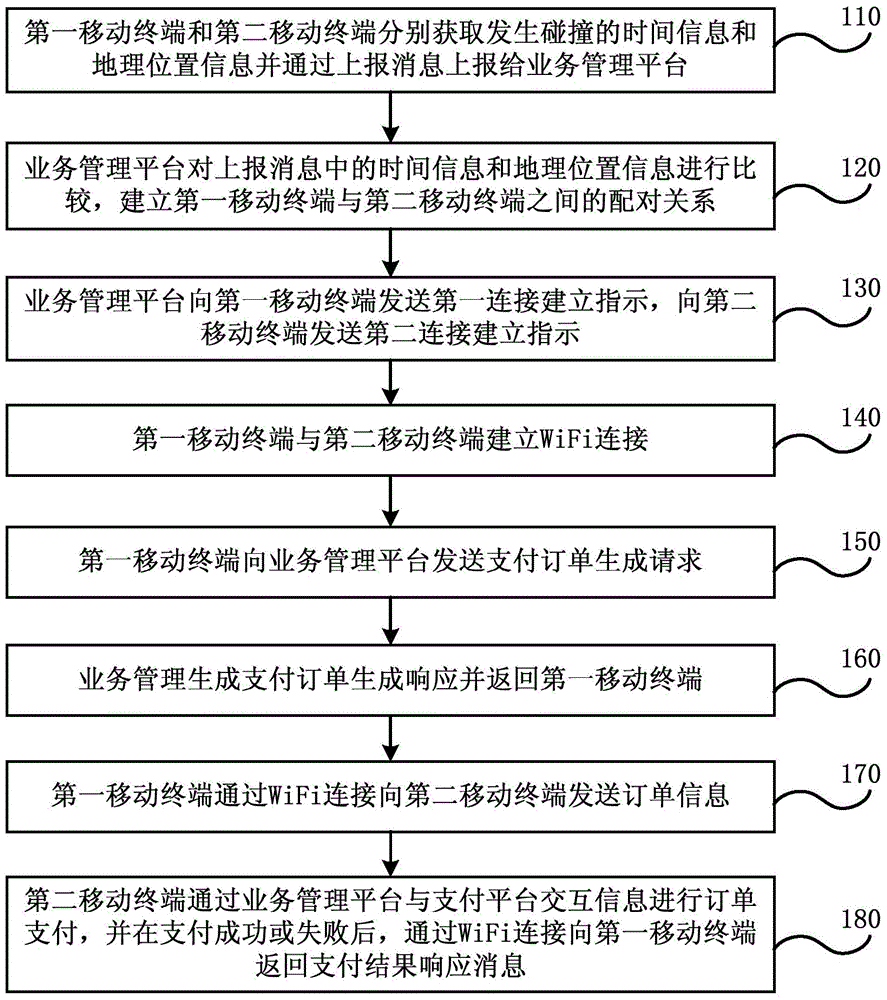

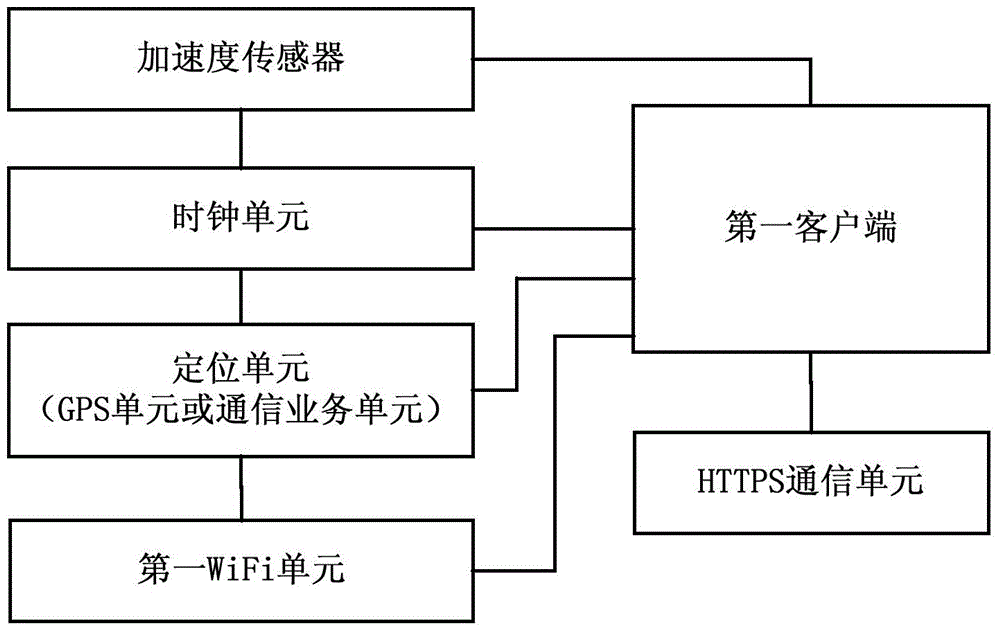

Data processing method and system based on touching manner of mobile terminals

InactiveCN105321070ALess susceptible to interferenceImprove pairing accuracyPayment architecturePaymentTime information

The invention discloses a data processing method and system based on the touching manner of mobile terminals. The method comprises that a pairing relation between a first mobile terminal and a second mobile terminal is established by matching time information and geographical position information of touching between the mobile terminals; the first mobile terminal is indicated to establish WiFi connection with the second mobile terminal; the first mobile terminal sends a payment order generation request to a service management platform; the service management platform generates a payment order generation response and returns the response to the first mobile terminal; the first mobile terminal sends order information to the second mobile terminal via WiFi connection; and the second mobile terminal interacts information with a payment platform via the service management platform to implement order payment, and returns a payment result response message, which comprises the number of payment order, to the first mobile terminal via WiFi connection after payment success or failure. The method and system provided by the invention can realize accurate pairing between the mobile terminals and are low in cost.

Owner:CHINA TELECOM CORP LTD

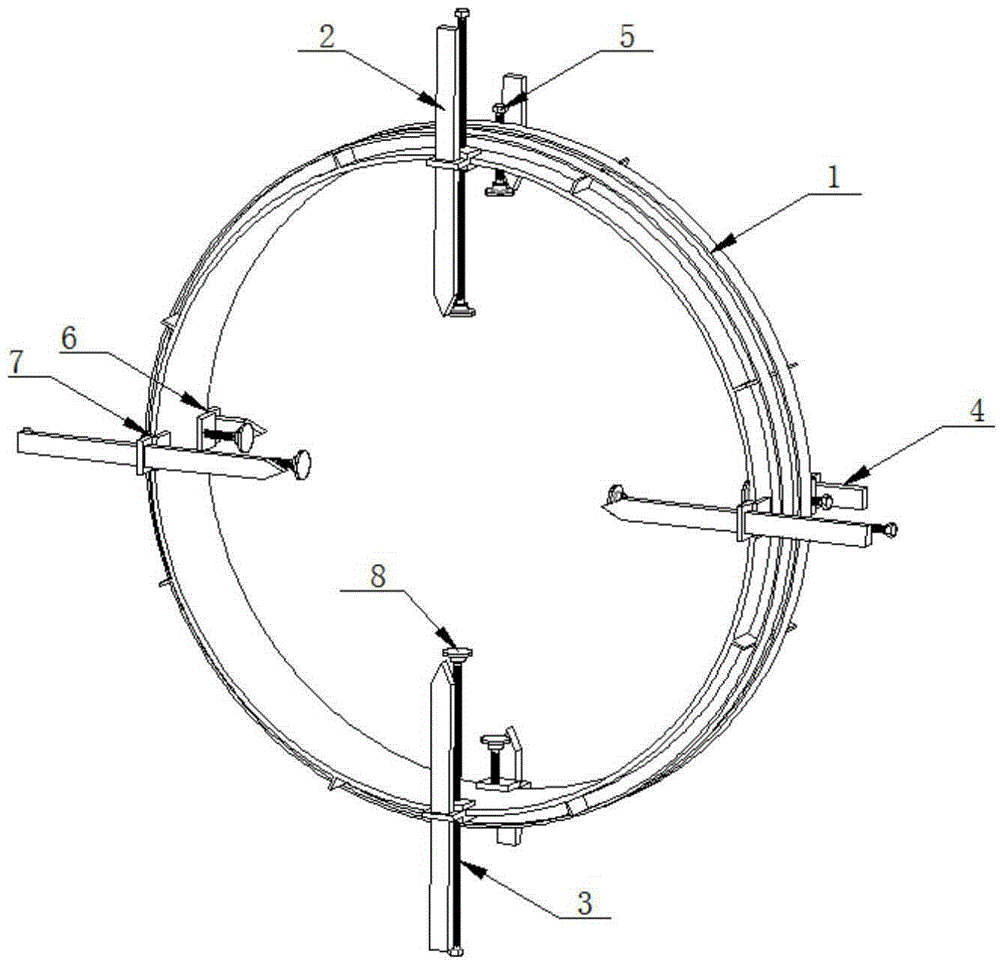

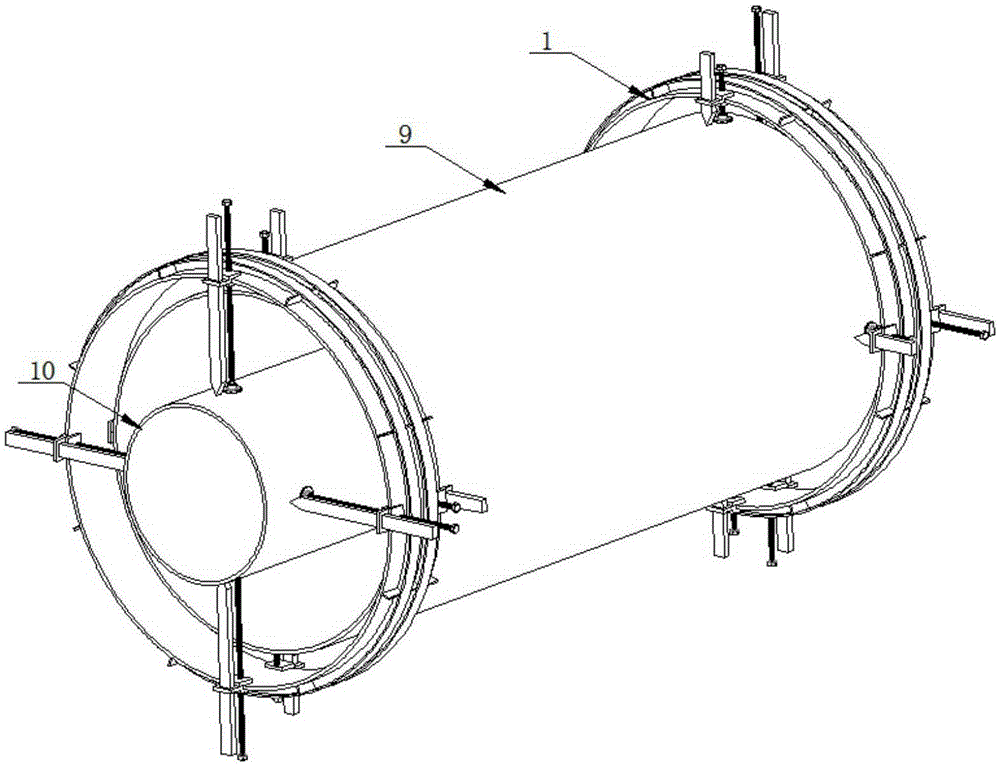

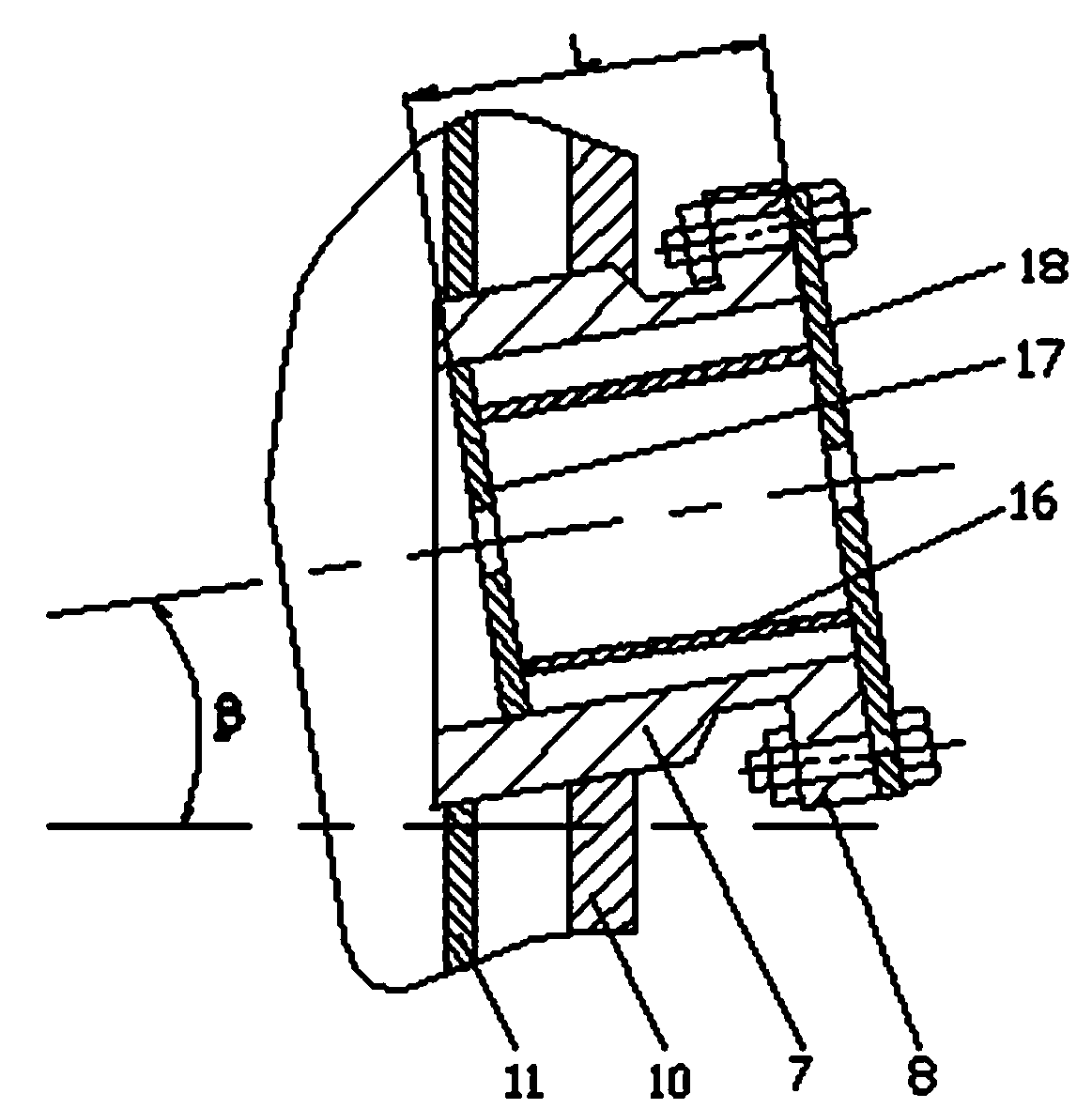

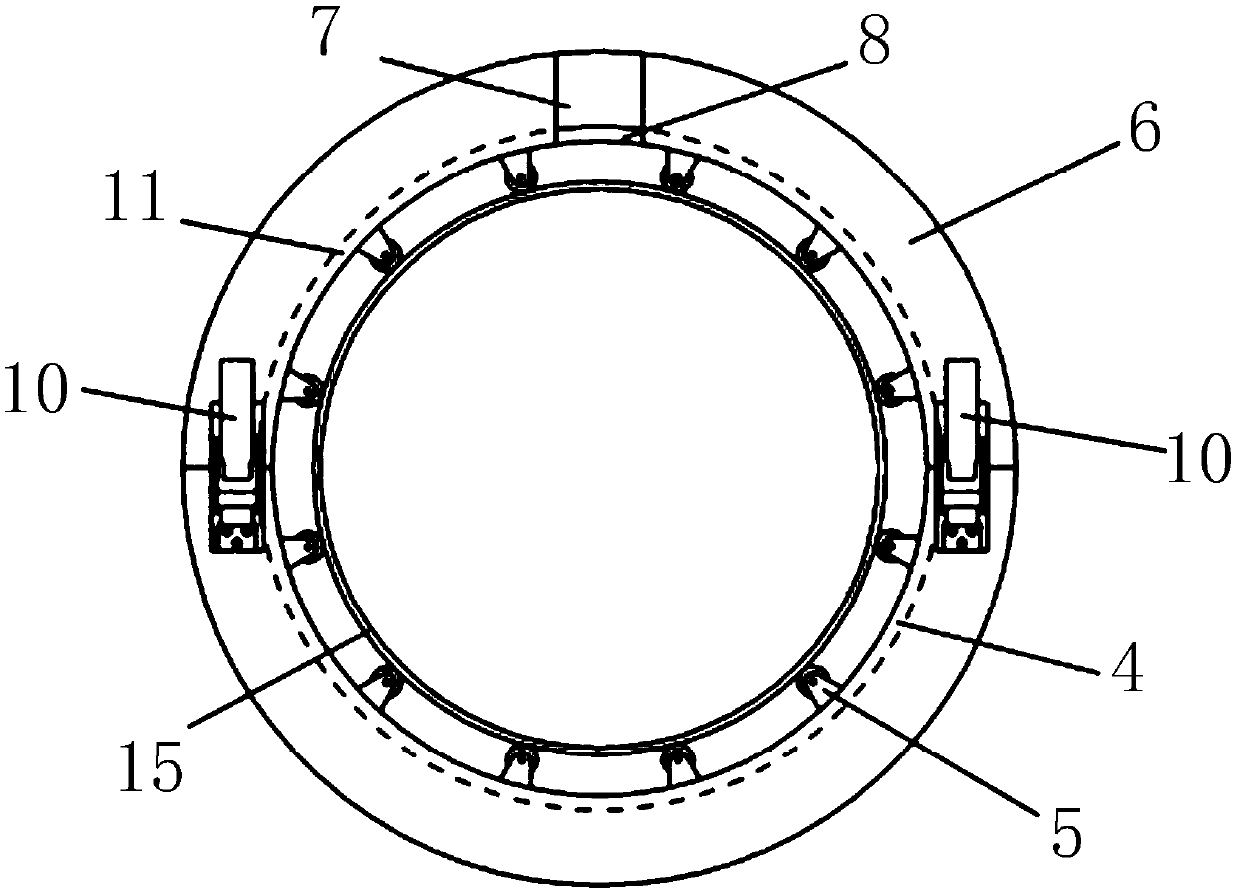

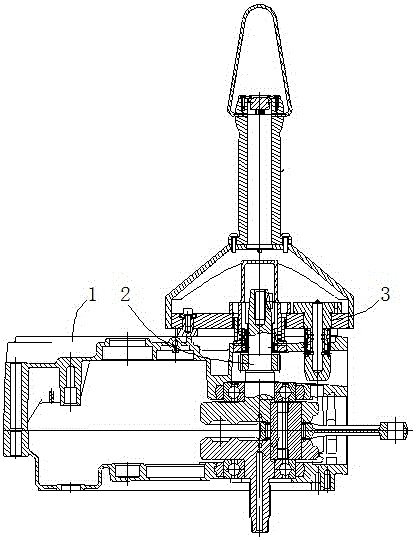

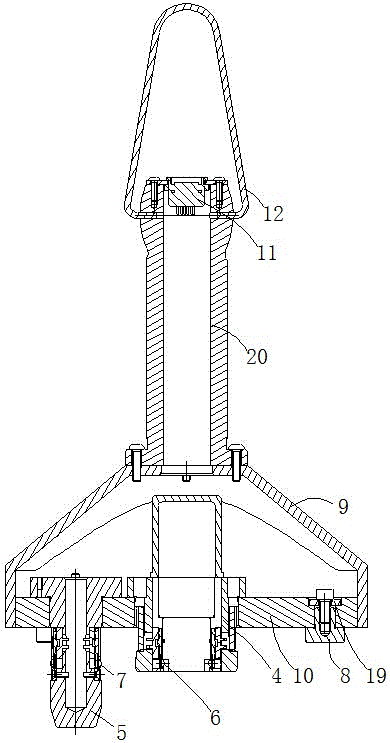

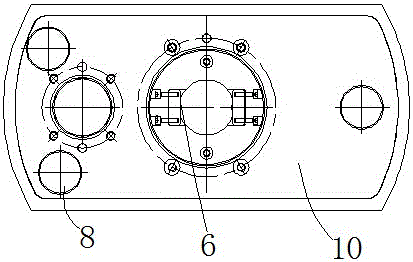

Coaxial casing pipe assembling device and method

ActiveCN105234669AReduce the difficulty of pairingReduce the number of adjustmentsMetal working apparatusEngineeringMechanical engineering

The invention provides a coaxial casing pipe assembling device and method. A die comprises an annular positioning ring, long adjusting devices and short adjusting devices. The annular positioning ring is of a cylindrical structure. The long adjusting devices and the short adjusting devices are evenly arranged on the two sides of the annular positioning ring in the circumferential direction at intervals and are fixed through clamps. The annular positioning ring and an outer casing pipe are positioned and connected through the short adjusting devices, and an inner casing pipe is adjusted and positioned through the long adjusting devices. According to the coaxial casing pipe assembling device and method, the structure is simple, operation is convenient, universality is high, precision is high, and repeated use can be achieved.

Owner:WUHAN YIYE STEEL STRUCTURE

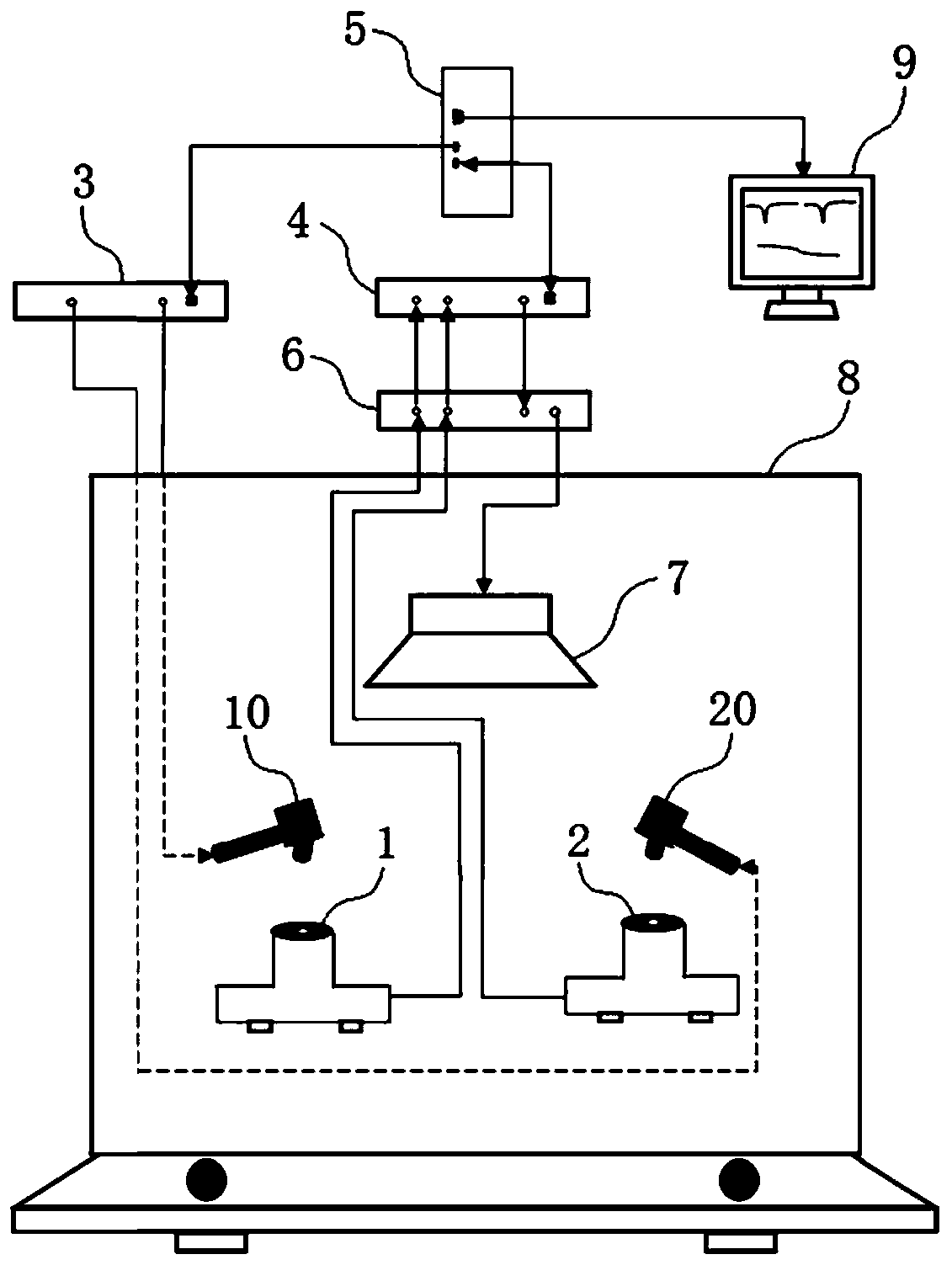

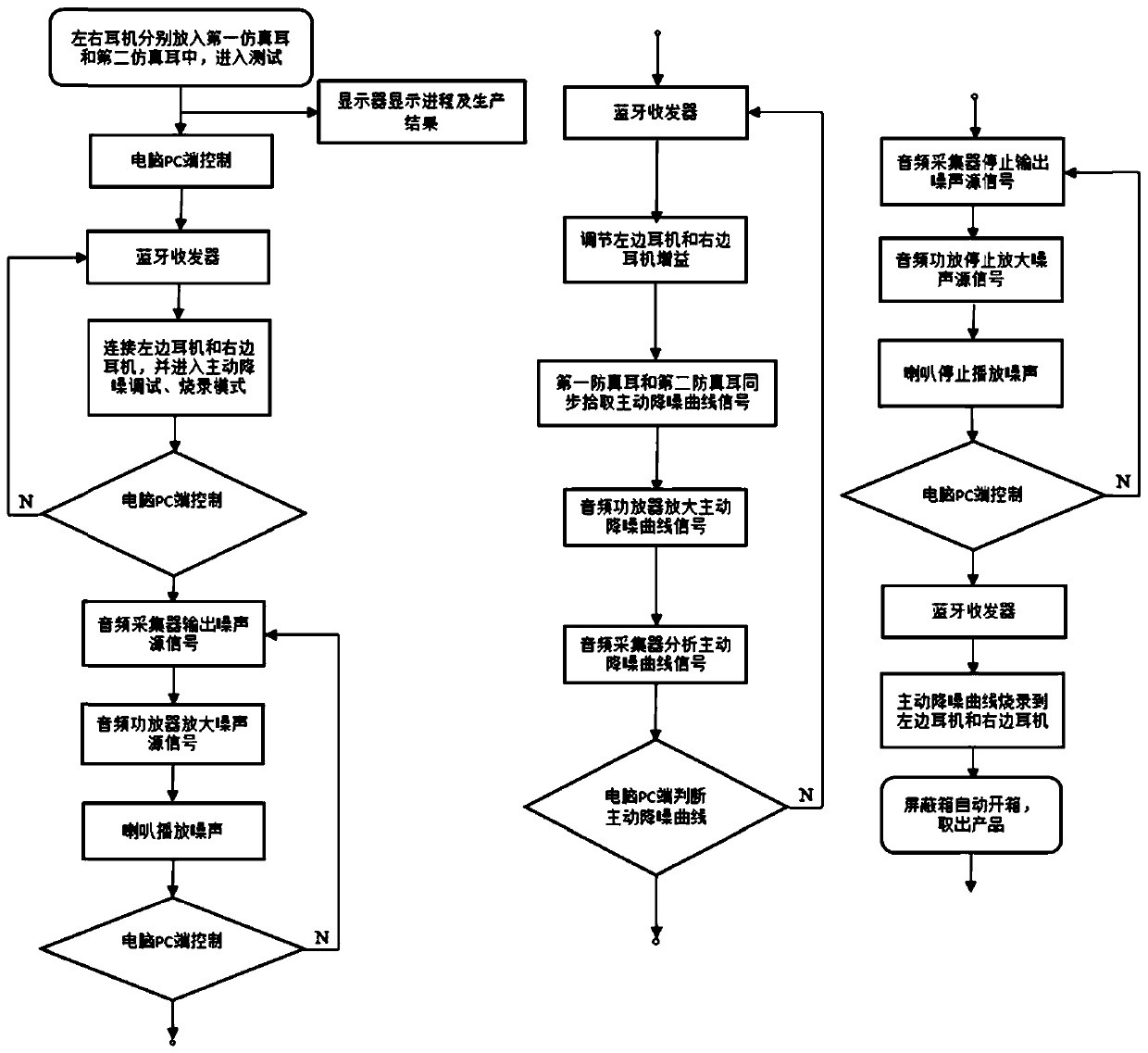

TWS Bluetooth earphone active noise reduction binaural automatic debugging and pairing system and method

PendingCN110278506AHigh precision of control standardsHigh precisionMicrophonesLoudspeakersBluetoothNoise reduction

The invention discloses a TWS Bluetooth earphone active noise reduction binaural automatic debugging and pairing system and method. The automatic debugging and pairing system can automatically produce active noise reduction curves for the left and right earphones of the TWS Bluetooth earphone at the same time, the automatic system is high in management and control standard precision, errors caused by manual gain adjustment and manual judgment are effectively avoided, the active noise reduction effect is good, the tone quality is high, and the user experience is effectively improved. Moreover, repeated operation of production actions of respective production of the left and right earphones is not needed, so that the operation time is saved, the pairing accuracy is improved, the production benefit is effectively improved, the manual operation is reduced, and the labor cost is reduced. The automatic debugging and pairing method can effectively complete debugging and pairing of the active noise reduction curves automatically produced by the left earphone and the right earphone of the TWS Bluetooth earphone at the same time, and can effectively produce the TWS Bluetooth left earphone and the TWS Bluetooth right earphone with the active noise reduction curves with high pairing precision, good active noise reduction effect and high tone quality.

Owner:HUIZHOU SOUTHVNDA ELECTRONICS TECH

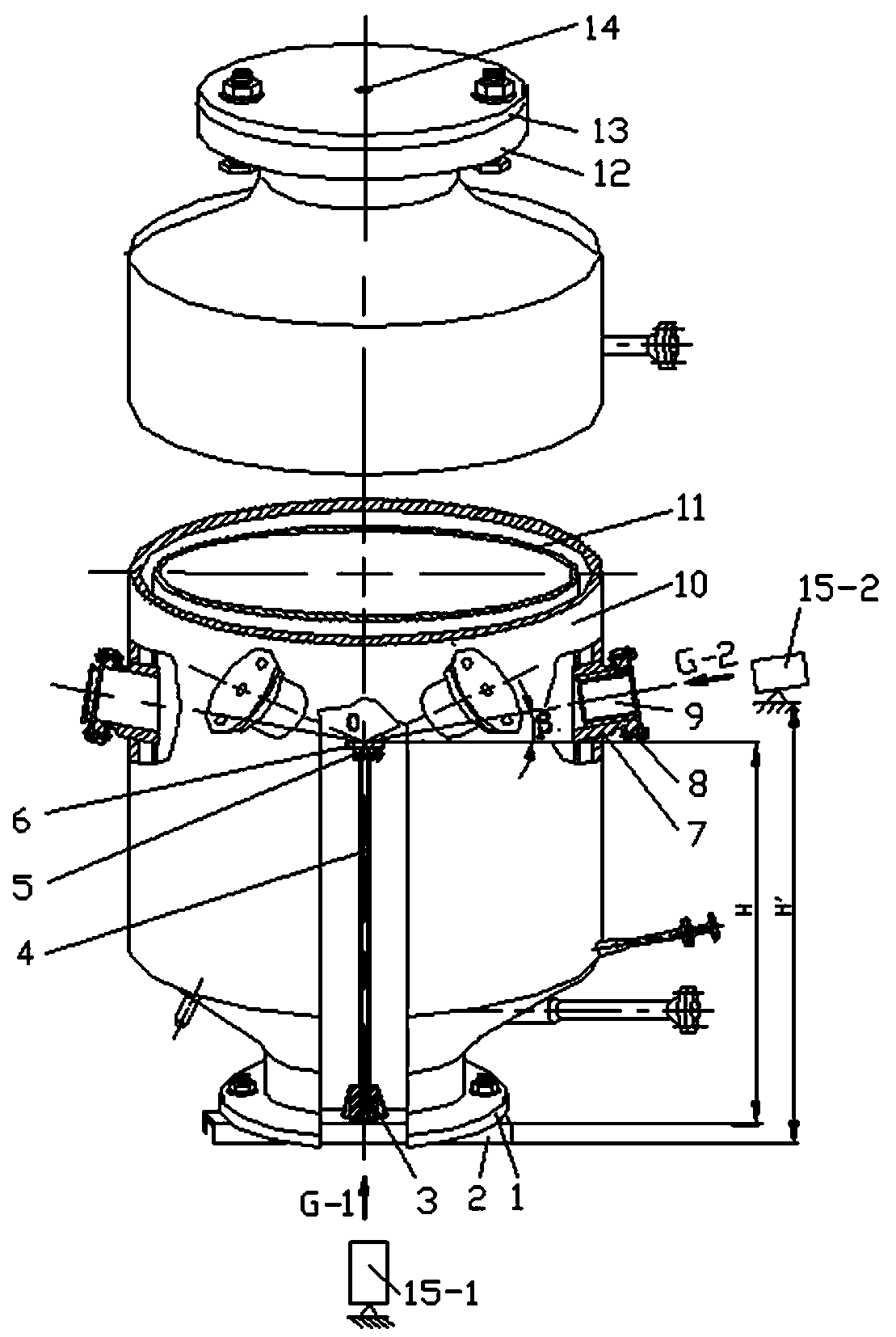

Accurate assembly method for oblique cutting connection pipes on large-diameter metal cylinder

ActiveCN103769744AExact pairingPrecision weldingWelding/cutting auxillary devicesAuxillary welding devicesPetrochemicalEngineering

Disclosed is an accurate assembly method for oblique cutting connection pipes on a large-diameter metal cylinder. A lower laser alignment hole seat, a positioning adjustment seat, a supporting pipe, a target plate seat, a target plate and an upper laser alignment hole seat are arranged by taking the bottom of a lower flange of a container as a datum, and laser beams are emitted from the lower laser alignment hole seat and penetrate a target hole and an upper laser alignment hole to determine the longitudinal axis of the cylinder. A scribing rod is mounted on the target plate seat, the included angle between the upper surface of the scribing rod and the upper surface of the target plate is adjusted into an angle stipulated by a design drawing, the centers of oblique cutting connection pipe holes are marked on the cylinder, and the oblique cutting connection pipe holes are formed. Connection pipe laser alignment hole seats are mounted on connection pipe flanges and inserted into the oblique cutting connection pipe holes of the cylinder, the laser beams are emitted by a laser collimator, penetrates hole in a top plate and a bottom plate of the hole seat and are intersected at the target hole in the target plate to perform welding, and the oblique cutting connection pipes on the large-diameter metal cylinder of pressure containers, metal pipelines and the like in petrochemical industry can be accurately assembled.

Owner:云南大为化工装备制造有限公司

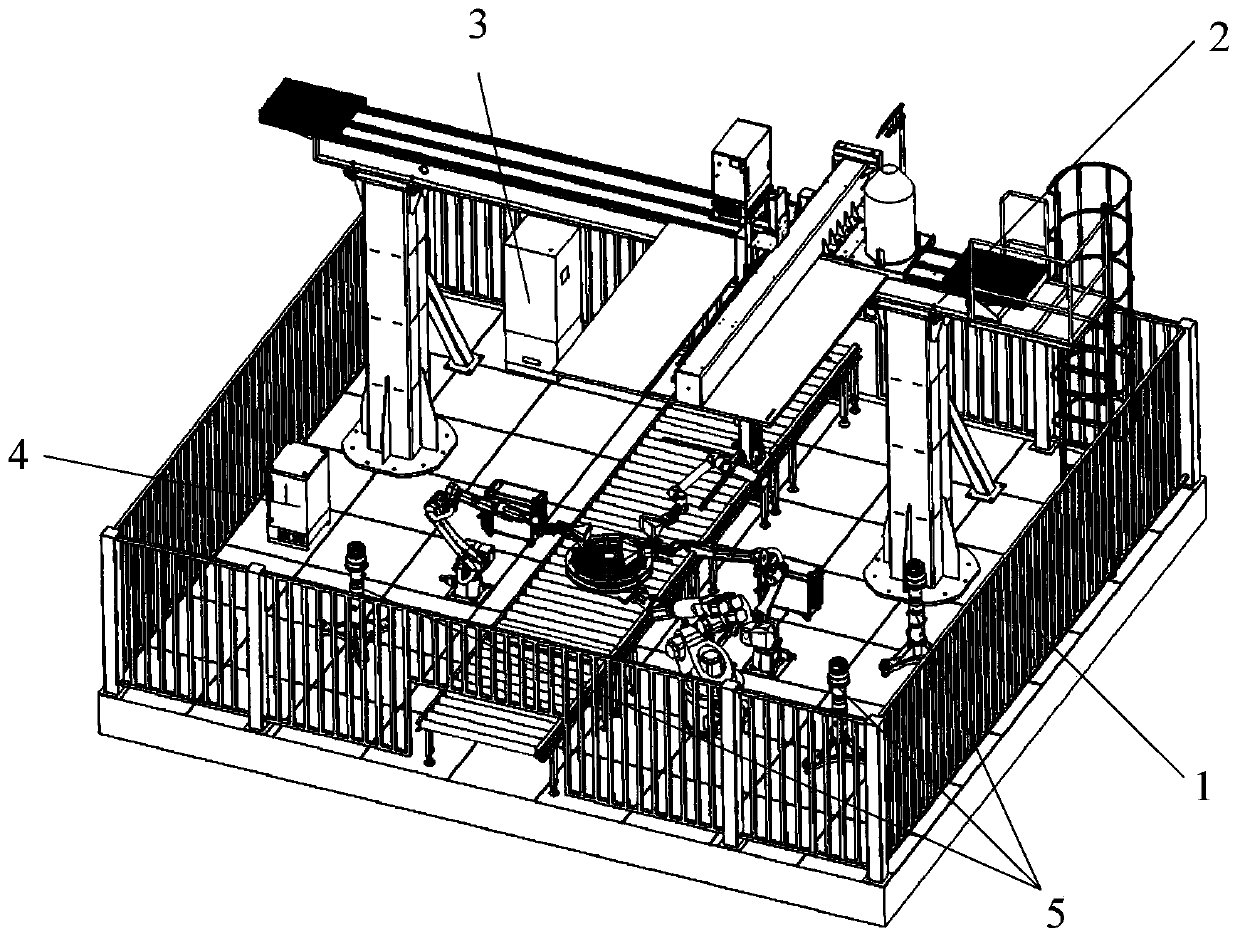

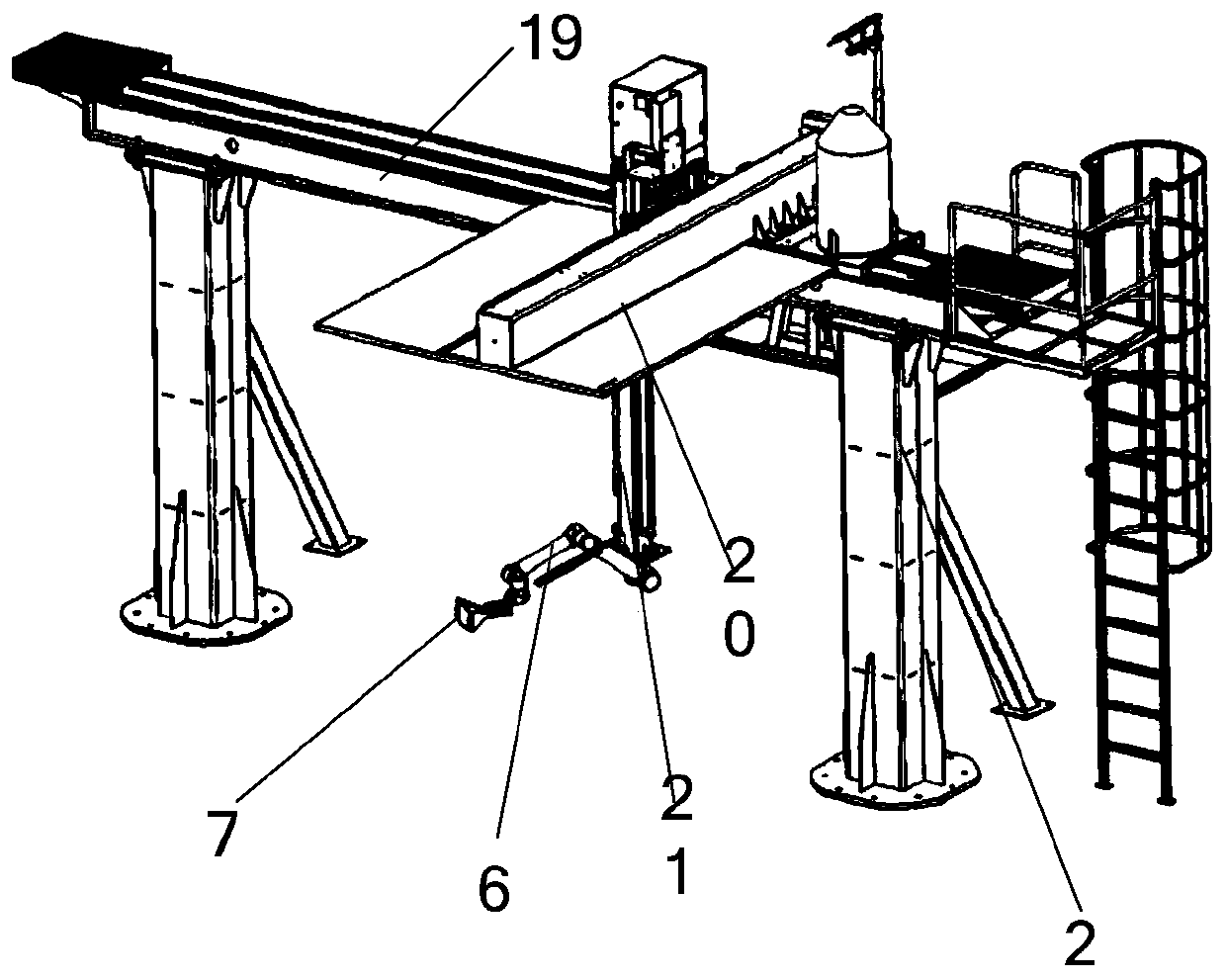

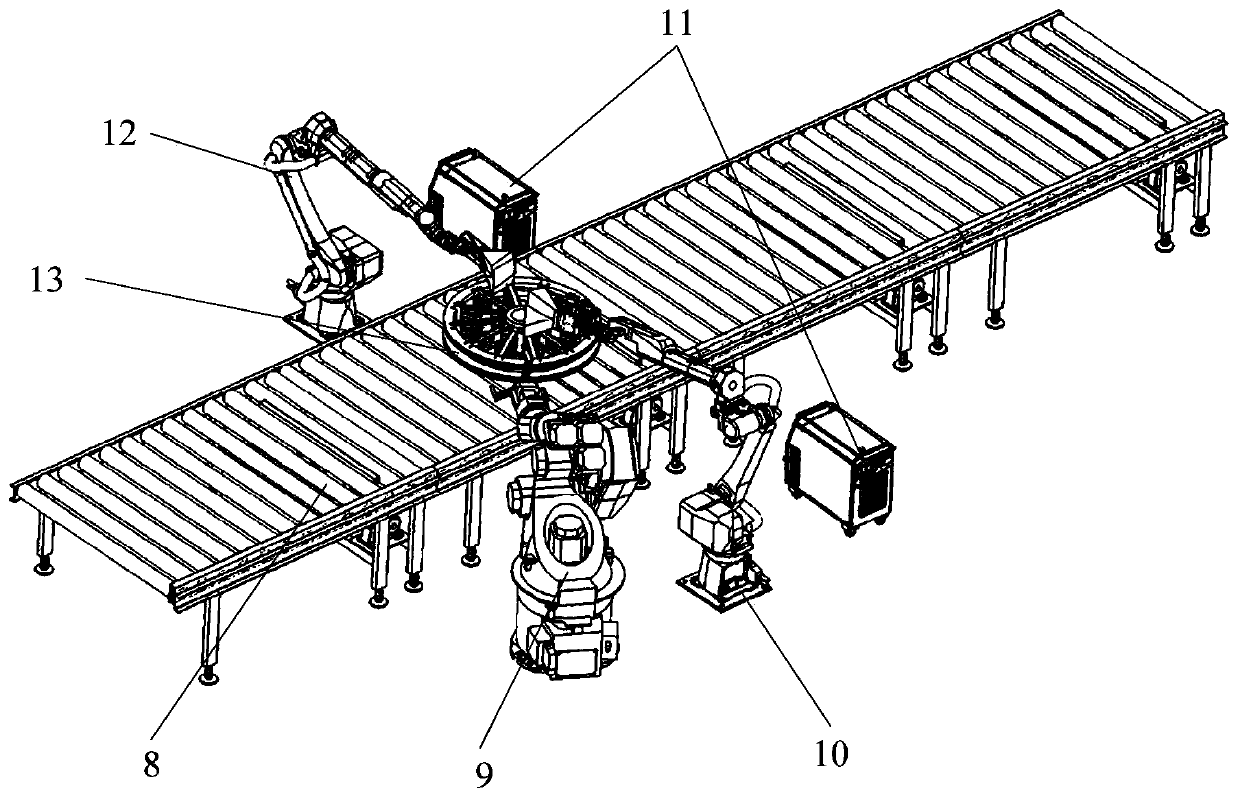

Flexible assembly welding robot workstation

ActiveCN110524582AImprove flexibilityHighly integratedProgramme-controlled manipulatorTotal factory controlEngineeringSpot welding

The invention discloses a flexible assembly welding robot workstation that comprises a global vision unit, a flexible welding robot group, a gantry truss detection unit, a master control unit and a conveying platform; the flexible welding robot group is arranged on the two sides of the conveying platform, welding workpieces are arranged on the conveying platform, the global vision unit is arrangedon the periphery of the flexible welding robot group, the gantry truss detection unit is arranged above the conveying platform, and the flexible welding robot group is controlled by the master control unit to conduct welding according to obtained image information. The high integration degree, high flexibility and high efficiency of the welding robot are achieved, the problems that manual assembly spot welding position deviation is large, and workpiece consistency is poor are solved, and the workpiece clamping and transferring frequency is effectively reduced. Multi-position assembly spot welding of workpieces is achieved, seamless connection of welding procedures is achieved, and the assembly precision, the welding consistency and the welding quality are improved.

Owner:XIAN ZHONGKE PHOTOELECTRIC PRECISION ENG CO LTD

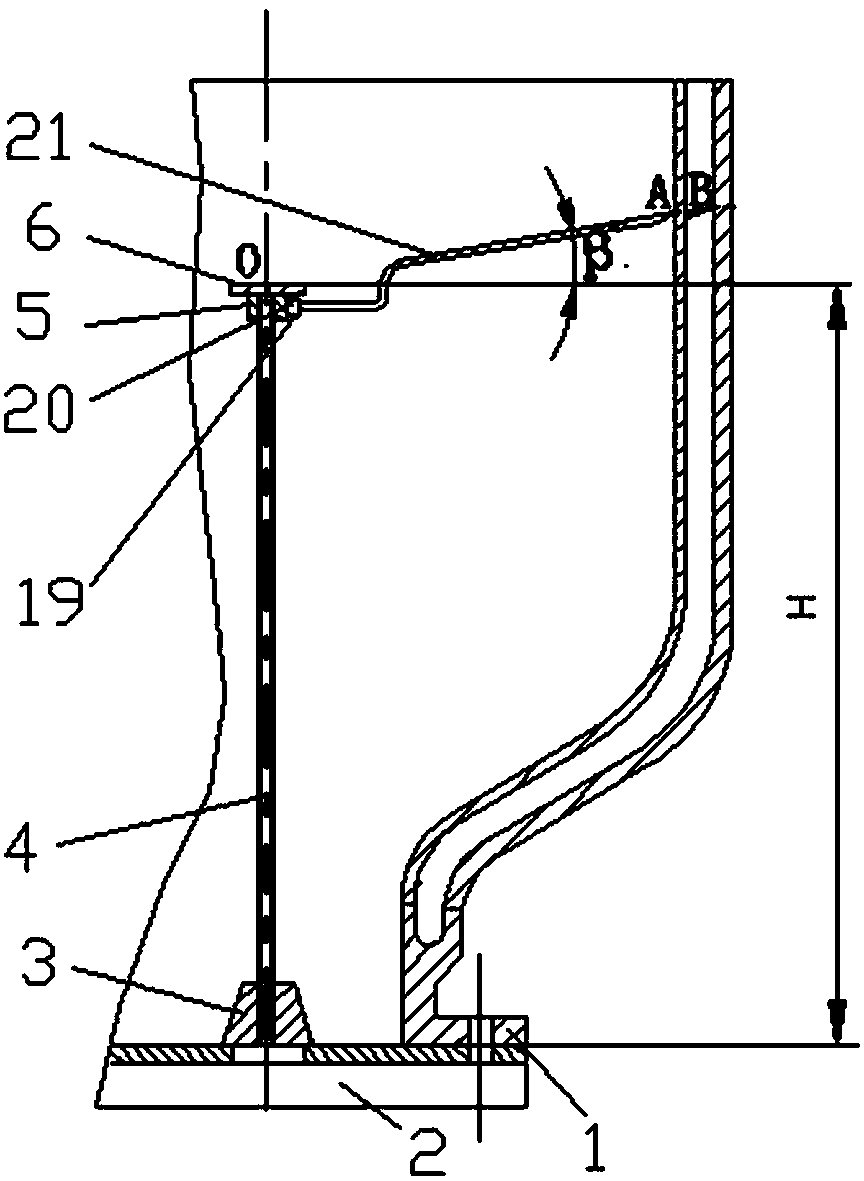

Metal framework and electrostatic discharging ring integrated structure for fingerprint sensor and manufacturing method thereof

InactiveCN104269393AAvoid position shiftImprove pairing accuracySemiconductor/solid-state device detailsSolid-state devicesManufacturing technologyMetal framework

The invention relates to a metal framework and electrostatic discharging ring integrated structure for a fingerprint sensor and a manufacturing method of the metal framework and electrostatic discharging ring integrated structure. The metal framework and electrostatic discharging ring integrated structure comprises a metal framework (1), wherein a groove is formed in the front side of the metal framework (1), an electrostatic discharging ring (10) is arranged on the periphery of the groove, a base island (2) and a pin (3) are arranged in the groove, the base island (2) comprises an upper base island portion and a lower base island portion, the pin (3) comprises an upper pin portion and a lower pin portion, a sensing chip (5) is arranged on the front side of the upper portion of the base island through chip mounting glue (4), and the front side of the sensing chip (5) is connected with the front side of the upper portion of the pin through a metal bonding wire (6). The metal framework and electrostatic discharging ring integrated structure for the fingerprint sensor and the manufacturing method of the metal framework and electrostatic discharging ring integrated structure have the advantages that the electrostatic discharging ring and the metal framework are of the integrated structure, the manufacturing technology is simple, the problem of position offset caused when a traditional electrostatic discharging ring is assembled to a framework is avoided, the matching accuracy of the positions of the electrostatic discharging ring and the sensing chip is improved, and thus the recognition effect of the sensing chip is improved.

Owner:JCET GROUP CO LTD

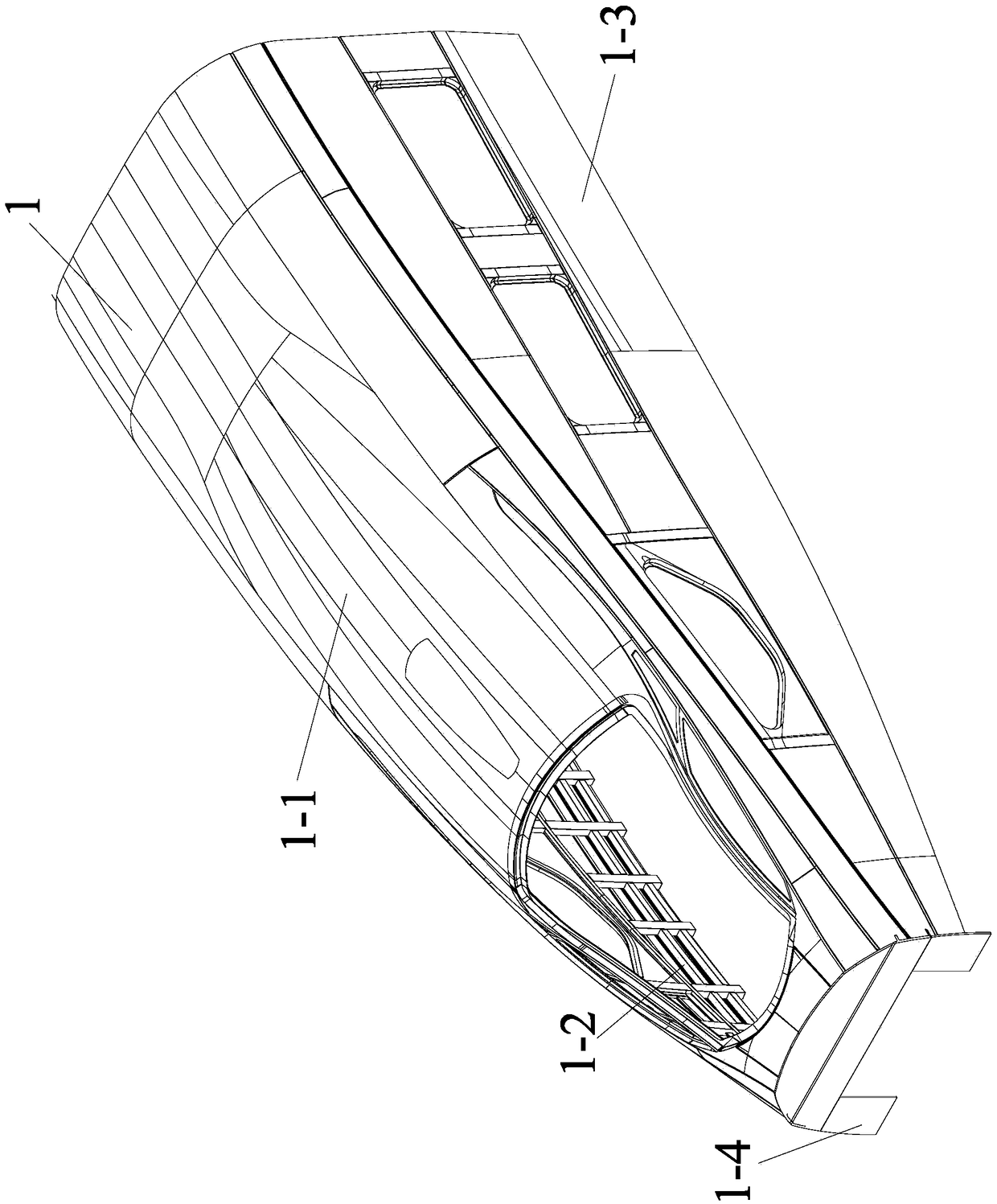

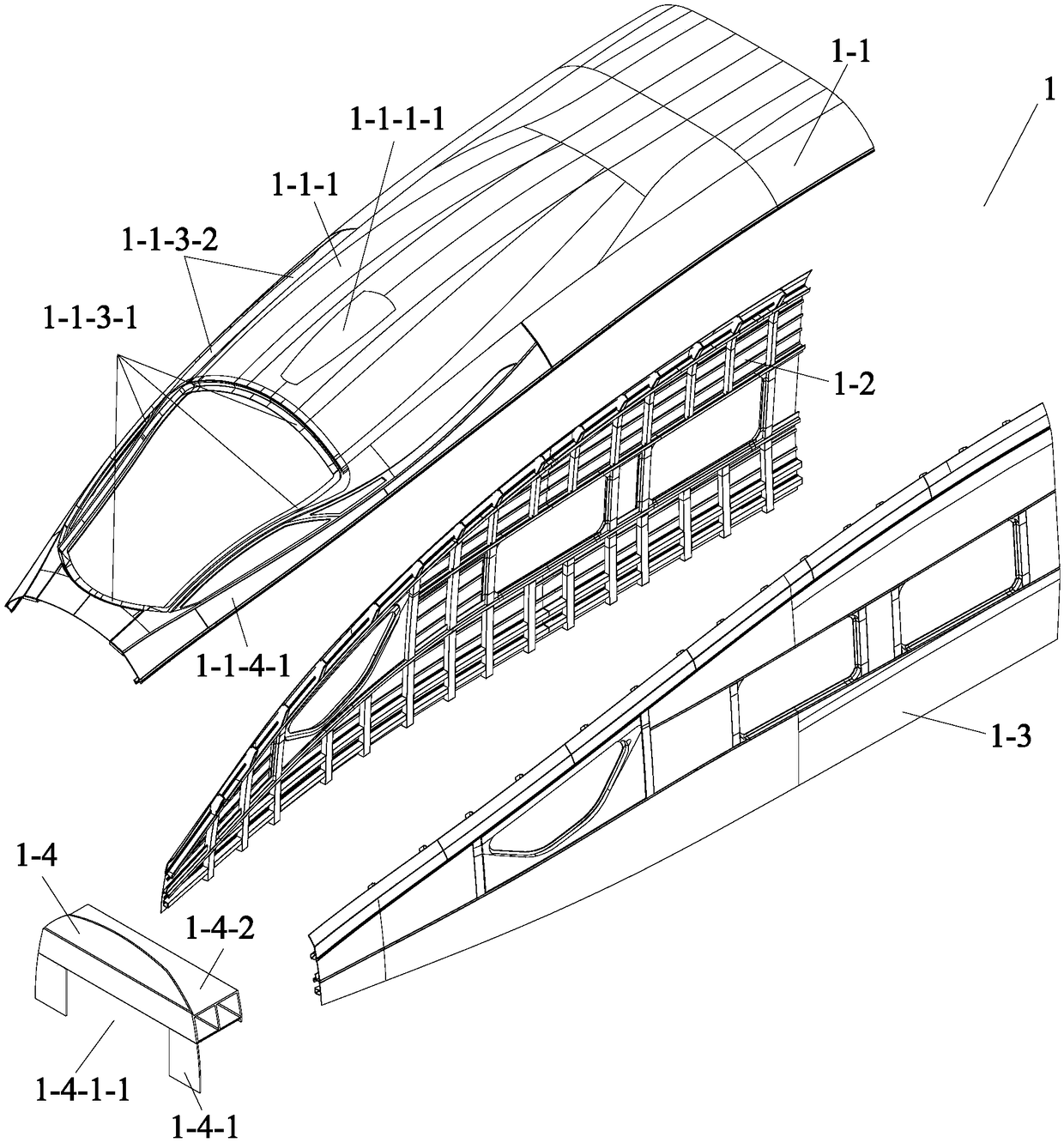

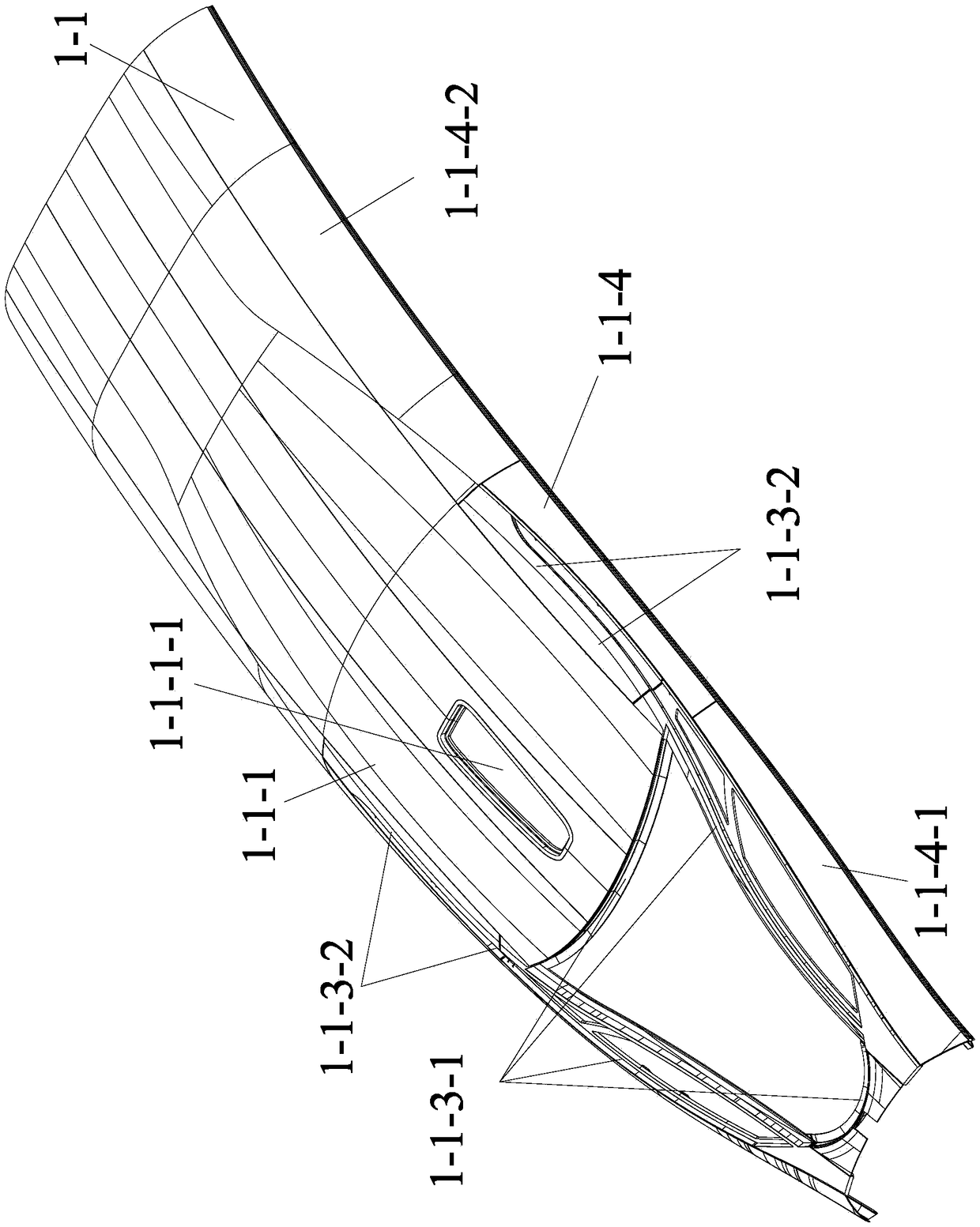

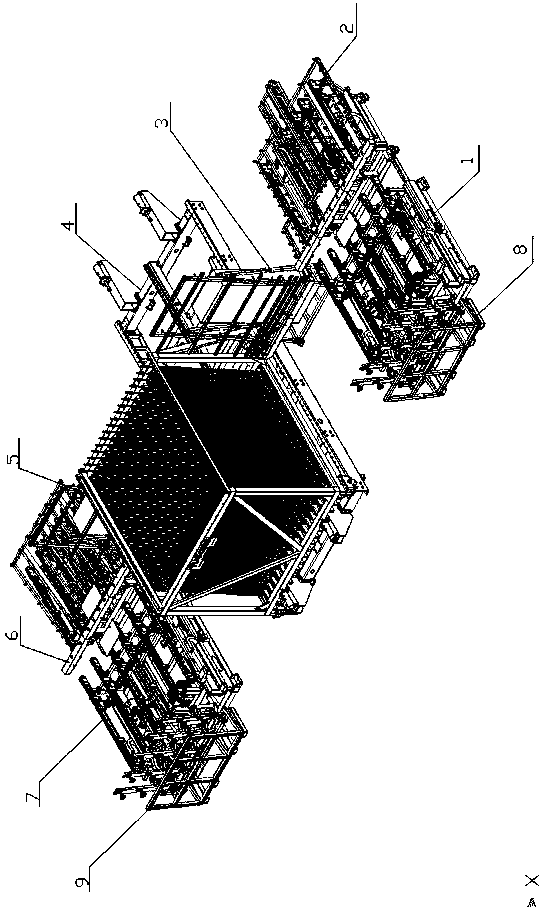

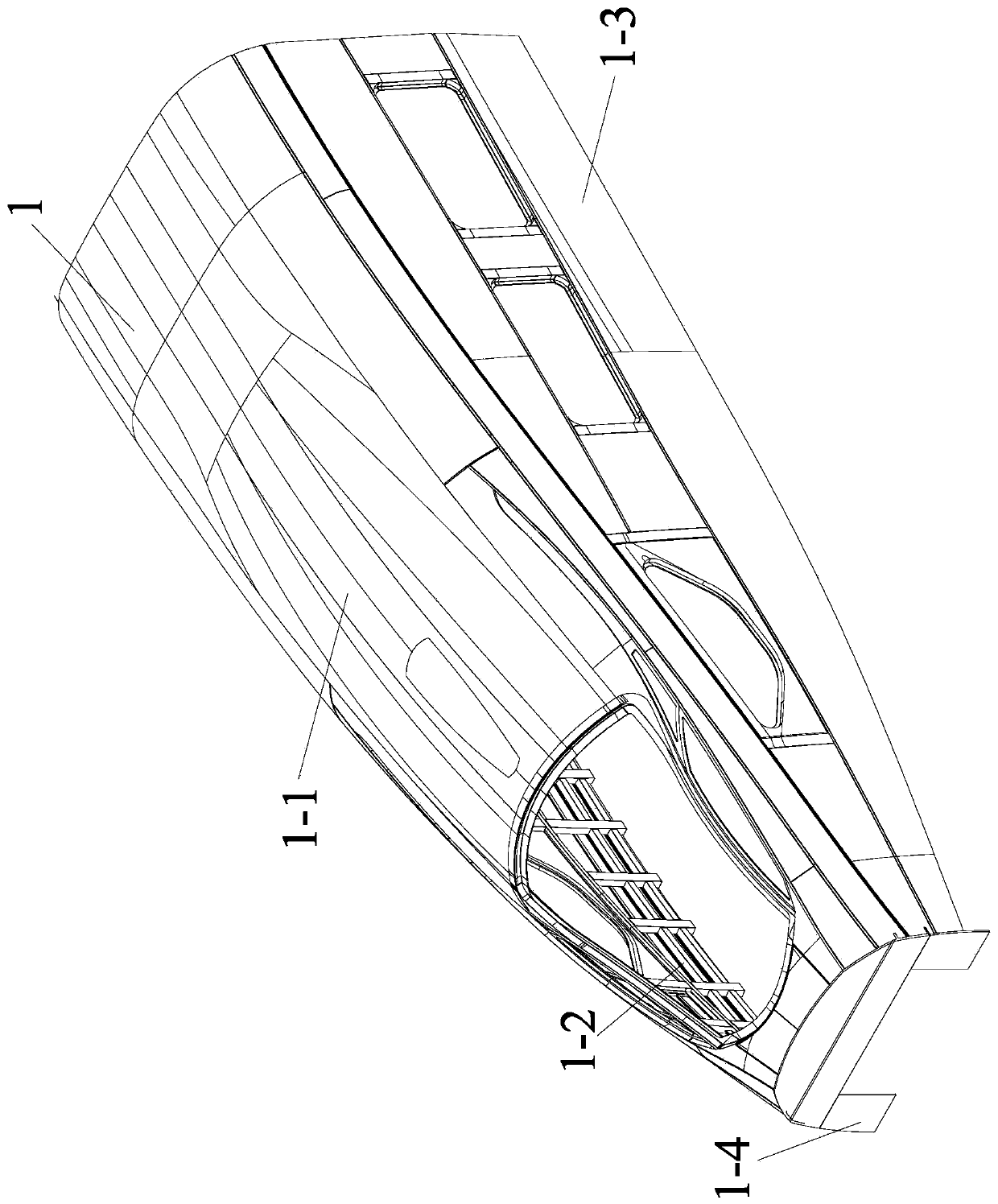

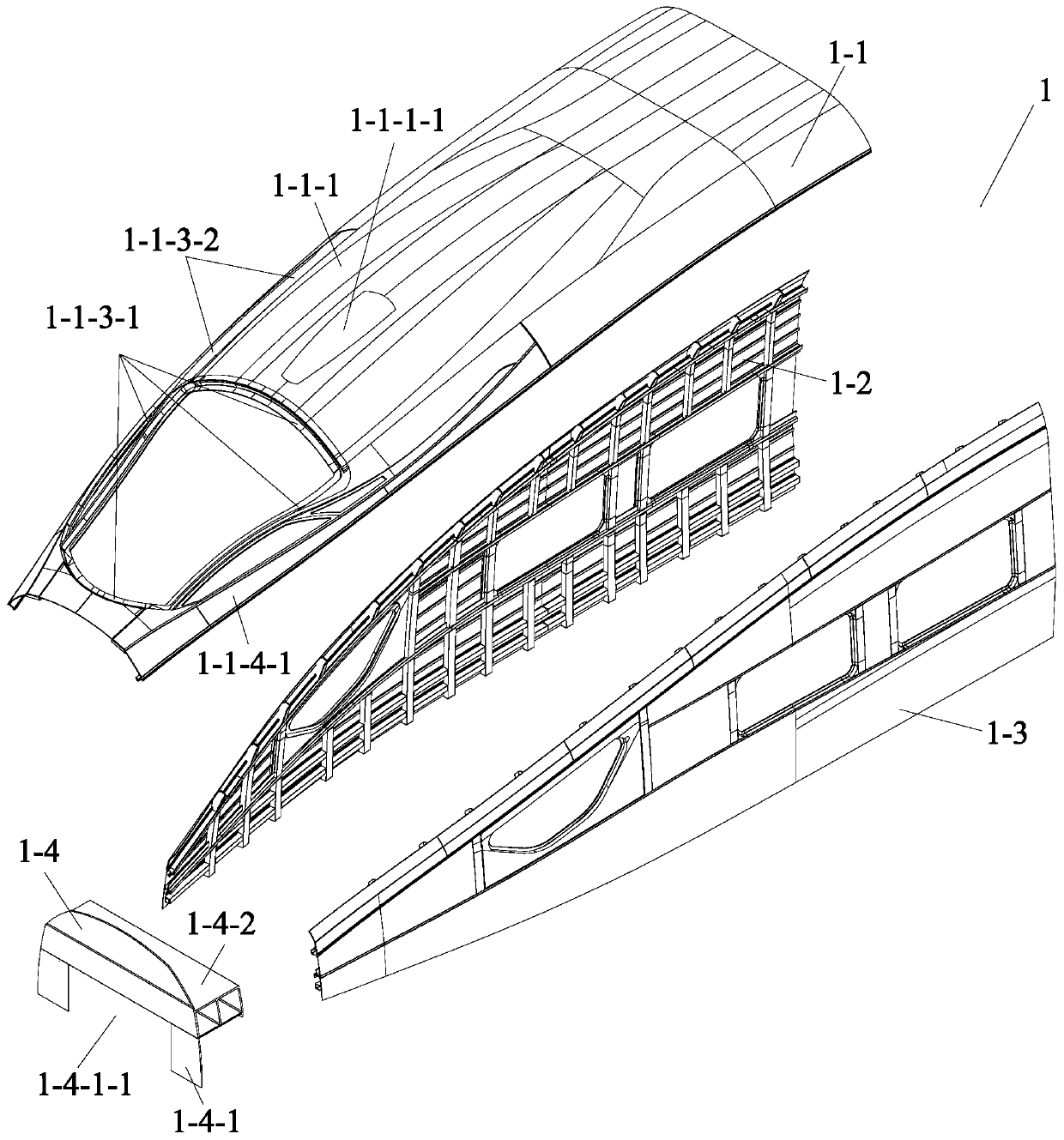

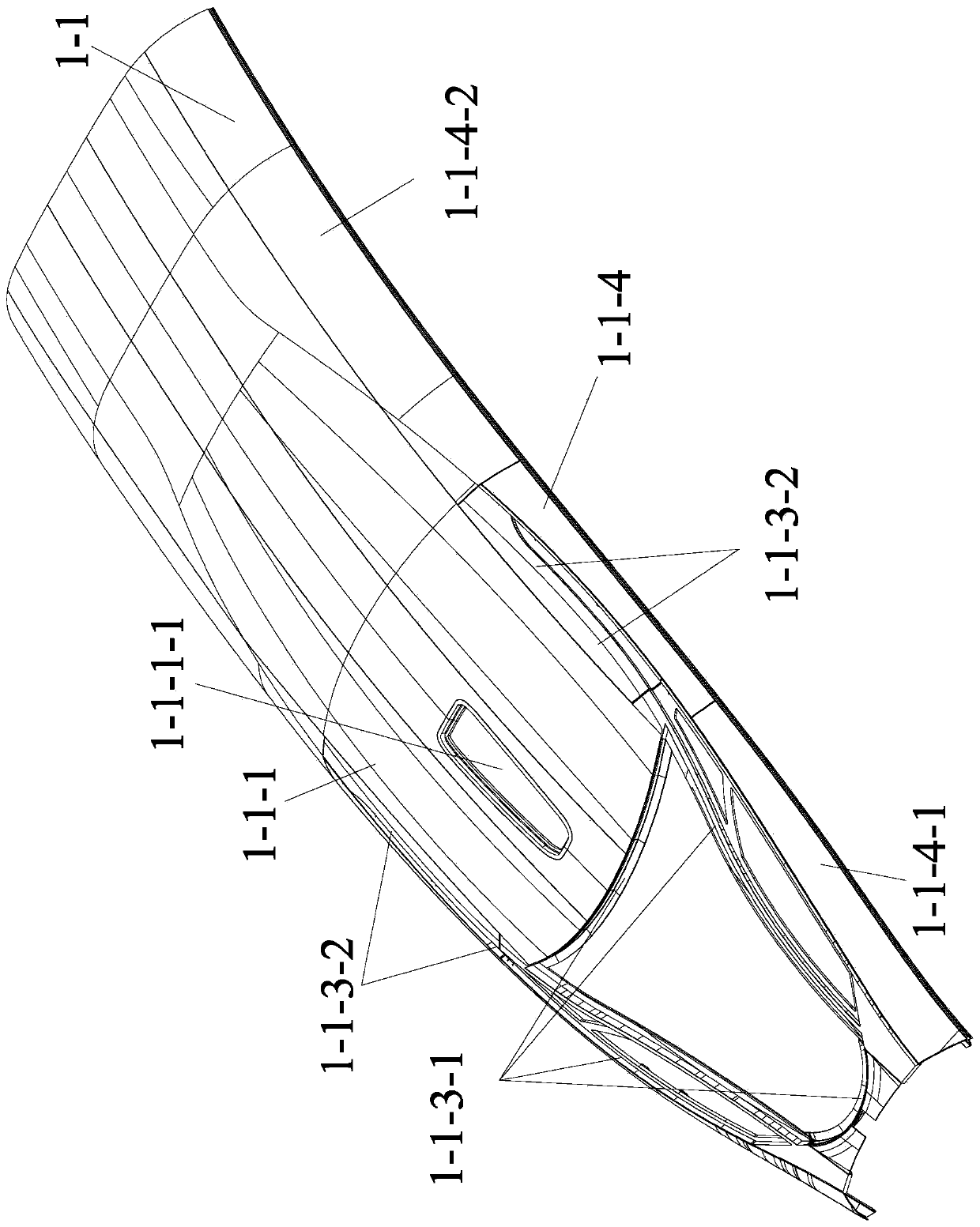

High-speed train first train body assembling device and assembling method thereof

ActiveCN109483128AAdjustable lengthPrecise positioningWelding/cutting auxillary devicesAuxillary welding devicesVertical planeUltimate tensile strength

The invention discloses a high-speed train first train body assembling device and an assembling method thereof, and belongs to the field of welding, assembling and auxiliary positioning devices for train first train bodies. The device comprises a train roof assembling tool, a front window frame positioning tool, a train roof hoisting tool, a side wall assembling tool and a train body front end plate assembling tool; train roof assembling and welding are completed through the train roof assembling tool; train body front end plates are located at the standard positions of the end of the side wall assembling tool through the train body front end plate assembling tool; and positioning operation of train roofs and the side wall assembling tool is completed through the train roof hoisting tool and the front window frame positioning tool. According to the high-speed train first train body assembling device and an assembling method thereof, the train roofs can be assembled, welded and machinedon the ground through the train roof assembling tool, the positioning efficiency and the assembling precision of all parts of the train roofs both can be significantly improved, then the symmetry ofthe central vertical plane of the train roofs is significantly improved, therefore, the wind resistance and waggling and noise which are generated when a train runs at high speed can be significantlyreduced, the mechanical transmission path can be optimized, and the structural strength of a train body is further improved.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

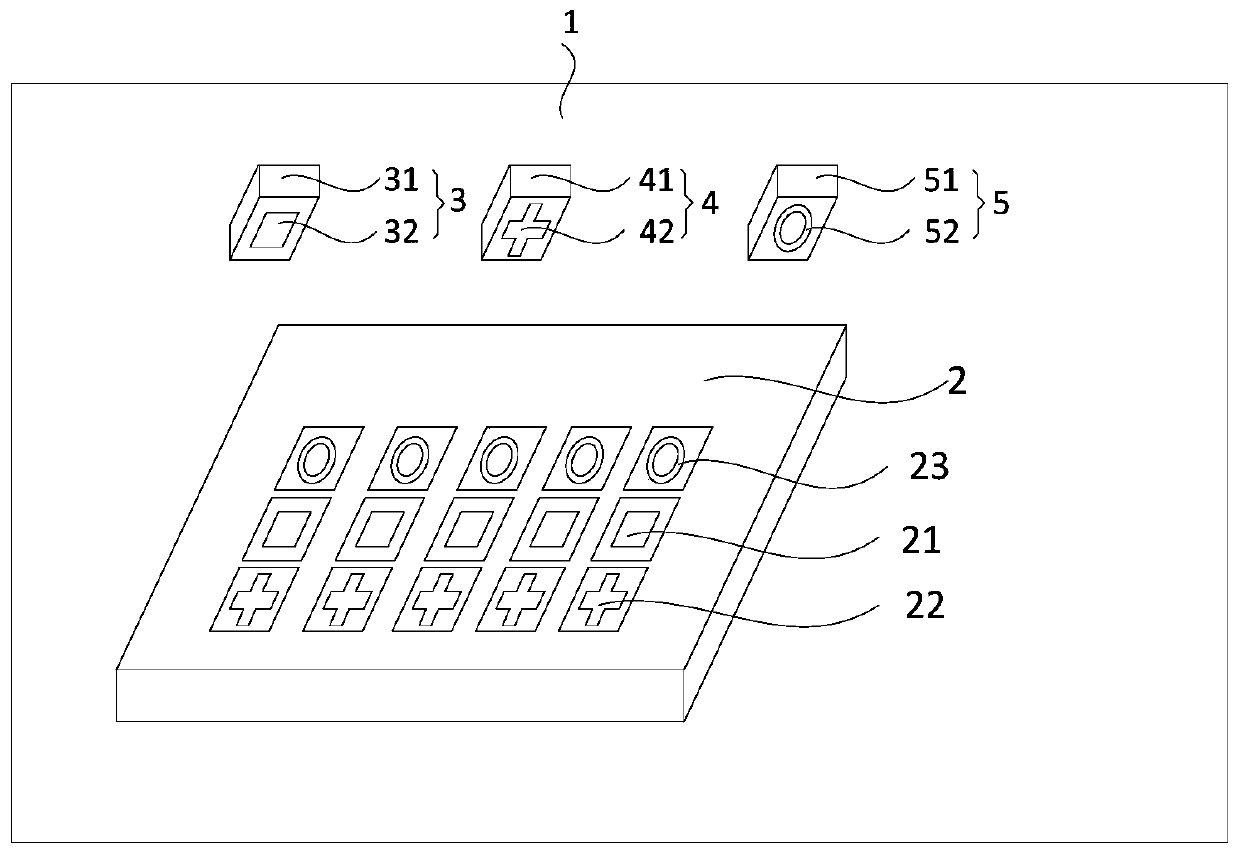

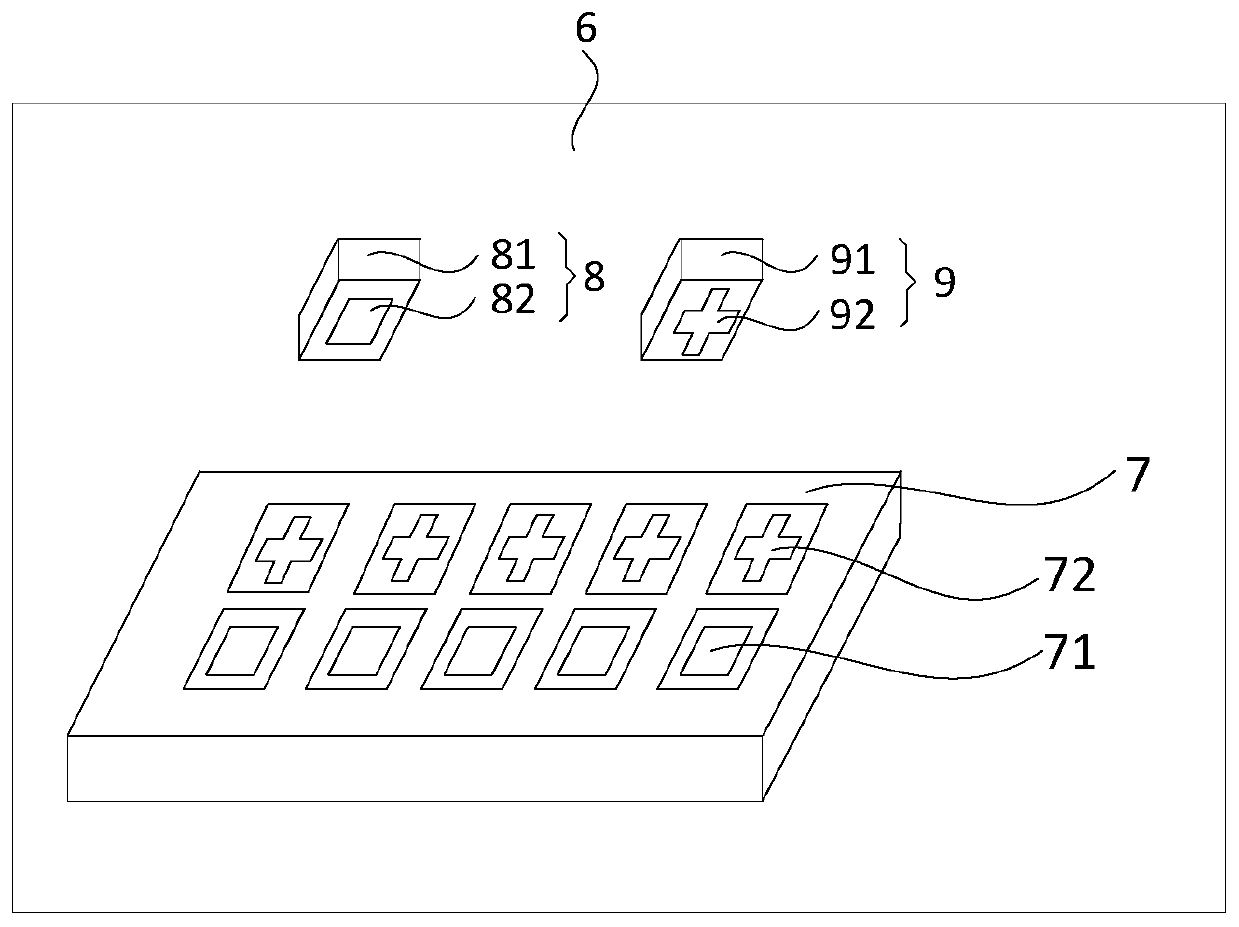

Light emitting diode display

ActiveCN110634906ASolve the problem of mass transferImprove pairing accuracySolid-state devicesSemiconductor devicesLED displayDisplay device

The invention discloses a light emitting diode display, which comprises a plurality of light emitting diodes and a circuit substrate, wherein each light emitting diode comprises a light emitting diodechip and a first patterned magnetic electrode layer, and the first magnetic electrode layer is the positive electrode and / or the negative electrode of the light emitting diode chip; and the circuit substrate is used for driving the plurality of light emitting diodes, the circuit substrate comprises a plurality of second patterned magnetic electrode layers which are arranged in a matrix, and the second magnetic electrode layers are used for adsorbing and connecting the light emitting diodes. On the basis of not influencing the structure of the original device, the problem of massive transfer is solved, higher pairing accuracy is achieved, and the assembly efficiency is improved.

Owner:SHENZHEN SITAN TECH CO LTD

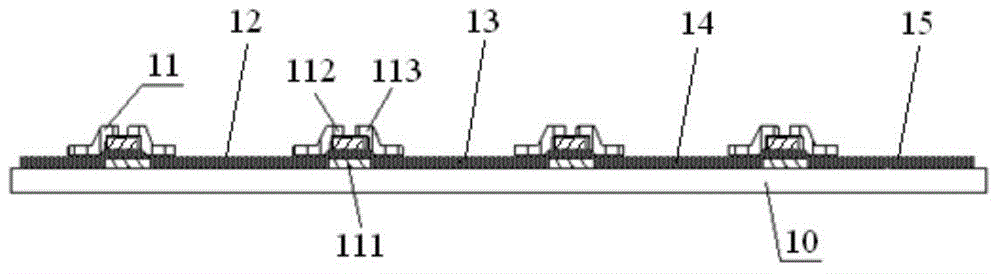

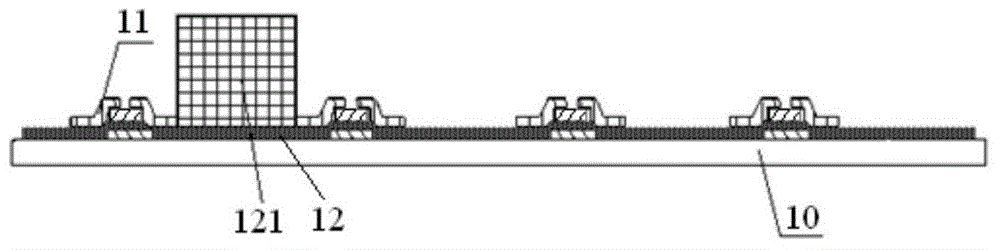

Manufacturing method for array substrate and array substrate

InactiveCN105068336AIncrease opening ratioImprove pairing accuracyNon-linear opticsOptoelectronicsResistor

The invention discloses a manufacturing method for an array substrate and the array substrate. The method includes the steps that a plurality of control electrodes are formed on the substrate so that a first color resistance area, a second color resistance area, a third color resistance area and a fourth color resistance area are formed between adjacent control electrodes respectively; a first color resistor is formed on the first color resistance area, a second color resistor is formed on the second color resistance area and a third color resistor is formed on the third color resistance area in sequence; the substrate where the control electrodes, the first color resistor, the second color resistor and the third color resistor are formed, and the fourth color resistance area are internally coated with transparent color resistors to form a flat layer. The manufacturing method further improves production efficiency of the array substrate.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD +1

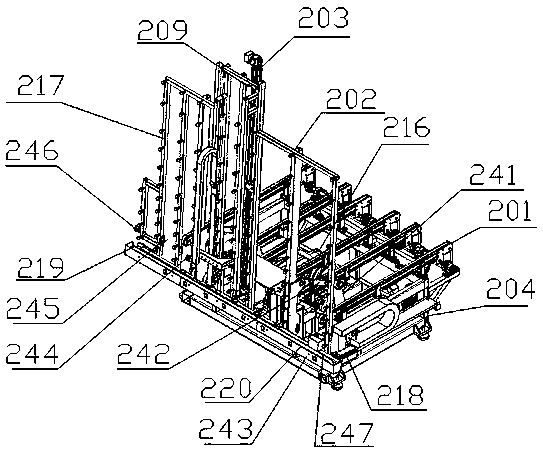

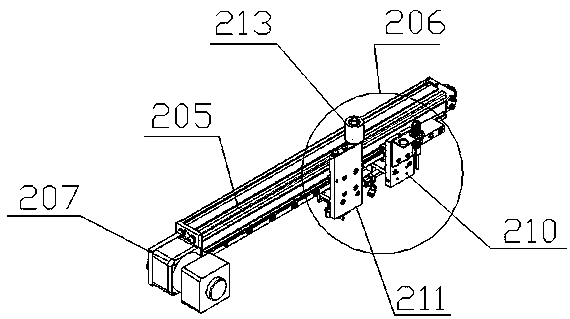

Automatic glass inspection and film production system and application method thereof

PendingCN108680113AVersatileEfficient and accurate length and width measurementUsing optical meansEngineeringMechanical engineering

The invention discloses an automatic glass inspection and film production system and an application method thereof. The system comprises an automatic loading platform and an automatic unloading platform used for automatically loading and unloading the glass, and a horizontal measurement roll-over platform, a film machine and a vertical roll-over platform which are sequentially arranged between theautomatic loading platform and the automatic unloading platform according to operation. The automatic loading platform is used for loading the glass to the horizontal measurement roll-over platform,the horizontal measurement roll-over platform is used for realizing rotation of the glass from a horizontal state to a vertical state, after length of the glass is measured, the glass is sent to the film machine, the output-needing glass in the film machine is conveyed to the vertical roll-over platform, the vertical roll-over platform is used for realizing rotation of the glass from a vertical state into a flat state, and the glass is unloaded through the automatic unloading platform. The system is advantaged in that functions are complete, the automation degree is high, work efficiency is improved, manpower is greatly reduced, length measurement of the glass is efficient and accurate, film matching precision is high, connection performance in the glass conveying process is excellent, andscratch is not easy to occur.

Owner:HANGZHOU YUGONG INTELLIGENT EQUIP CO LTD

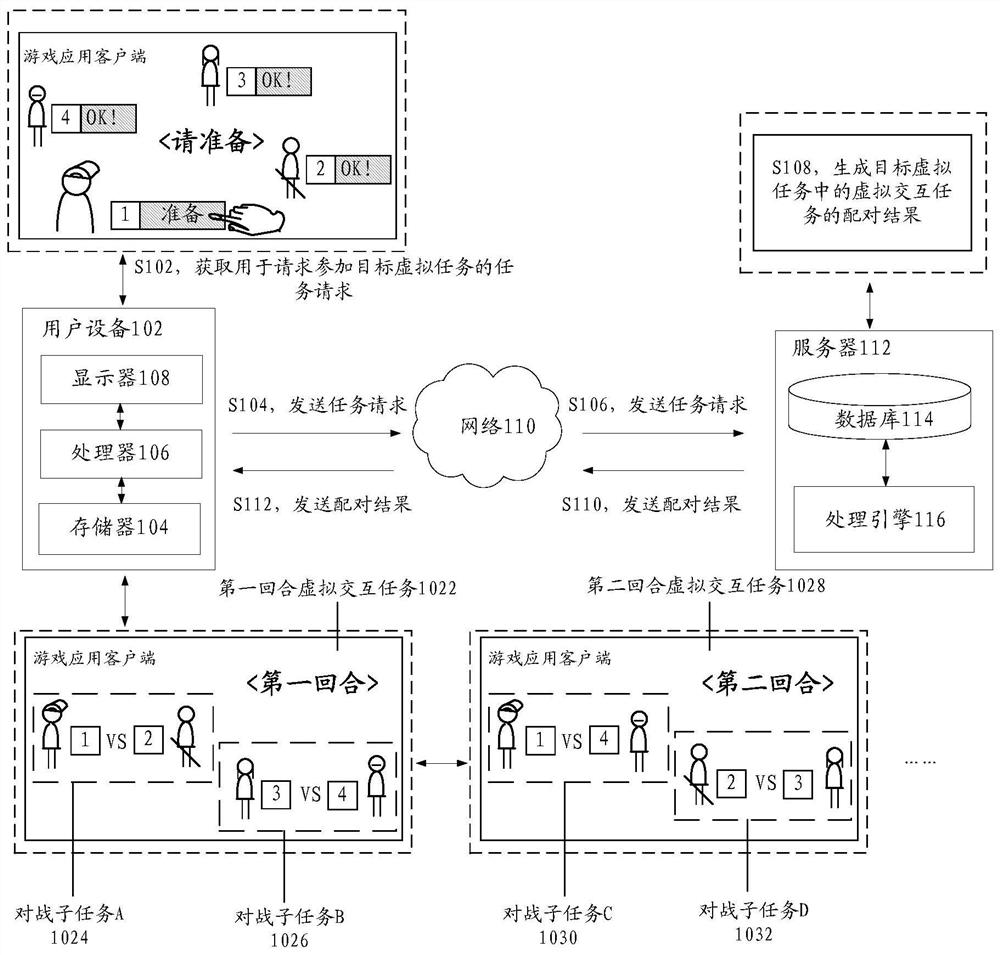

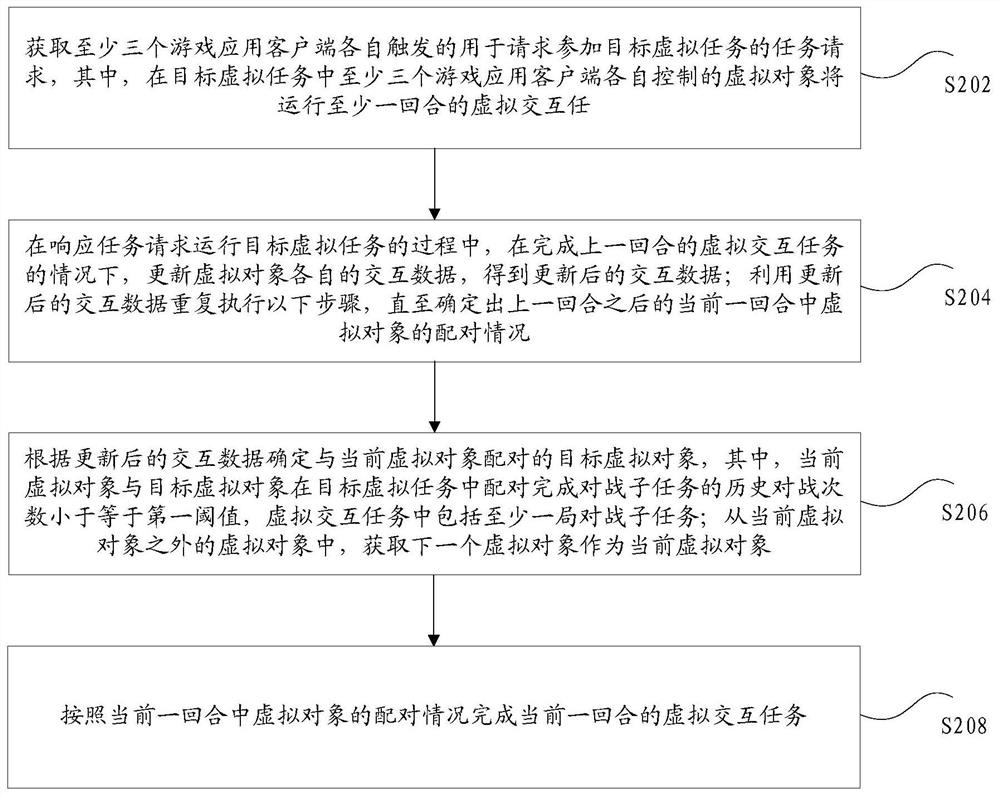

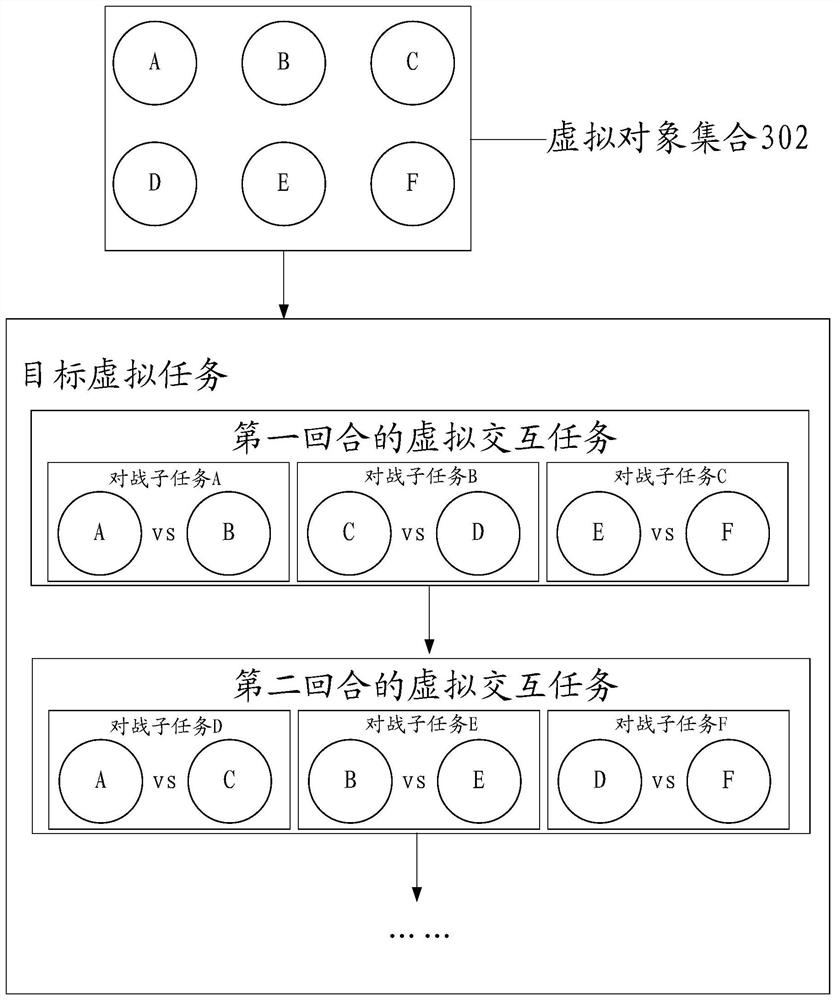

Virtual object pairing method and device thereof and storage medium

ActiveCN112121441AImprove pairing accuracySolve technical issues with low pairing accuracyVideo gamesComputer hardwareComputer engineering

The invention discloses a virtual object pairing method and a device and a storage medium. The method comprises the steps that task requests triggered by game application clients respectively and usedfor requesting to participate in a target virtual task are acquired; in the process of responding to the task request to run the target virtual task, under the condition that the last round of virtual interaction task is completed, the interaction data of the virtual objects are updated, and the updated interaction data are obtained; the following steps are repeatedly executed by utilizing the updated interaction data until the pairing condition of the virtual object in the current round after the previous round is determined; a target virtual object paired with the current virtual object isdetermined according to the updated interaction data; the next virtual object is obtained from the virtual objects except the current virtual object as the current virtual object; and the virtual interaction task of the current round is completed according to the pairing condition of the virtual object in the current round. According to the invention, the technical problem of low pairing accuracyof the virtual object is solved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

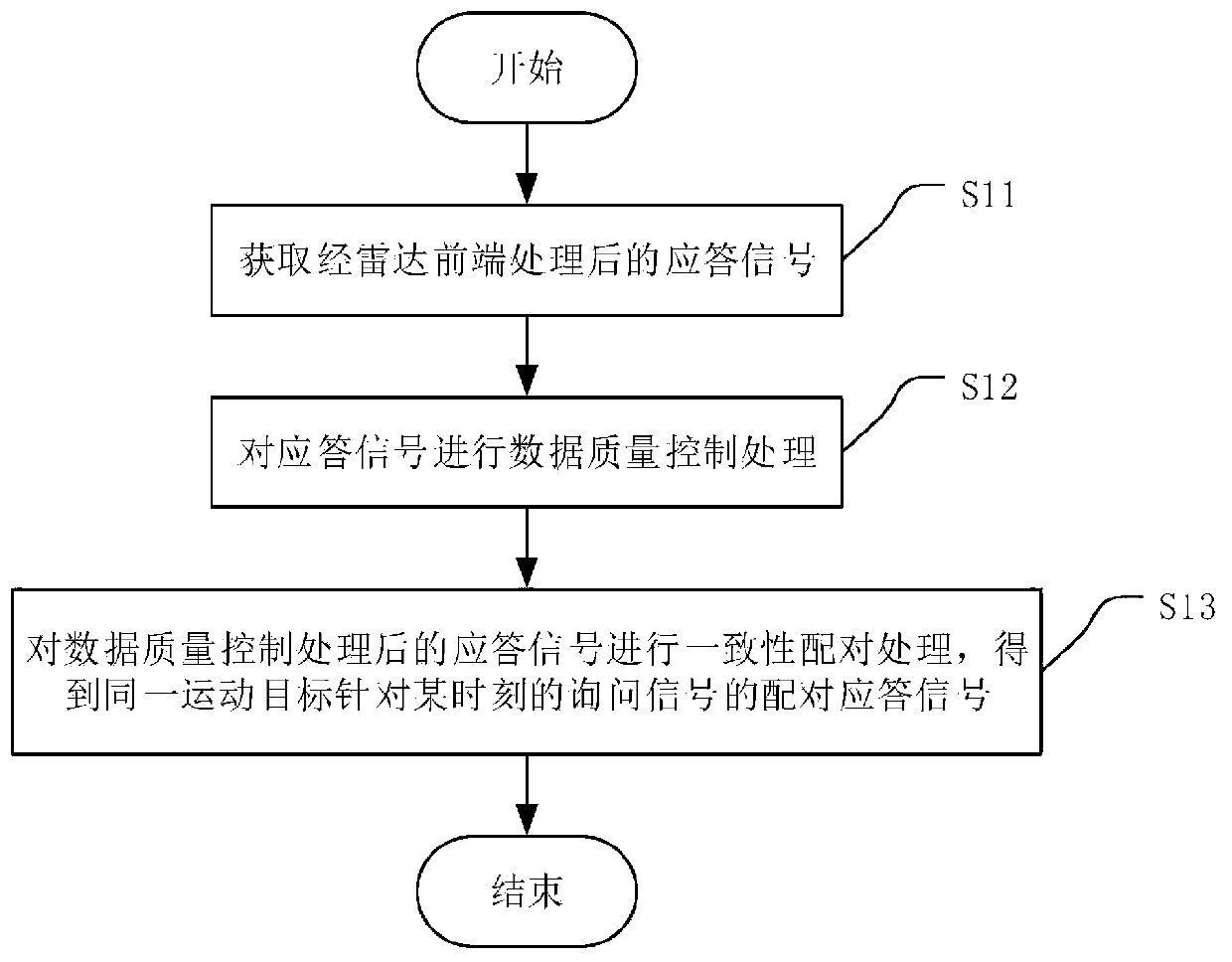

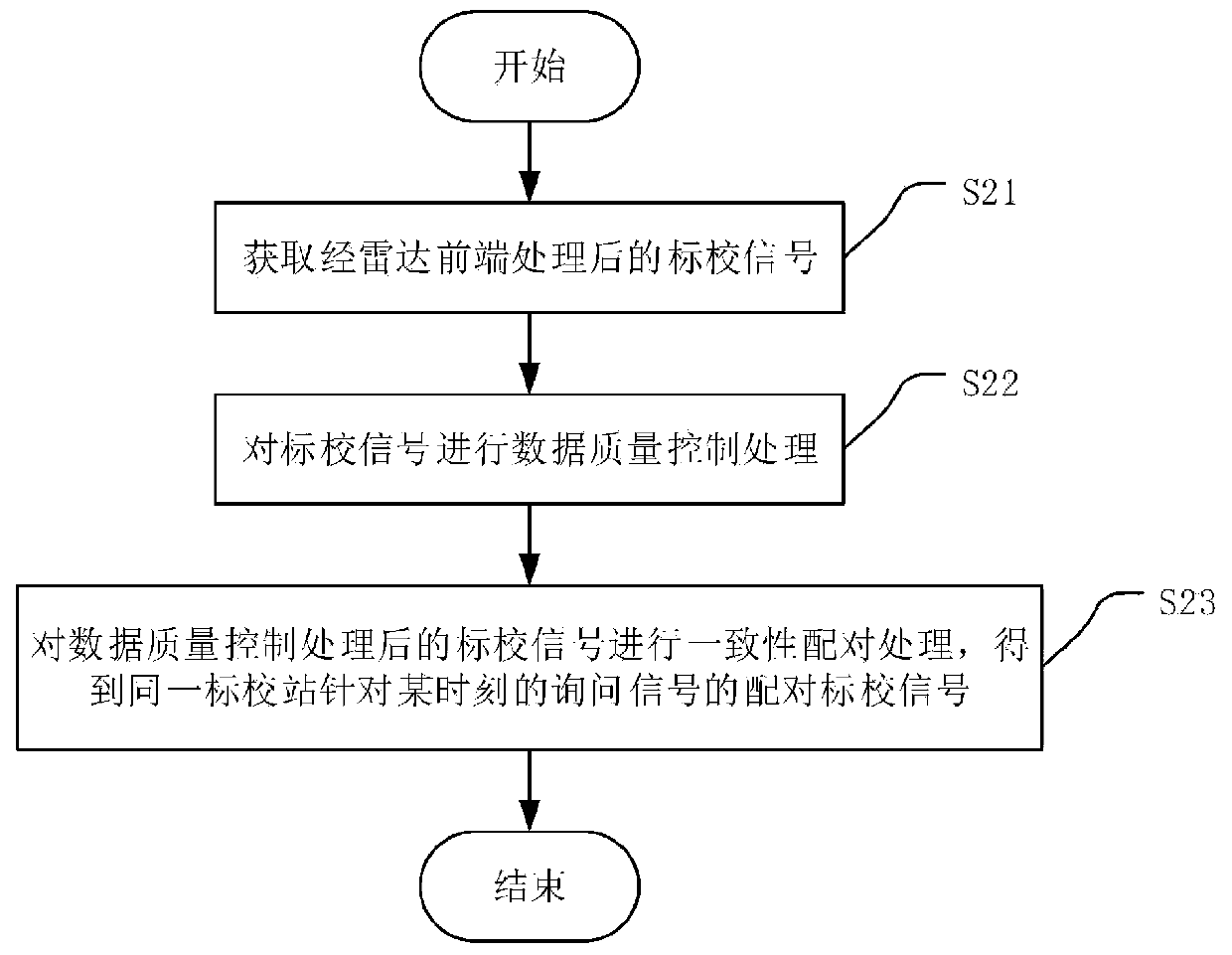

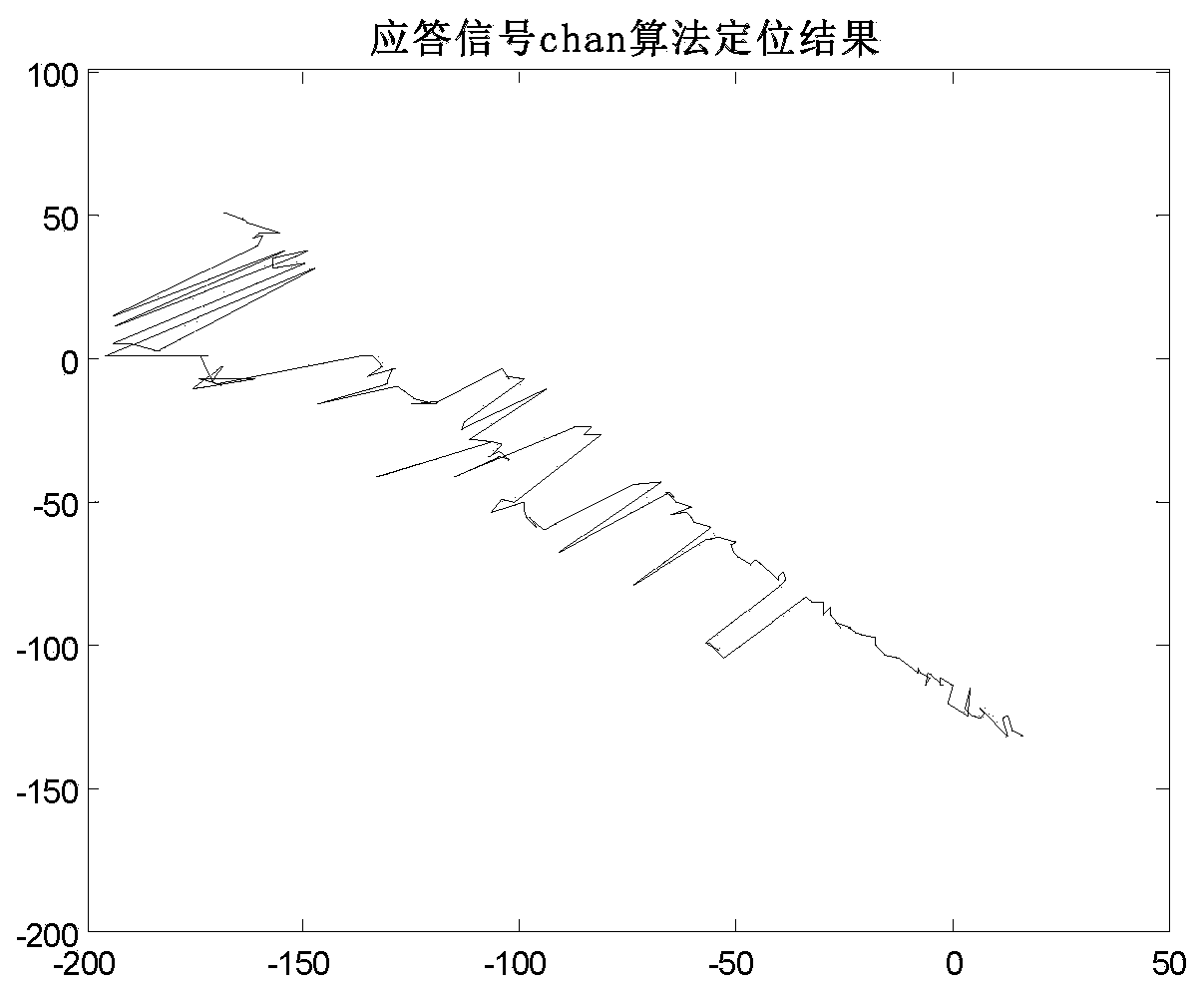

Pairing method used for distributed multi-point positioning and monitoring system

ActiveCN110261817AImprove data qualityImprove position solution accuracyPosition fixationQuality controlMonitoring system

The invention discloses a pairing method used for a distributed multi-point positioning and monitoring system. The method is used for pairing response signals and is also used for pairing calibration signals. Subsequently, error compensation of a system is obtained according to a calibration station measurement position which is calculated according to the paired calibration signals and an actual position of the calibration station. And then, the error compensation of the system is used to carry out error compensation the measurement position of a target so as to achieve accurate target positioning. By using the pairing method of the invention, data quality control processing is performed on the signals, and then consistency matching processing is performed on the signal after the data quality control processing. Through the method of the invention, pairing accuracy of a response signal and a calibration signal is increased, positioning accuracy of the response signal and the calibration signal is improved, and a risk that local convergence is generated because of incorrect pairing or divergence can not be correctly solved is reduced, and a reliable data basis is provided for real-time accurate positioning of the target and the calibration station.

Owner:ANHUI SUN CREATE ELECTRONICS

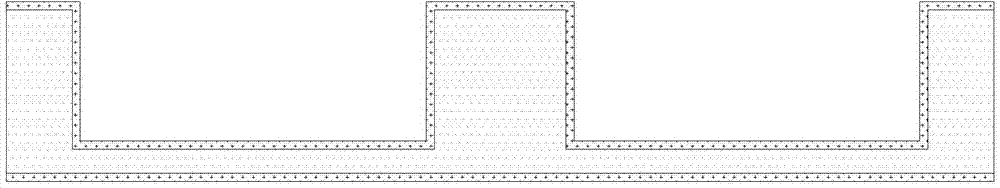

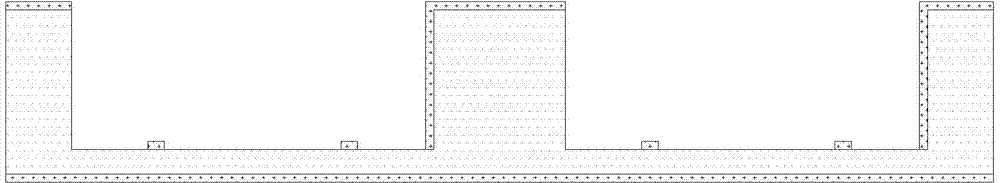

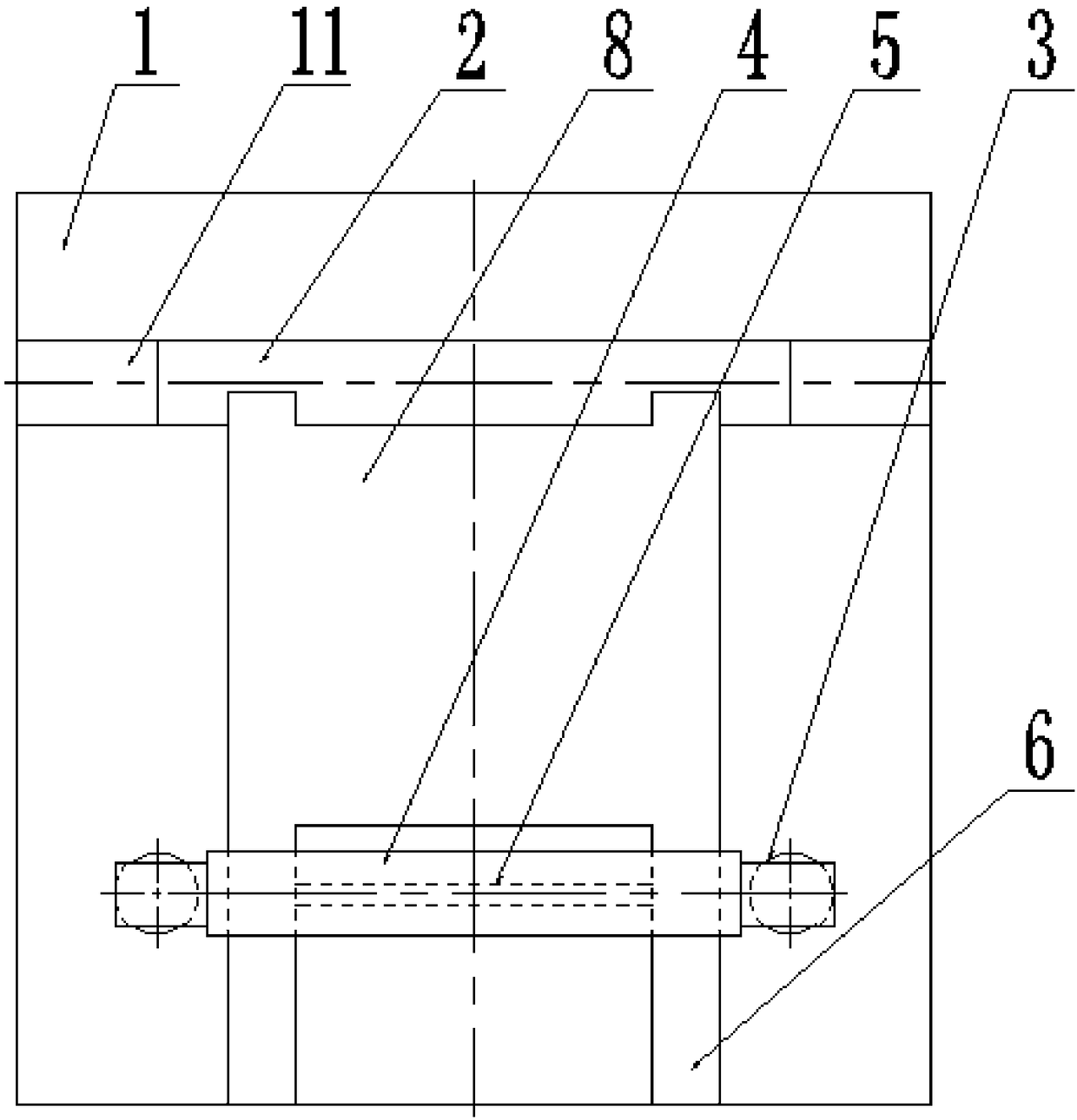

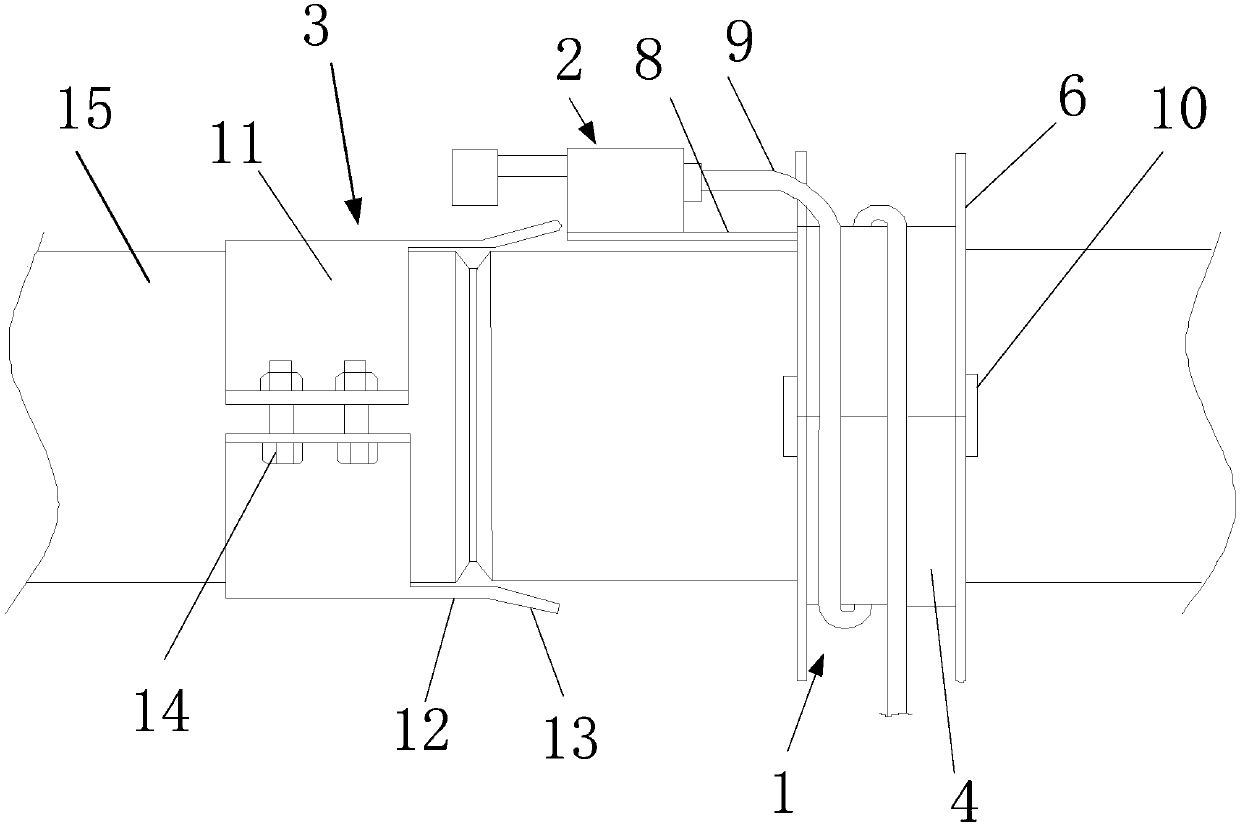

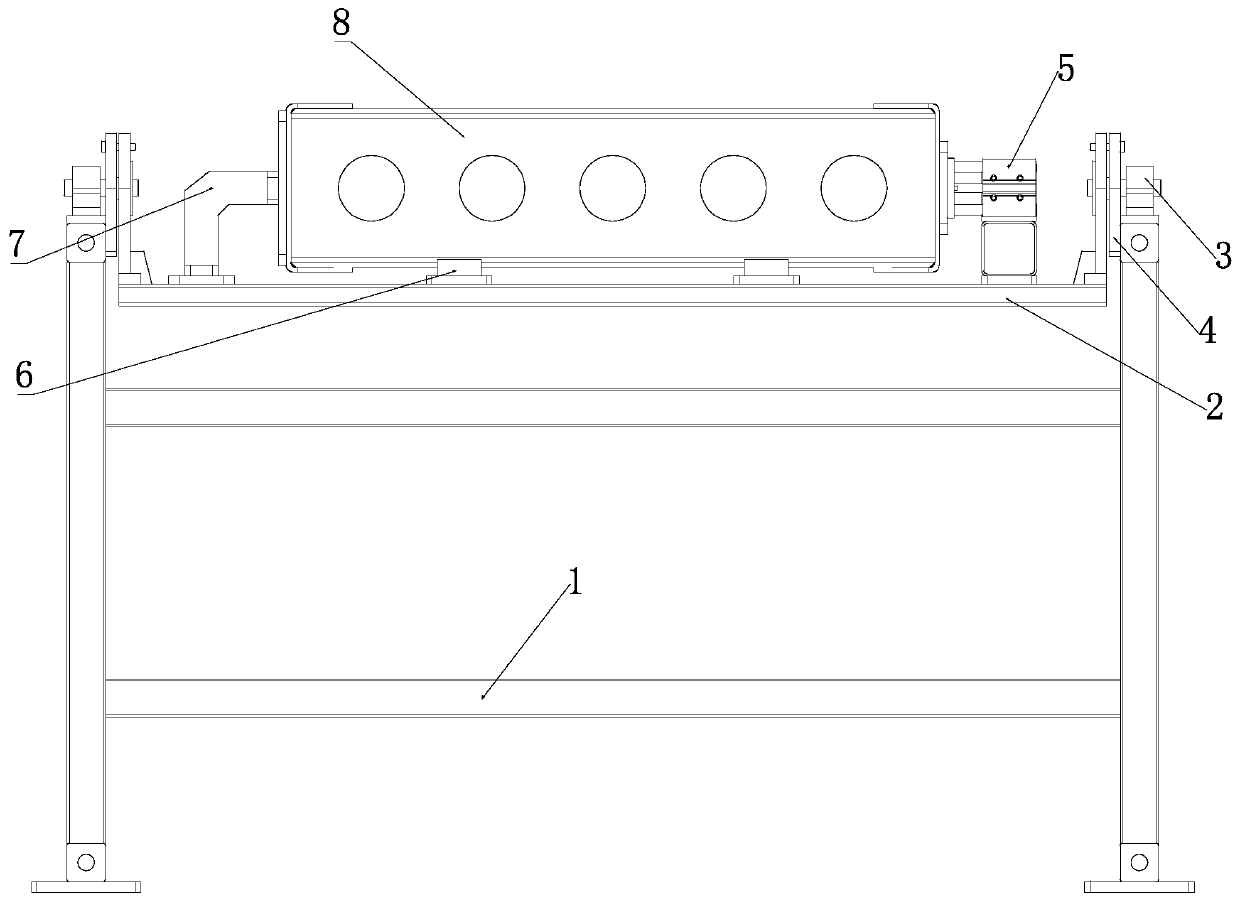

Installing and welding tool for hydraulic shock absorber seat

PendingCN108544169AEffective mechanical fixationImprove pairing accuracyWelding/cutting auxillary devicesAuxillary welding devicesAgricultural engineeringHydraulic shock

The invention belongs to the technical field of welding tools. An installing and welding tool for a hydraulic shock absorber seat comprises a bottom plate and a vertical plate, wherein two rows of longitudinal assembling grooves are processed in the bottom plate, the bottom ends of seat plates are separately placed in seat plate assembling grooves on corresponding sides on the bottom plate, two rows of vertical limiting grooves corresponding to the two rows of longitudinal assembling grooves are processed in the front end surface of the vertical plate, and the back ends of the seat plates leanagainst the vertical limiting grooves on the corresponding sides of the vertical plate, separately; a cover plate assembling groove is also processed between the two rows of seat plate assembling grooves in the bottom plate, two sides of the cover plate assembling grooves communicate to the seat plate assembling grooves, and cover plates are placed in the cover plate assembling grooves; and two positioning grooves are also processed in same longitudinal positions on the upper surface of the bottom plate, the bottom plate is fixedly connected to columns through the positioning grooves, a crossbeam is connected between the two columns on the bottom plate, the lower end of the cross beam is fixedly connected to a rib plate, and two side faces of the rib plate are in separately contact withthe inner side face of the seat plate on the corresponding side of the hydraulic shock absorber seat. The tool can guarantee the flatness, the linearity and the weld joint quality of a product.

Owner:CRRC LUOYANG CO LTD

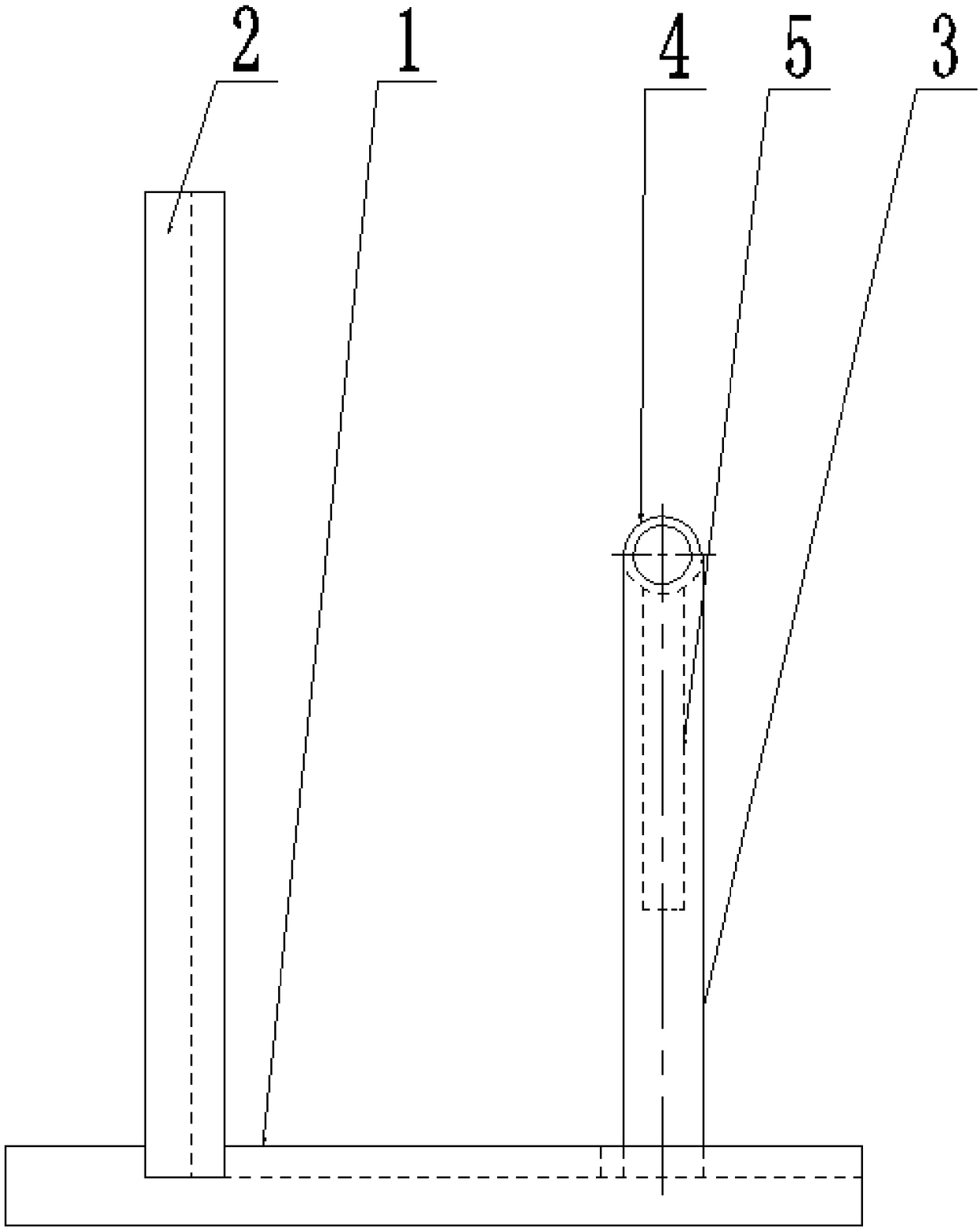

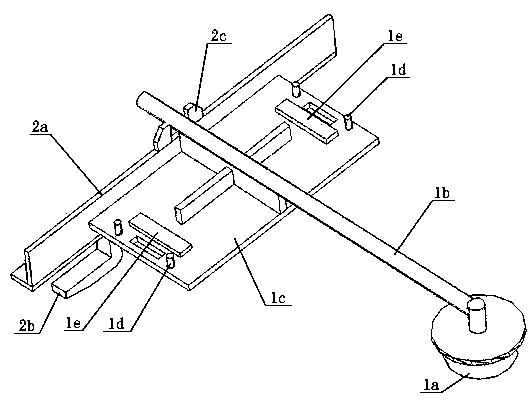

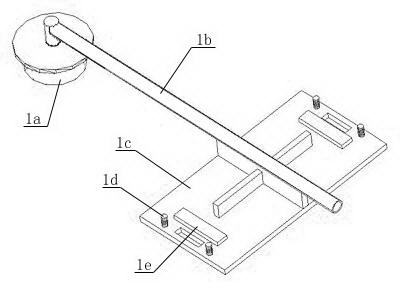

Assembly sample rod for mounting base of weight measuring mechanism of railway vehicle and assembly process thereof

ActiveCN104339115AImprove efficiencyImprove pairing accuracyWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringMachine

The invention discloses an assembly process of an assembly sample rod machine for a mounting base of a weight measuring mechanism of a railway vehicle. The assembly sample rod comprises a first sample rod assembly and a second sample rod assembly, wherein the first sample rod assembly comprises an upper center pan locating pin, a connecting rod and a baseplate, the second sample rod assembly comprises a support rod, two transverse locating blocks for the support rod are arranged on the lower end of the support rod, two transverse locating blocks for the connecting rod are arranged on the upper end of the support rod, a support block is arranged at one side of the support rod, when the first sample rod assembly and the second sample rod assembly are assembled, the baseplate of the first sample rod assembly is placed on the support block of the second sample rod assembly. By adopting integrated positioning of the first sample rod assembly and the second sample rod assembly, the location dimension of the mounting base of the weight measuring mechanism is determined, so that the assembly efficiency and the assembly precision are effectively improved, the quality of products is improved, the repair rate is reduced, the one-time handover percent of pass is improved, and the assembly sample rod for the mounting base of the weight measuring mechanism of the railway vehicle and the assembly process thereof are suitable for production of all kinds of state railway vehicles provided with the mounting base of the weight measuring mechanism.

Owner:CRRC MEISHAN

Dedicated pipeline welding device

InactiveCN107617838AKeep the distance constantQuality improvementWelding/cutting auxillary devicesAuxillary welding devicesCircular discStraight segment

The invention discloses a dedicated pipeline welding device. The device comprises a guide device, a welding gun, a clamping pipe sleeve, a straight segment, a flaring segment and a nut; the guide device comprises a disc, rollers fixedly arranged on the inner wall of the disc and two baffles arranged on the two ends of the disc; at least three rollers are evenly distributed, one of the two bafflesis provided with a gap, a connecting plate fixedly connected with the disc is arranged under the gap, the welding gun is fixedly arranged on the connecting plate, the welding gun comprises a cable, and the cable penetrates the gap and is wound on the disc, each baffle is divided into two parts, a locking device is fixedly arranged on the outer wall of each baffle, and two parts of each baffle areconnected through a locking clamp. Pipeline opening alignment and welding are integrated, unstability caused by the manual factor can be reduced, and welding quality stability is ensured.

Owner:UNIV FOR SCI & TECH SICHUAN

Mounting method of transmission gear of CG engine crankcase

InactiveCN105736680AImprove pass rateExtend your lifeMeasurement devicesGearing detailsCrankcaseEngineering

The invention discloses a mounting method of a transmission gear of a CG engine crankcase. The method comprises the steps that before mounting, a plurality of groups of timing driven gears with different cross-rod distances are designed and produced in a manner of corresponding to one timing driving gear; during mounting, the timing driving gear is firstly mounted on a crankshaft in a press-fit manner, the matched timing driven gears are selected, and mounting and gear matching are completed; and the method is characterized in that according to two sets of displacement sensors which are corrected in advance and have the mutually-fixed distance, the error detection of the center distance of the crankshaft and a camshaft hole is achieved, and the matched timing driven gears are automatically selected through a computer to be mounted. The method has the beneficial effects of being more convenient to detect and operate, higher in automation degree, smaller in detection error, and more precise and reliable in result, timing abnormal sounds caused by the improper gear backlash can be more effectively eliminated, and the service life of an engine is prolonged.

Owner:力帆科技(集团)股份有限公司

Liquid crystal display and manufacture method thereof

InactiveCN101650489APrecise positioningExact pairNon-linear opticsLiquid-crystal displayControl signal

The invention discloses a liquid crystal display and a manufacture method thereof. The liquid crystal display comprises a display panel and a backlight module, wherein the display panel comprises a display zone and a light shading zone; the backlight module is arranged at the opposite side of the display panel and comprises a lighting zone and a marginal zone consisting of a first mark and a second mark. Production equipment which is provided by the manufacture method comprises a fixed pedestal, a sensing element, a control element and a loading element; the backlight module is fixed in the fixed pedestal; the sensing element senses the first mark and the second mark of the backlight module and outputs a sensing signal to the control element; the control element outputs a control signal tothe loading element according to the sensing signal; and the loading element clamps the display panel and move a certain distance according to the control signal so that the display panel and the backlight module are precisely assembled in a para-position way.

Owner:AU OPTRONICS (SUZHOU) CORP LTD +1

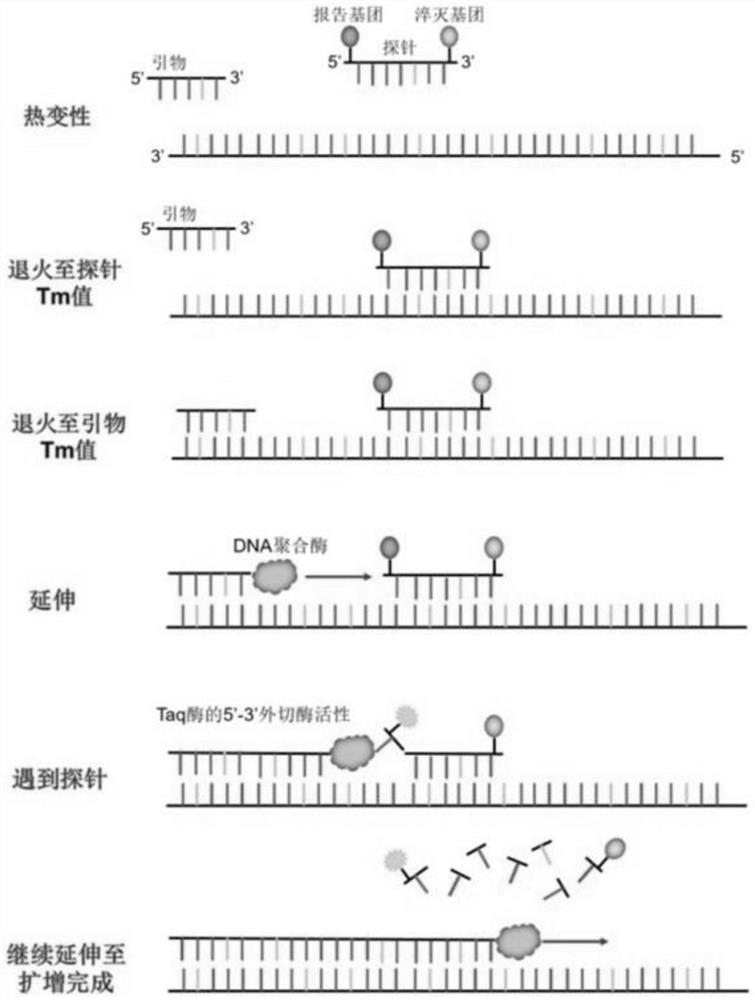

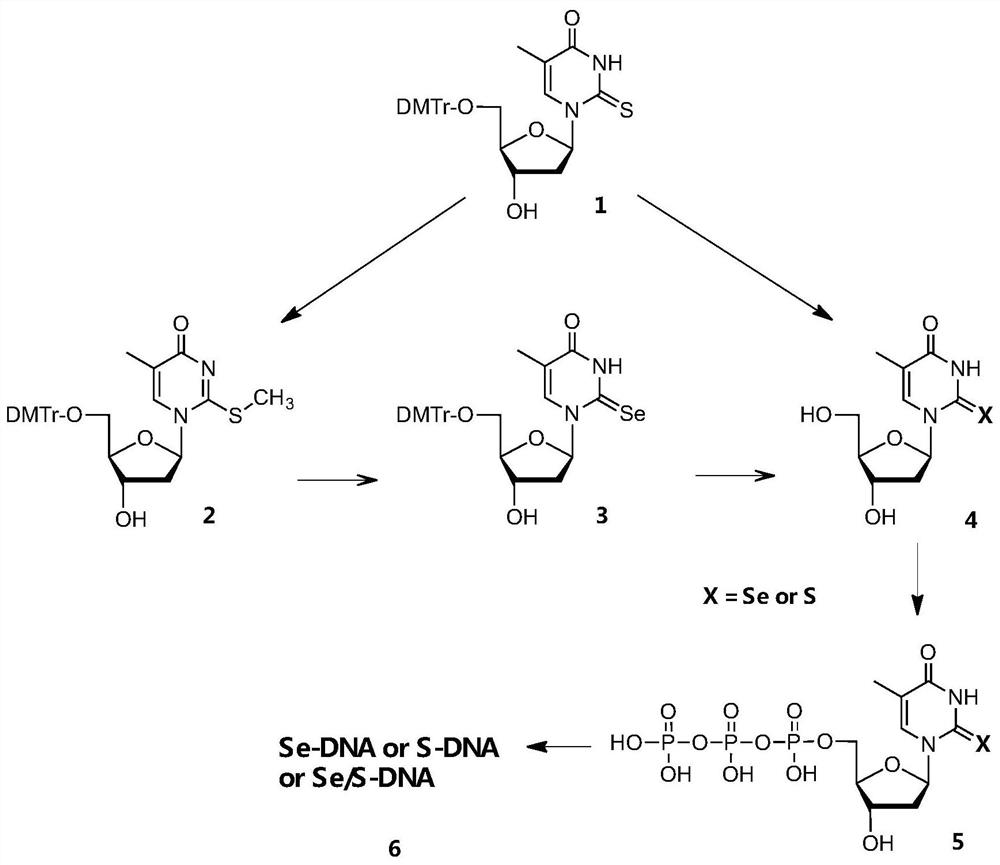

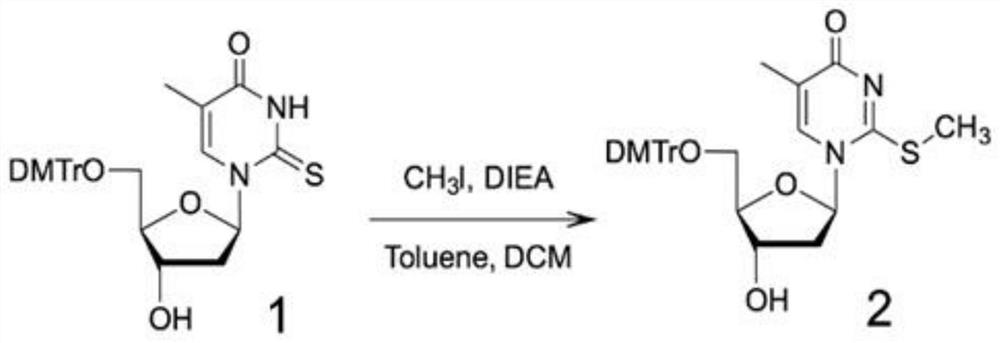

Selenium or thiothymine nucleoside-5 '-triphosphoric acid and synthesis method thereof

PendingCN113004358AMatching accuracy improvedImprove sensitivity and accuracySugar derivativesSugar derivatives preparationOne-pot synthesisPyrimidine

The invention discloses selenium or thiothymine nucleoside-5 '-triphosphoric acid and a synthesis method of the selenium or thiothymine nucleoside-5'-triphosphoric acid. The synthesis method comprises the following partial synthesis steps: a deprotection reaction is carried out on a compound 3 or 1 and trichloroacetic acid to respectively obtain SeT (namely 4Se) or ST (namely 4S); then, the compound 4Se and the compound 4S are respectively converted into a compound 5Se and a compound 5S through a one-pot synthesis method, SeTTP is the compound 5Se, and STTP is the compound 5S; next, the compounds 5Se and 5S are purified, the purified compounds 5Se and 5S are characterized to confirm the structure and purity of the compounds 5Se and 5S, and then DNA enzymatic synthesis is carried out by using SeTTP or STTP and DNA polymerase to obtain a compound 6, namely Se-DNA or S-DNA or selenium sulfo Se / S-DNA; according to the invention, a selenium or sulfur atom specific modification strategy SAM is established by innovatively synthesizing SeTTP and STTP and innovatively synthesizing DNA polymerase, so that T / G mismatch in DNA polymerization is inhibited, the specificity of base pairing is improved, and the SAM method is proved to be capable of improving the accuracy and sensitivity of polymerase reaction, nucleic acid molecule recognition and molecule detection.

Owner:纽奥维特(成都)生物科技有限公司 +1

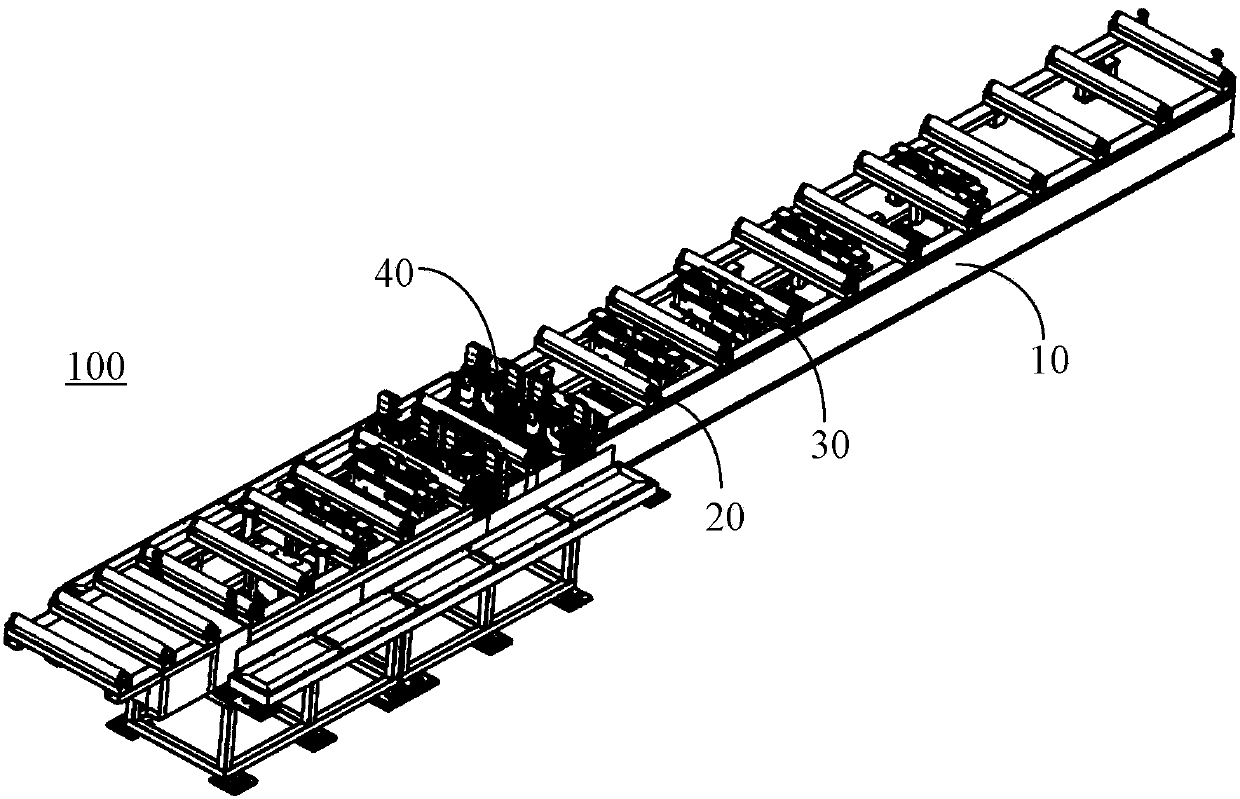

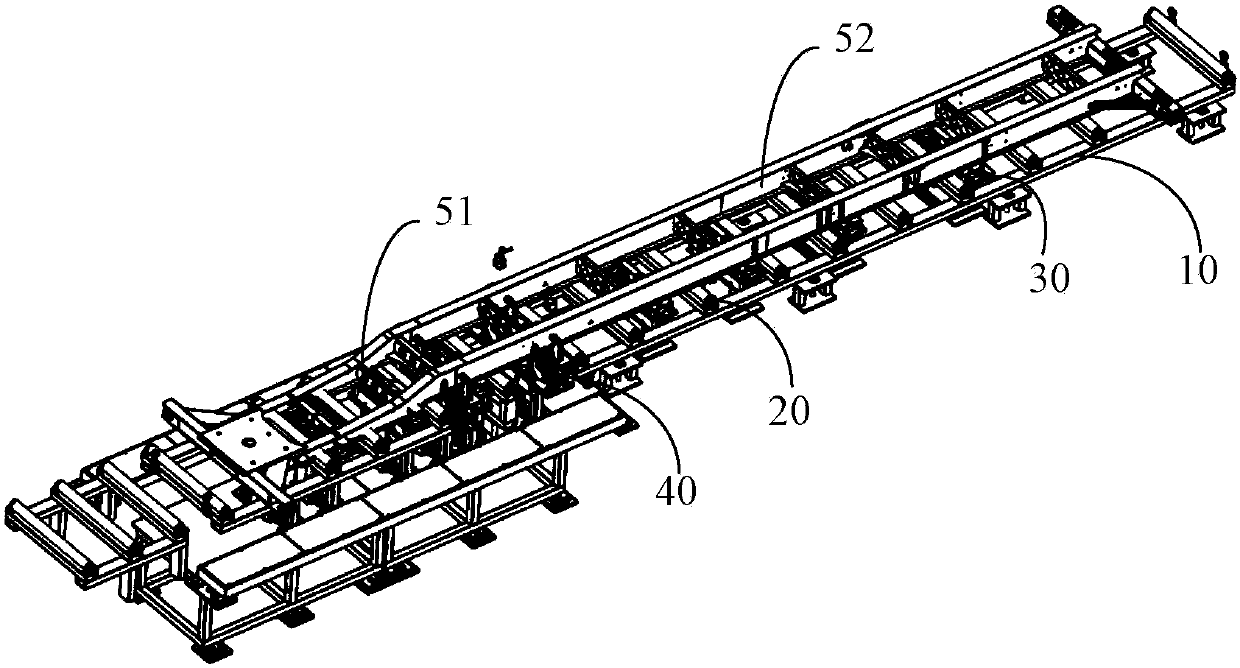

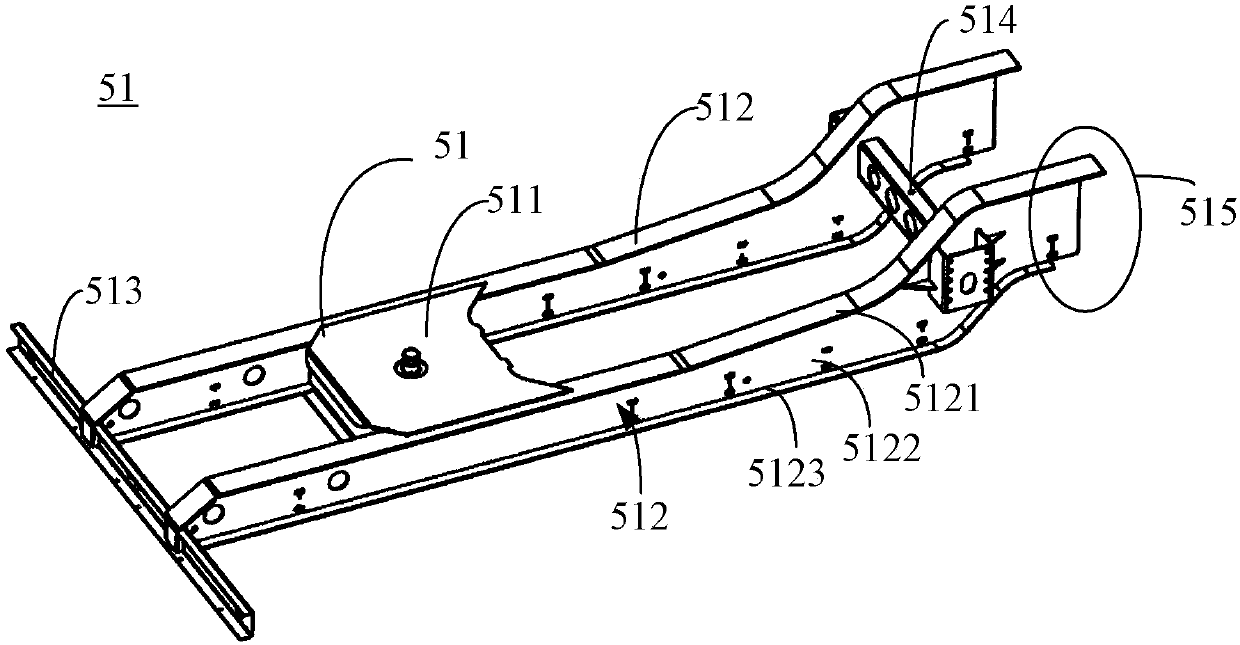

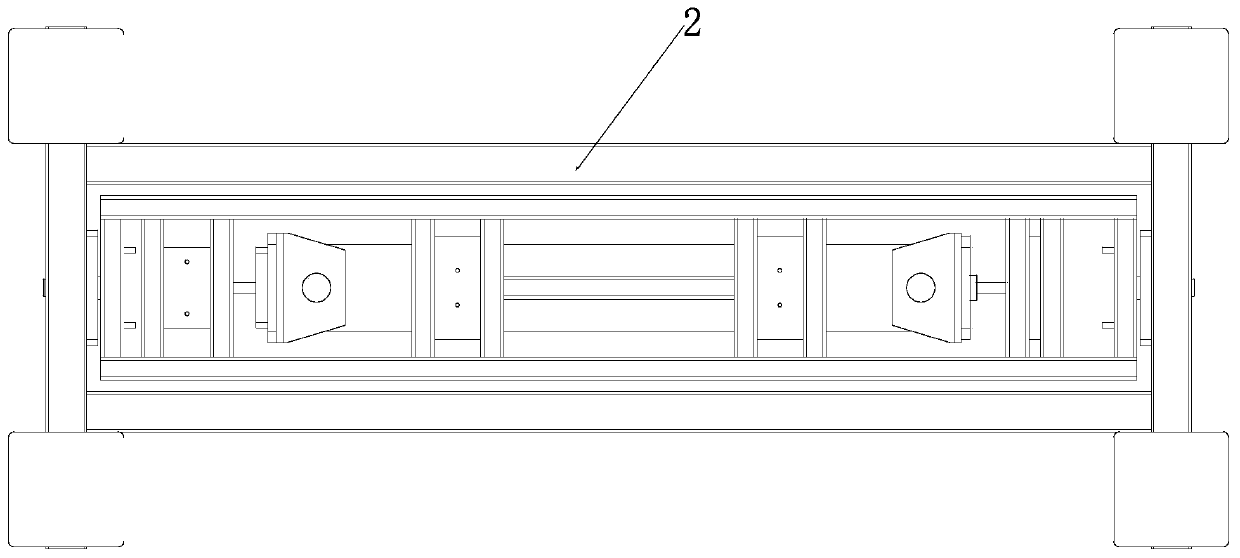

Semitrailer assembling equipment

PendingCN110340589AExact pairingPrecise pairingWelding/cutting auxillary devicesAuxillary welding devicesWeld seamMechanical engineering

The invention discloses the semitrailer assembling equipment. The semitrailer assembling equipment is used for assembling a front section frame and a rear section frame of a semitrailer, the semitrailer assembling equipment comprises an assembling table, a plurality of rollers, a plurality of centering and clamping mechanisms and at least one welding seam clamping mechanism, wherein the pluralityof rollers are arranged at intervals in the length direction of the assembling table and are used for conveying the front section frame and the rear section frame of the semitrailer, the plurality ofcentering and clamping mechanisms are arranged at intervals in the length direction of the assembling table, and are used for positioning and tightly supporting the front section frame and the rear section frame, and the welding seam clamping mechanisms are used for clamping the front section frame and the rear section frame at the vehicle combining and welding joint between the front section frame and the rear section frame. According to the semitrailer assembling equipment, the assembling precision of the front section frame and the rear section frame can be improved, so that the phenomena of staggered edges during vehicle combining and assembling are avoided, and meanwhile the assembling efficiency is also improved.

Owner:CIMC VEHICLES (GROUP) CO LTD +1

A Construction Method for Underwater Grooving and Immersed Pipe Crossing the River

ActiveCN103912721BGuarantee smooth constructionSinking smoothlyWater resource protectionPipe laying and repairUnderwaterBuoy

The invention discloses an underwater grooving and pipe sinking river traversing construction method, and belongs to the field of underwater pipeline laying technologies. The underwater grooving and pipe sinking river traversing construction method includes steps of preparing for construction; arranging pipes of pipelines, performing preliminary assembling procedures and photon assembling procedures in assembling procedures for arranging the pipes of the pipelines, particularly, preliminarily assembling the first pipelines to be preliminarily assembled and the second pipelines to be preliminarily assembled on river banks, marking location point information on the end surfaces of the pipelines, and assembling straight pipe sections of first river beds and straight pipe sections of second river beds on platforms of photons; sinking the pipes of the pipelines, implementing an integral pipeline sinking technology in procedures for sinking the pipes of the pipelines, tying first buoys at first elbow sections on the pipelines, tying second buoys on second elbow sections on the pipelines, and controlling first valves, second valves, the first buoys and the second buoys to always keep the first valves, the second valves, the first buoys and the second buoys on the center lines of pipe trenches so as to guarantee that the pipelines are accurately sunken in the pipe trenches; pouring concrete and stabilizing the pipes; refilling the pipelines and restoring rivers. The underwater grooving and pipe sinking river traversing construction method has the advantage that the integral pipelines can be accurately and stably sunken in the specified pipe trenches under the control of the underwater grooving and pipe sinking river traversing construction method.

Owner:CHINA NAT CHEM ENG THIRD CONSTR

High-speed train head car body assembling device and assembling method

ActiveCN109483128BAdjustable lengthPrecise positioningWelding/cutting auxillary devicesAuxillary welding devicesVertical planeEngineering

The invention discloses a high-speed train first train body assembling device and an assembling method thereof, and belongs to the field of welding, assembling and auxiliary positioning devices for train first train bodies. The device comprises a train roof assembling tool, a front window frame positioning tool, a train roof hoisting tool, a side wall assembling tool and a train body front end plate assembling tool; train roof assembling and welding are completed through the train roof assembling tool; train body front end plates are located at the standard positions of the end of the side wall assembling tool through the train body front end plate assembling tool; and positioning operation of train roofs and the side wall assembling tool is completed through the train roof hoisting tool and the front window frame positioning tool. According to the high-speed train first train body assembling device and an assembling method thereof, the train roofs can be assembled, welded and machinedon the ground through the train roof assembling tool, the positioning efficiency and the assembling precision of all parts of the train roofs both can be significantly improved, then the symmetry ofthe central vertical plane of the train roofs is significantly improved, therefore, the wind resistance and waggling and noise which are generated when a train runs at high speed can be significantlyreduced, the mechanical transmission path can be optimized, and the structural strength of a train body is further improved.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

Semitrailer beam welding tool and welding process thereof

InactiveCN109986272AGuaranteed pair clearanceGuaranteed welding sizeWelding/cutting auxillary devicesAuxillary welding devicesArchitectural engineeringAir cylinder Press

The invention belongs to the technical field of aluminum alloy welding, and relates to a semitrailer beam welding tool and a welding process thereof. The tool comprises a tool fixing frame, a turnoversupport rotationally arranged on the tool fixing frame, an air cylinder pressing device and a connecting groove fixing end limiting device, wherein the air cylinder pressing device and the connectinggroove fixing end limiting device are fixedly arranged at the two ends of the turnover support, a to-be-assembled-and-welded welding beam wing plate is clamped between the air cylinder pressing device and the connecting groove fixing end limiting device, and a plurality of beam turnover limiting blocks used for clamping the to-be-assembled-and-welded welding beam wing plate are fixedly arranged on the turnover support. The tool solves the problems that in the prior art, when a semitrailer framework cross beam is independently welded, grouping errors are prone to occur, and the welding efficiency is low.

Owner:LIAONING ZHONGWANG SPECIAL VEHICLE MFG

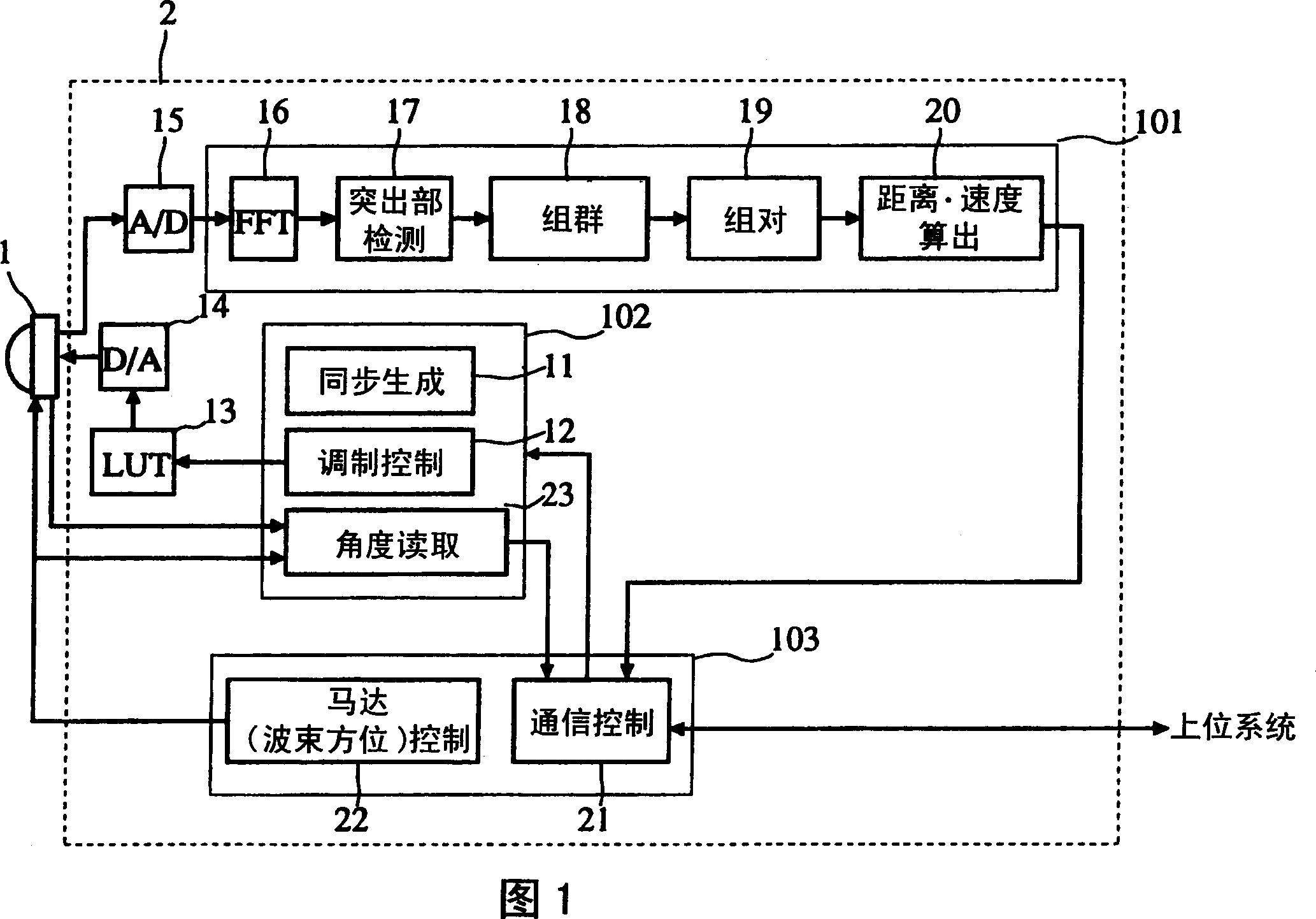

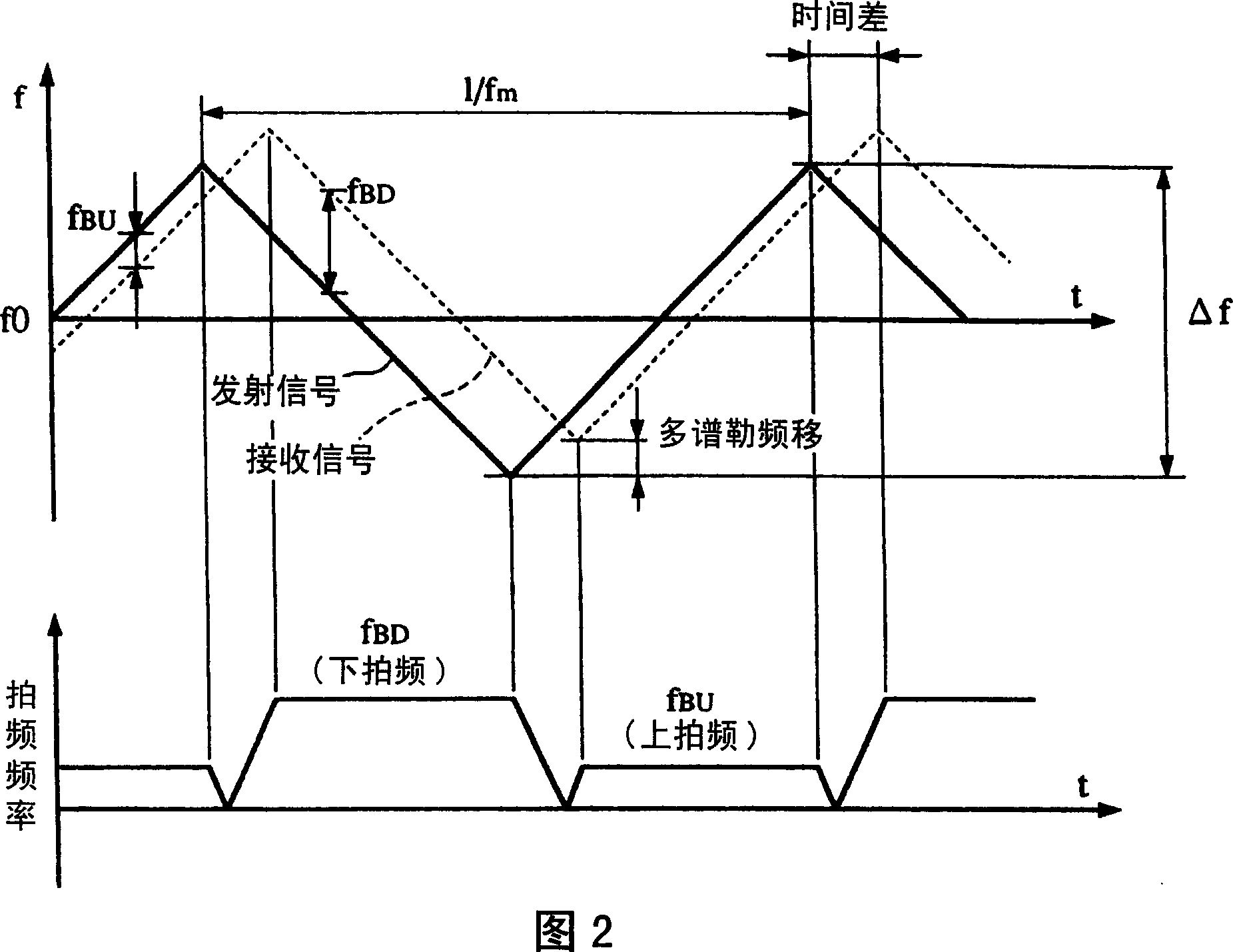

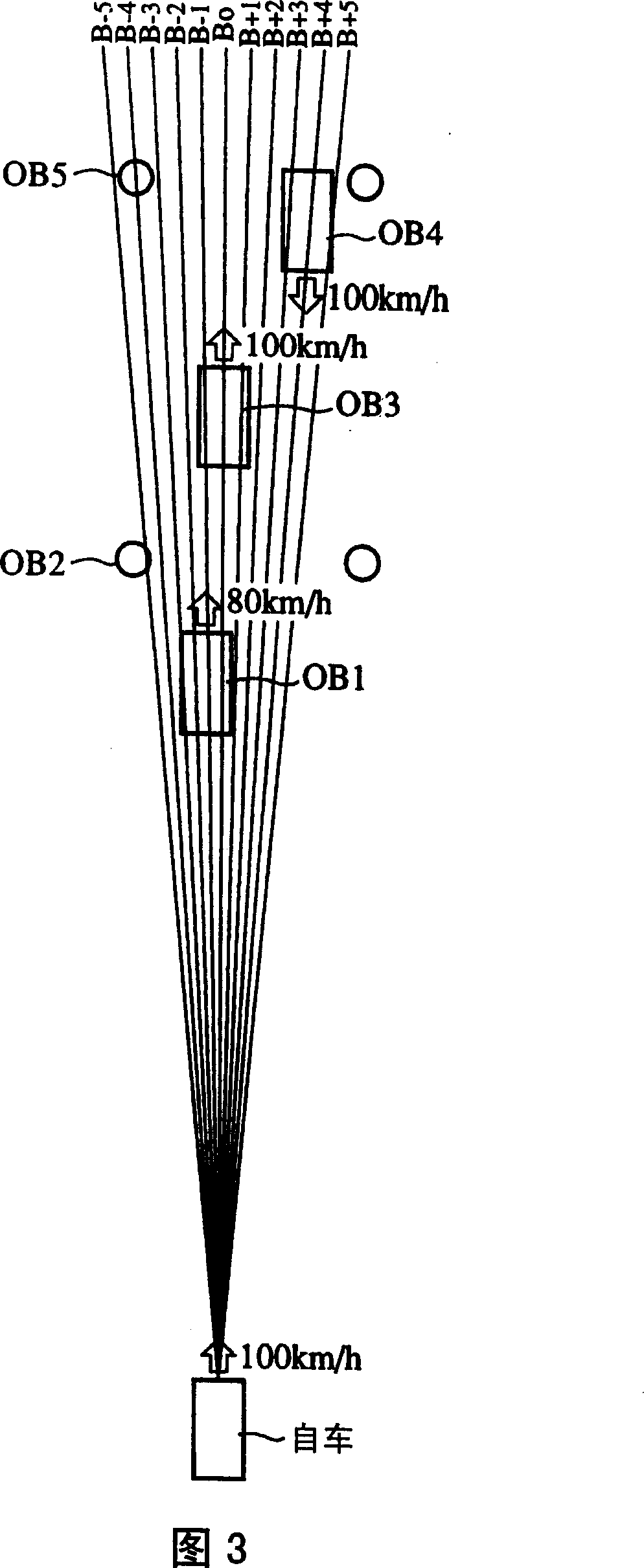

Radar

InactiveCN1932551AImprove pairing accuracyAnti-collision systemsRadio wave reradiation/reflectionRadar systemsFrequency spectrum

In an FM-CW radar system (2), regarding peaks appearing in the frequency spectrum of a beat signal in an FM-CW radar, groups of consecutive peaks in beam bearings within a predetermined frequency difference are regarded as being caused by reflected waves from a single target (OB1-OB5), and based on a combination of a peak group in an up-modulating interval and a peak group in a down-modulating interval, a relative distance to a target and its relative speed are determined.

Owner:MURATA MFG CO LTD

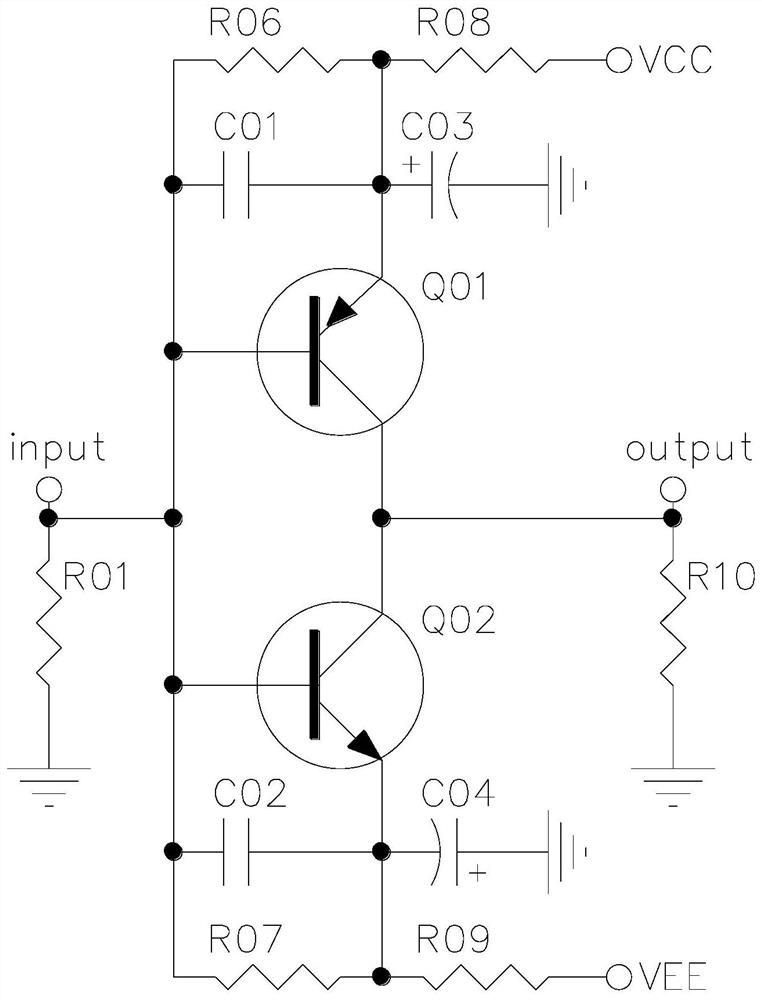

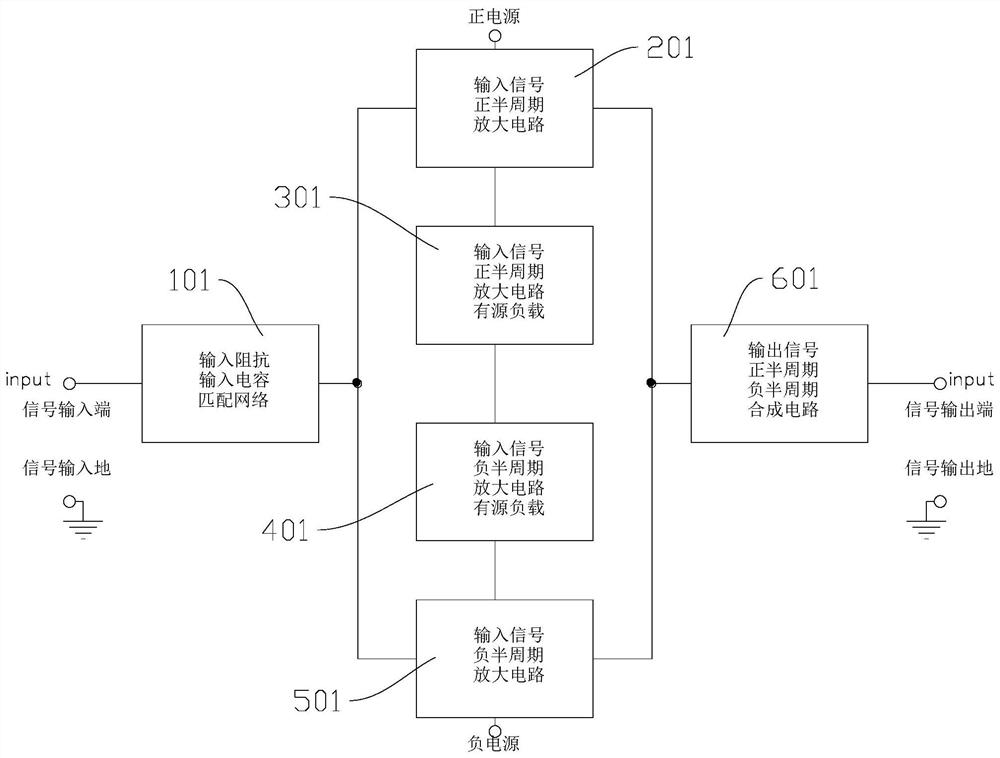

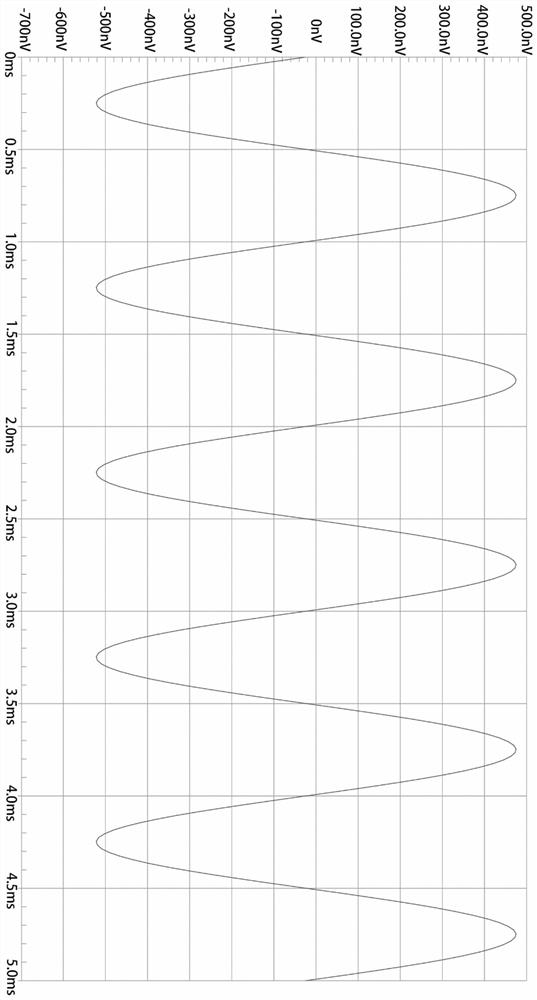

Moving-coil cartridge amplifying circuit

PendingCN113708730AReduce volumeEasy to debugAmplifier modifications to reduce non-linear distortionAmplifier modifications to reduce noise influenceLow noiseHemt circuits

The invention discloses a moving-coil cartridge amplifying circuit, and the circuit comprises: a matching network electrically connected with a signal input end; low-frequency response filter circuits, wherein the low-frequency response filter circuits are symmetrically arranged and electrically connected with a positive power supply and a negative power supply respectively, and the low-frequency response filter circuits are electrically connected with the matching network; quiescent operating point circuits, wherein the quiescent operating point circuits are electrically connected with the low-frequency response filter circuit and the matching network, and the quiescent operating point circuits are symmetrically arranged and electrically connected with a positive power supply and a negative power supply respectively; an amplifying unit, wherein the amplifying unit comprises a first transistor and a second transistor, and the amplifying unit is electrically connected with the matching network, the low-frequency response filter circuit, the quiescent operating point circuit, a signal input end and a signal output end; and an output end load, wherein the output end load is electrically connected with the amplification unit and the signal output end. The advantages of low noise, low distortion, high signal-to-noise ratio, high dynamic range and wide frequency response are realized.

Owner:东莞凯韵科技有限公司

Assembly tooling and method for frame and pedestal body

ActiveCN106514112BSimple structureEasy to adjustWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention discloses an assembly tooling and method of frameworks and guide frame bodies. The tooling comprises a locating seat used for fixing the four guide frame bodies and framework measurement pins, wherein a clamping device used for clamping the guide frame bodies is arranged on the locating seat; the frameworks are arranged on the guide frame bodies; first adjusting workpieces are arranged on the two sides of the frameworks; the first adjusting workpieces can be adjusted relative to the guide frame bodies to be in contact with the frameworks to adjust the positions, relative to the guide frame bodies, of the frameworks; and the framework measurement pins are arranged in central holes of the frameworks. According to the assembly tooling, the structure is simple, the guide frame bodies are convenient to adjust, after being determined on the locating seat, the guide frame bodies and the frameworks are welded in pairs, the pairing precision is high, follow-up processing is not required, and the operation is convenient; and the assembly tooling cooperates with a measurement ruler to quickly determine the positions of the guide frame bodies and the frameworks, so that the production efficiency is effectively improved, and the production cost is reduced.

Owner:CRRC SHANDONG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com