High-speed train head car body assembling device and assembling method

A locomotive head and high-speed technology, applied in the field of auxiliary positioning devices for welding groups, can solve problems such as uneven vertical planes, unreasonable assembly sequences, and difficult control of positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0089] The present invention will be described in further detail below in conjunction with the accompanying drawings.

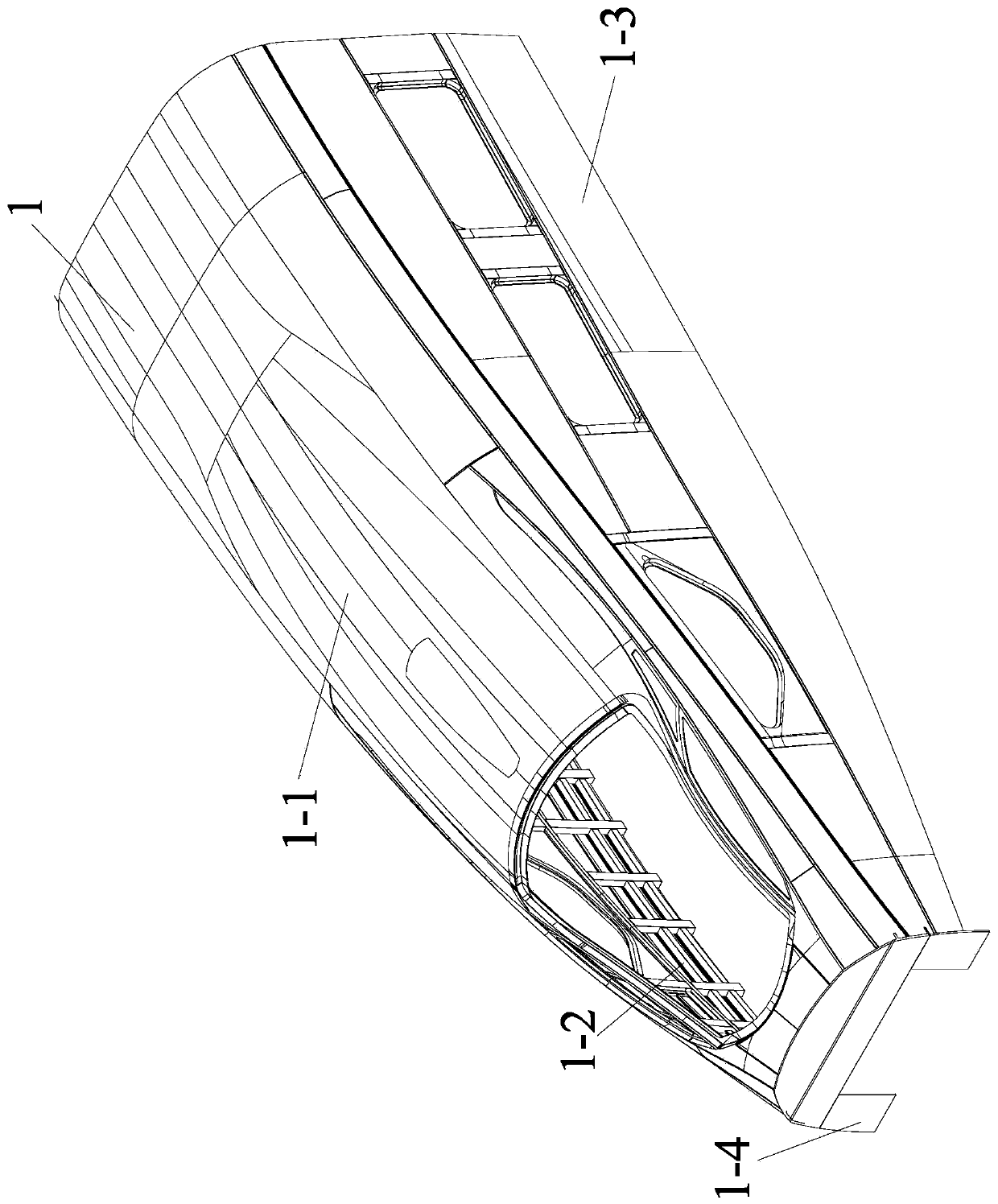

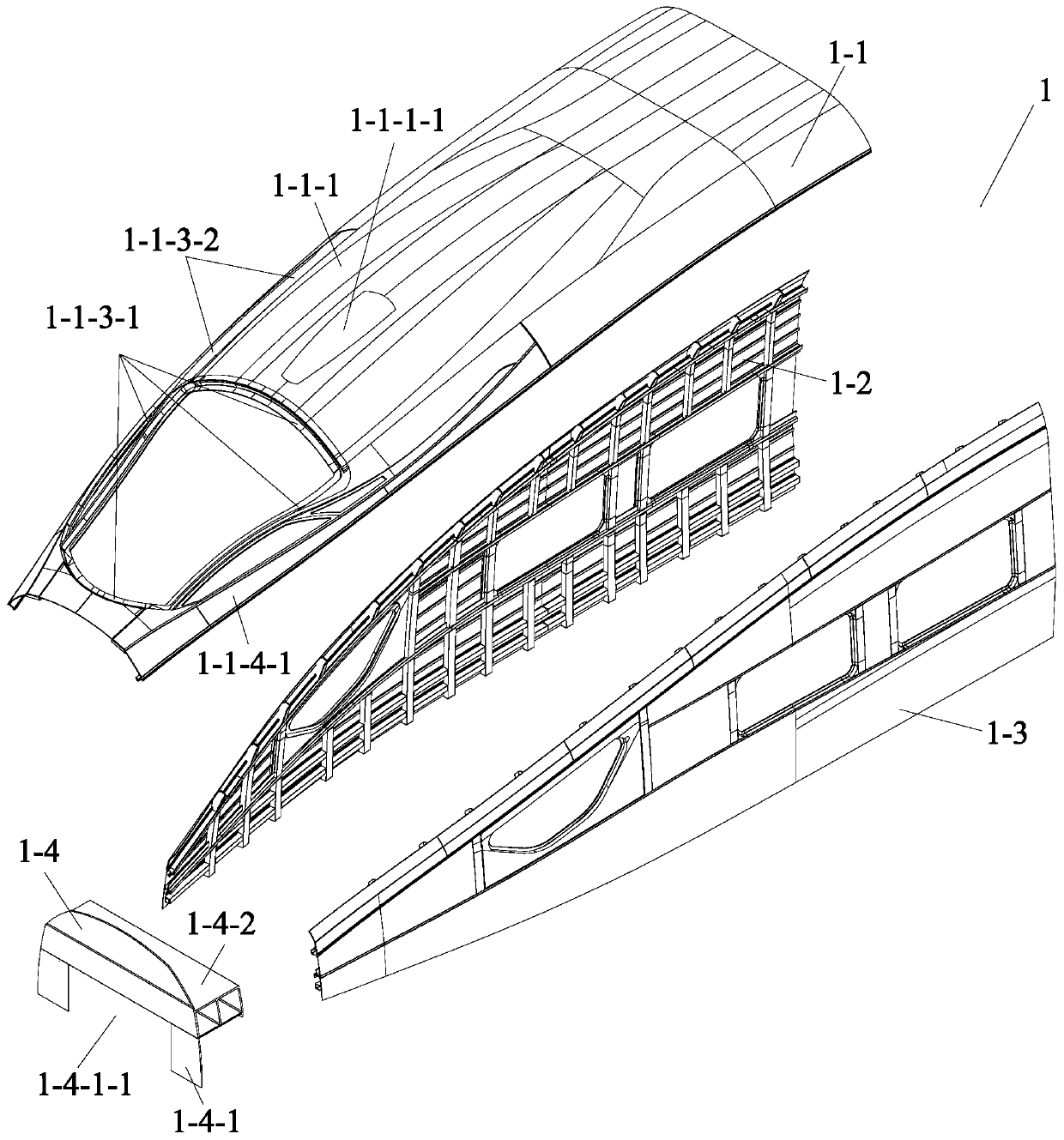

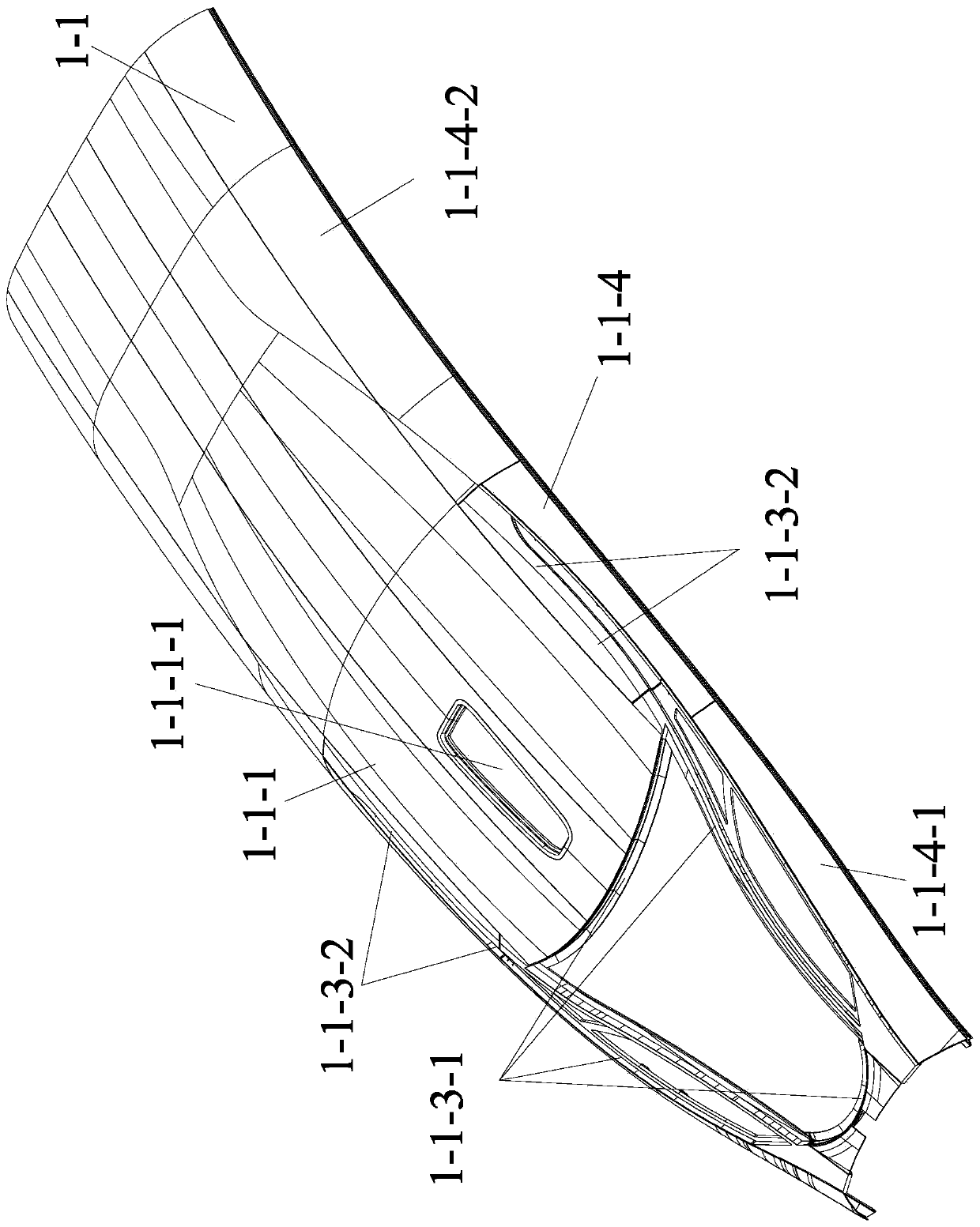

[0090] like Figure 5 to Figure 23 As shown, the high-speed train head car body assembly device of the present invention includes roof assembly tooling A, front window frame positioning tool B, roof hoisting tool C, side wall assembly tooling P and car body front panel assembly tooling Q.

[0091] The roof group tooling A is a left-right symmetrical structure, which includes a roof group frame 2, a front window frame tooling connection seat, a ceiling light frame positioning seat 4, a plurality of keel curved beam center line positioning seats 5, and three sets of light frame bends. Beam support seat 6, multiple sets of side beam front positioning seats 7, multiple sets of curved beams and side beam rear positioning seats 8, multiple sets of keel curved beam support mechanisms 9 and two side beam end limit seats 10; The inside of the pair frame 2 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com