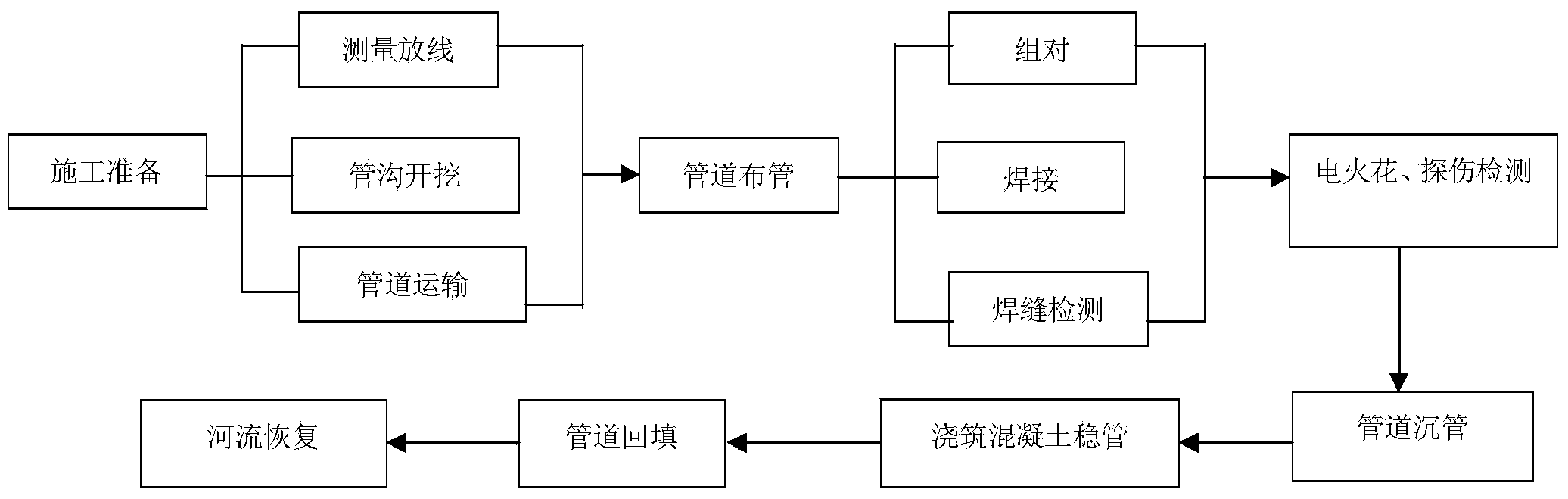

Underwater grooving and pipe sinking river traversing construction method

A technology for crossing rivers and construction methods, applied in water resources protection, pipeline laying and maintenance, pipes/pipe joints/pipe fittings, etc., can solve problems such as large errors, failure to put pipes into pipe trenches, etc., and achieve high matching accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

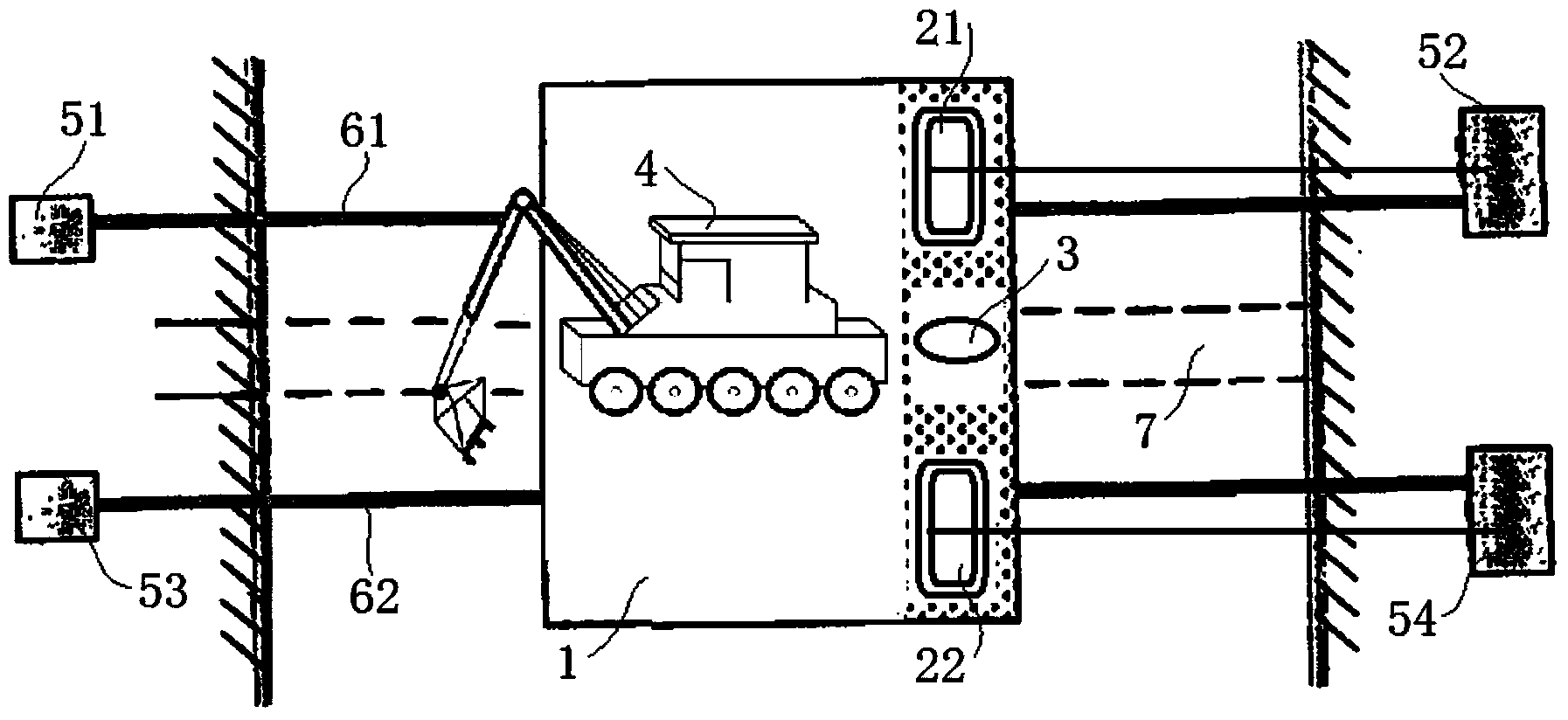

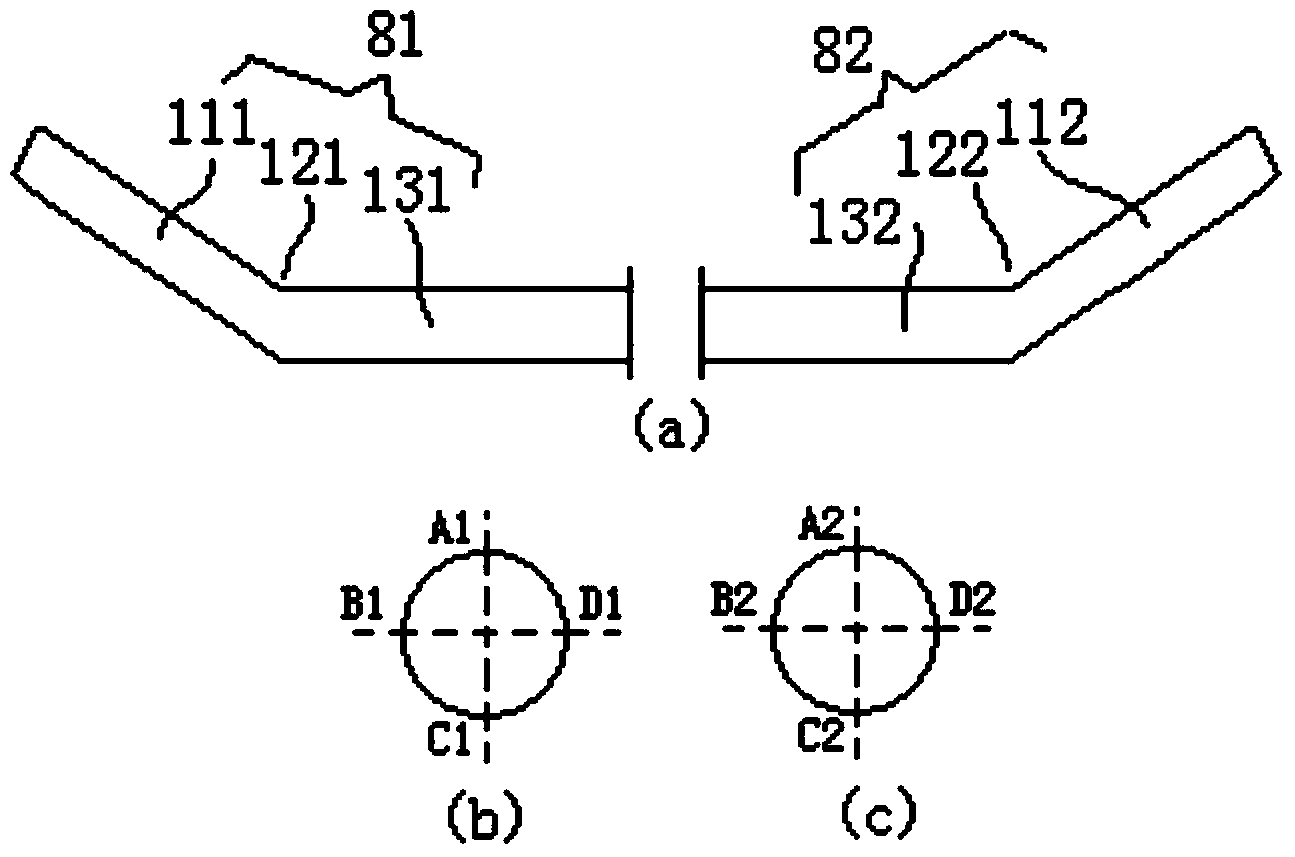

Method used

Image

Examples

Embodiment 1

[0043] For the construction of pipelines crossing rivers, the conventional cofferdam diversion method is suitable for shallow riverbeds and small water flows. For rivers with rocky river beds and complex geological conditions, directional drilling is not suitable for construction. What this embodiment is aimed at is the project that the gas transmission pipeline crosses a certain river in the natural gas pipeline project, and the hydrogeological situation of this river is as follows: a), the river is not navigable, and there is no road on both banks, which belongs to the natural river bank; b), the river is sandwiched between two mountains Between the two banks, the slope is relatively large, the river bed is rocky near the bank, and the middle of the river bed is organic silt; c), the width of the river at the crossing point of the pipeline is 110m, the depth of the river bed is 4-5m, and the water flow on the river is relatively fast. After retrieving relevant literature and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com