Assembly tooling and method for frame and pedestal body

A technology for assembling tooling and guide frames, applied in auxiliary devices, manufacturing tools, metal processing and other directions, can solve the problems of low efficiency and high cost, and achieve the effects of reducing production costs, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

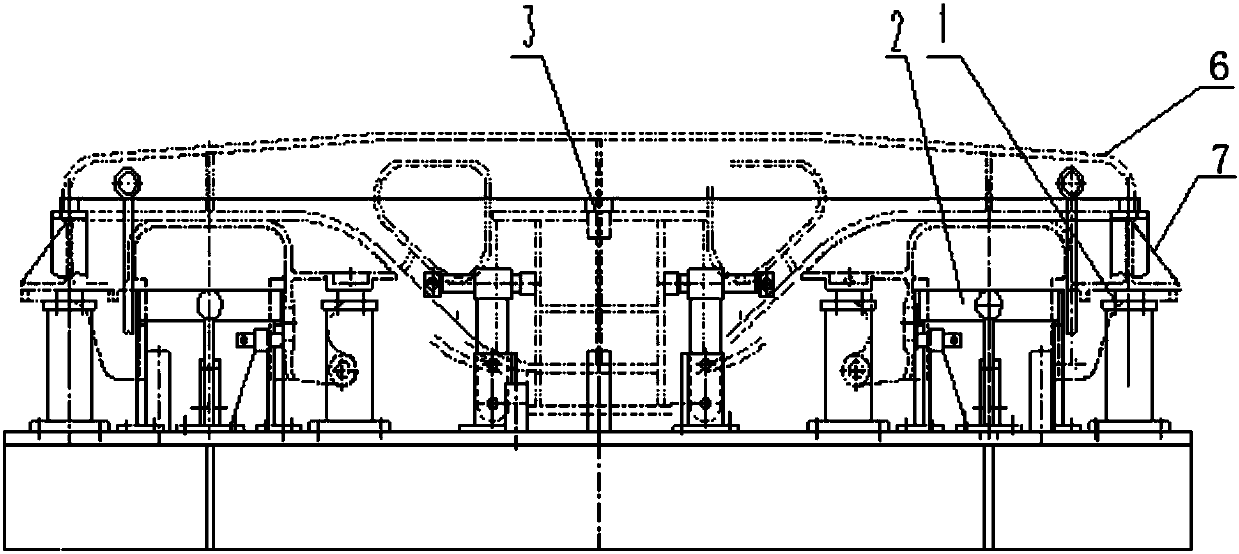

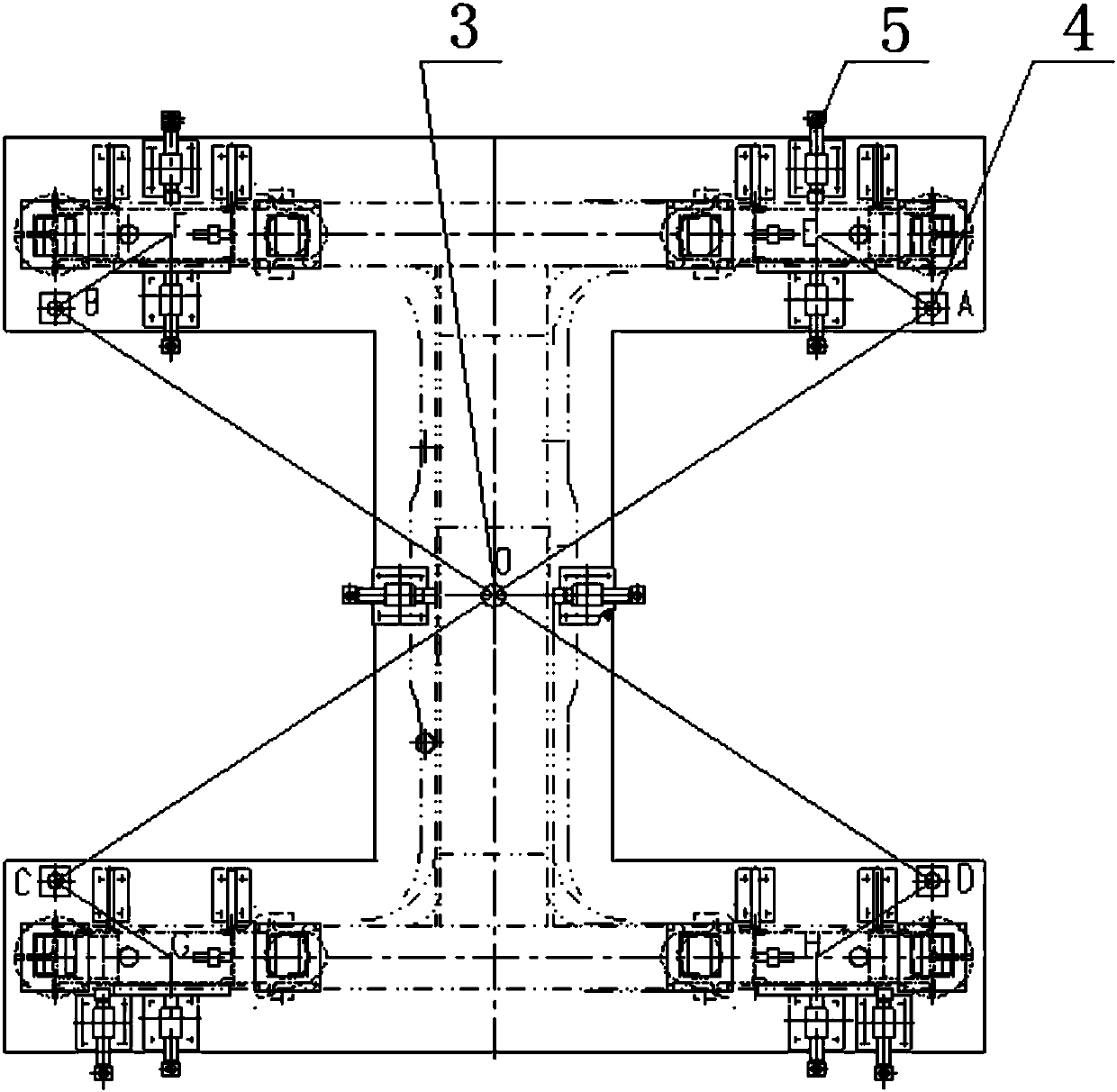

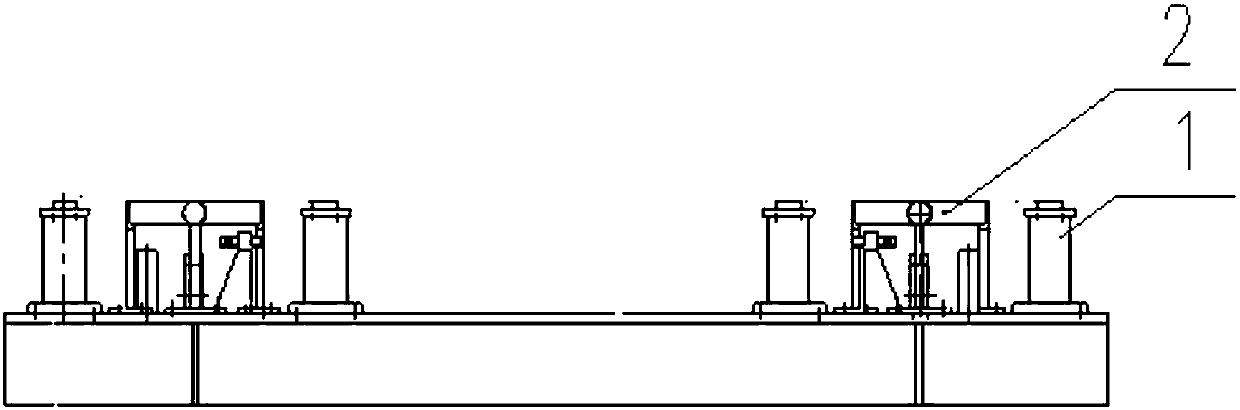

[0041] Assembly tooling for frames and pedestals, such as figure 1 shown, including:

[0042] The positioning seat for fixing the four pedestal bodies, the clamping device for clamping each pedestal body is arranged on the positioning seat, the frame is arranged on the pedestal body, and the first adjustment workpiece 5 is arranged on both sides of each frame , the first adjustment workpiece 5 can be adjusted relative to the pedestal body to be in contact with the frame to adjust the position of the frame relative to the pedestal body;

[0043] Frame measuring pin 3, frame measuring pin 3 is located in the frame center hole, frame measuring pin 3 is a stepped cylinder, the bottom of frame measuring pin 3 is positioned with the frame center hole, and the top has a center measur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com