Mounting method of transmission gear of CG engine crankcase

A technology of transmission gear and installation method, which is applied in the direction of transmission parts, belts/chains/gears, measuring devices, etc., can solve the problems of inaccurate gear matching results, increase the error of measured values, and low assembly efficiency, etc., to achieve detection Easy to operate, improve the pass rate, and improve the effect of assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

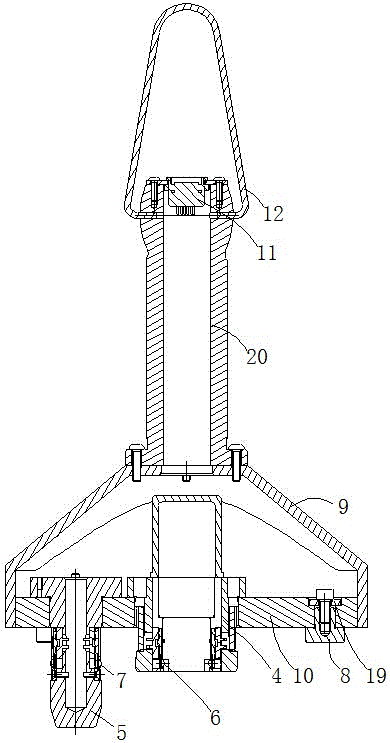

[0036] Optimum implementation mode: a method for installing a CG engine crankcase transmission gear, the method includes the step of designing and producing a plurality of groups of timing driven gears with different cross rod distances corresponding to a timing driving gear before installation; When installing, firstly press-fit the timing driving gear on the crankshaft, and then select the matching timing driven gear to complete the installation and gear matching; To realize the center distance error detection of the crankshaft and camshaft holes, and rely on the computer to automatically select the matching timing driven gear for installation.

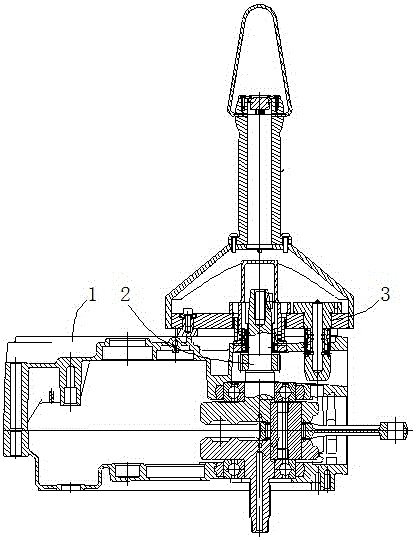

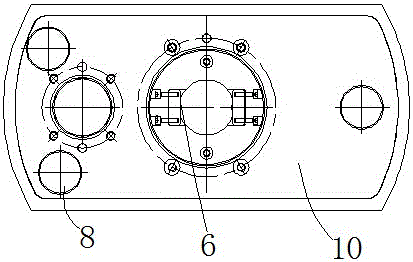

[0037] More specifically, in this optimal implementation mode, such as Figure 1-5 The shown a CG engine crankcase 1 transmission gear assembly measurement aids to achieve calibration and testing, said aids include crankshaft camshaft center distance measurement device and crankshaft camshaft center distance measurement and calibrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com