Standing column assembly welding tool

A technology for assembling welding fixtures and columns, which is applied in welding equipment, manufacturing tools, auxiliary devices, etc., can solve the problems of complex structure of mixing station columns, failure to meet refinement requirements, and failure to meet production capacity requirements, etc., to achieve fast demoulding of workpieces , high repeat positioning accuracy and short auxiliary time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

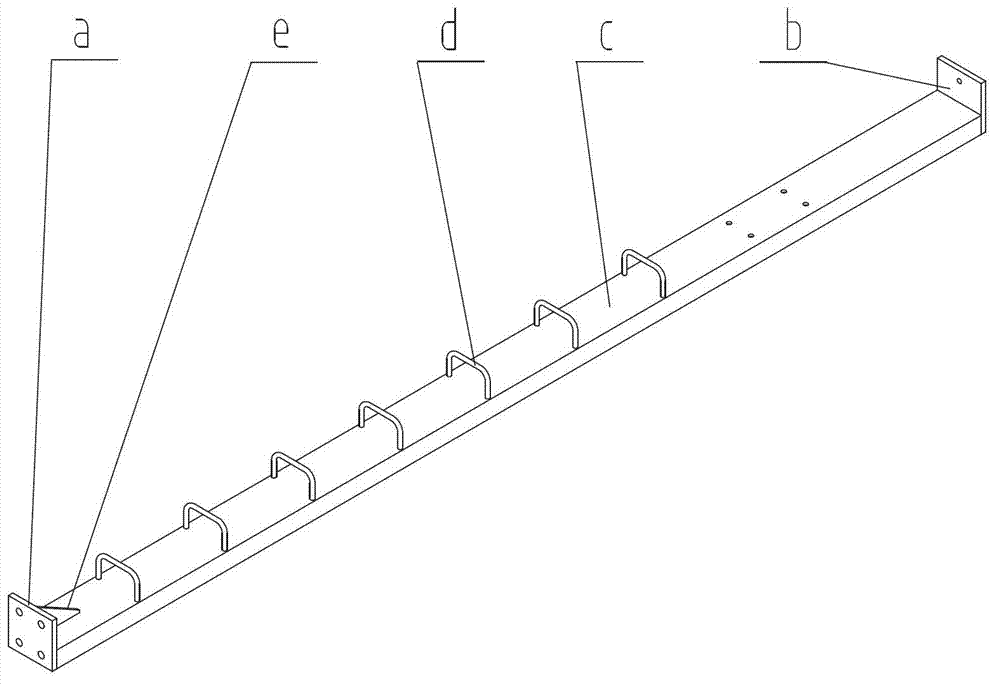

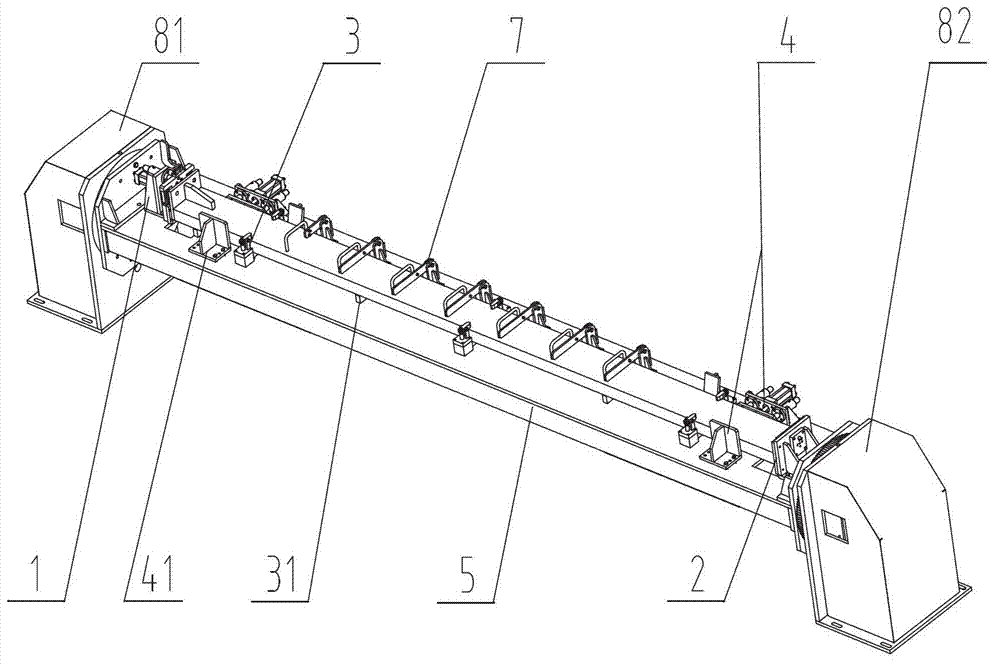

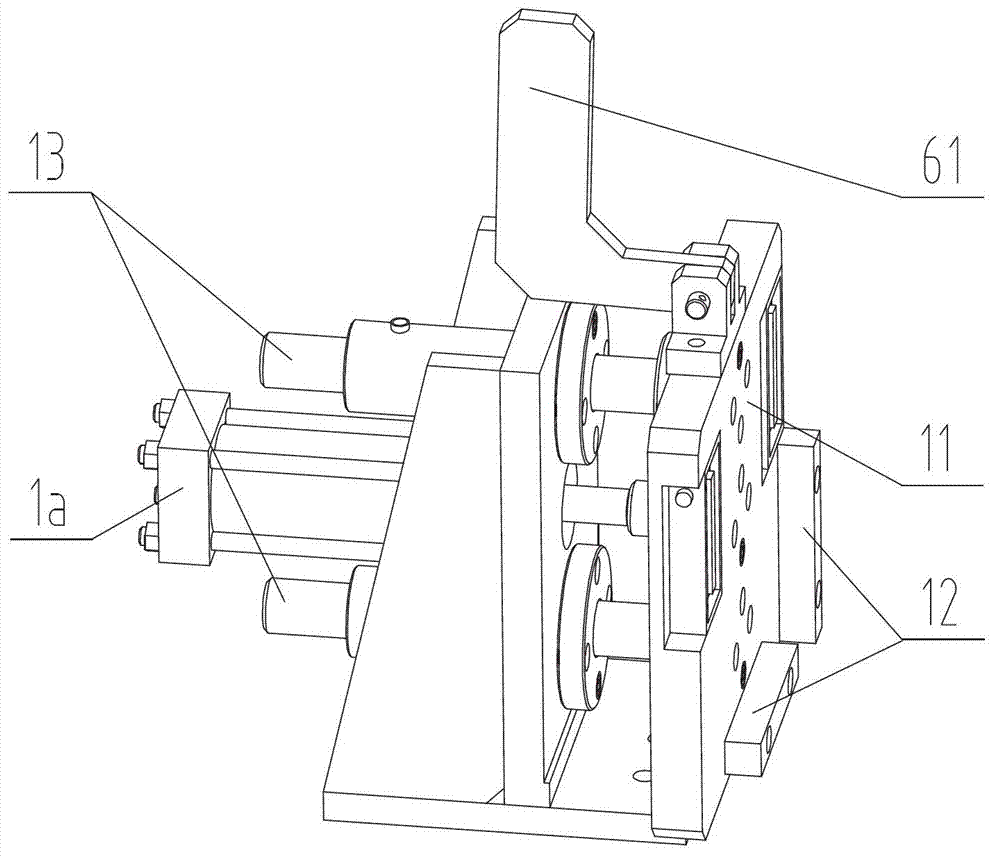

[0040] figure 2 Shown is an overall structural diagram of a column assembly welding tool according to an embodiment of the present invention. The column welding tool can be used for figure 1 The welding process of the mixing station column. From figure 2 It can be seen from the figure that the column assembly welding tool of the present invention at least includes a left and right limiting mechanism, an upper and lower limiting mechanism 3 and a side limiting mechanism 4 . The positioning and clamping of the column in the left and right, up and down and front and rear directions can be ensured by the limit of each limit mechanism, so as to facilitate the subsequent welding process. It shou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com