Quick positioning demoulding device for casting iron pan pressure casting production

A technology of demoulding device and cast iron pot, which is applied in the field of rapid positioning and demoulding device for cast iron pot die-casting production, which can solve the problems that the mold cannot be positioned quickly and accurately, consumes energy, and is damaged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

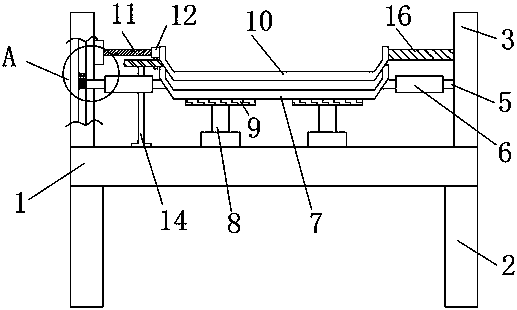

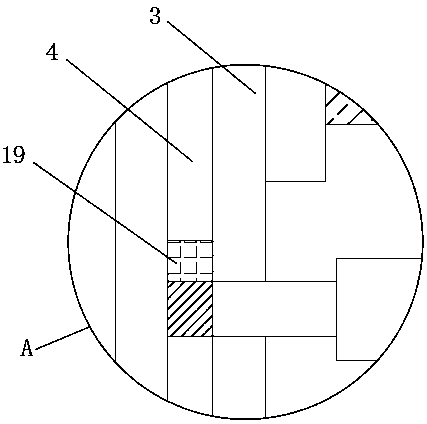

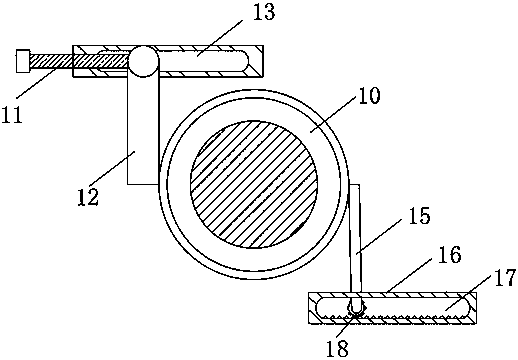

[0024] A rapid positioning and demoulding device for cast iron pot die-casting production, including a workbench 1 and legs 2, the lower end of the workbench 1 is fixedly connected with the outrigger 2, and the upper surface of the workbench 1 is fixedly installed with two sets of fixing plates 3, the fixing plates 3 The middle part is provided with a damping chute 4, and the damping chute 4 is fixedly connected with the first fixed rod 5 through a slider, the outer surface of the first fixed rod 5 is provided with a heat insulating sleeve 6, and the end of the first fixed rod 5 is connected with a lower mold 7 The upper end of the workbench 1 is located below the lower mold 7, and a hydraulic lifting device 8 is fixedly installed, and an upper mold 10 is arranged above the lower mold 7. An electric push rod 11 is fixedly installed on the upper part of a group of fixed plates 3, and the end of the electric push rod 11 is fixedly connected. The sliding rod 12, the lower end of t...

Embodiment 2

[0026] A rapid positioning and demoulding device for cast iron pot die-casting production, including a workbench 1 and legs 2, the lower end of the workbench 1 is fixedly connected with the outrigger 2, and the upper surface of the workbench 1 is fixedly installed with two sets of fixing plates 3, the fixing plates 3 The middle part is provided with a damping chute 4, and the damping chute 4 is fixedly connected with the first fixed rod 5 through a slider, the outer surface of the first fixed rod 5 is provided with a heat insulating sleeve 6, and the end of the first fixed rod 5 is connected with a lower mold 7 The upper end of the workbench 1 is located below the lower mold 7, and a hydraulic lifting device 8 is fixedly installed, and an upper mold 10 is arranged above the lower mold 7. An electric push rod 11 is fixedly installed on the upper part of a group of fixed plates 3, and the end of the electric push rod 11 is fixedly connected. The sliding rod 12, the lower end of t...

Embodiment 3

[0029] A rapid positioning and demoulding device for cast iron pot die-casting production, including a workbench 1 and legs 2, the lower end of the workbench 1 is fixedly connected with the outrigger 2, and the upper surface of the workbench 1 is fixedly installed with two sets of fixing plates 3, the fixing plates 3 The middle part is provided with a damping chute 4, and the damping chute 4 is fixedly connected with the first fixed rod 5 through a slider, the outer surface of the first fixed rod 5 is provided with a heat insulating sleeve 6, and the end of the first fixed rod 5 is connected with a lower mold 7 The upper end of the workbench 1 is located below the lower mold 7, and a hydraulic lifting device 8 is fixedly installed, and an upper mold 10 is arranged above the lower mold 7. An electric push rod 11 is fixedly installed on the upper part of a group of fixed plates 3, and the end of the electric push rod 11 is fixedly connected. The sliding rod 12, the lower end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com