Filling injecting pastry demolding needle

A core injection needle and core injection technology, applied in food science, food coating, application, etc., can solve the problems affecting food quality and yield, inconvenient operation, cake deformation, etc., to improve production efficiency, automation, and removal. Convenience and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

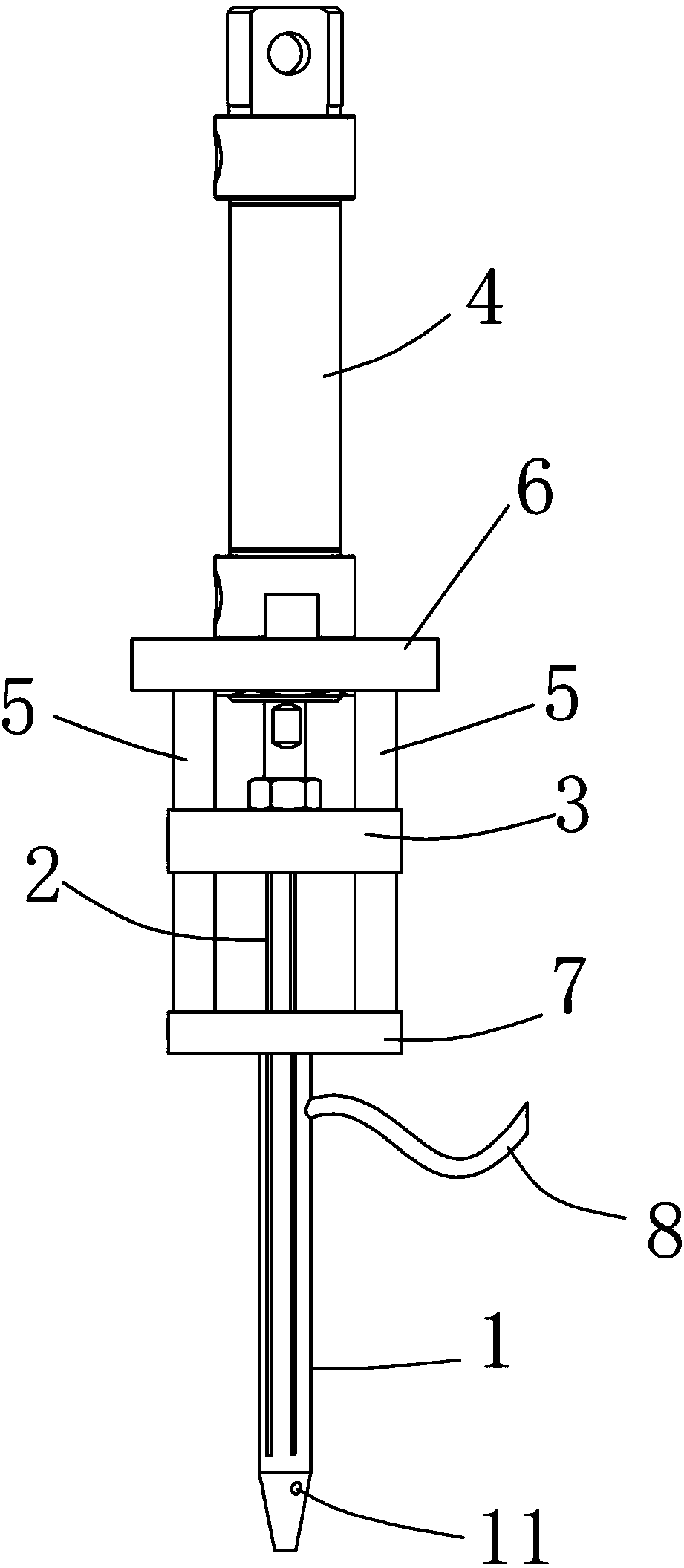

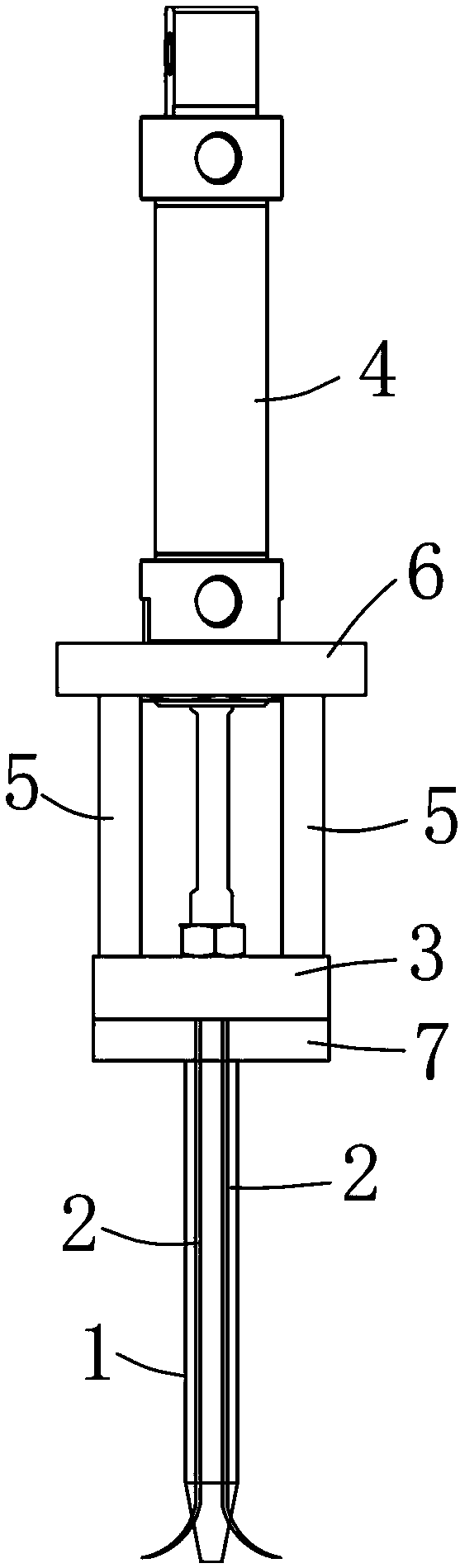

[0012] The idea, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present invention.

[0013] refer to figure 1 , 2 As shown, it is a schematic diagram of a preferred embodiment of the present invention. The present invention relates to a core injection demoulding needle, which has a core injection syringe 1. The core injection syringe 1 has a mounting end and a core injection end. The core injection syringe 1 The core injection end has a core injection port (not shown) connected to the feed pipe 8; a retractable demoulding pin 2 is assembled on the core injection syringe 1, and the demoulding form of the demoulding pin 2 is stretching. Extrude the core injection end of the core injection syringe 1 and form a bent shape for demoulding. The invention realizes the integration of core injection and demoulding structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com