Patents

Literature

104results about How to "Keep the distance constant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

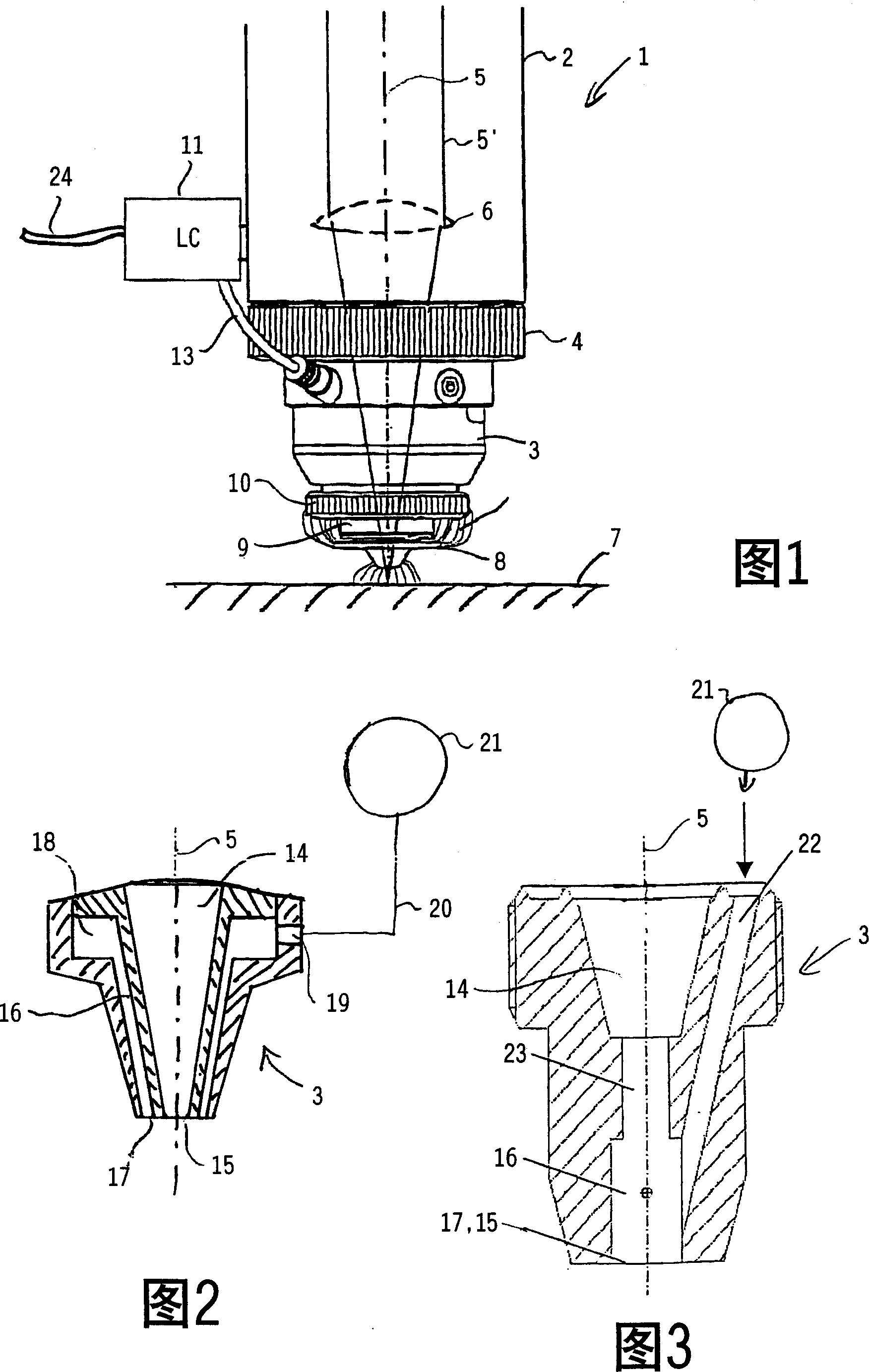

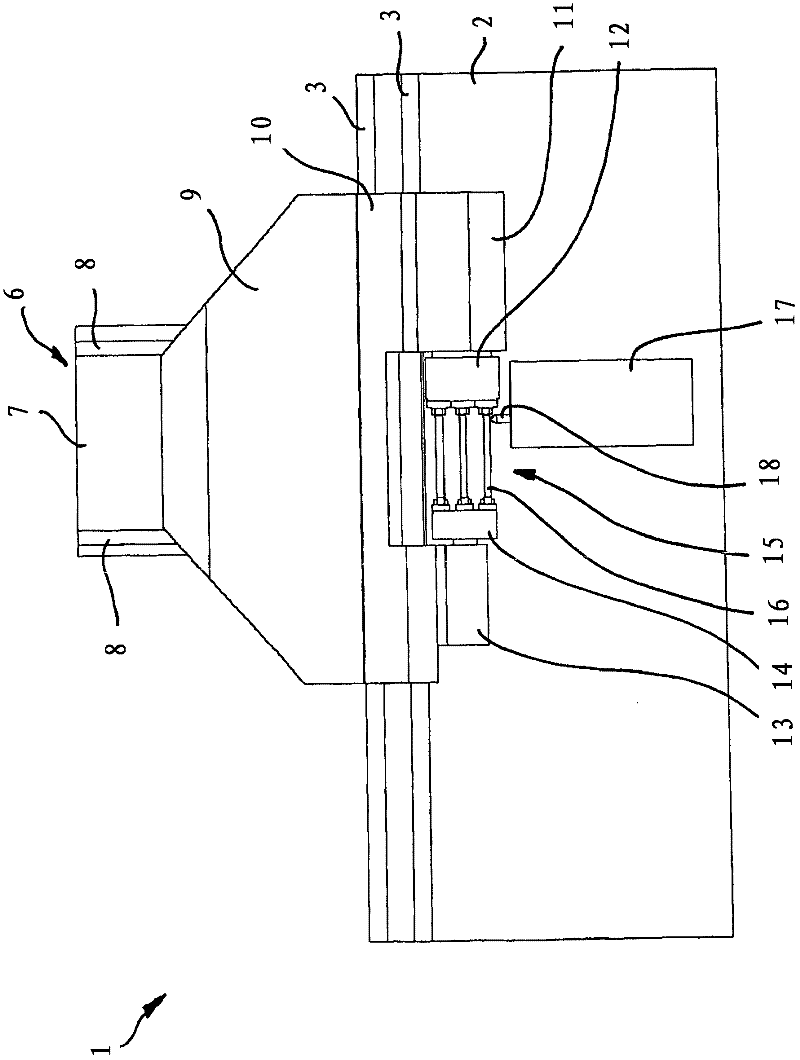

Laser machining apparatus and its running and controlling methods

InactiveCN1981976AAvoid damageKeep the distance constantLaser beam welding apparatusLaser processingOptoelectronics

A laser machining apparatus has a laser machining head, which is composed of a casing, a nozzle with a central channel of laser beam for an emitting outlet and a channel of processing gas, a focusing lens set for focusing the laser beam to a working focus point, a processing gas delivering unit, a sensor electrode for measuring the distance between nozzle and workpiece, and a distance regulator. Its control method is also disclosed.

Owner:PRECITEC GMBH

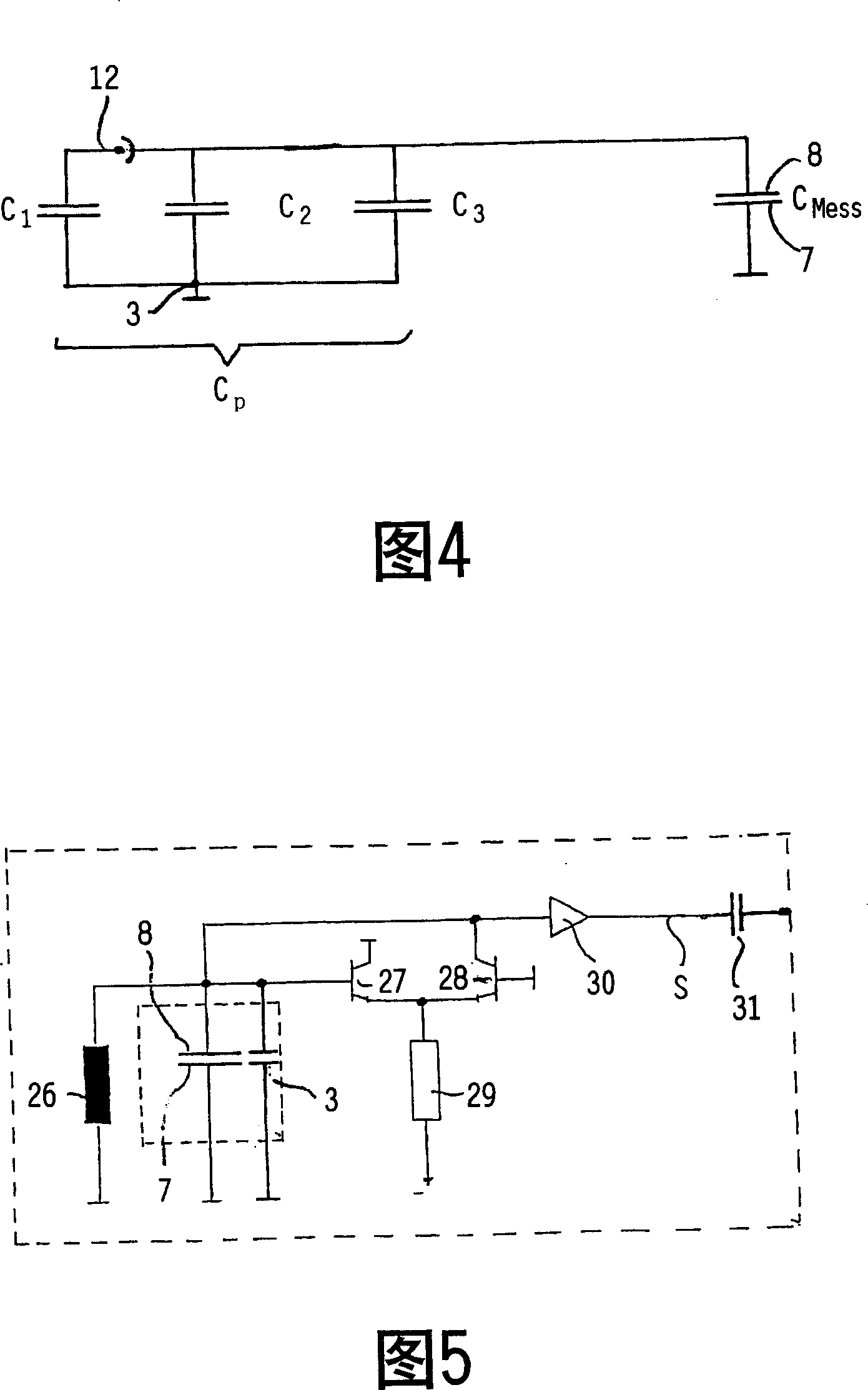

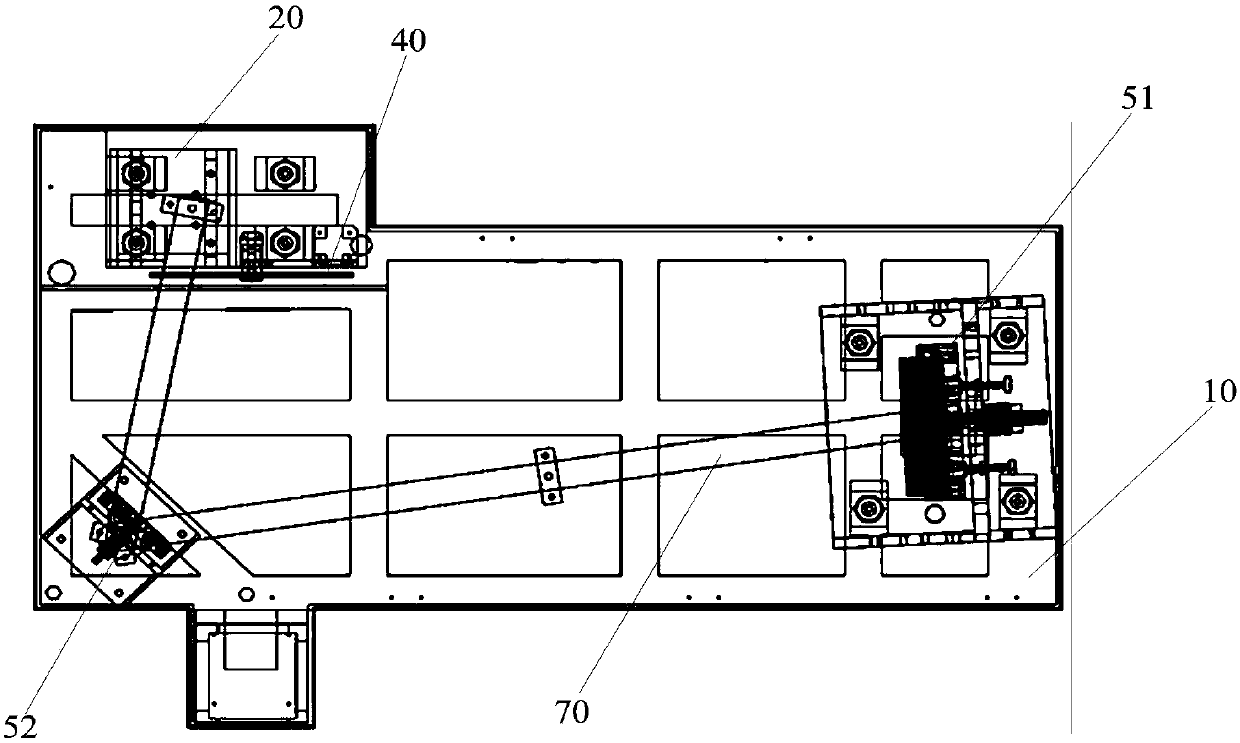

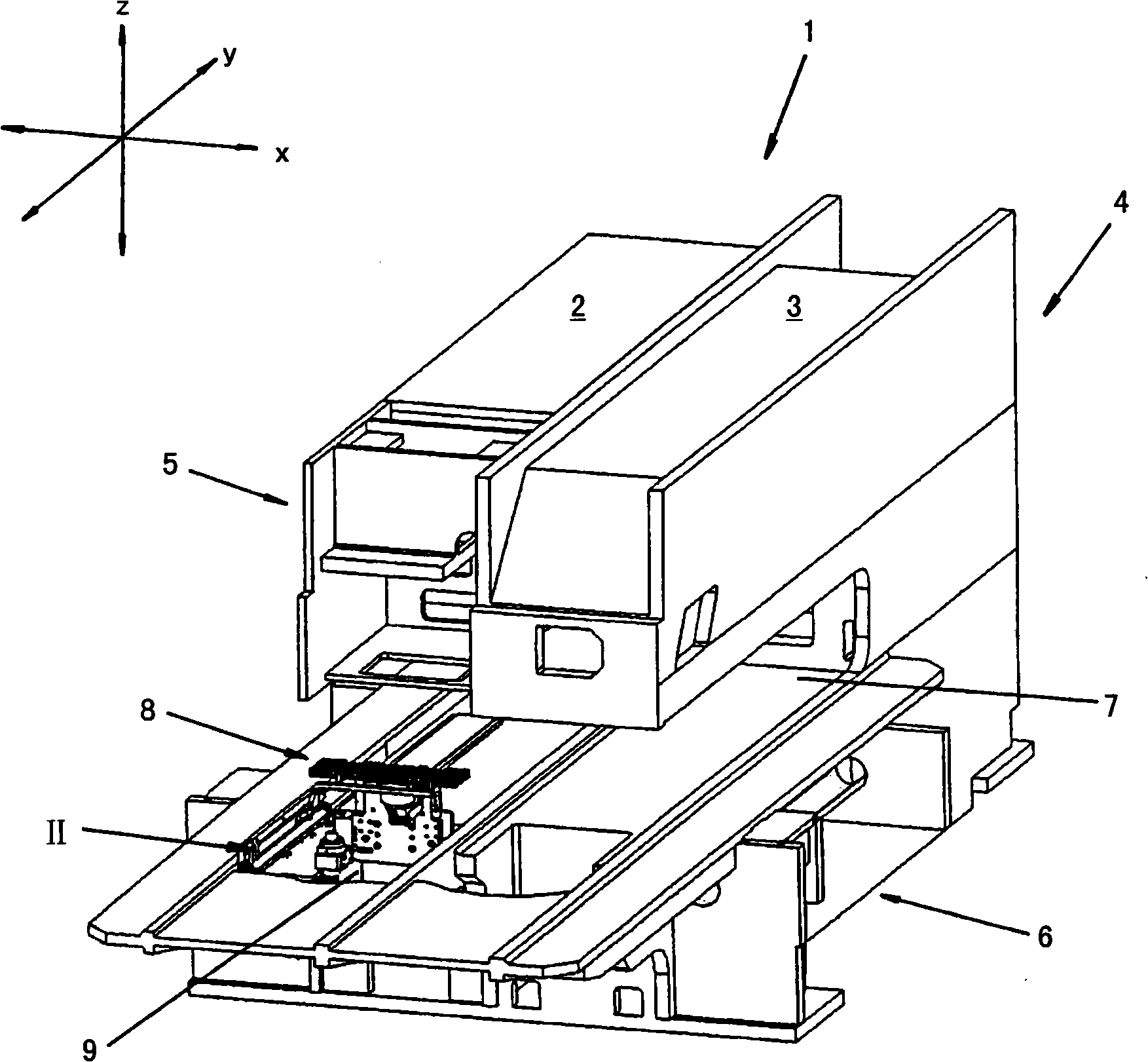

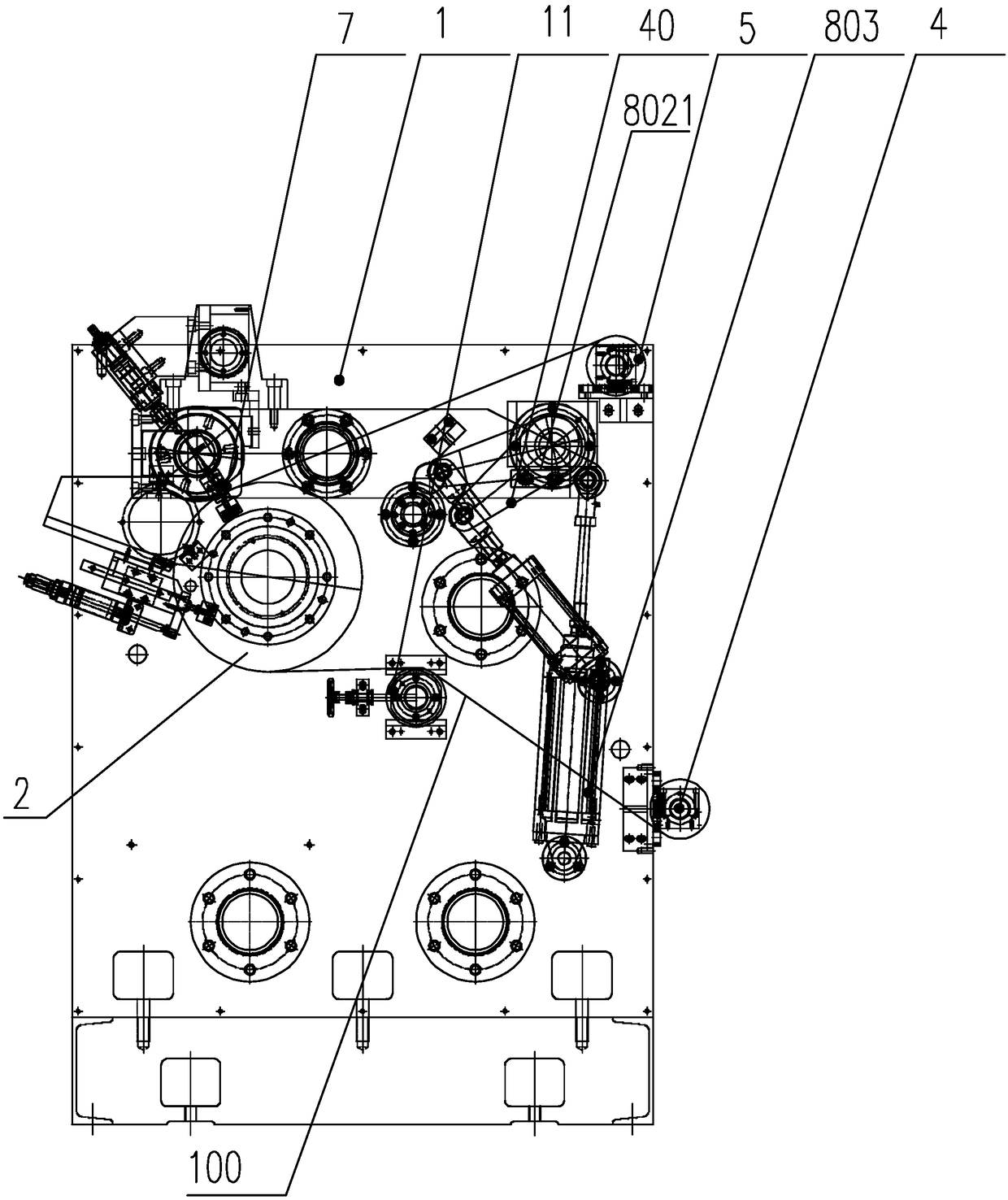

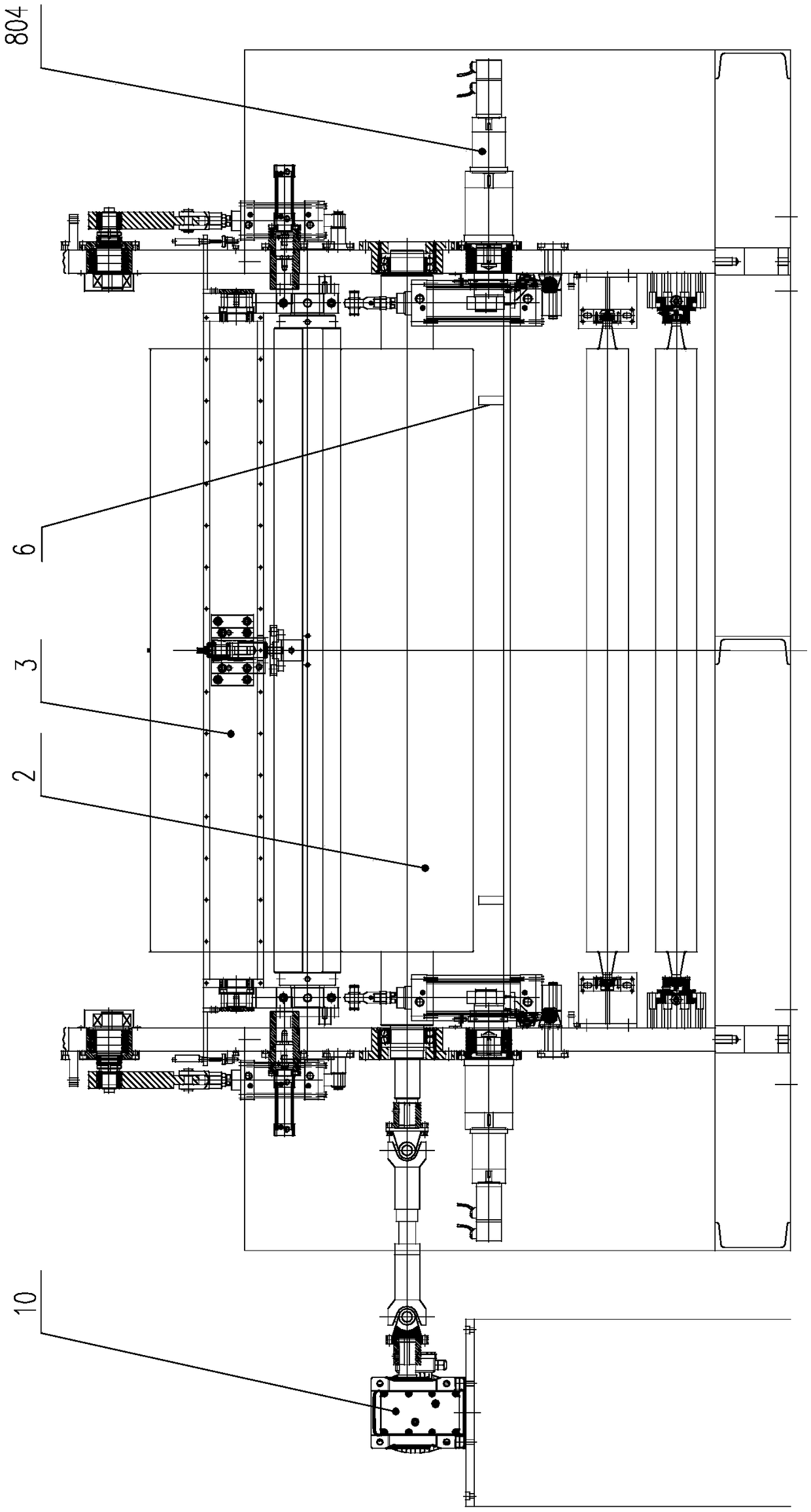

Laser cutting machine

InactiveCN106735940AImprove applicabilityKeep the distance constantLaser beam welding apparatusEngineeringLaser cutting

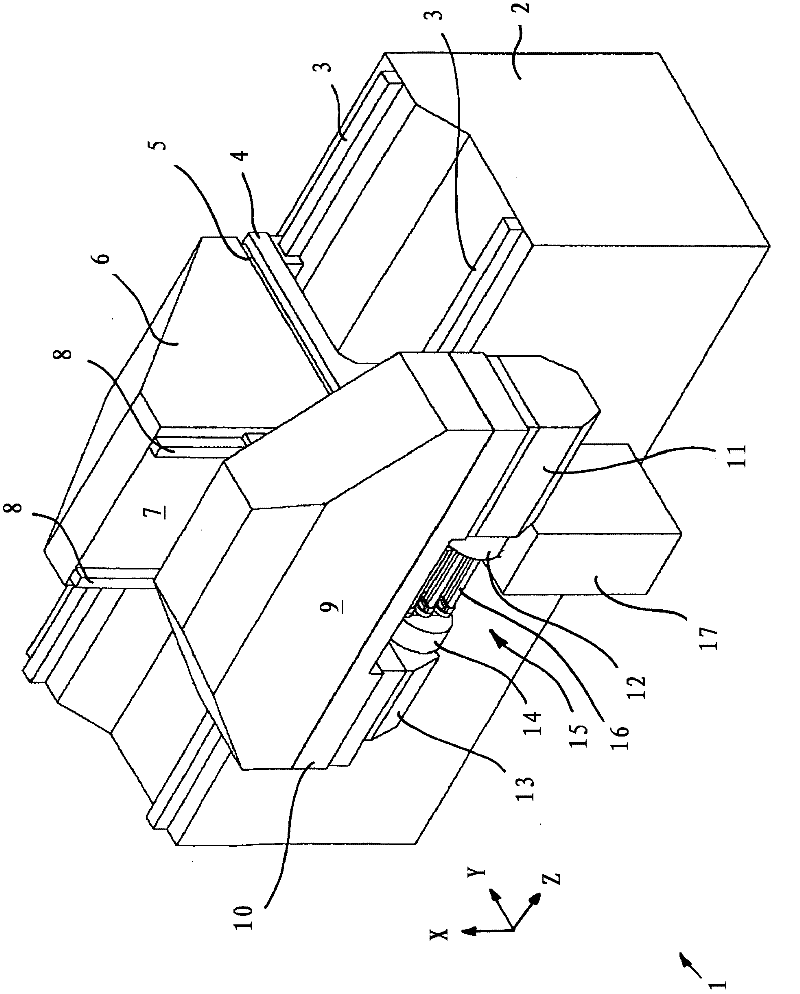

The invention discloses a three-dimensional laser cutting machine. The three-dimensional laser cutting machine comprises a machine tool, wherein the machine tool comprises an X-axis assembly used for driving a cutting head in an X direction, a Z-axis assembly used for driving the cutting head in a Z direction, a Y-axis assembly used for driving a workpiece in a Y direction, a workpiece rotary shaft assembly used for driving the workpiece to rotate, a cutting head rotary shaft assembly and a follower shaft assembly; the workpiece rotary shaft assembly is capable of driving the workpiece to rotate in the Z direction; the cutting head rotary shaft assembly is capable of driving the cutting head to rotate in the Y direction; the follower shaft assembly is arranged on the cutting head rotary shaft assembly; the cutting head is arranged in the follower shaft assembly; a capacitive sensor is arranged at the nozzle of the cutting head; and each two of the X direction, the Y direction and the Z direction are mutually vertical. The three-dimensional laser cutting machine further comprises a control terminal used for carrying out control operation on the machine tool. The follower shaft assembly is capable of automatically adjusting the height of the cutting head according to the change of the surface of a cutting sample to ensure a constant distance between the cutting head and the cutting sample during a three-dimensional laser cutting process, thereby solving the out-of-focus problem generated during a cutting process.

Owner:GUANGDONG ZHENGYE TECH

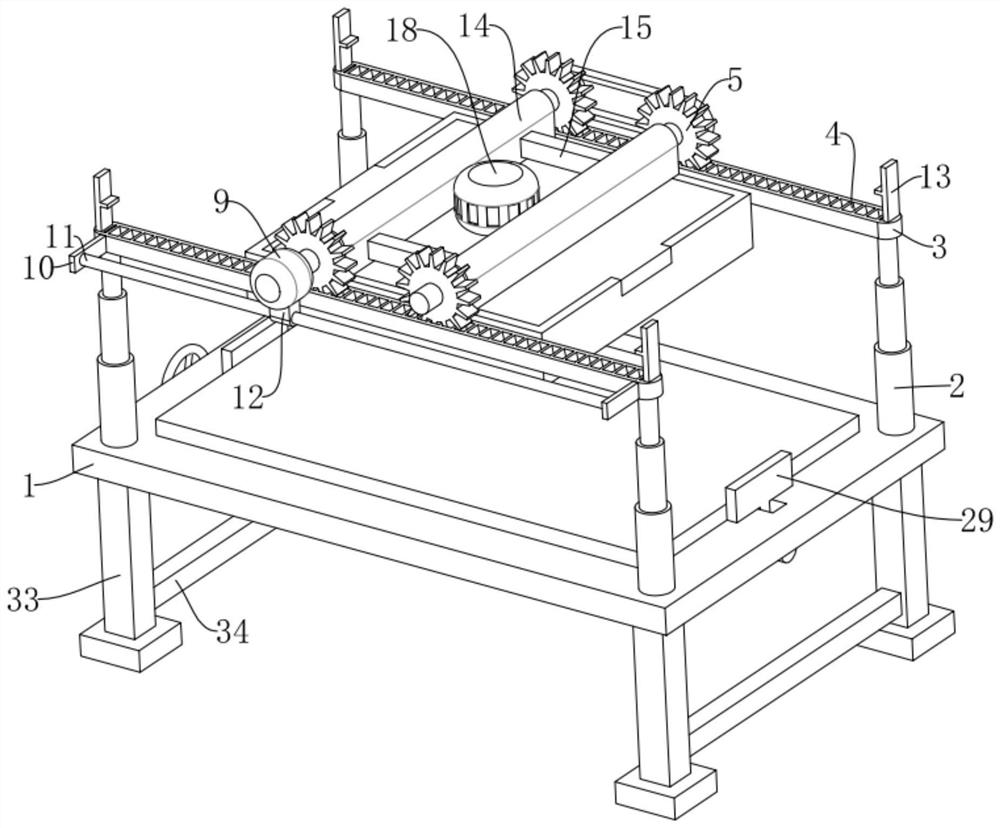

Unrolling device for winders

InactiveCN101428715ASimple structureKeep the distance constantFunction indicatorsWebs handlingEngineeringMechanical engineering

Owner:WILL-PEMCO

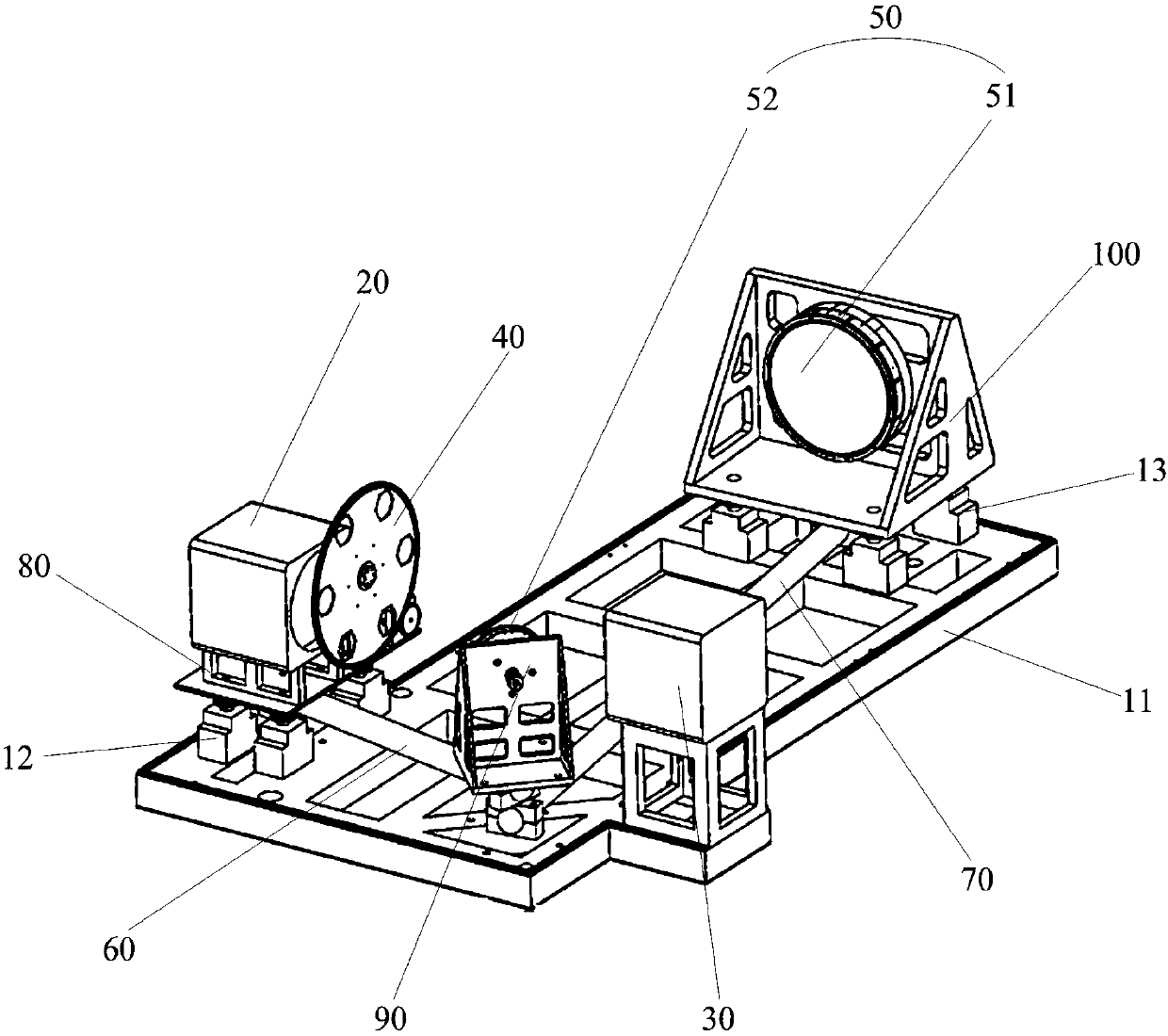

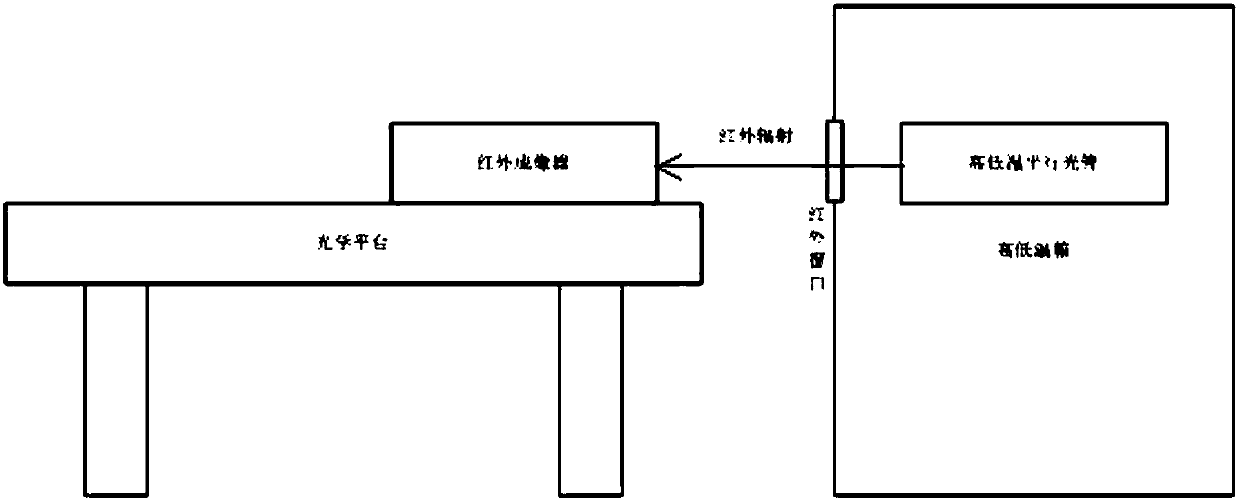

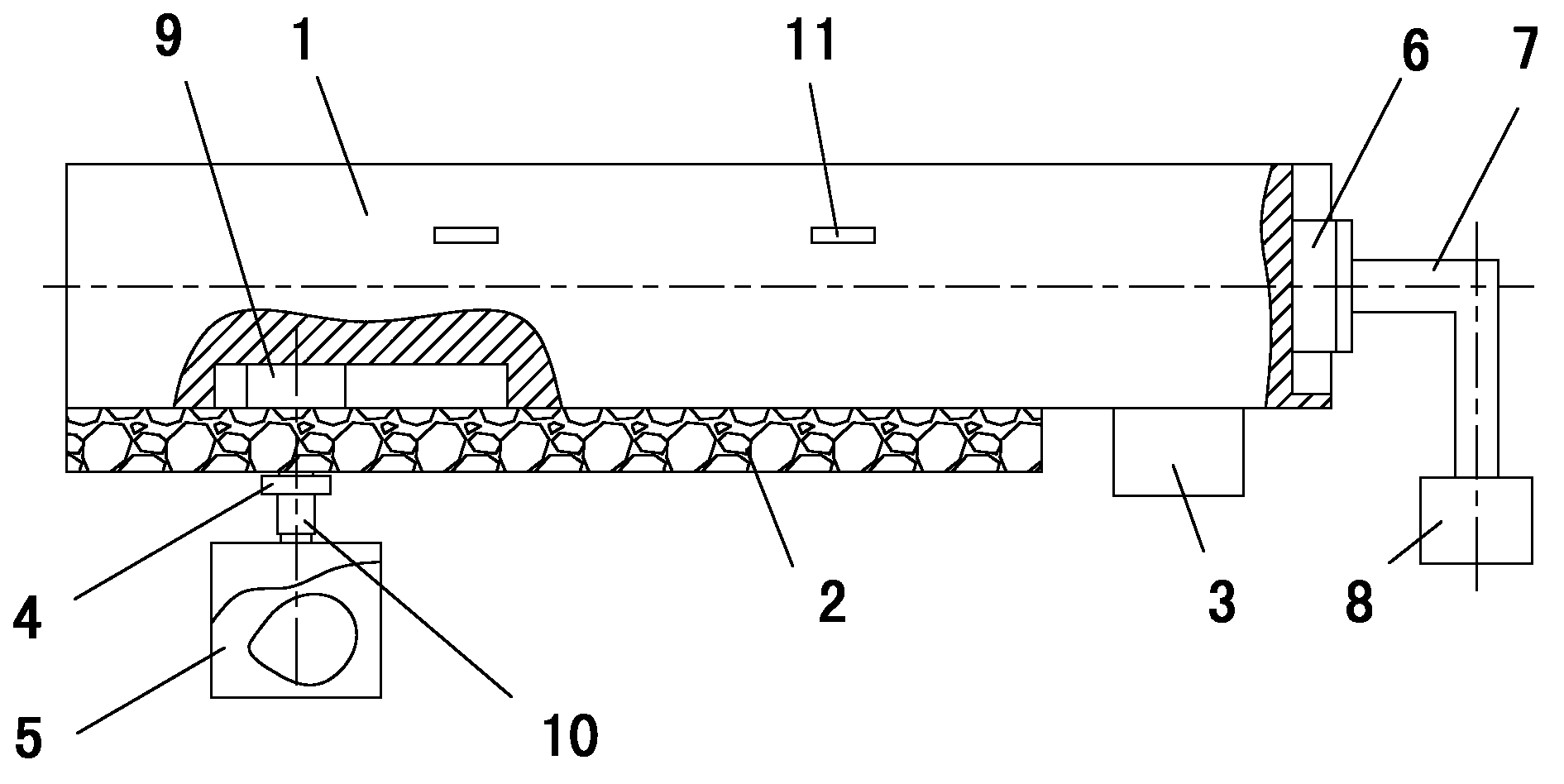

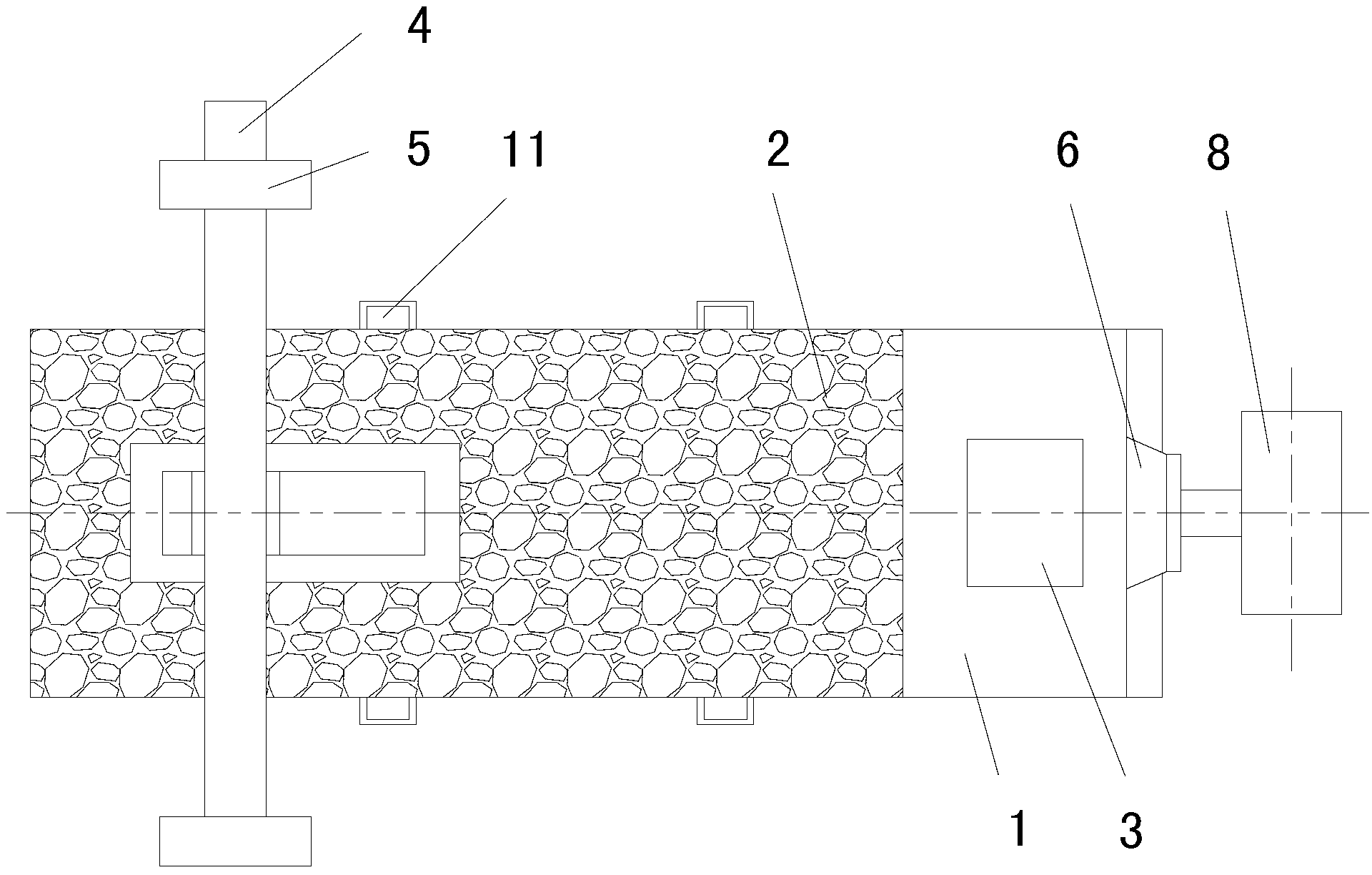

High and low-temperature infrared imaging system detecting device

ActiveCN110017900AKeep the distance constantWide temperature rangeRadiation pyrometryBlack bodyEngineering

The invention provides a high and low-temperature infrared imaging system detecting device, which comprises a platform supporting assembly, a target black body assembly, a background black body assembly, a target assembly, a high and low-temperature optical assembly, a first athermalization mechanism and a second athermalization mechanism, wherein the target black body assembly, the background black body assembly and the target assembly are all detachably arranged on the platform supporting assembly; the target infrared radiation generated by the target black body assembly and the background infrared radiation generated by the background black body assembly enter the high and low-temperature optical assembly through the target assembly to form an infrared target with a background; the first athermalization mechanism is used to ensure that the distance between the target assembly and a secondary mirror unit is unchanged; and the second athermalization mechanism is used to ensure that the distance between the secondary mirror unit and a primary mirror unit is unchanged. When the technical scheme provided in the invention is applied, the technical problem that the infrared imaging system detecting device in the prior art can not realize target simulation test in a deep space background, a complex background and a wide temperature range can be solved.

Owner:BEIJING ZHENXING METROLOGY & TEST INST

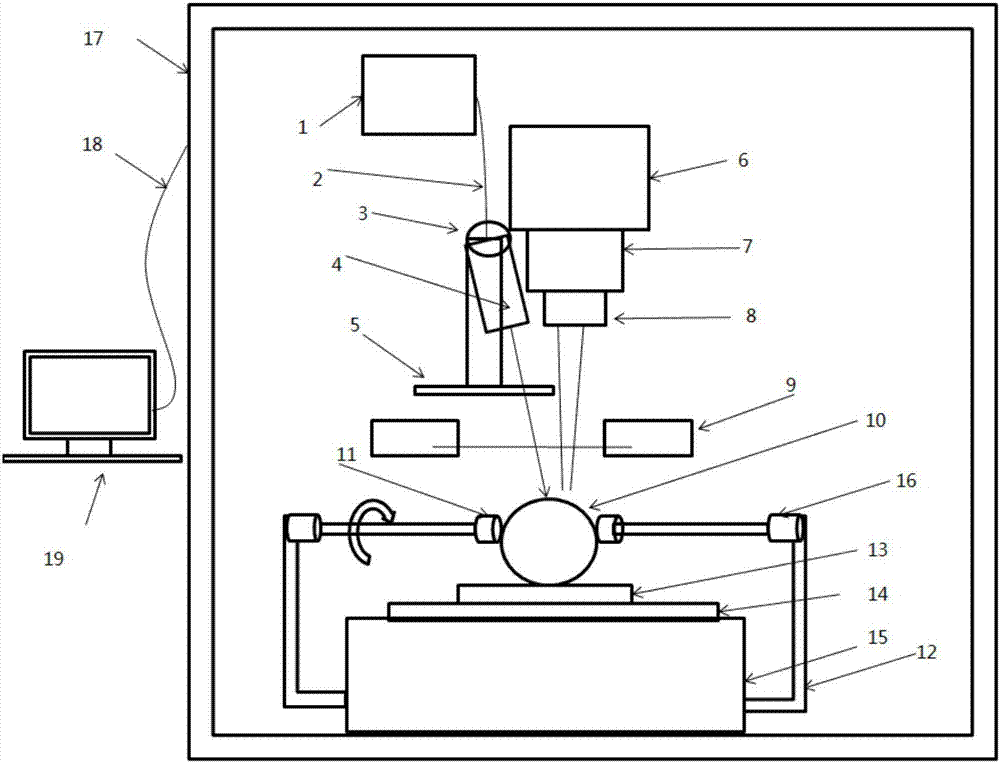

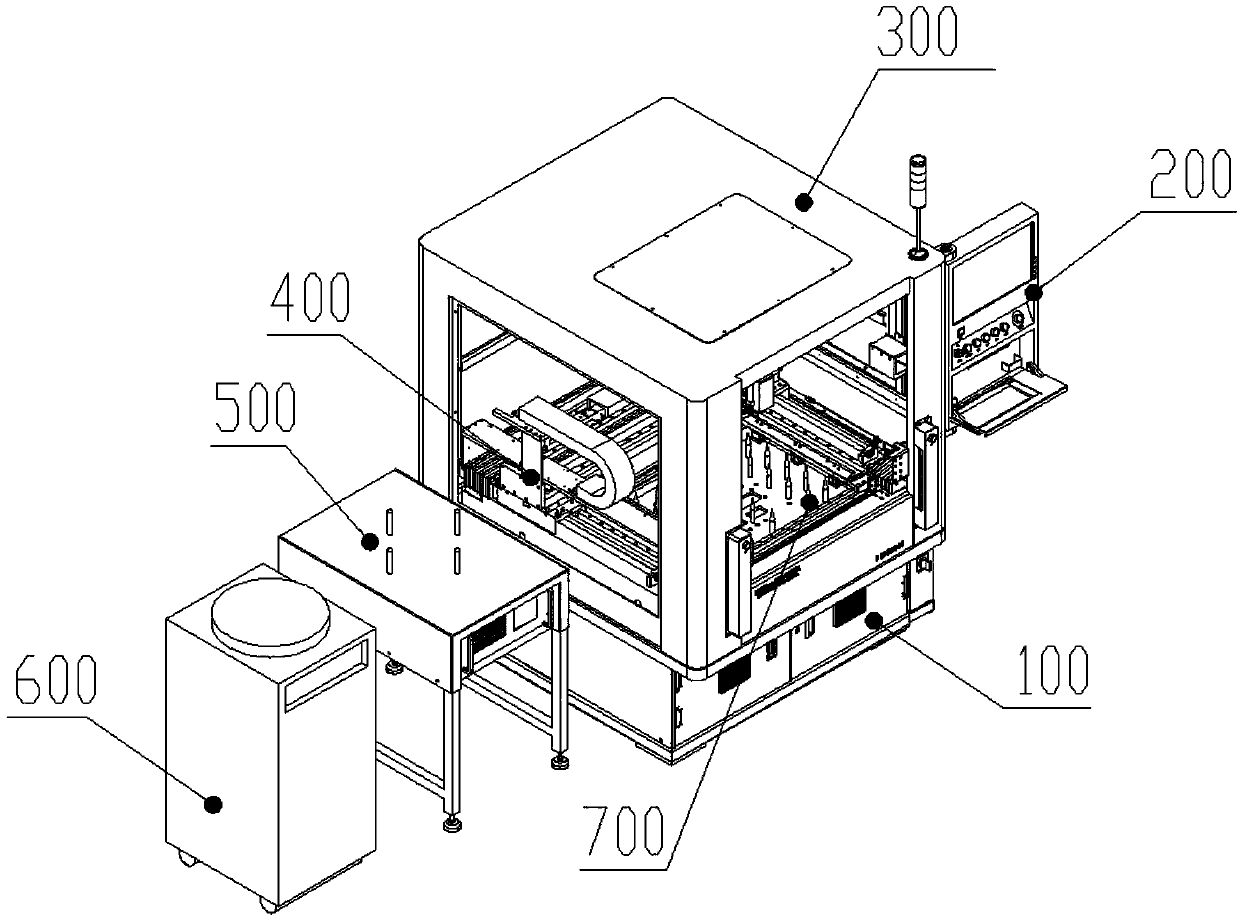

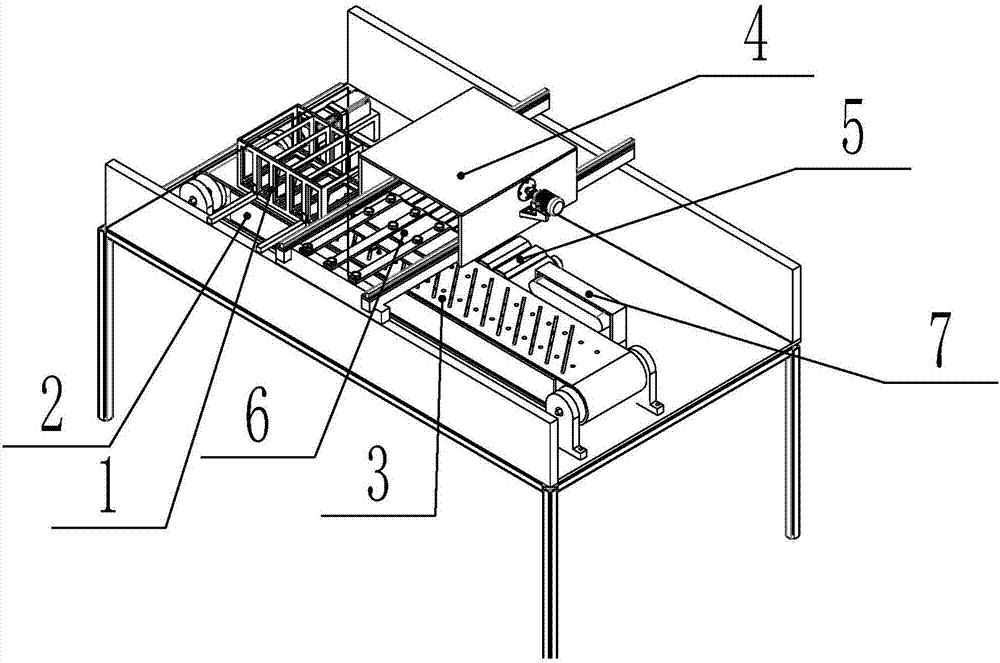

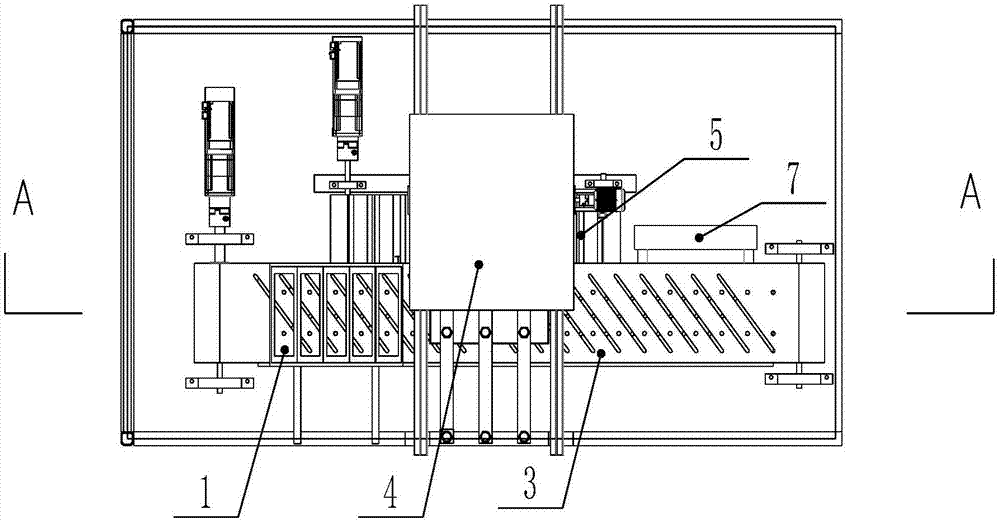

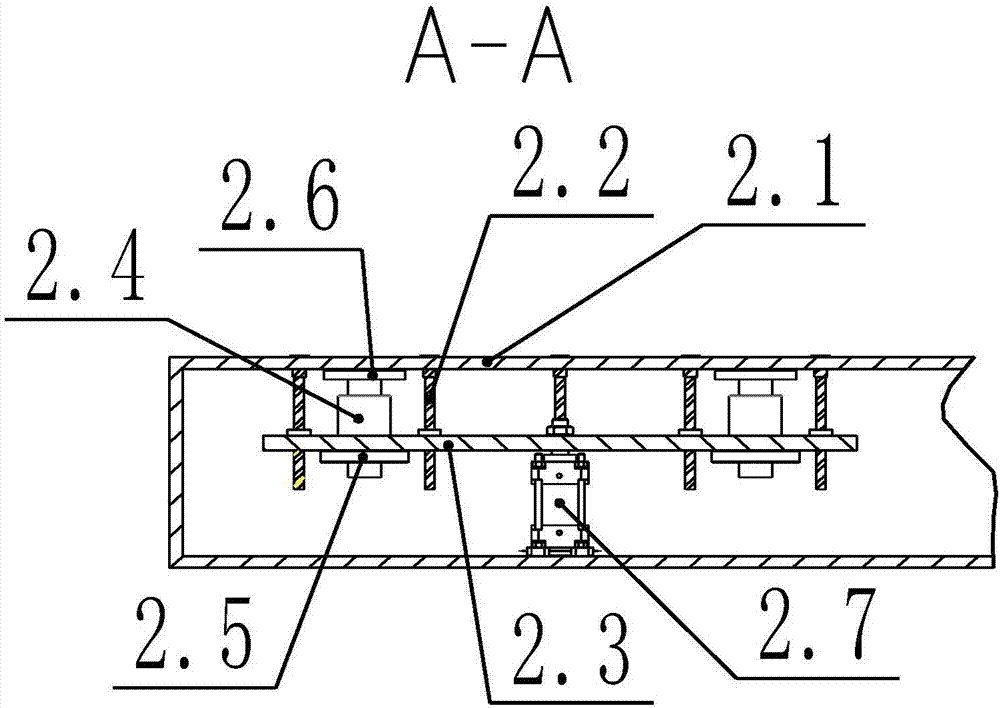

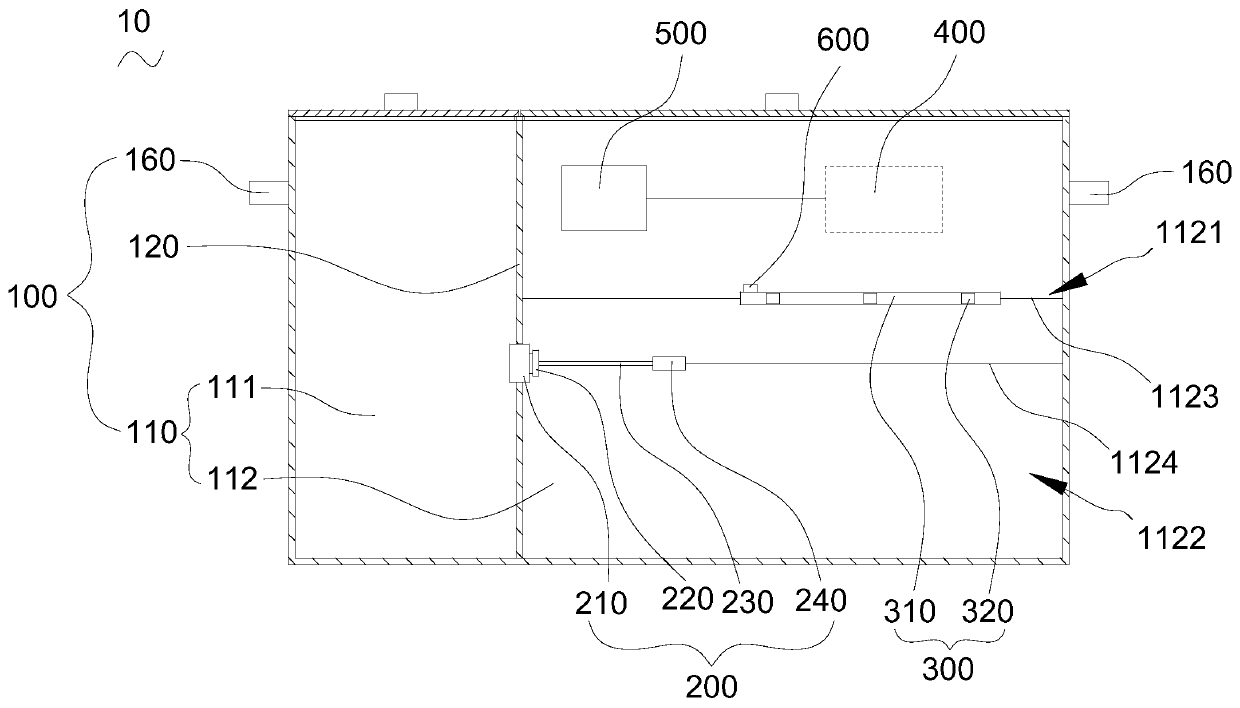

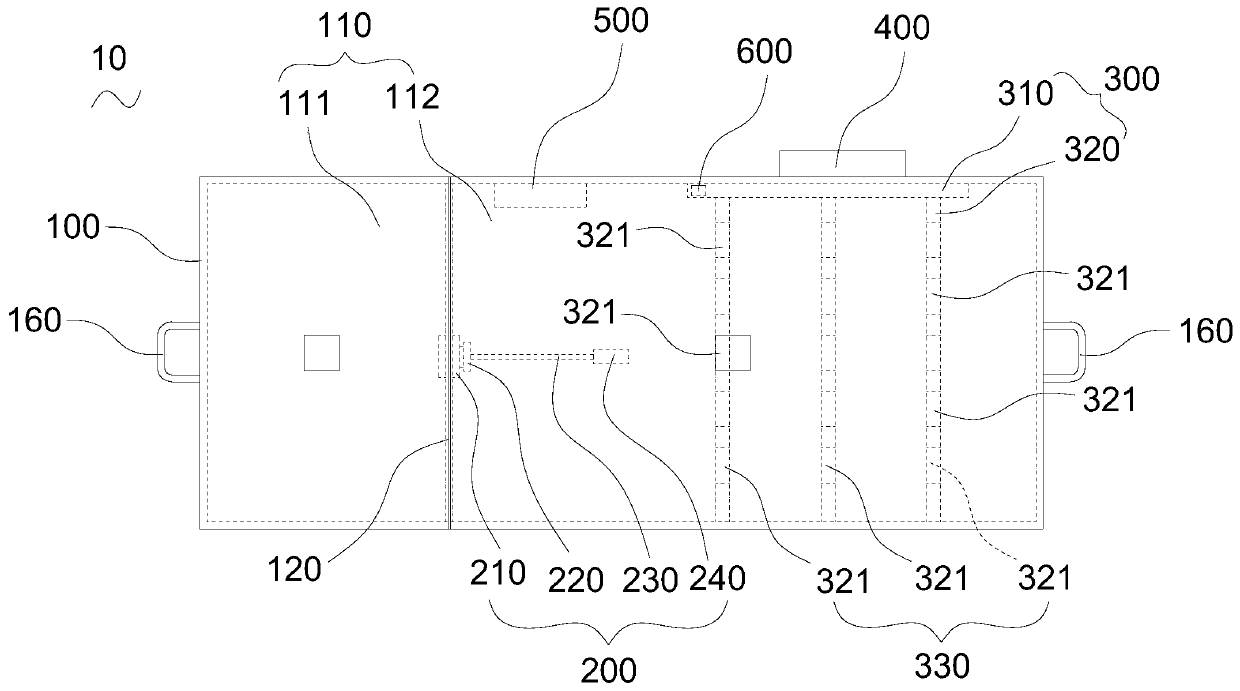

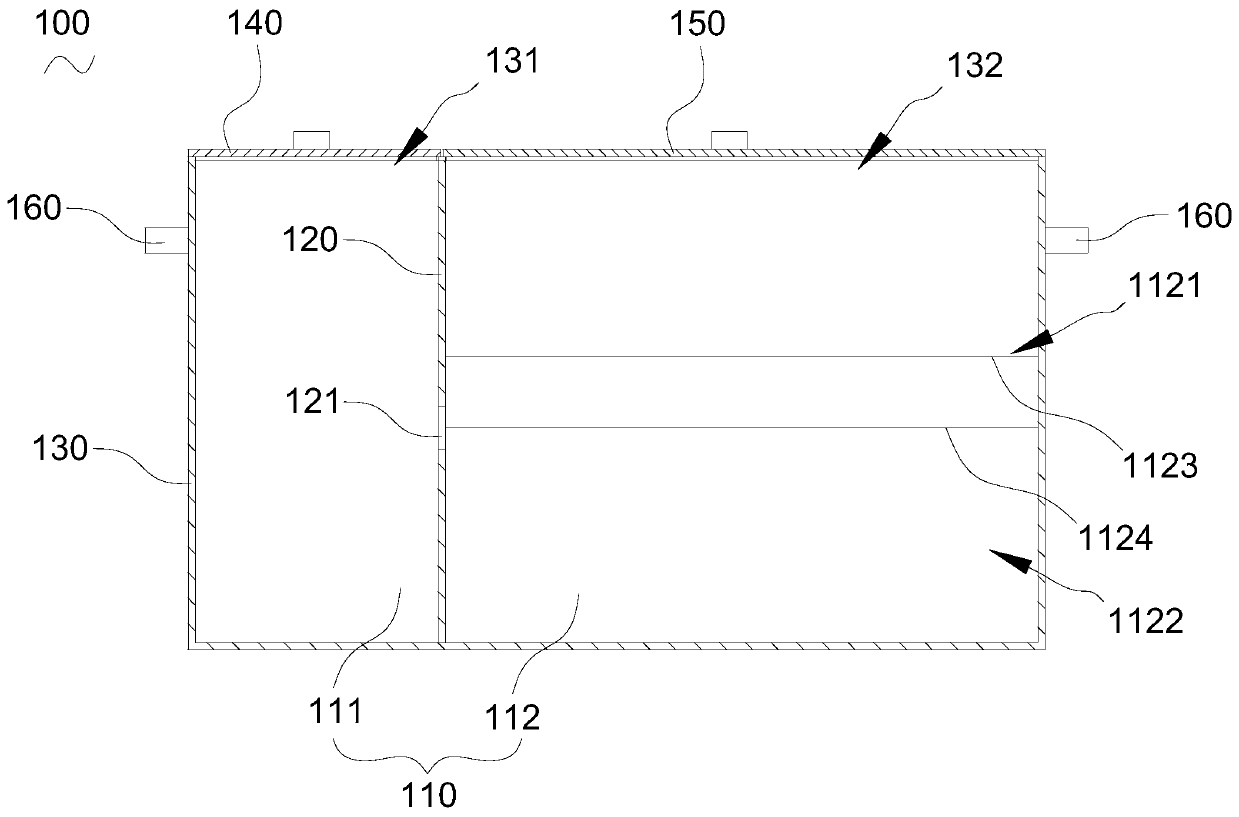

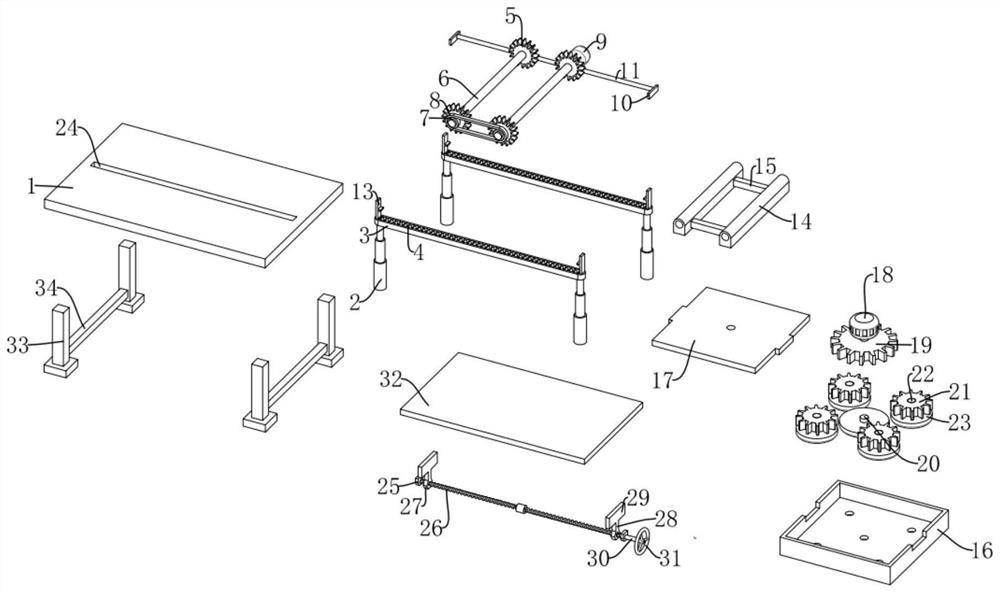

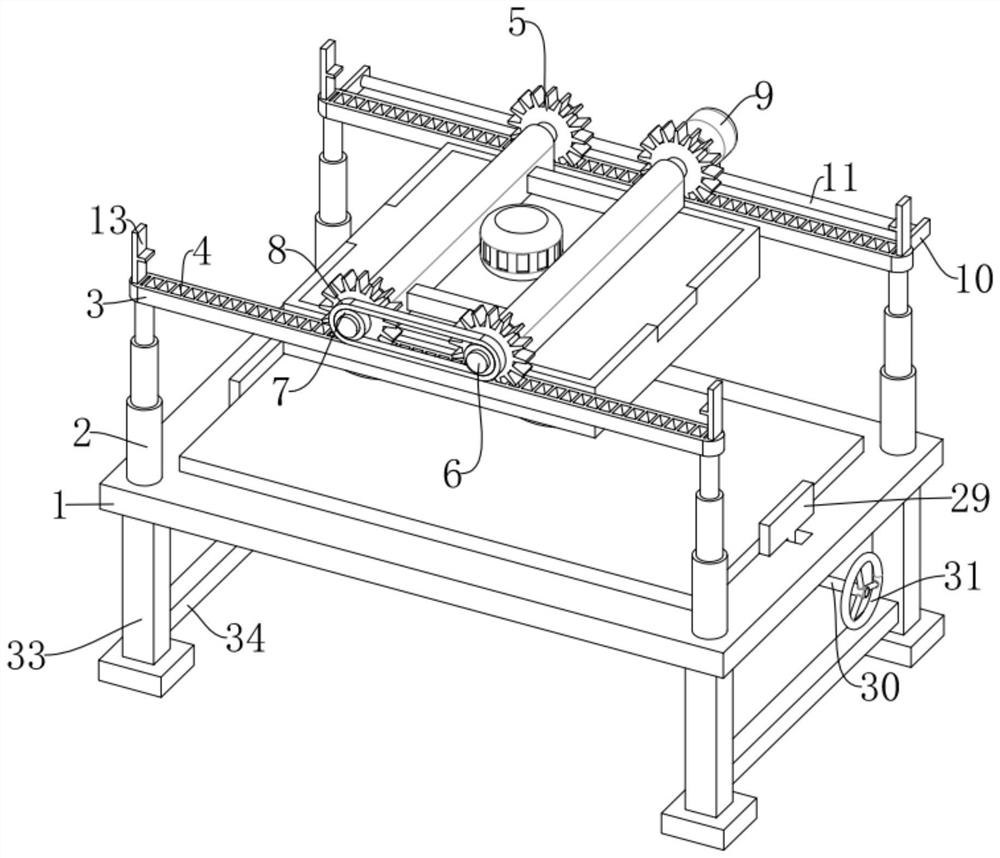

Scattering system for obtaining multi-faced diffuse reflection information of fruit

ActiveCN107345908AGuaranteed Diffuse ReflectanceImprove scalabilityScattering properties measurementsComputer control systemComputational physics

The invention discloses a scattering system for obtaining multi-faced diffuse reflection information of a fruit. The scattering system comprises a box body, a light source system, an imaging system, a sample delivery system, a sample rotating system and a computer control system located outside the box body, wherein the light source system, the imaging system, the sample delivery system and the sample rotating system are arranged in the box body; the light source system is used for providing a light source for irradiating a sample; the imaging system is used for collecting diffuse reflection information of the light source entering inside the sample to be scattered on the surface; and the sample delivery system and the sample rotating system are used for adjusting the position of the sample and driving the sample to rotate to collect the multi-faced diffuse reflection information of the sample. The hyperspectral scattering system is good in expandability and high in precision, and is capable of quickly and accurately obtaining the diffuse reflectivity of the fruit on a wave band of 400-1,000nm.

Owner:ZHEJIANG UNIV

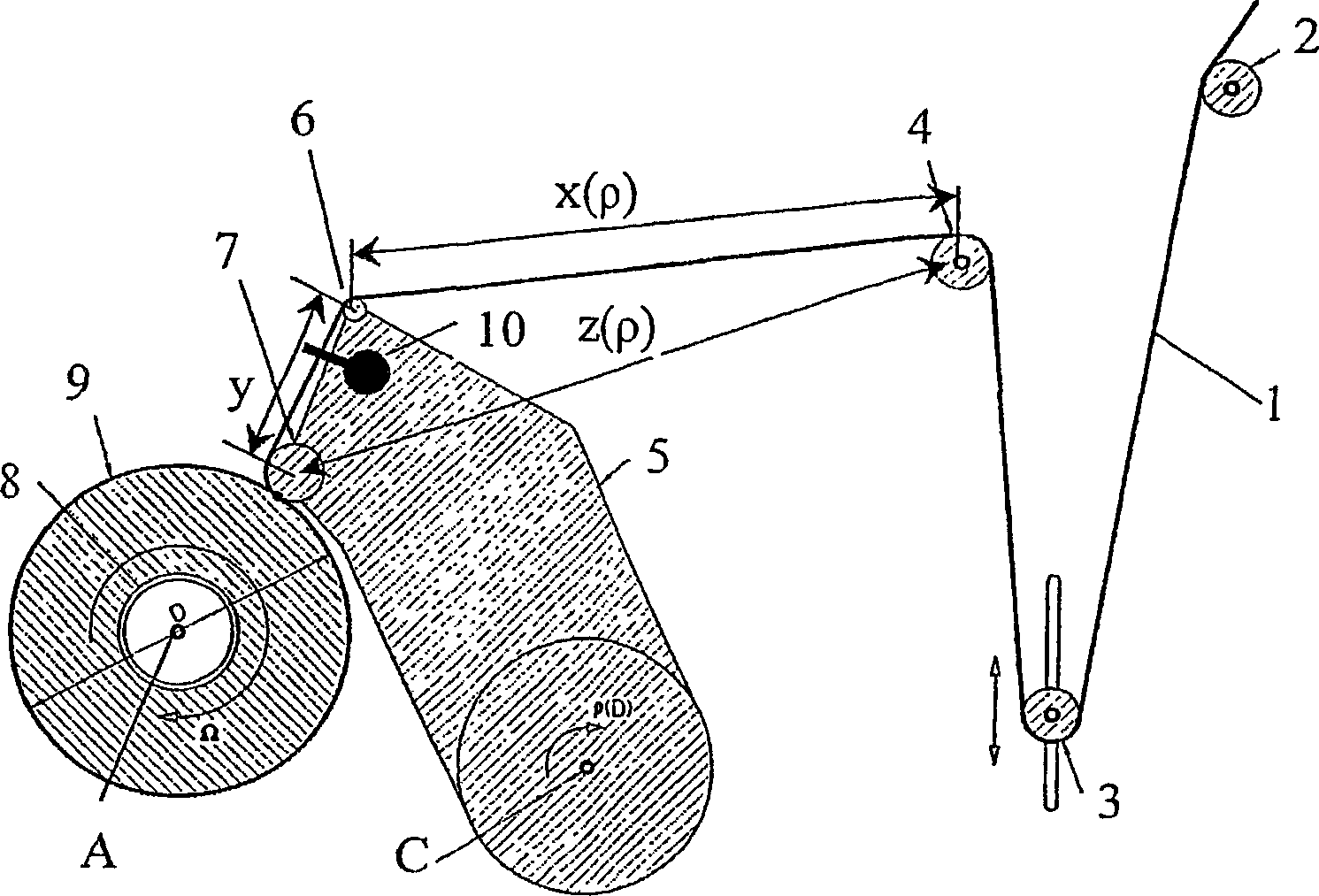

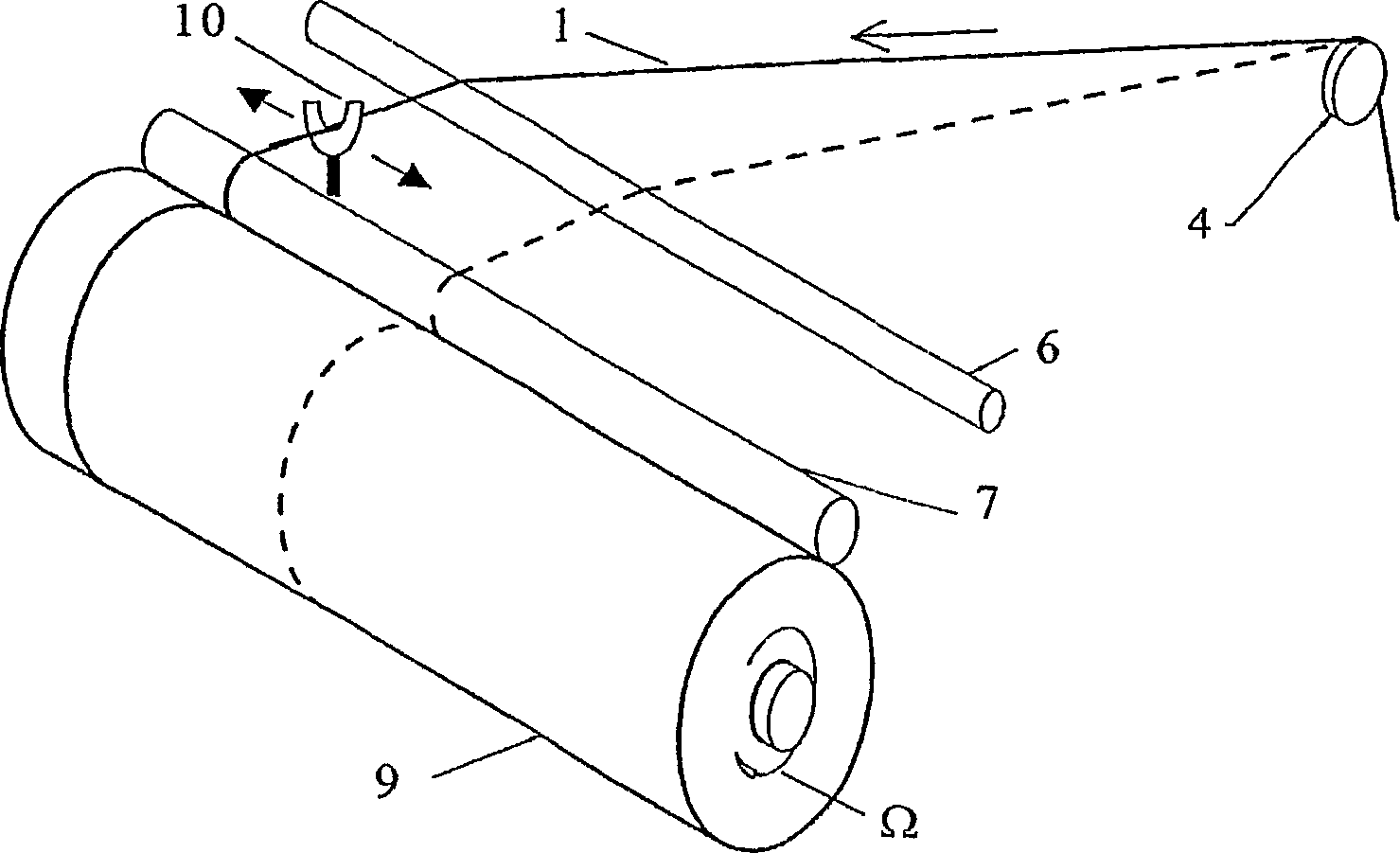

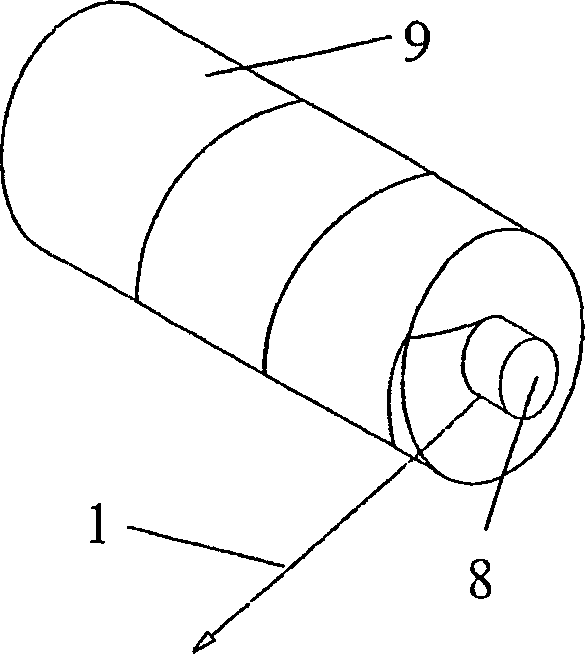

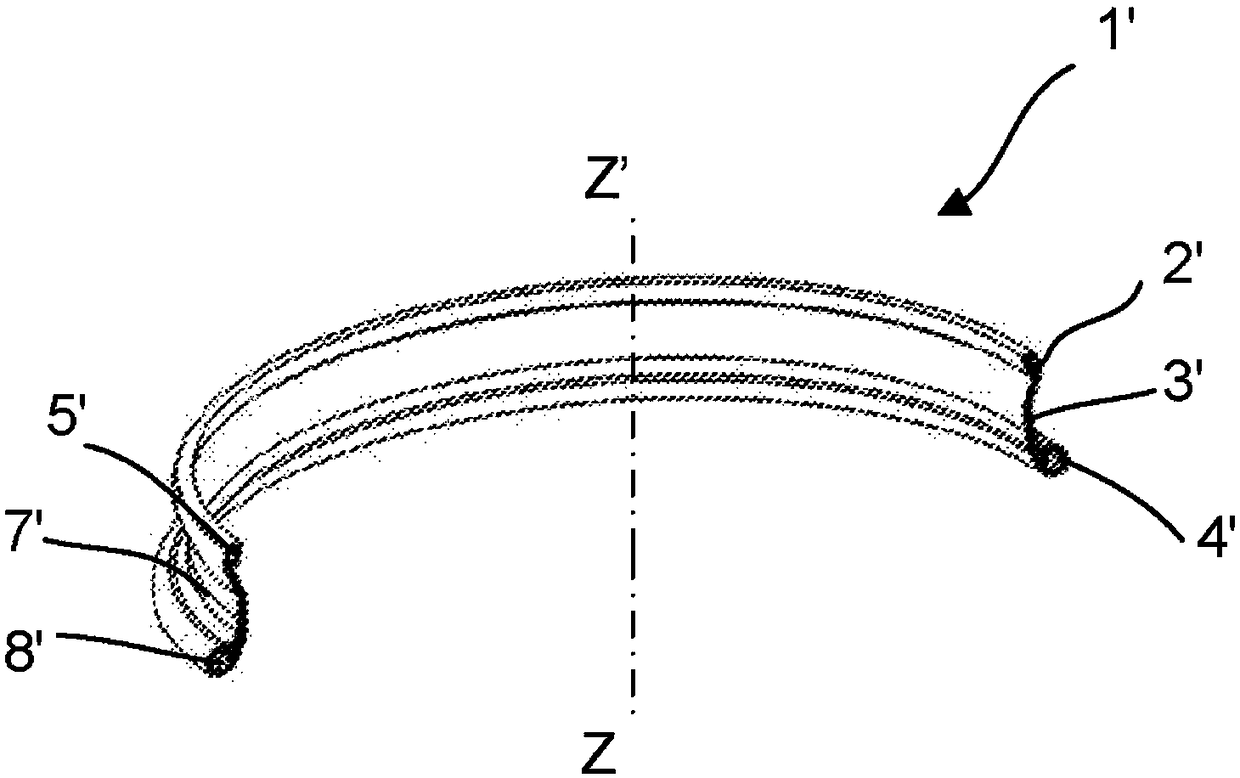

Winding device

A bobbin winding device for generating a bobbin by winding a thread or bandlet onto a bobbin core comprises fixing means ( 12 ) for holding a bobbin core ( 8 ) and rotating it around an axis of rotation (A), thread-pressing means ( 7 ) for pressing a thread ( 1 ) or bandlet against the peripheral surface of a bobbin ( 9 ) that builds up on the bobbin core ( 8 ), whereby the thread-pressing means are movable essentially radially relative to the axis of rotation (A), a traversing thread guide ( 10 ) located close to the thread-pressing means ( 7 ) for reciprocating the thread ( 1 ) or bandlet along the axis of rotation (A), and thread-support means ( 14 ) for conducting the thread supplied to the bobbin or bobbin core, respectively, in an axially stationary manner relative to the axis of rotation (A). The thread-pressing means ( 7 ) are movable essentially radially relative to the axis of rotation (A) together with the thread-support means ( 14 ) so that the distance (z) between the thread-pressing means ( 7 ) and the thread-support means ( 14 ) will remain constant.

Owner:STARLINGER & CO GMBH

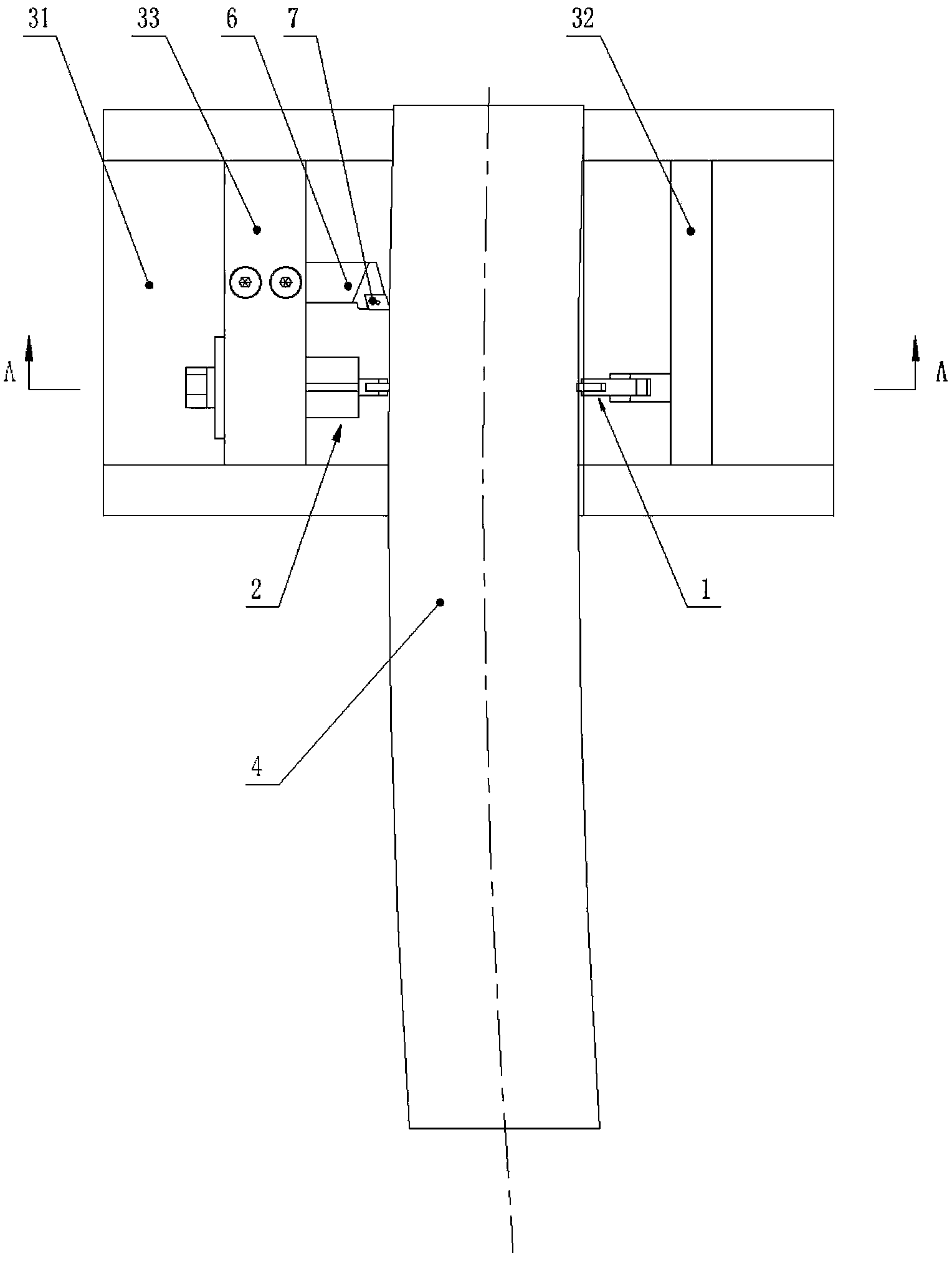

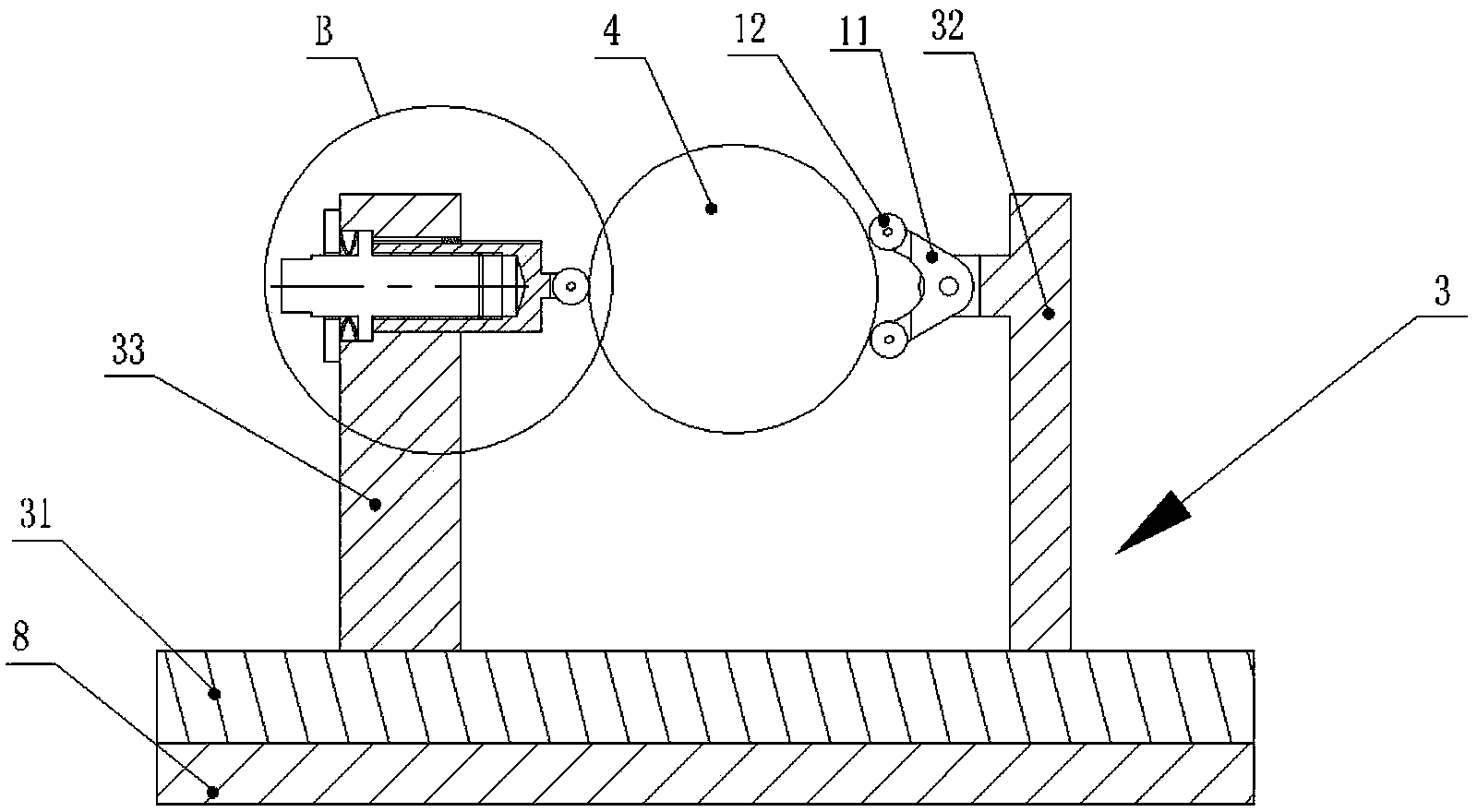

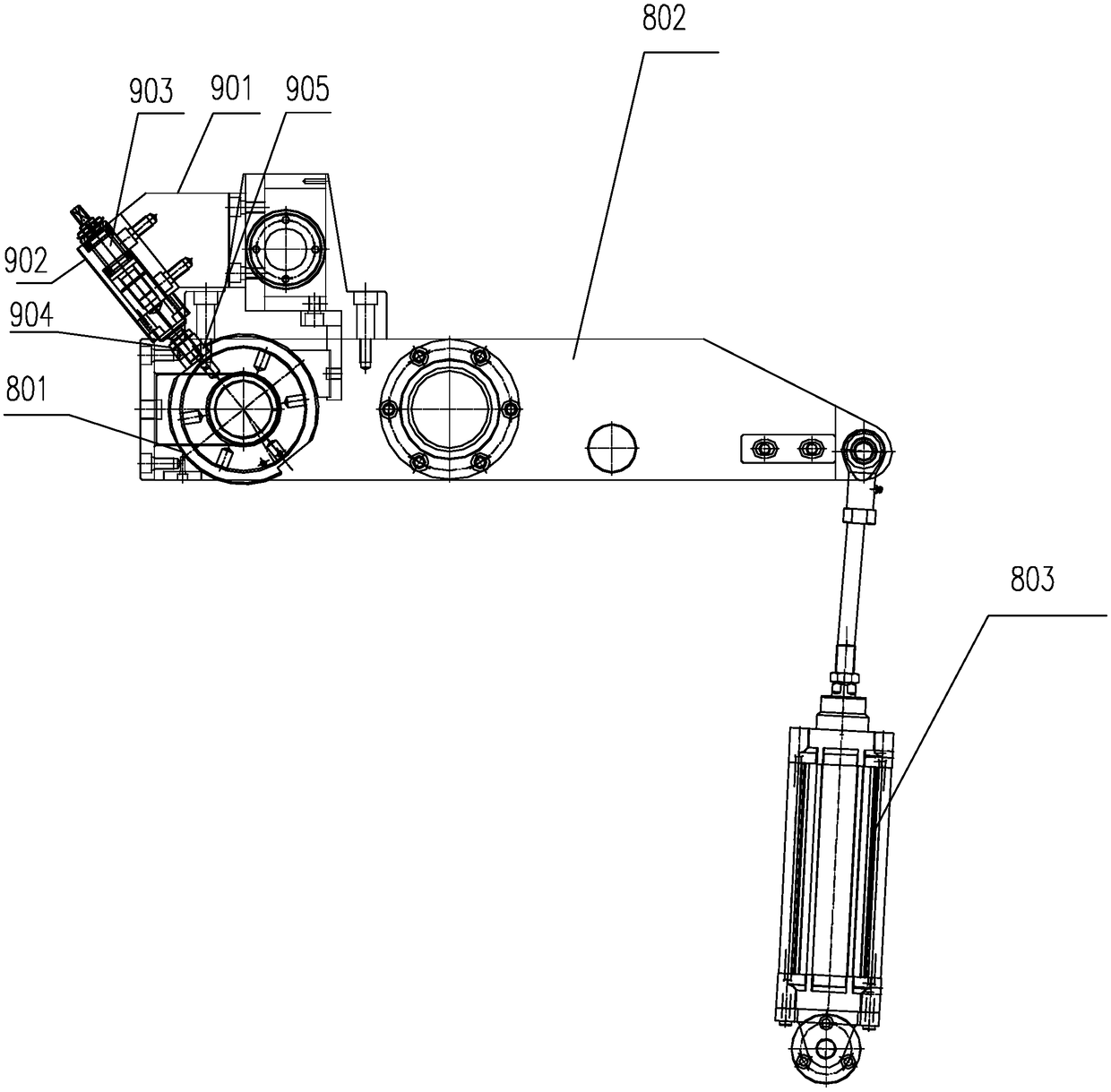

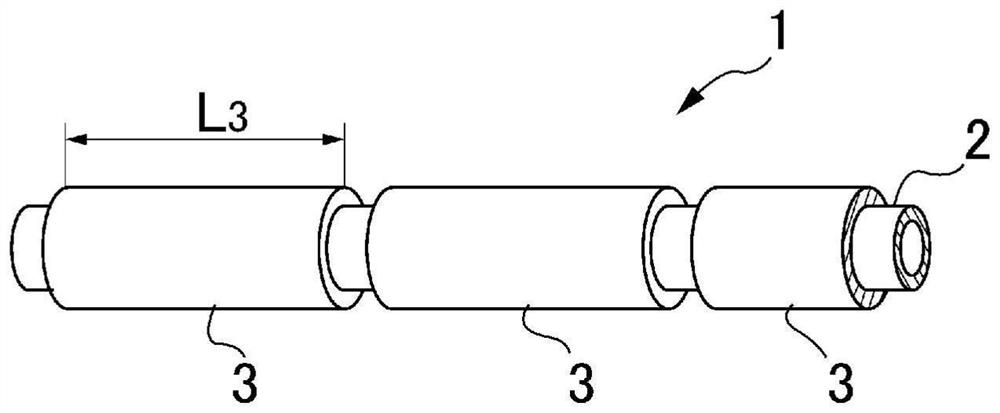

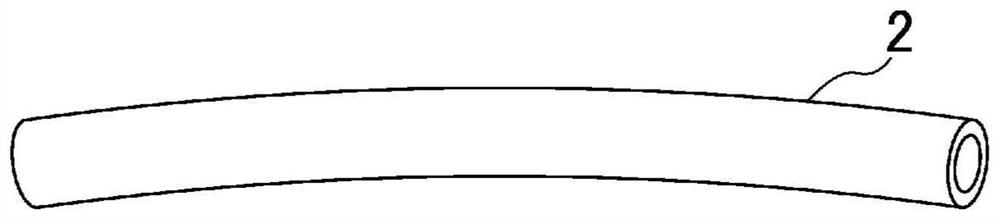

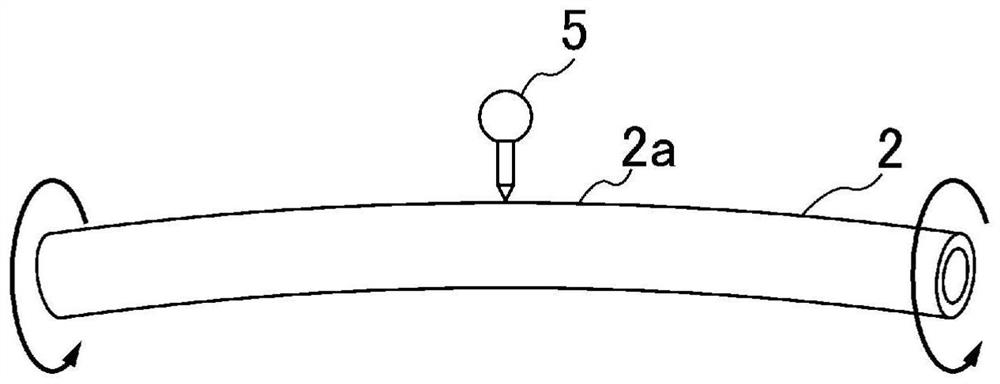

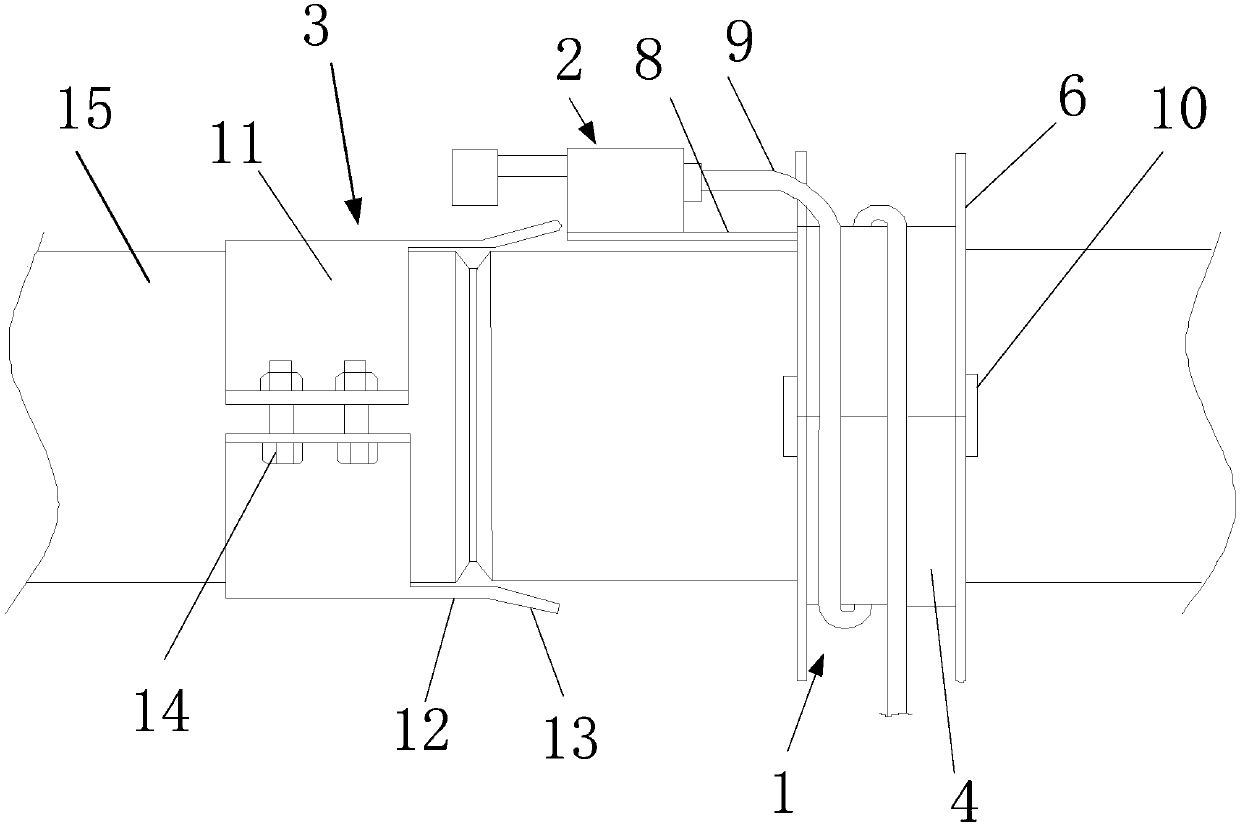

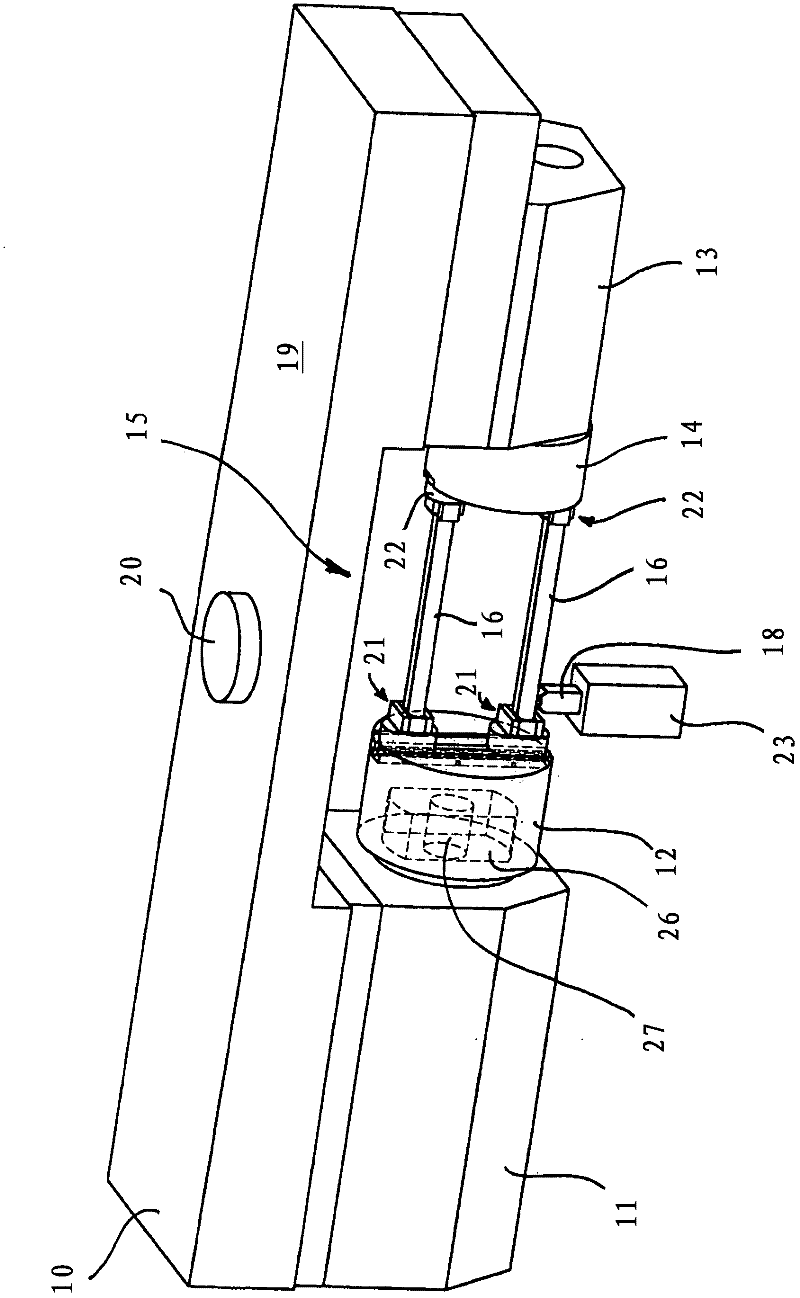

Bending long shaft turning device

ActiveCN104259487AAvoid damageConstant curvaturePositioning apparatusTurning machinesReciprocating motionFixed frame

The invention discloses a bending long shaft turning device. The bending long shaft turning device comprises a compression roller device which radially clamp a to-be-machined bending shaft and a fixing base of the compression roller; the compression roller device comprises an inelastic compression roller mechanism and an elastic compression roller mechanism which are respectively arranged on transverse bilateral sides of the to-be-machined bending shaft; a fixing frame is slidably connected to a large carrying plate of a turning lathe in a mode of being perpendicularly to the turning lathe machining axis; the fixing frame is connected with a turning tool frame. Along with rotation of the to-be-machined bending shaft, the fixing base drives an integral device to perform straight reciprocating motion in a mode of being perpendicular to turning lathe machining axis, the two compression roller mechanisms measure the shape of the bending shaft on line and meanwhile adjust a turning tool position during the turning process in real time through the fixing frame, the distance between a tool tip and the bending shaft axis is guaranteed unchanged, and the constant back cutting depth of the turning tool is guaranteed through a mechanical mode to achieve machining of the bending shaft and unchanged original curvature of the bending shaft. Axial feeding during the turning process is achieved in a mode that the large carrying plate drives the integral device to perform axial movement along the bending shaft.

Owner:汤子尧

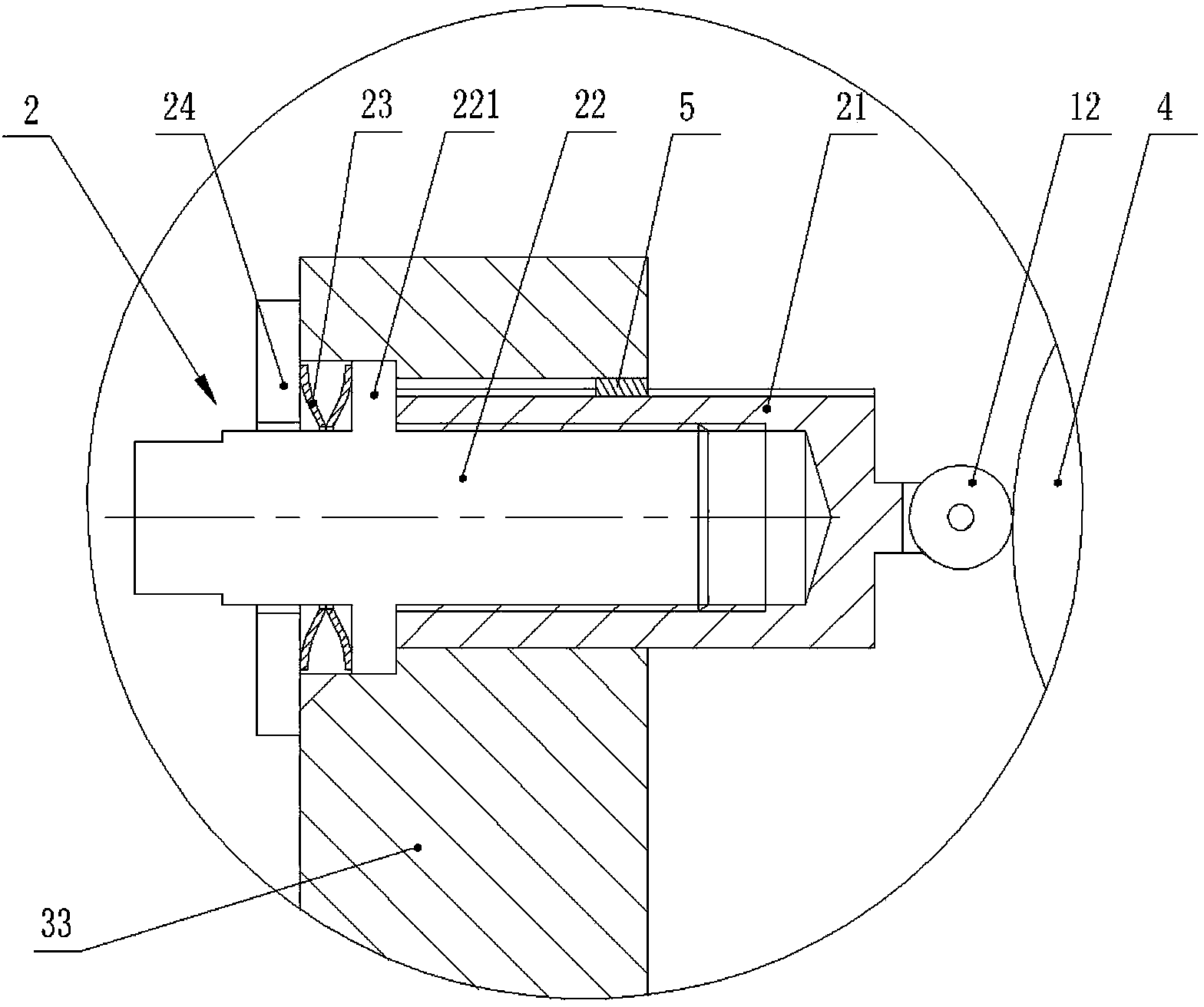

Welding gun clamping structure

InactiveCN103612052AConstant distanceImprove welding or cutting qualityWelding/cutting auxillary devicesAuxillary welding devicesBatch productionMoving speed

The invention provides a welding gun clamping structure. A welding gun is fixed to a positioning plate, at least two supporting parts are arranged on the lower surface of the positioning plate, the supporting parts are distributed around the welding gun, the length by which every supporting part extends out of the lower surface of the positioning plate is larger than that by which the welding gun extends out of the lower surface of the positioning plate, the positioning plate is connected with a guide post in a sliding mode, and the guide post is fixedly connected with a machine tool arm. When the welding gun of the clamping structure is adopted for work, the supporting parts are supported on a workpiece to be welded, when a machine tool drives the positioning plate to move on the workpiece to be welded, the supporting parts will move up and down according to the surface shape of the workpiece to be welded, so that it is ensured that the distance between the welding gun and the workpiece to be welded is constant, the welding gun works normally, no influence on the moving speed of the welding gun can be caused, and welding and cutting quality of the welding gun can be effectively improved. The clamping mechanism is easy to machine, low in production cost, easy to achieve and capable of achieving large-scale batch production.

Owner:苏州盟通利环境科技有限公司

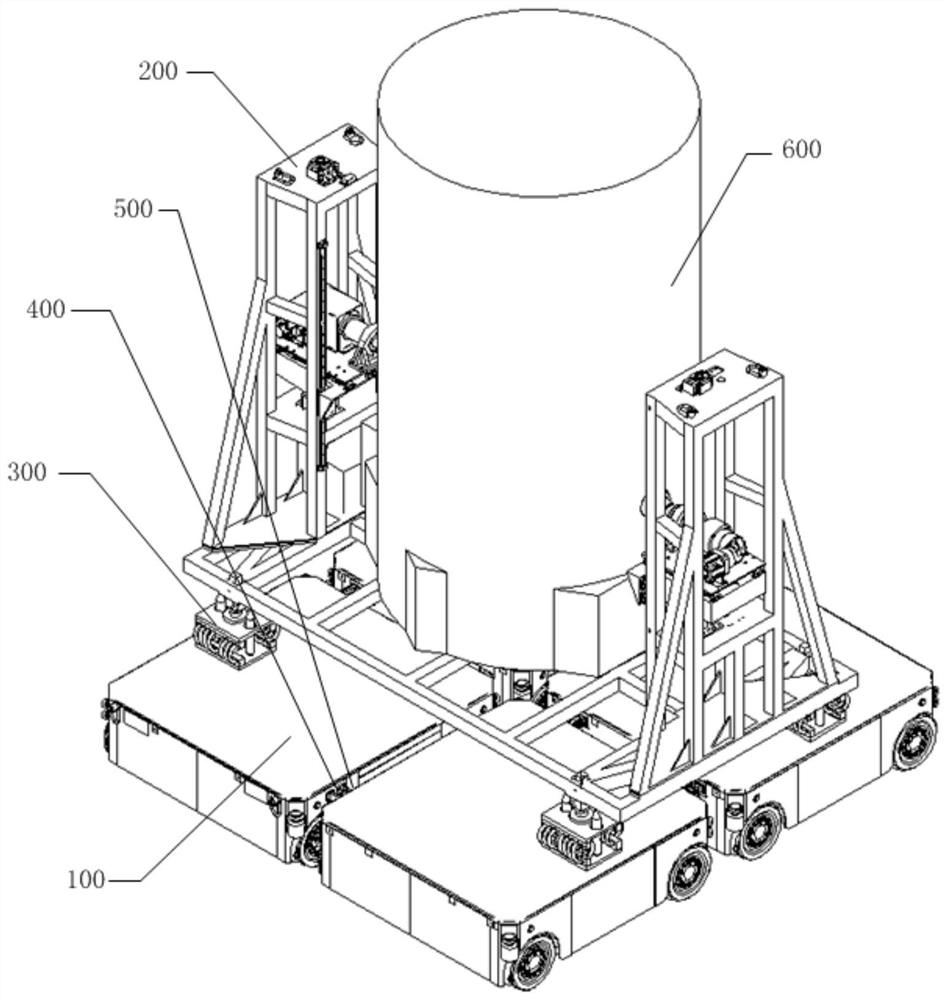

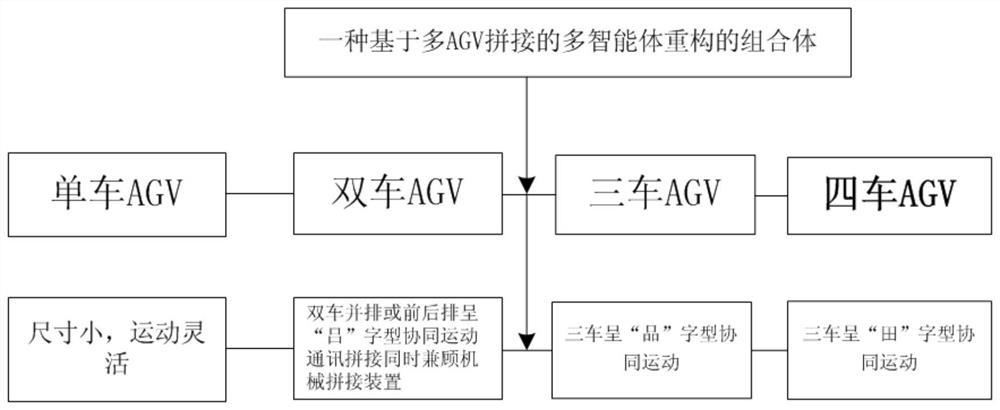

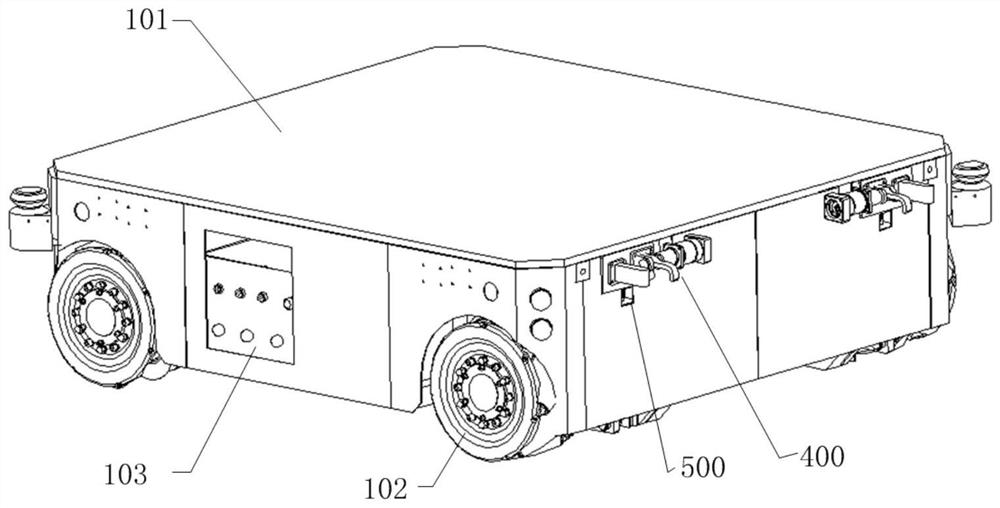

Multi-intelligent-body reconstruction assembly and multi-degree-of-freedom attitude adjusting system

ActiveCN112896365AHigh degree of flexibilityMotion synchronization accuracy weakenedLoad securingElectromagnetic wave reradiationMotion ModeIndustrial engineering

The invention relates to a multi-intelligent-body reconfigurable assembly and a multi-degree-of-freedom attitude adjusting system, and aims at the transfer and attitude adjustment requirements of large-size, large-load and heterogeneous high-end equipment in a large-range complex environment through different numbers of AGVs in a combined splicing layout cooperative motion mode of Chinese character lv, Chinese character delta, Chinese character tian and other special shapes. Meanwhile, an automatic leveling two-shaft overturning scheme based on a high-damping shock absorption system is carried, and the influence of displacement caused by climbing and uneven road surfaces on equipment is eliminated; mechanical splicing devices, wireless communication devices and laser range finders are arranged among the AGVs to realize a high-precision synchronous working scene of dynamic detection and real-time correction, so the flexibility degree of intelligent equipment is improved, manual labor in the product transfer and butt joint process is reduced, resource waste caused by a traditional transfer mode is avoided, and efficient application of collaborative operation of the intelligent equipment in a precise transfer link is realized.

Owner:BEIJING SATELLITE MFG FACTORY

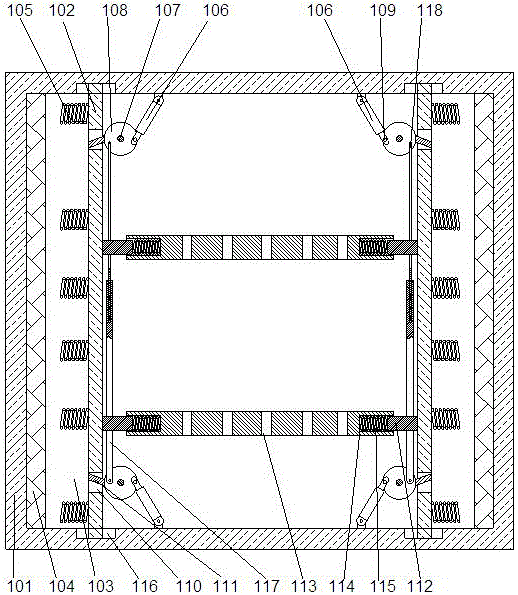

Electric energy metering box protector

The invention discloses an electric energy metering box protector comprising a box body and an isolation board arranged in the box body; a cavity is formed between the isolation board and the box body; the top and bottom of the isolation board are respectively connected on the box body inner wall in a slide manner; the box body inner wall is provided with a protection pad; the end face of one side, facing the protection pad, of the isolation board is provided with a buffer spring; the end of the buffer spring vertically points to the protection pad; the buffer spring axis is parallel to the box body bottom end face; the box body inner end face is provided with a cylinder; the end face of one side, far away from the protection pad, of the isolation board is provided with a support rod; two ends of the support rod bend to the isolation board and are fixedly connected on the isolation board. The cylinder can buffer the isolation board, thus providing better anti-impact performance when the box body receives large impact force.

Owner:PENGLAI POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO

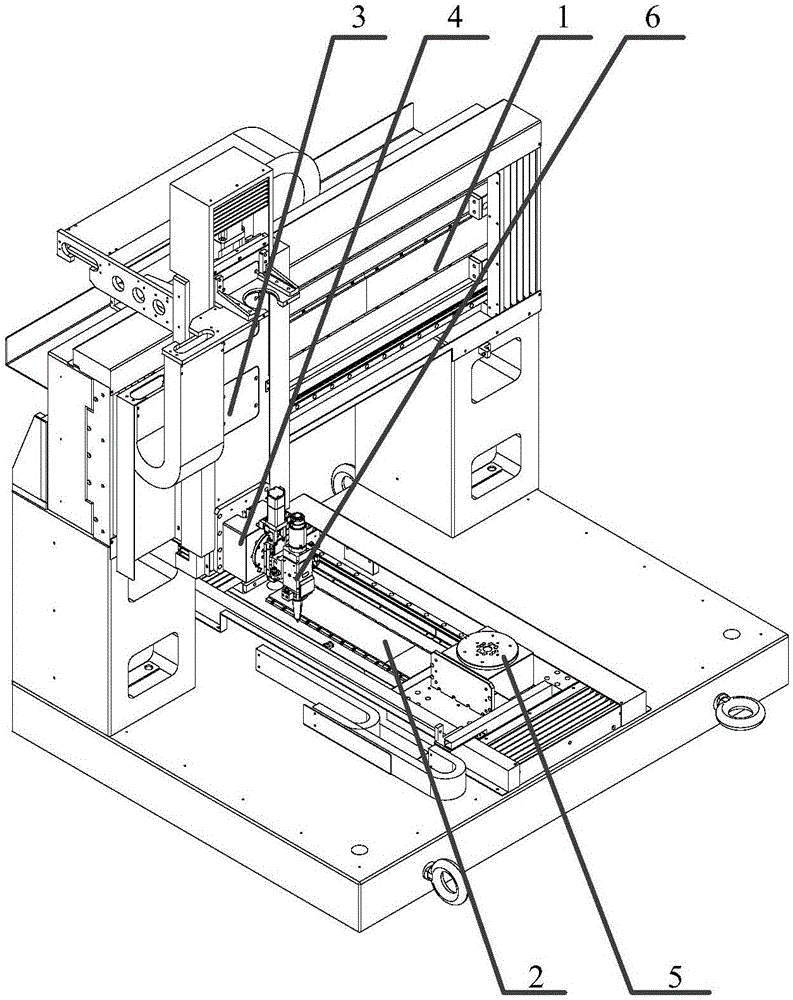

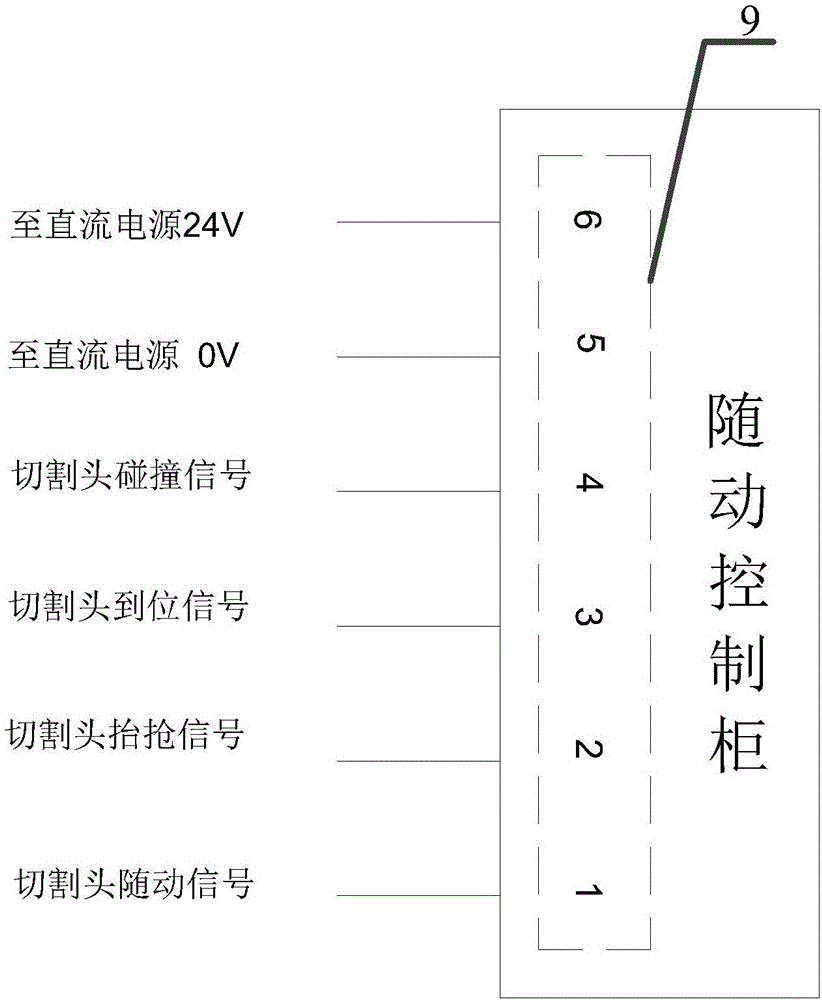

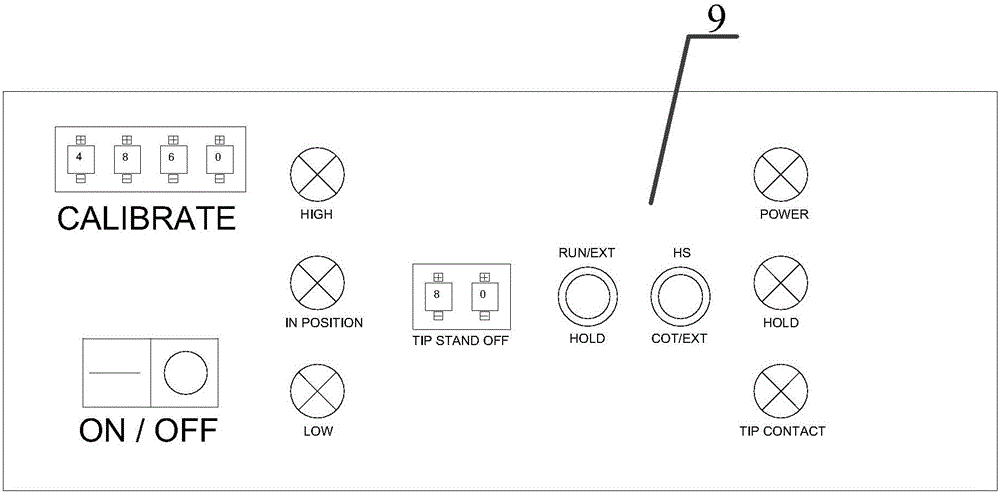

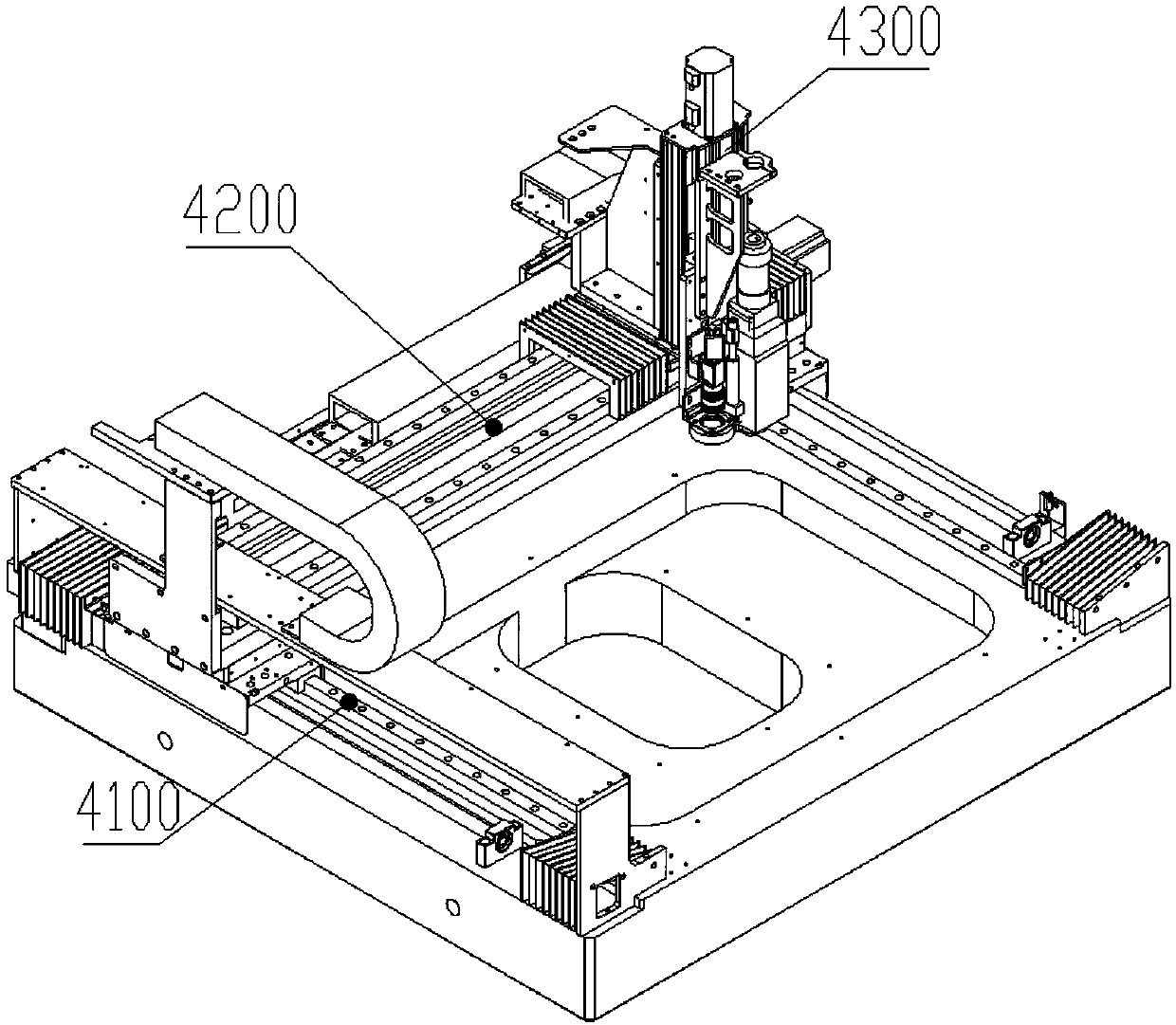

Laser cutting machine

PendingCN107745195AConvenient focal lengthGuaranteed powerLaser beam welding apparatusLaser cuttingLaser source

The invention discloses a laser cutting machine which comprises a bottom frame assembly, a gantry mechanism, a fixture assembly, a laser assembly, a laser cutting head and a follow-up controller. Thelaser assembly is used for providing a laser source for the laser cutting machine. The gantry mechanism comprises a Y-axis assembly, an X-axis assembly and a Z-axis assembly, wherein the Y-axis assembly, the X-axis assembly and the Z-axis assembly are used for driving the laser cutting head to move in the preset Y-axis direction, the X-axis direction and the Z-axis direction respectively. The follow-up controller is used for controlling the motion state of the Z-axis assembly, so that the distance from the bottom end of the laser cutting head to the surface of a workpiece is constant. In thisway, the laser cutting head is driven by the gantry mechanism to move during operation, so that the moving precision is high and the moving efficiency is high. Meanwhile, a plate workpiece is cut through laser, so that the incision is fine and smooth, burrs are basically avoided, and thus the burr removal process can be omitted, and the process flow is saved. In addition, the follow-up controllercontrols the laser cutting head to perform follow-up during operation, so that the cutting precision is greatly improved, and the special process machining on the plate workpiece is successfully realized.

Owner:GUANGDONG ZHENGYE TECH

Automatic bagging production line of rod-shaped foods

ActiveCN106945882ASimple structureIncrease productivityWrapper twisting/gatheringEngineeringLow vacuum

The invention discloses an automatic bagging production line of rod-shaped foods. The production line is characterized by comprising a packing bag holding frame body, a lower vacuum box, a packing bag conveying belt, a pushing structure, a feeding belt, an upper vacuum box and a hot sealing machine; the packing bag conveying belt is used for conveying packing bags; the packing bag holding frame body is used for placing the packing bags; the lower vacuum box is used for sucking one surfaces of the packing bags to guarantee fixed positions of the packing bags on the packing bag conveying belt; the feeding belt is used for conveying the rod-shaped foods to enable the rod-shaped foods to align to one opening sides of the packing bags; the upper vacuum box is used for sucking the other surfaces of the packing bags to finish the opening process of the packing bags; the hot sealing machine is used for hot sealing of openings of the packing bags; and the pushing structure is used for pushing the rod-shaped foods into the packing bags. The production line needs no manual operation, realizes full-automatic production of bag taking, bag opening, feeding and hot sealing, improves the production efficiency, and improves the food sanitation quality.

Owner:HEBEI UNIV OF TECH +1

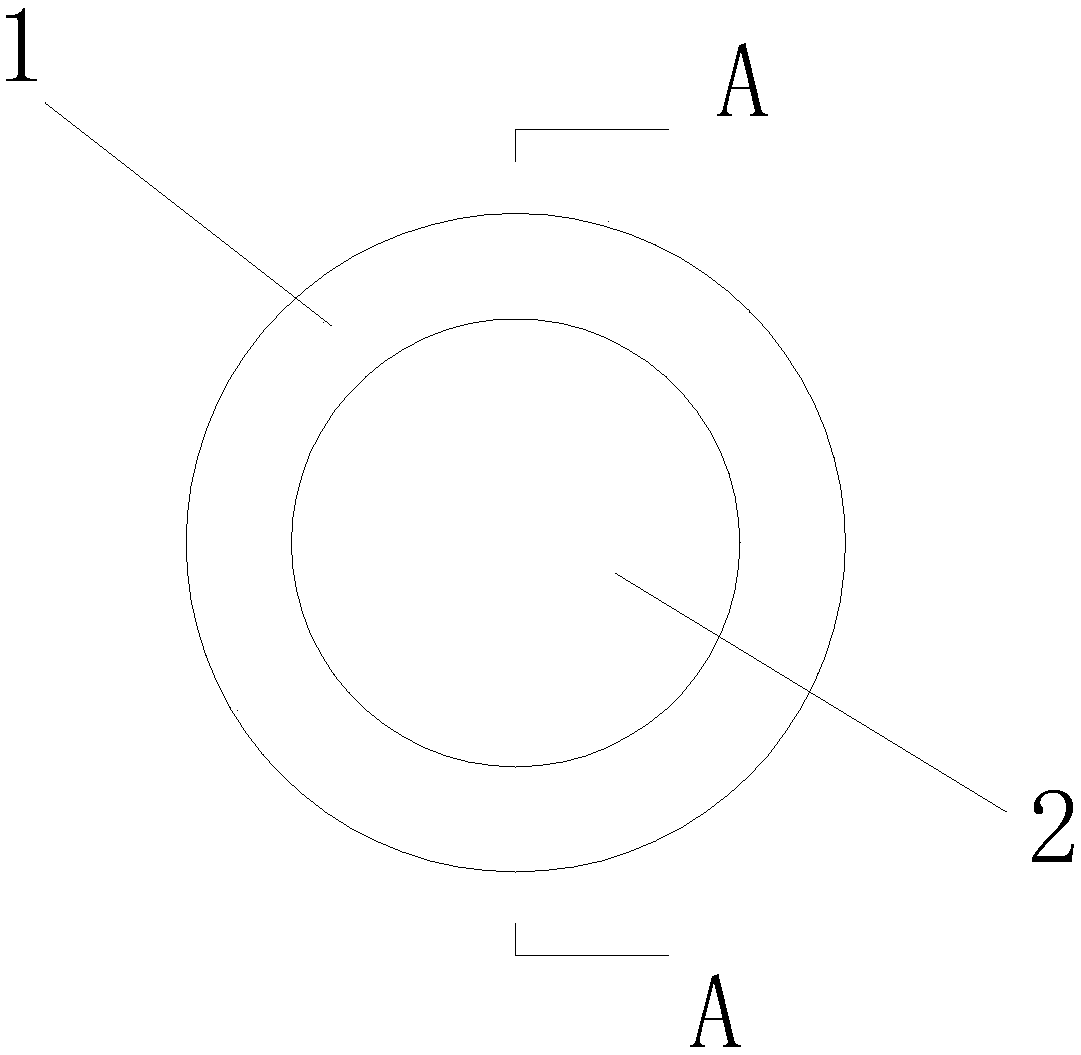

An orientation device for improving magnetic powder of a microwave absorbing magnetic sheet and an implementation method thereof

ActiveCN109148135APromote orientationUniform magnetic fieldInductances/transformers/magnets manufactureMagnetic powderAdhesive

The invention discloses an orientation device for improving magnetic powder of a microwave absorbing magnetic sheet, comprises a sleeve and a permanent magnet, wherein the permanent magnet comprises aplurality of cylindrical magnets, and the permanent magnet is positioned inside the sleeve, the sleeve is a non-magnetic conductive member, and the sleeve and the permanent magnet are bonded througha non-magnetic adhesive; the invention also discloses an implementation method of the orientation device for improving the magnetic powder of a microwave absorbing magnetic sheet; The orientation device provided by the invention has small magnetic flux leakage, is safe and reliable, is not limited by the width of the tape casting film, can conduct magnetic field orientation of a wide tape castingfilm, and is favorable for improving production efficiency.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

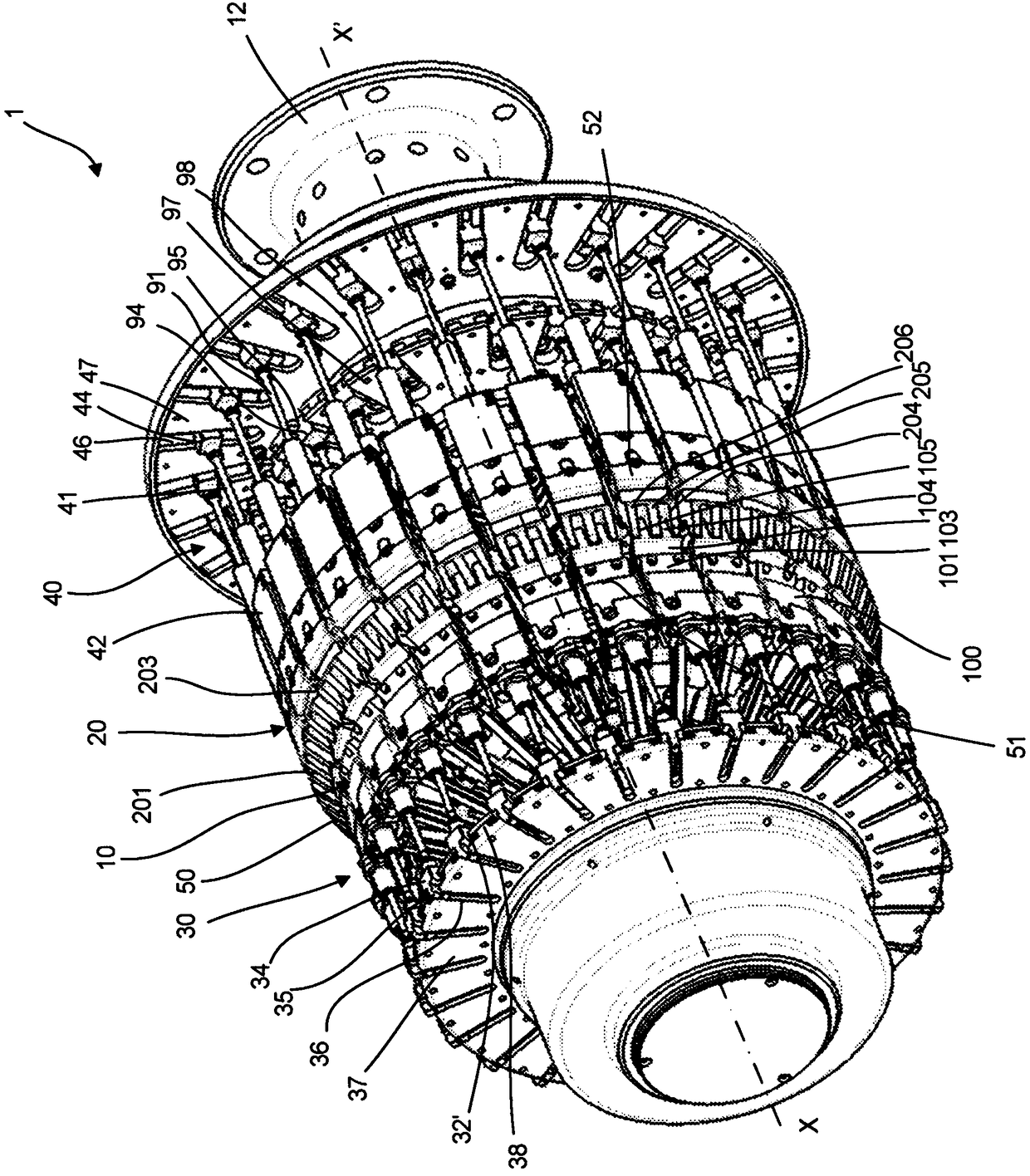

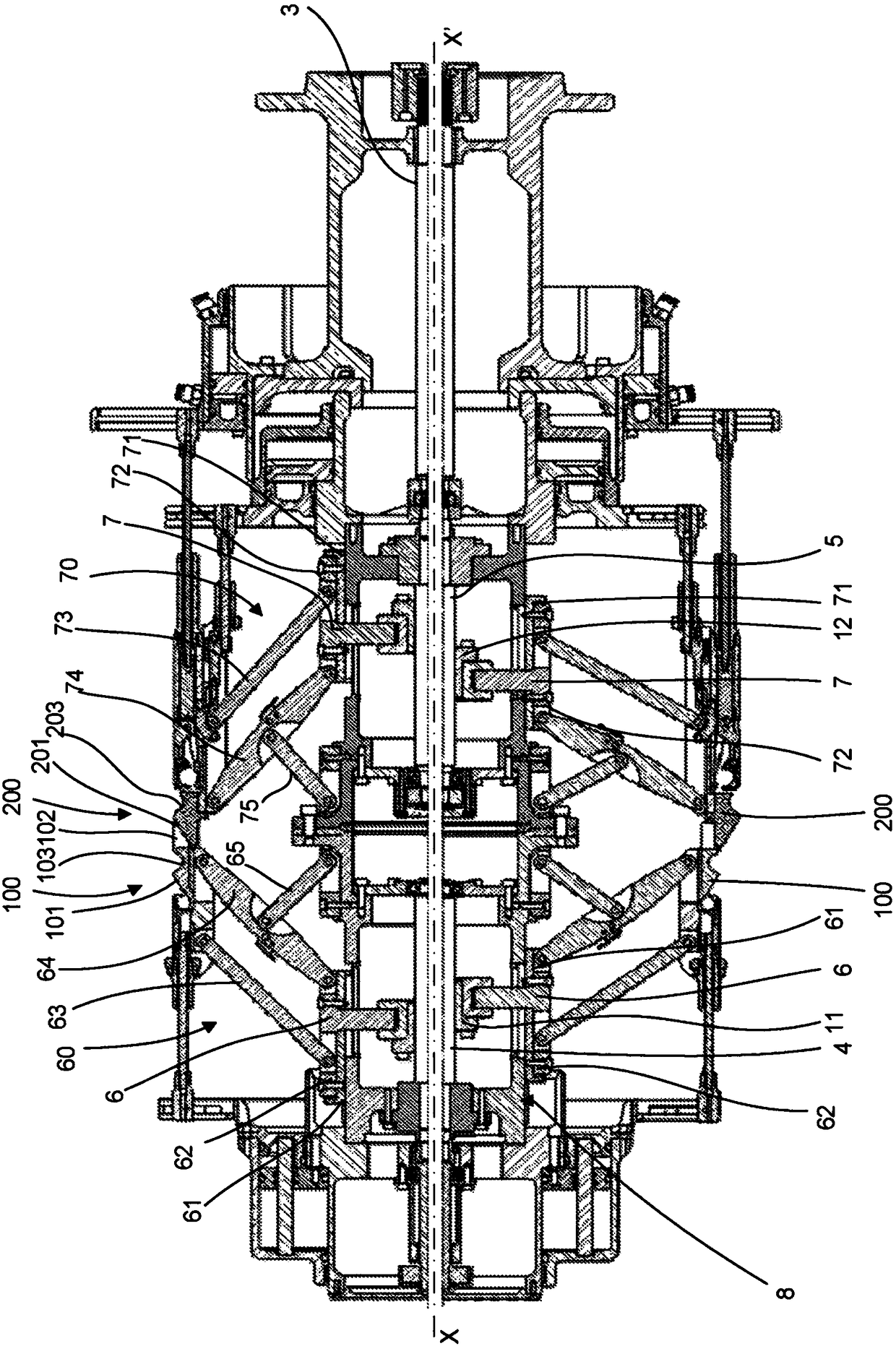

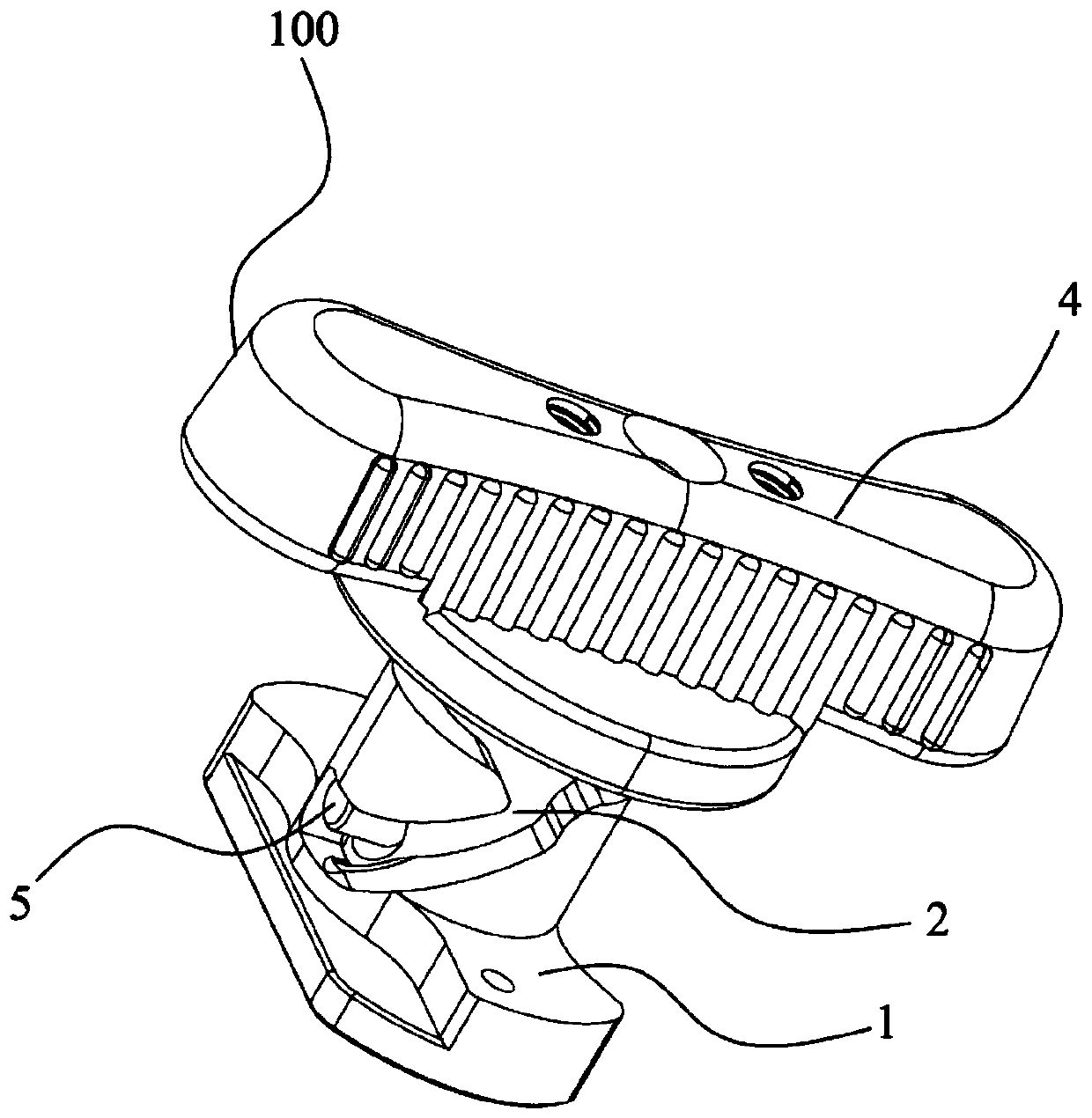

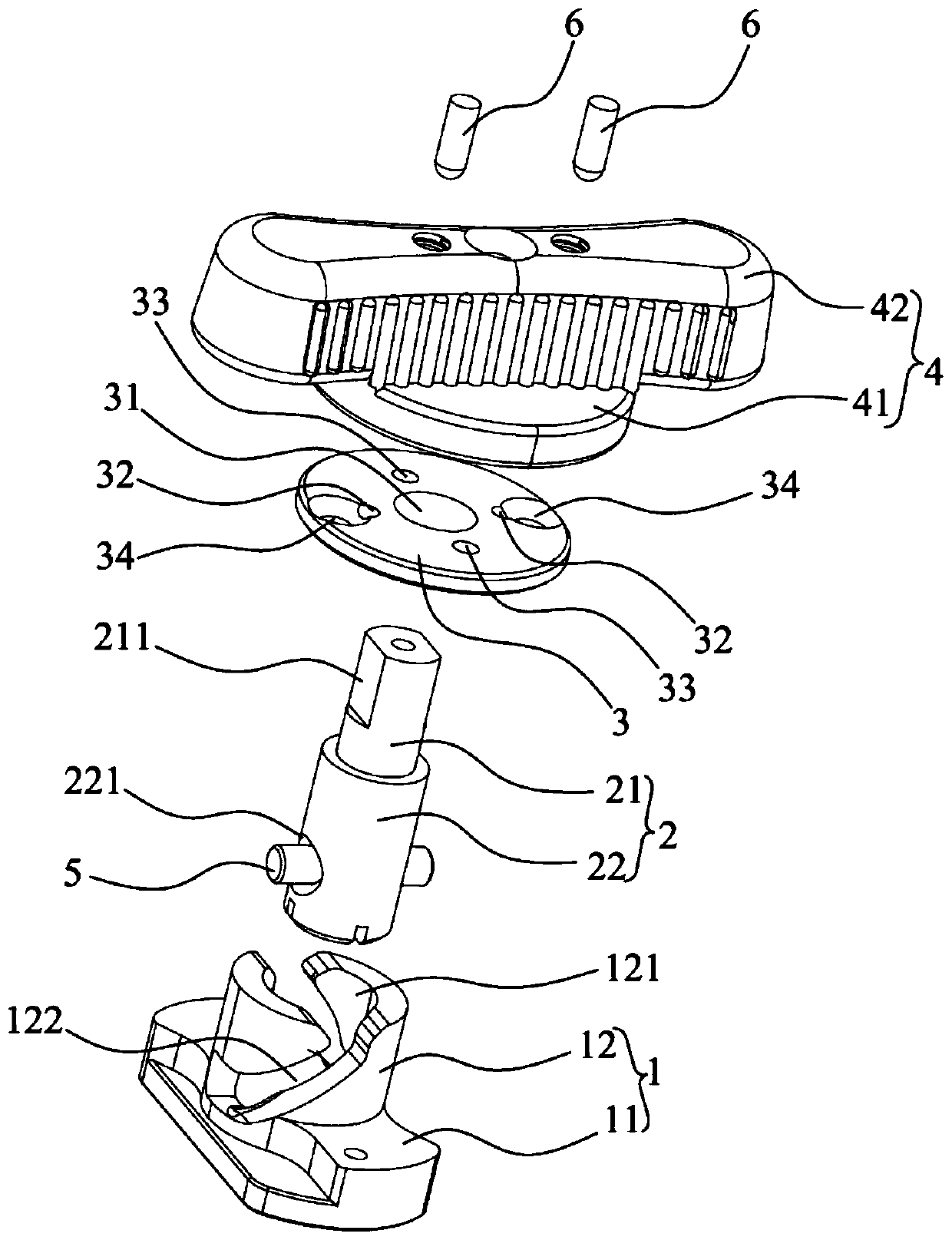

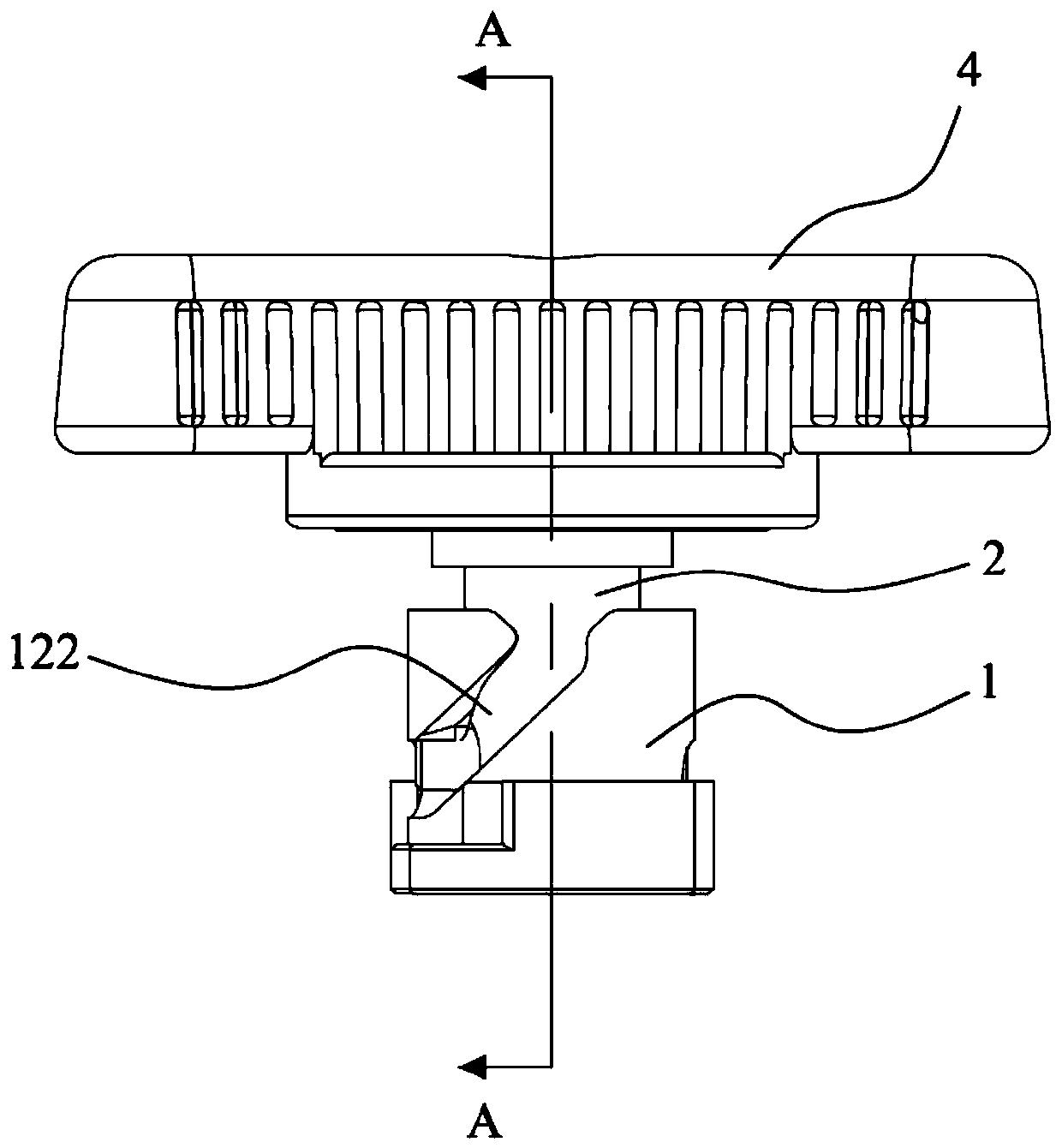

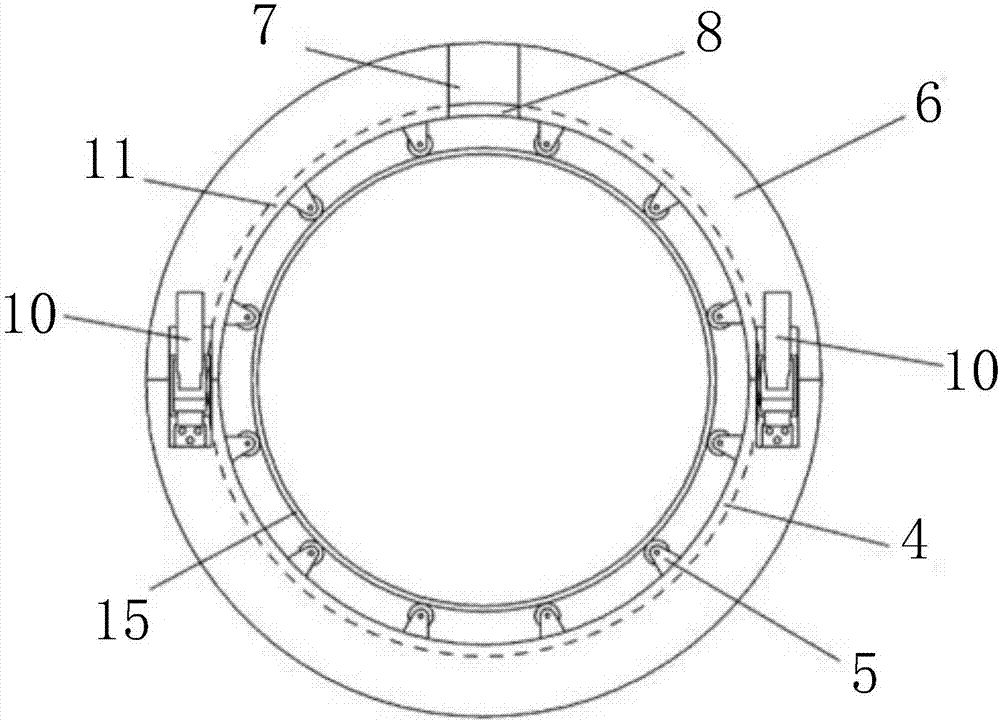

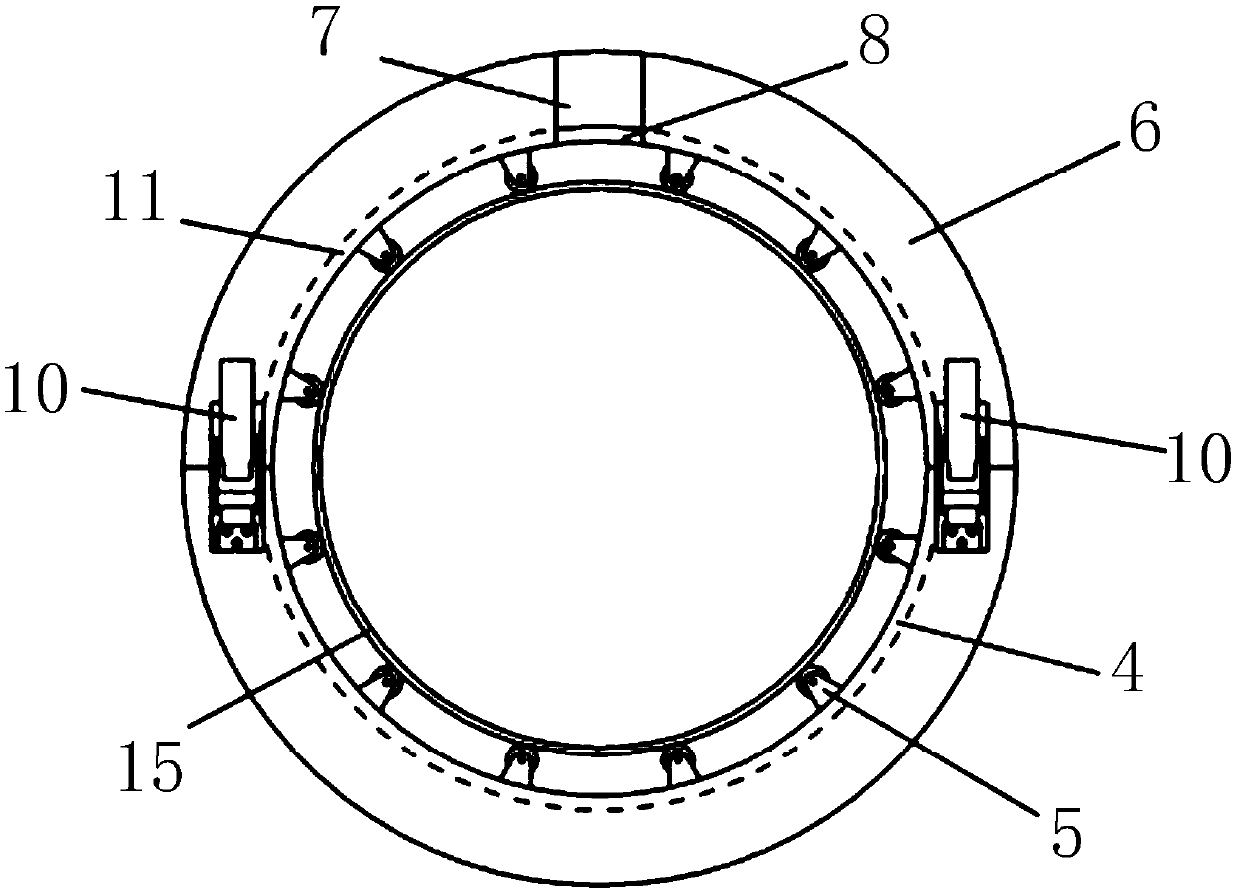

Drum and method for assembling a tyre adapter on a wheel rim

The invention relates to a radially expandable assembly drum (1) for producing a tyre adapter on a wheel rim, the drum comprising a central shaft (3), a first assembly (10) of segments (100), and a second assembly (20) of segments (200), all of the segments being peripherally arranged around the shaft (3) so as to form a generally cylindrical outer face (50) of the drum. According to the invention, the segments (100) of the first assembly (10) and the segments (200) of the second assembly (20) face each other axially, and the drum (1) is arranged so as to allow a different radial expansion ofthe segments of the first assembly (10) compared to the segments of the second assembly (20) of segments between two working positions.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

Stable knee joint shin offset amount measurement device

InactiveCN103239232AAvoid swingingPositioning datum consistentDiagnostic recording/measuringSensorsLeg typeMeasurement device

The invention discloses a stable knee joint shin offset amount measurement device which comprises a measurement seat, wherein a measurement mechanism and a positioning mechanism are arranged on the measurement seat. The positioning mechanism comprises a three-point positioning mechanism and a flexible positioning mechanism. The flexible positioning mechanism comprises a flexible positioning layer for adapting to patient leg types automatically. The three-point positioning mechanism comprises a top positioning head matched with a knee joint shin tubercle and a positioning support rotatably arranged on the bottom surface of the measurement seat in matching mode, and two ankle positioning heads matched with ankle joints are respectively arranged on the positioning support. The measurement mechanism comprises an axial measurement mechanism used for measuring front and back axial looseness of knee joints and a circumferential measurement mechanism used for measuring circumferential looseness of knee joints. The axial measurement mechanism comprises a measurement sliding block, the circumferential measurement mechanism comprises a measurement rod rotatably arranged on the measurement sliding block in matched mode, and a measurement head matched with patella is arranged at one end of the measurement rod facing to the knee joints. A metering device used for measuring the position of the measurement sliding block and the rotating angle of the measurement rod is further arranged on the measurement seat.

Owner:THE FIRST AFFILIATED HOSPITAL OF THIRD MILITARY MEDICAL UNIVERSITY OF PLA

Tensioning lock and LED display screen box

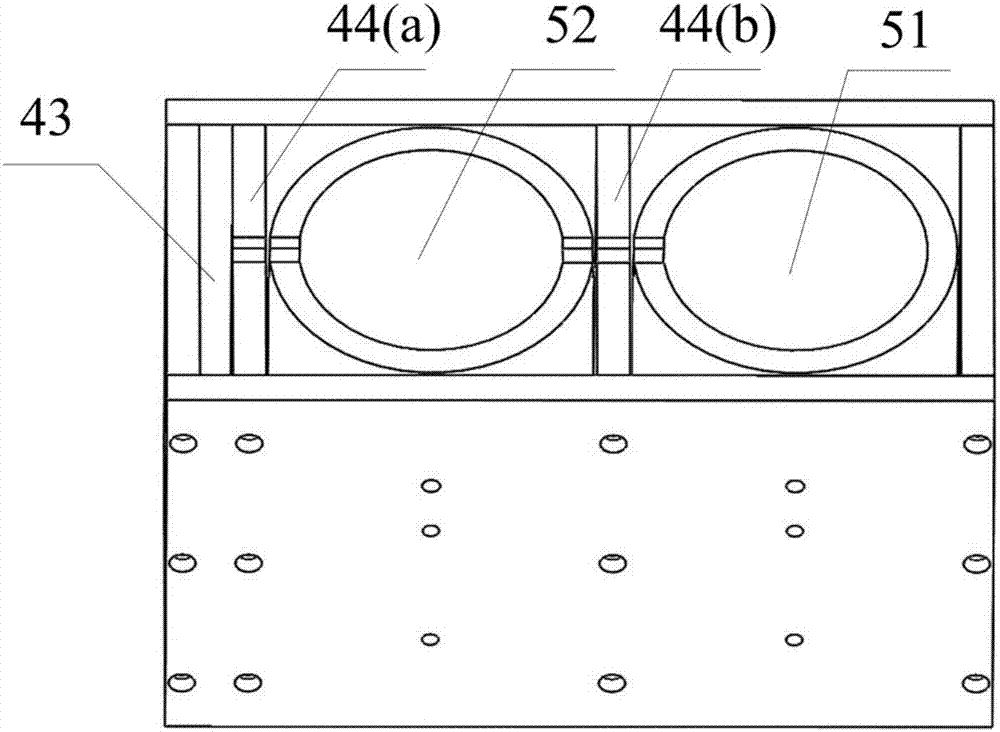

PendingCN109931317AKeep the distance constantClosed casingsCasings with display/control unitsLED displayEngineering

The invention belongs to the technical field of LED display screen box assembling, and relates to a tensioning lock and an LED display screen box. The tensioning lock comprises a base, a rotation shaft, a gasket and a rotary knob. The base is provided with a sliding hole, one end of the rotation shaft is fixedly connected with the rotary knob, the other end of the rotation shaft is inserted in thesliding hole, the gasket is rotationally connected to the rotation shaft, and the distance between the gasket and the rotary knob is kept constant. The rotary knob is rotated so that the rotation shaft can rotate and slide in the axial direction of the sliding hole, and accordingly the gasket can get away from or get close to the base. According to the tensioning lock, the LED display screen boxinstalling efficiency can be effectively improved.

Owner:SHENZHEN GLOSHINE TECH

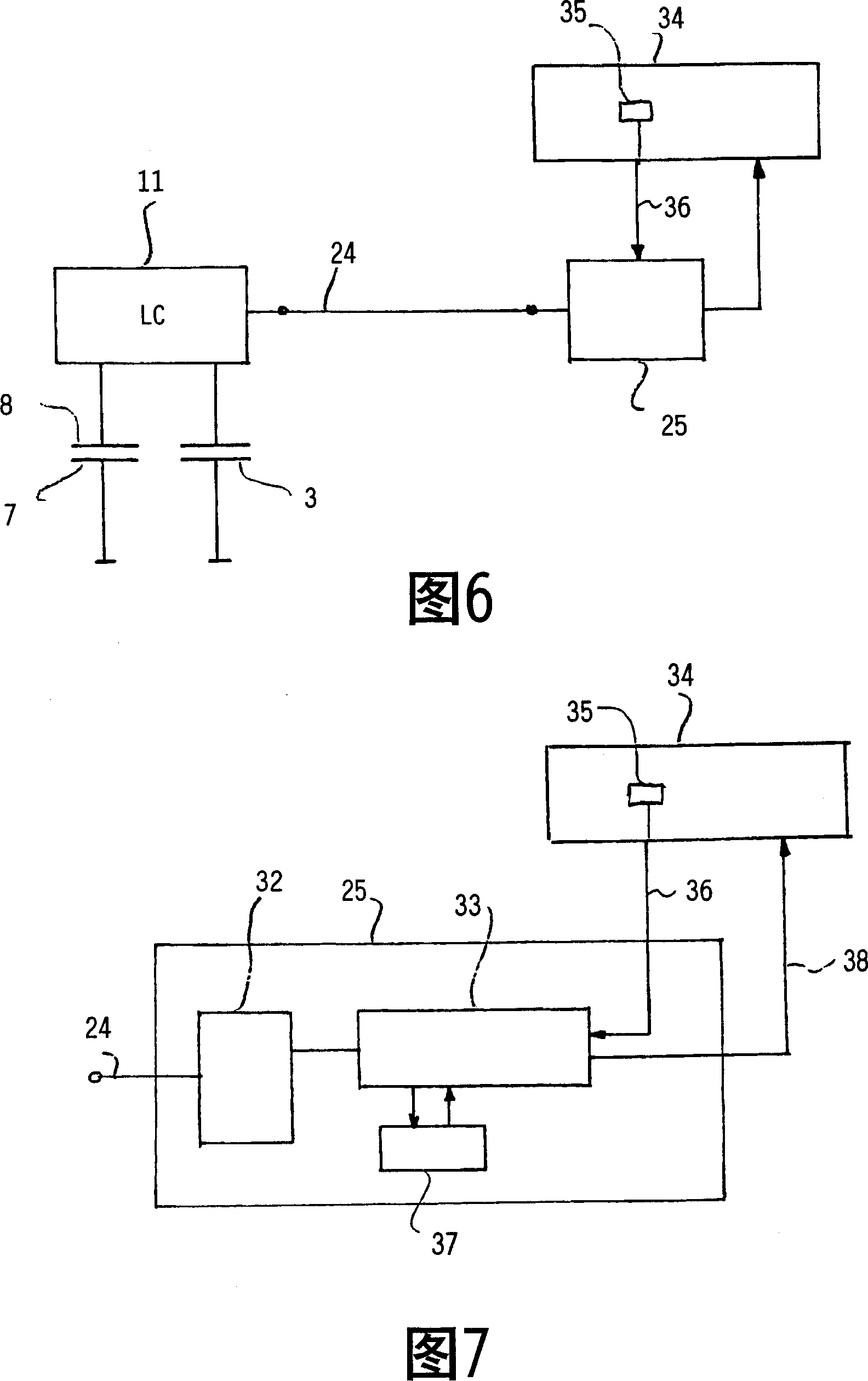

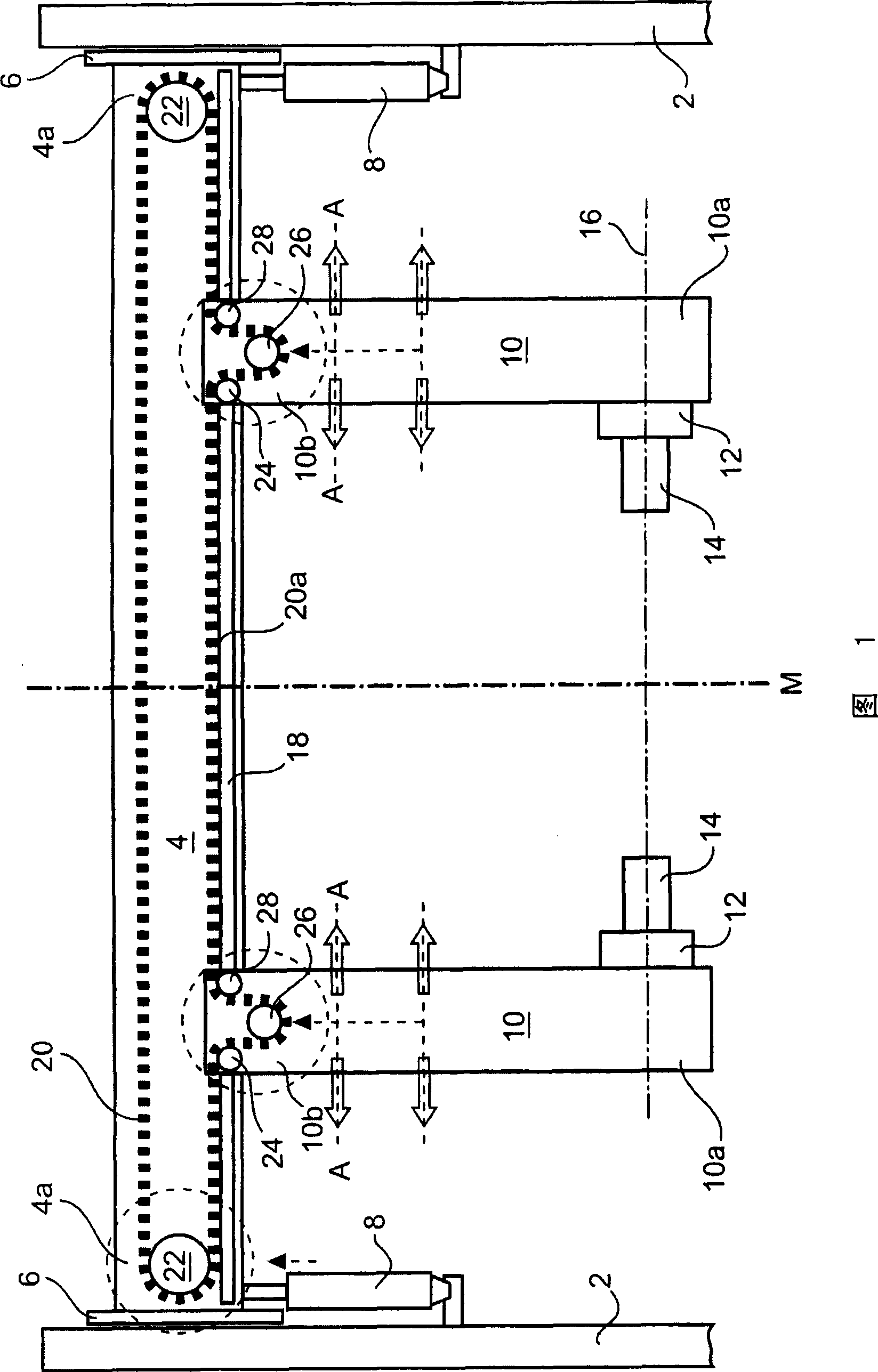

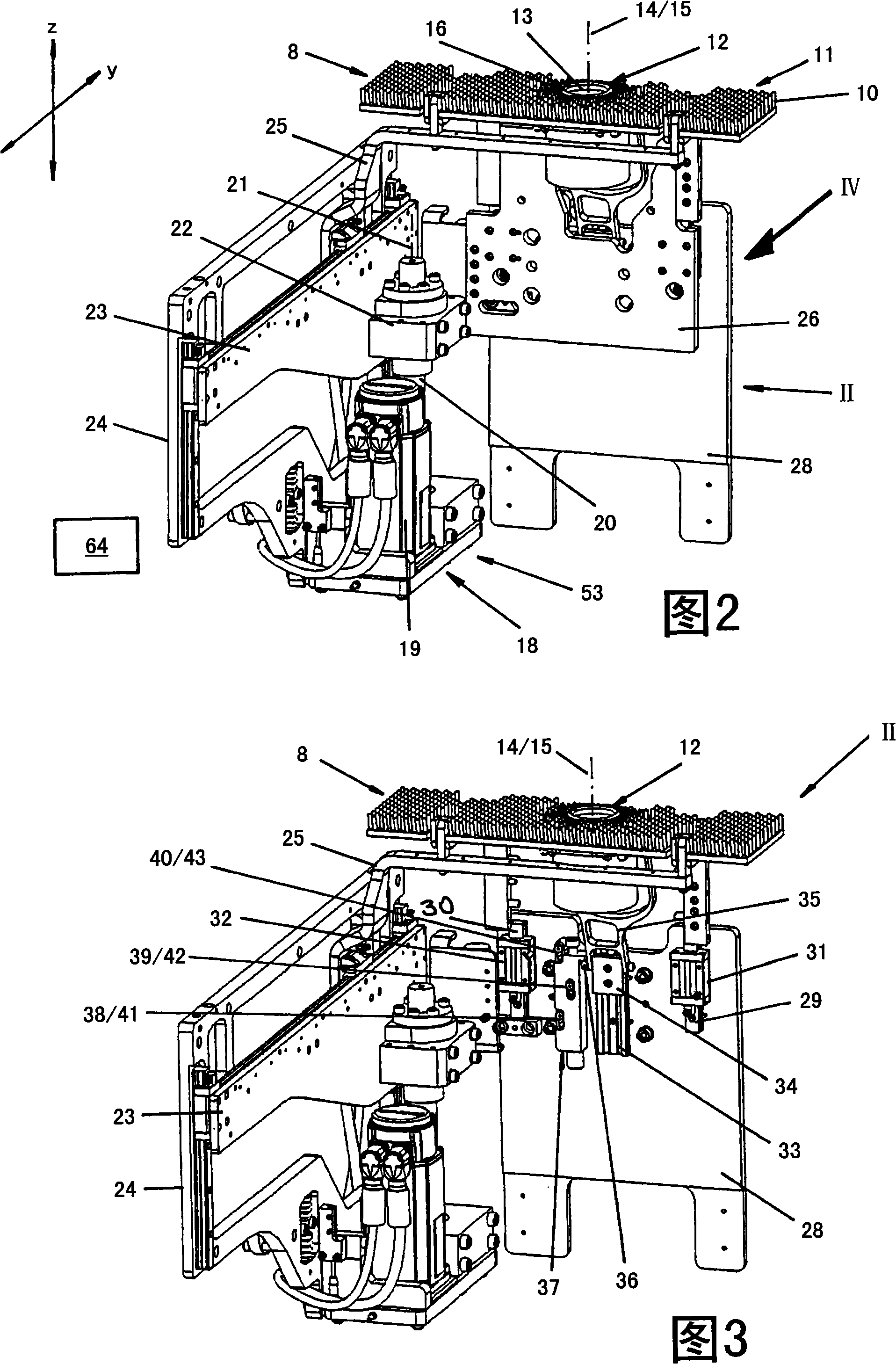

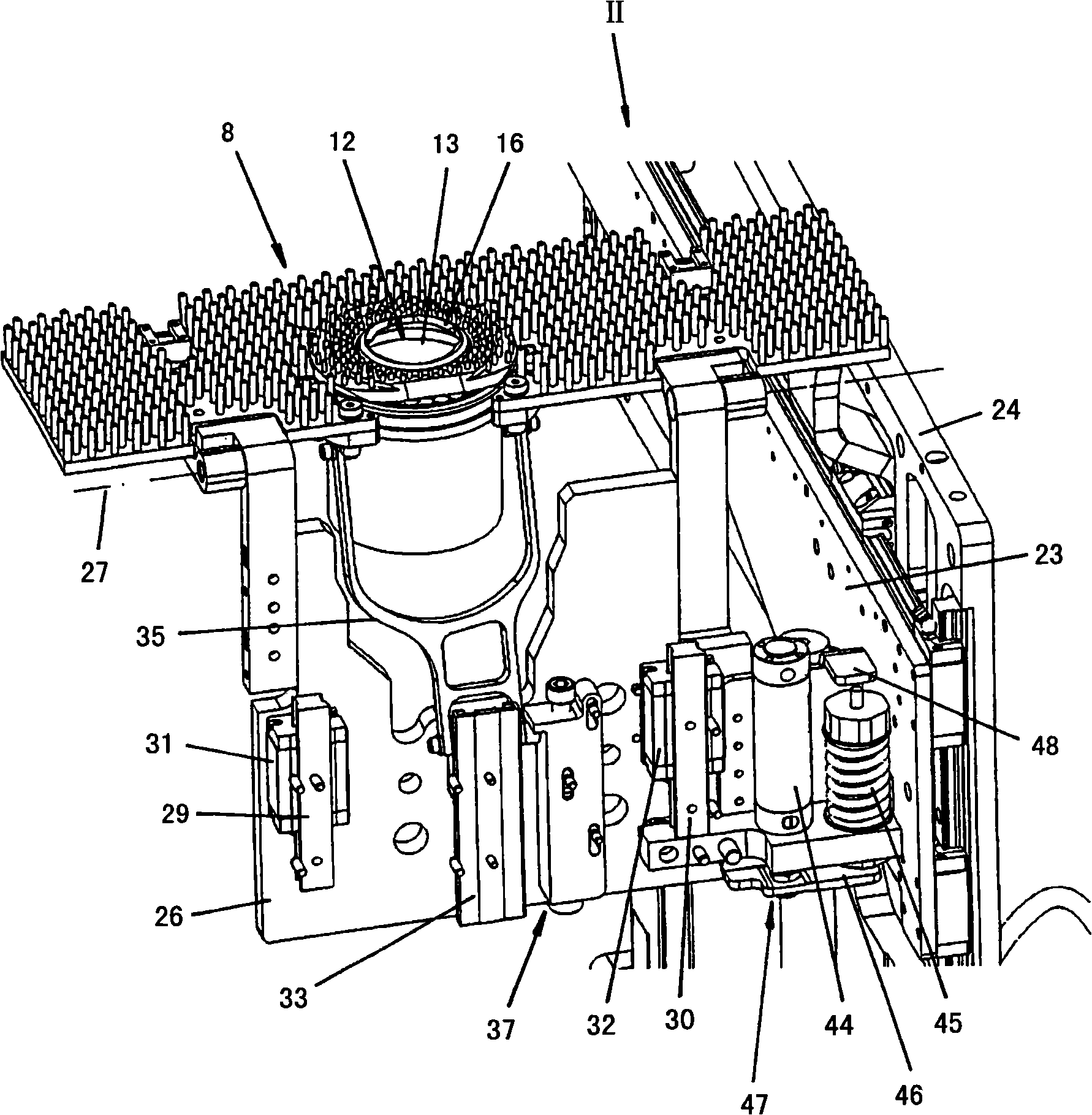

Laser processing machine for machining workpieces and machine method for machining workpieces using a laser beam

InactiveCN101357417AAvoid damageAvoid contactOther manufacturing equipments/toolsLaser beam welding apparatusData processing systemLaser processing

A processing workpiece, more particularly a laser processing apparatus for metal plates, is disclosed, comprising: a workpiece support (8) and a laser beam receiver (12) for receiving a laser beam served as a processing tool. A regulation driver (18) of a regulation device is utilized to enable, by means of a positioning movement having variable limited value, the workpiece support (8) and the laser beam receiver (12) to be positioned with respect to each other along a laser beam axis line (14) of a laser beam (15), in order to regulate the distance between the laser beam receiver (12) and the workpiece supported on the workpiece support (8). A mechanism method for processing the workpiece, more particularly the metal sheet, using the laser beam, comprises the corresponding methods and steps. With a view to implementation of the mechanical processing method, a processing program is used that is compiled in accordance with the corresponding method. The compilation method for the processing program is executed using a computer program product in a data processing system.

Owner:TRUMPF WERKZEUGMASCHINEN GMBH & CO KG

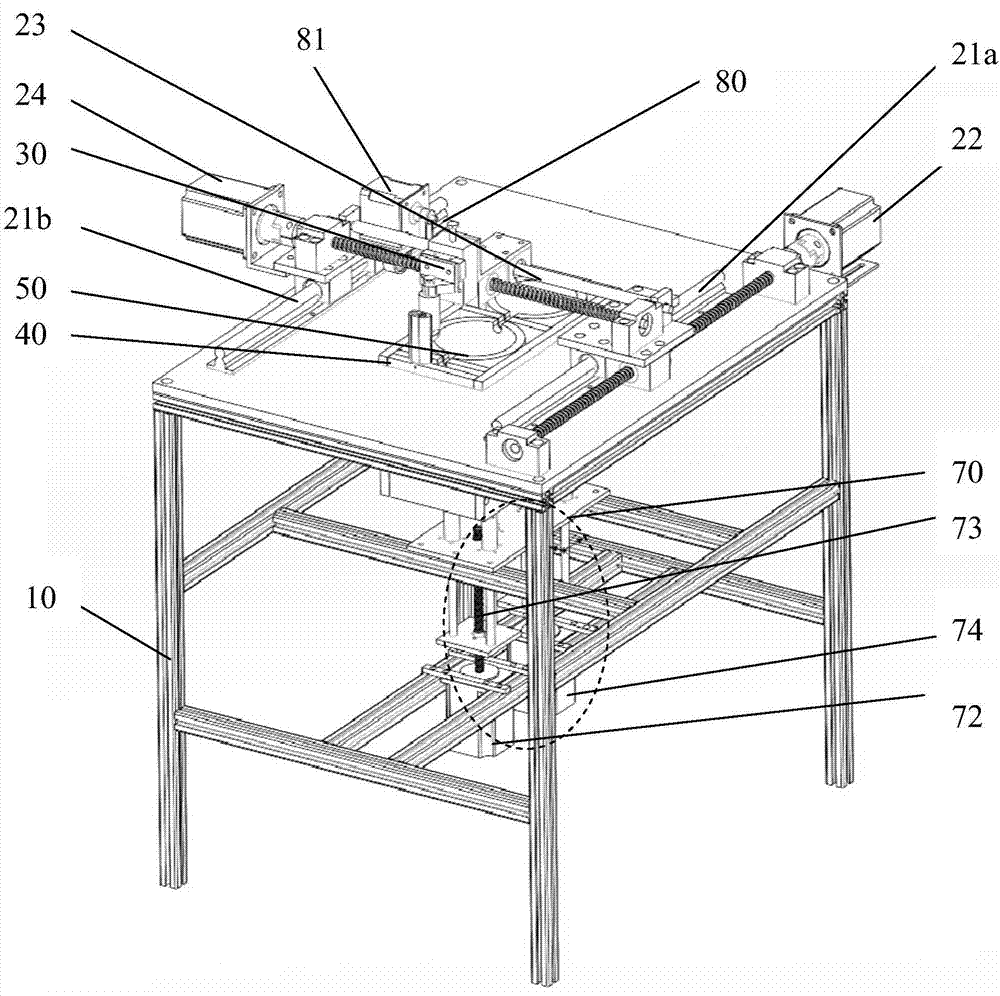

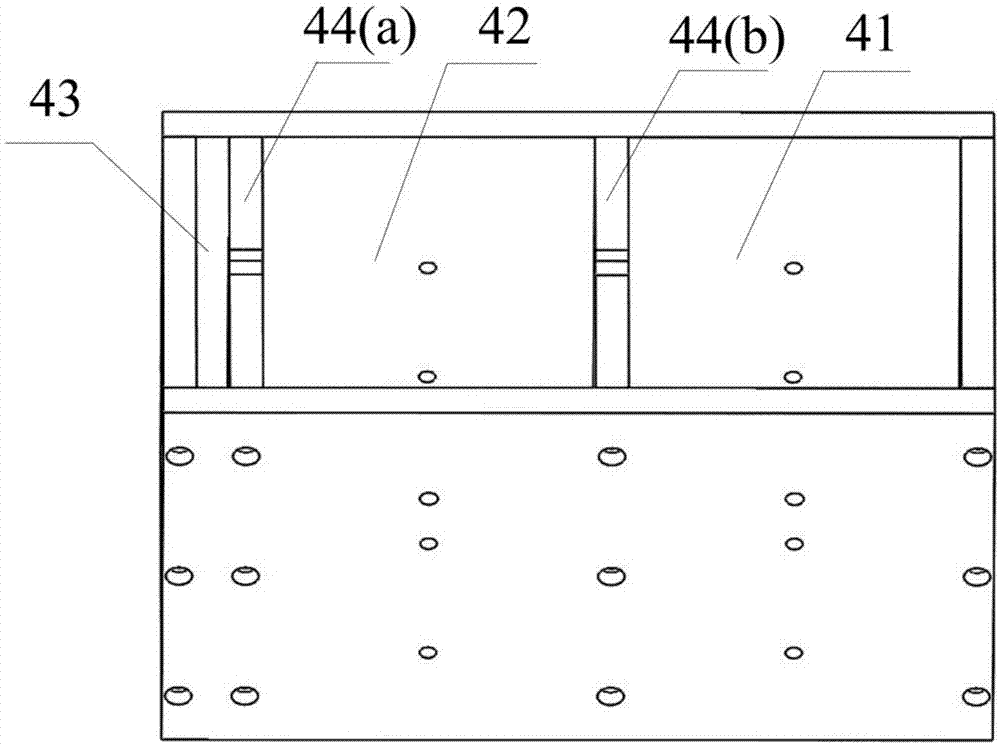

High-precision double-forming-mode 3D printer and forming method thereof

ActiveCN107984755ASwitch back and forth quicklyImprove experience3D object support structuresApplying layer meansEngineeringPrinting ink

The invention discloses a high-precision double-forming-mode 3D printer and a forming method thereof. The high-precision double-forming-mode 3D printer comprises a frame support structure, a plane mechanical motion structure, a piezoelectric micro nozzle structure and a powder forming bin which is inlaid in the upper surface of the frame support structure. A detachable gluing forming bin is arranged in the powder forming bin. A powder forming platform, a gluing forming platform and a vertical mechanical motion structure are arranged on the lower portion correspondingly, and the vertical mechanical motion structure drives the platforms to move. The plane mechanical motion structure, the piezoelectric micro nozzle structure and the vertical mechanical motion structure are connected to mastercontrol circuit control unit. According to the high-precision double-forming-mode 3D printer and the forming method thereof, the gluing forming bin is selectively installed in the powder forming bin,so that forming printing of different types of forming materials can be achieved; and through the piezoelectric glass combined micro nozzle structure, controllability of printing ink quantity can beimproved significantly, and the high-precision double-forming-mode 3D printer is particularly suitable for powder bonding of single-nozzle large ink quantity or gluing reflecting 3D printing forming.

Owner:NANJING NORMAL UNIVERSITY

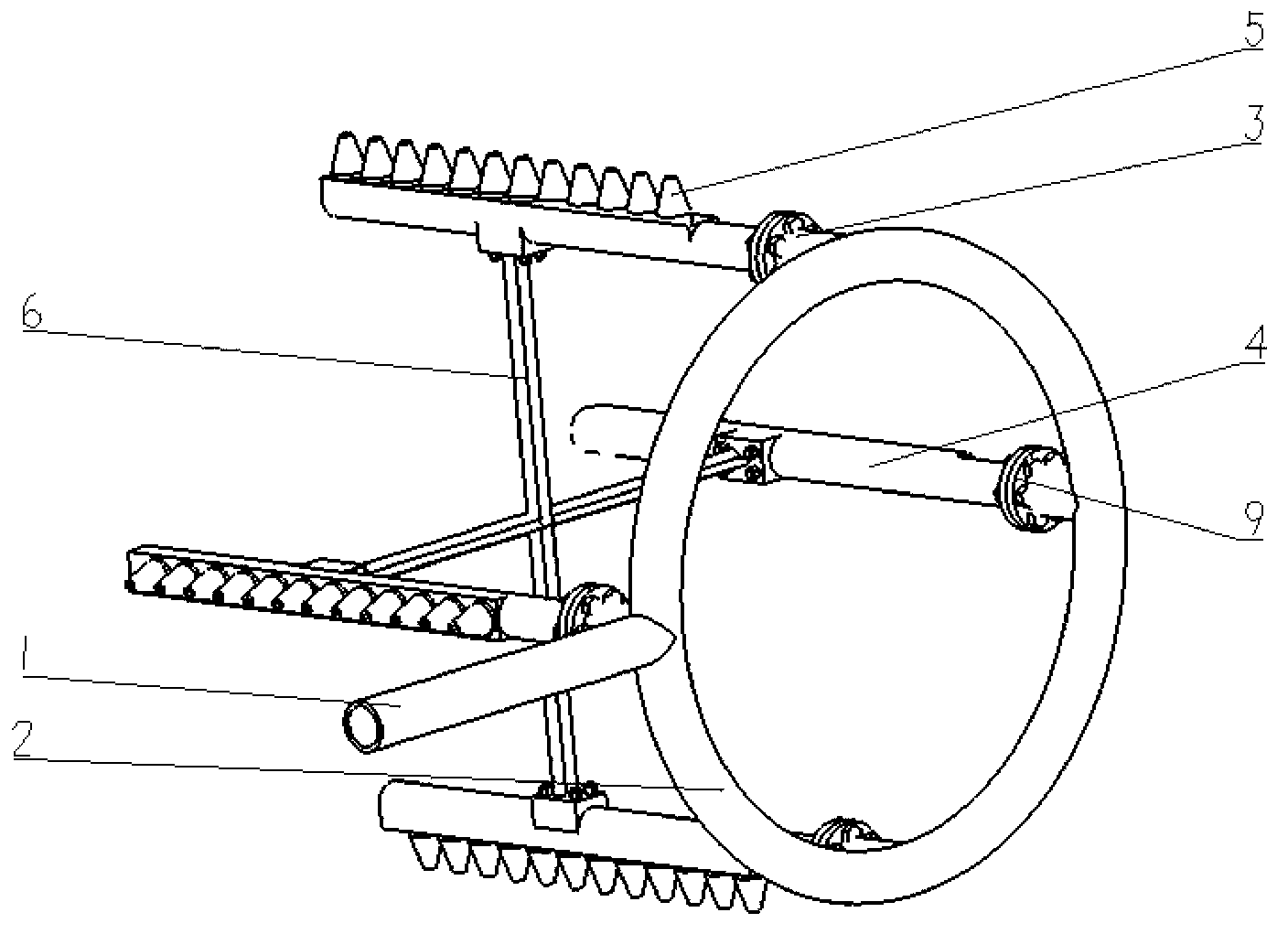

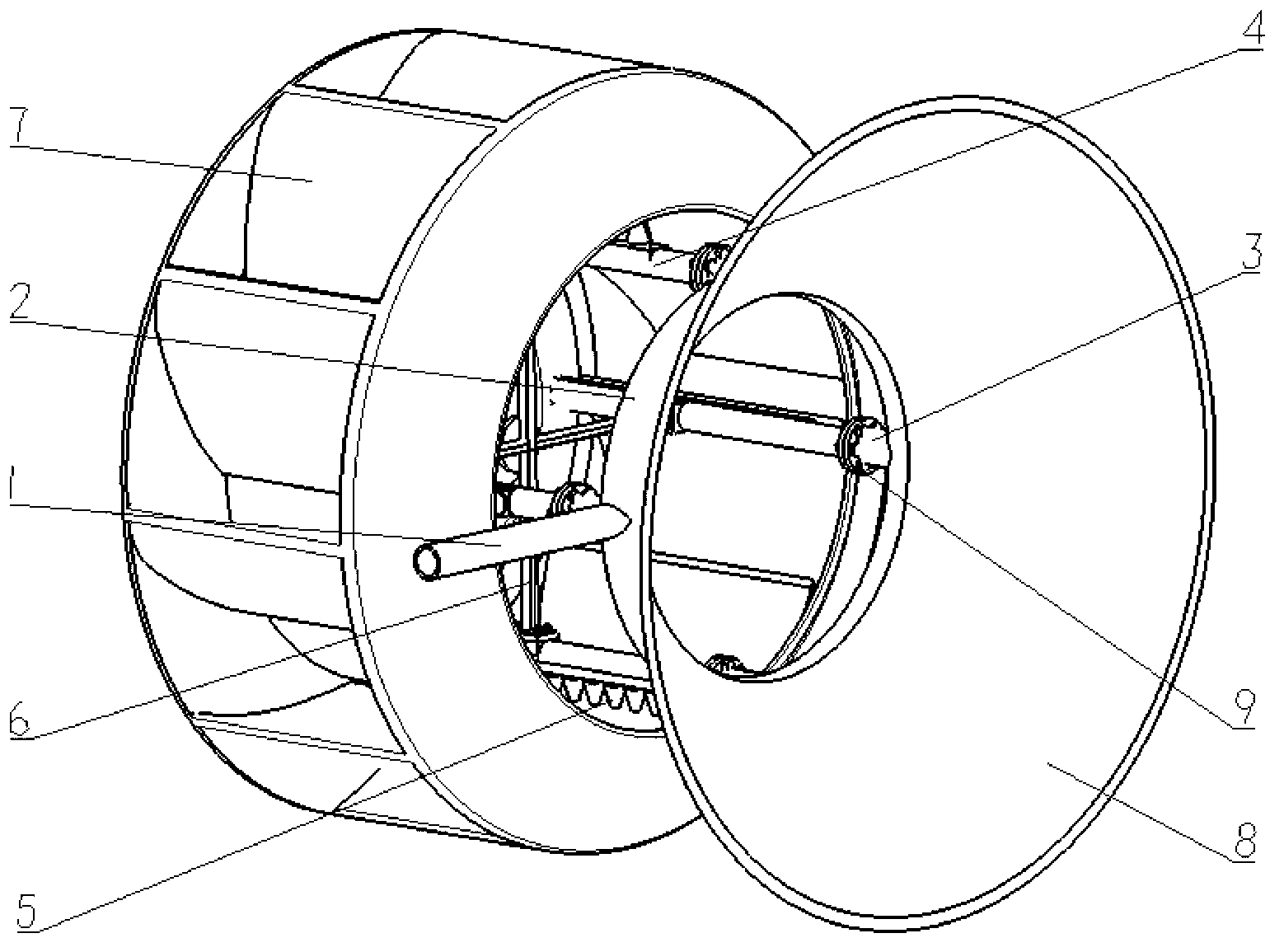

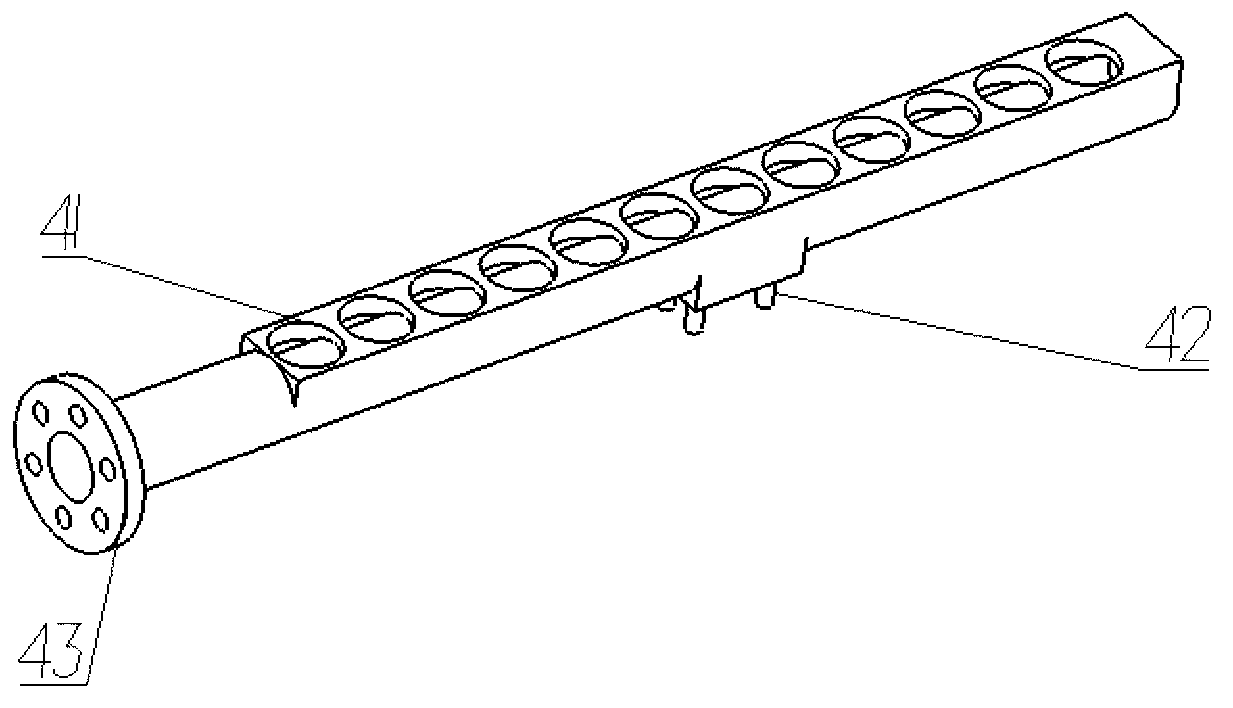

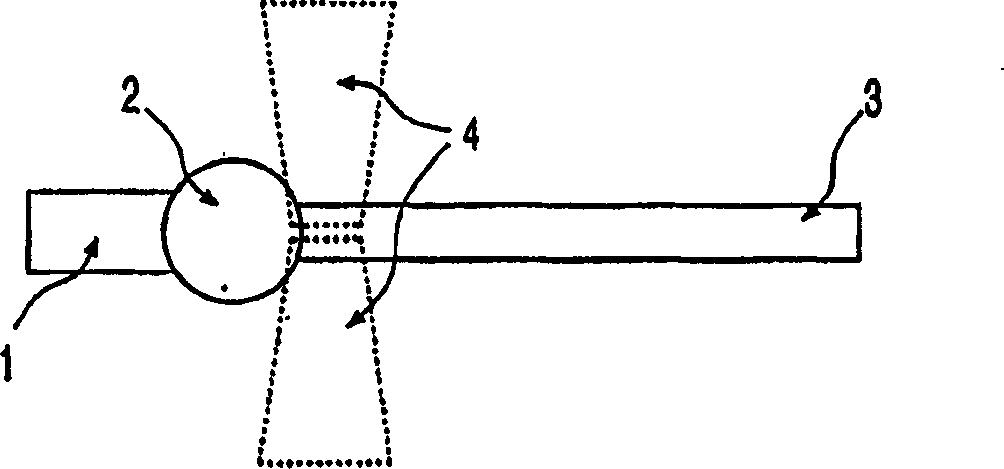

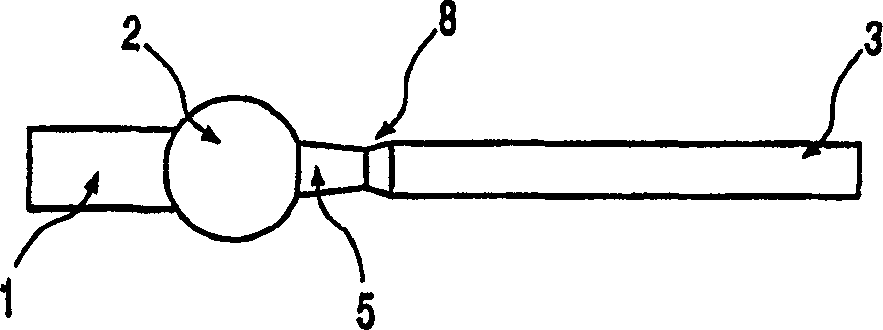

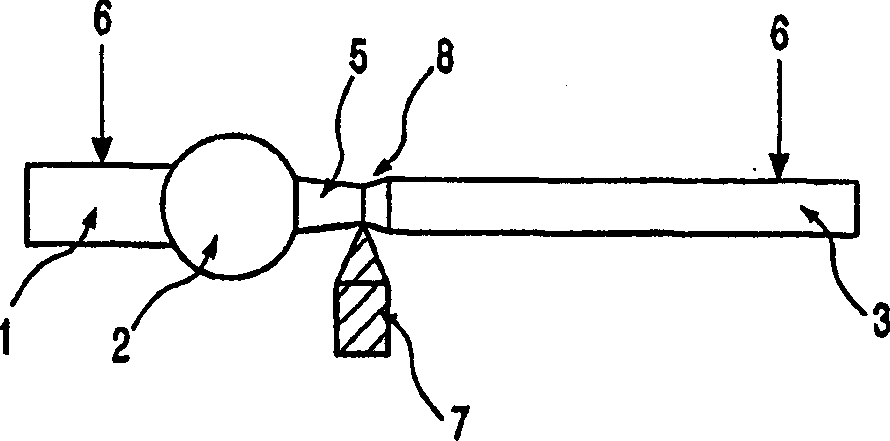

Boiler induced-draft fan soot blower

The invention discloses a boiler induced-draft fan soot blower which is composed of an air inlet (1), air distribution pipes (2), an air outlet pipe (3), a nozzle pipe (4), a nozzle (5) and a supporting frame (6). The air distribution pipes (2) are ring-shaped and are arranged on a round contracted port of a current collector (8), the air nozzle pipes (4) are arranged symmetrically, the nozzle (5) is a gradually-contracted nozzle and is installed with an outlet (41) through threads in a matched mode, and the supporting frame (6) is fixedly connected with the nozzle pipe (4) through bolts (42) to play the role in fixing the nozzle pipe (4). The boiler induced-draft fan soot blower blows air to remove dust in the radial direction from the center of the impeller of the induced draft fan, counter-acting force of air flow inside the nozzle are mutually cancelled, and under the fixing function of the supporting frame, stability and effectiveness of working of the soot blower are ensured. The boiler induced-draft fan soot blower can use air or steam to carry out dust blowing, is simple in part structure, and convenient to process and produce and assemble in batch.

Owner:章世斌

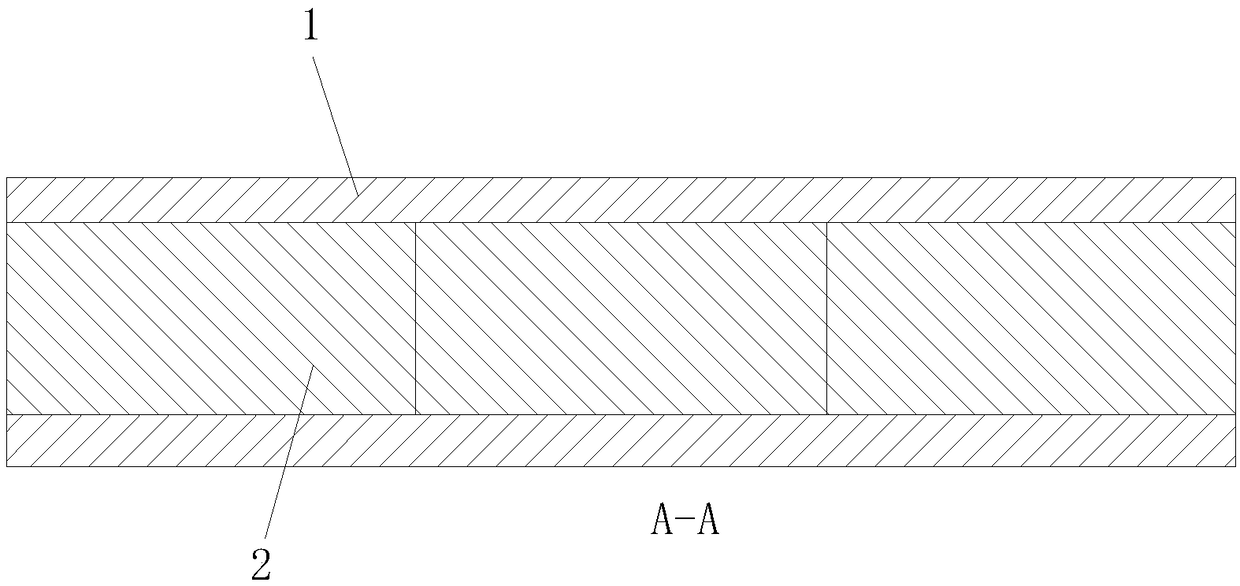

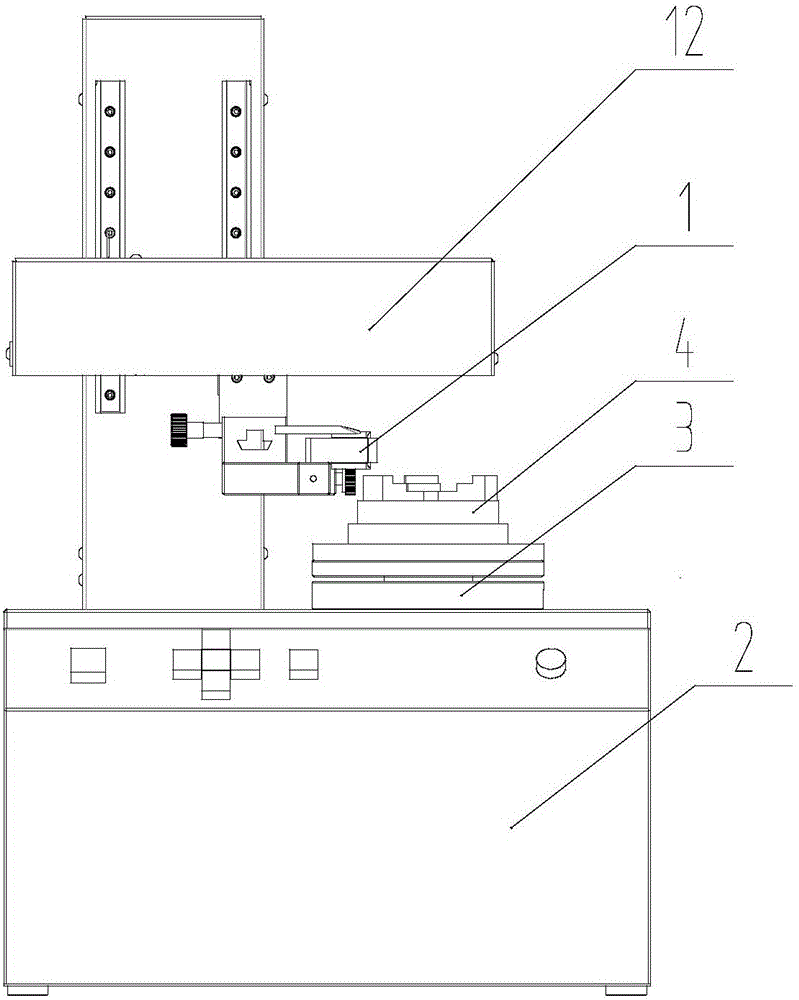

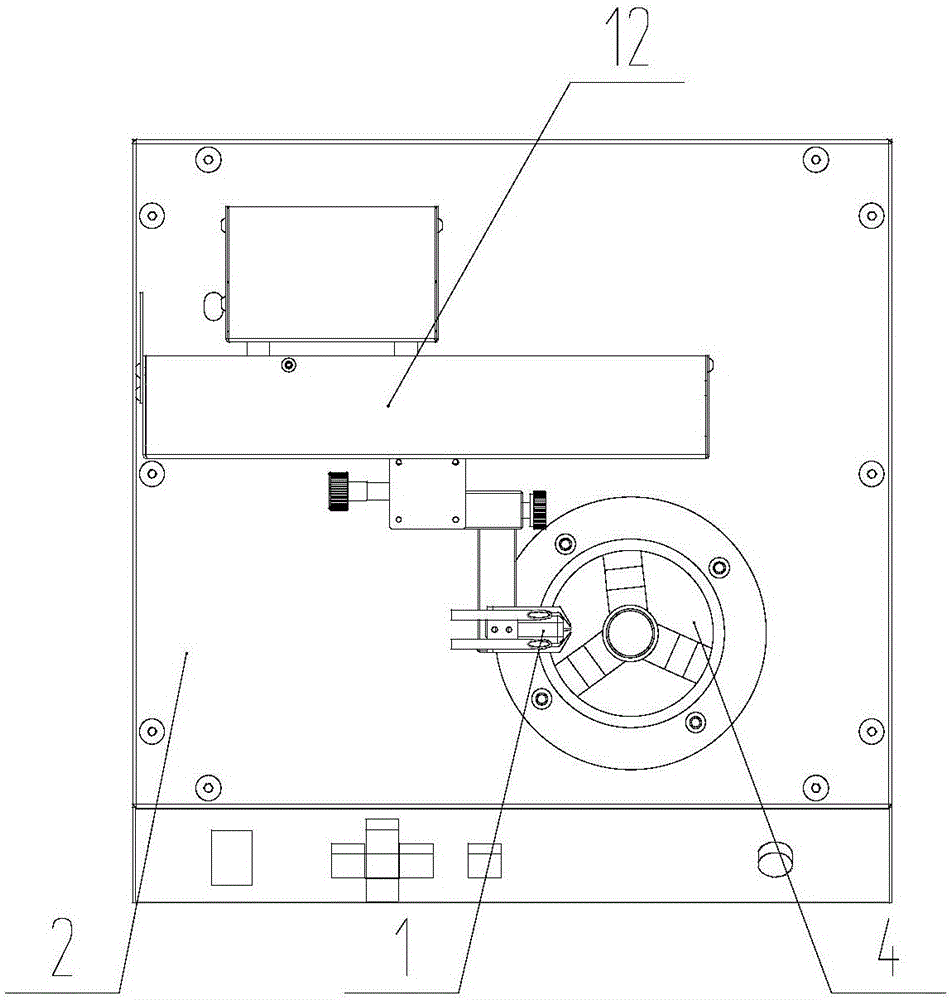

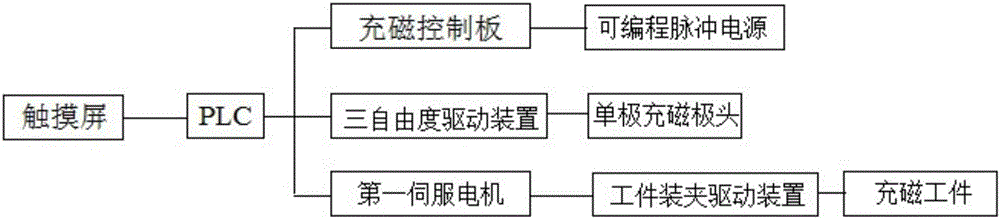

Single pole programmable magnetizing equipment

ActiveCN106601430ACompact structureReduce manufacturing costMagnetic bodiesMagnetizationPulse power supply

The invention discloses single pole programmable magnetizing equipment. A single pole magnetizing head is installed on a three-freedom driving device; a magnetizing work piece is mounted on a work piece assembling driving device; the three-freedom driving device is adjusted, so the single pole magnetizing head can be close to the magnetizing work piece and outputs pulse currents to the single pole magnetizing head; the single pole magnetizing head can magnetize the magnetizing work piece via instant pulse currents provided by a programmable pulse power supply; when one time magnetization is finished, the singe pole magnetizing head drives the magnetizing work piece to move to a next to-be-magnetized position at pulse current interval; and the single magnetizing pole head is reutilized for next time magnetization; the process is continued until the whole magnetizing work piece is magnetized. The single pole magnetizing head is employed for the magnetizing head, so the pole width and size of the single pole magnetizing head are suitable for magnetization of magnetizing products of various sizes and pole numbers; the operation is simple and the whole magnetizing process can be automatically controlled; and high magnetizing efficiency can be improved and high product pass percent can be achieved.

Owner:HANGZHOU MINGZHE MAGNETIC TECH

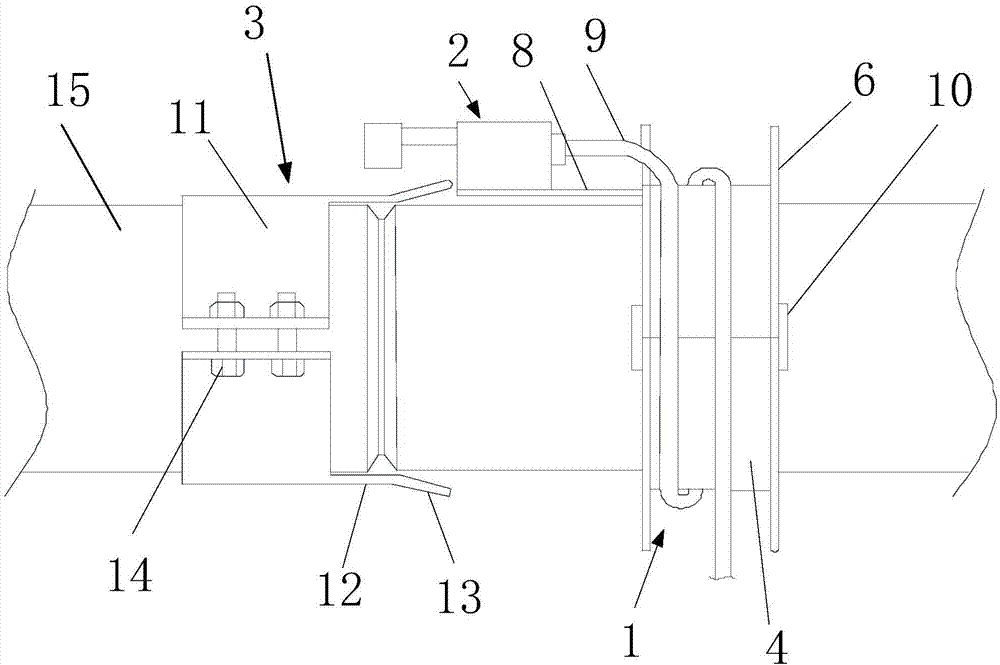

Pipe welding device

InactiveCN107350603AKeep the distance constantImprove welding qualityWelding/cutting auxillary devicesArc welding apparatusCircular discEngineering

The invention discloses a pipe welding device which comprises a guide mechanism, an electric welding gun and an opening assembly mechanism. The guide mechanism comprises a disc, rollers fixedly arranged on the inner wall of the disc and two baffles arranged at the two ends of the disc; the at least three rollers are evenly distributed, a notch is formed in one of the two baffles, and a connecting plate fixedly connected with the disc is arranged under the notch; the electric welding gun is fixedly arranged on a connecting plate; the electric welding gun comprises a connecting cable; the connecting cable penetrates the notch and is coiled on the disc; each baffle is divided into two parts, locking clamps are fixedly arranged on the outer walls of the baffles, and the two parts of each baffle are connected through the corresponding locking clamp; and the opening assembly mechanism comprises a pipe clamping sleeve formed by two semi-pipe rings, a horizontal section connected with the pipe clamping sleeve and extending out from one side of the pipe clamping sleeve in parallel, an expanding section fixedly connected with the horizontal section and outwards expanding along the center axis of the pipe clamping sleeve and an adjusting nut used for connecting the two semi-pipe rings.

Owner:苏鸿远

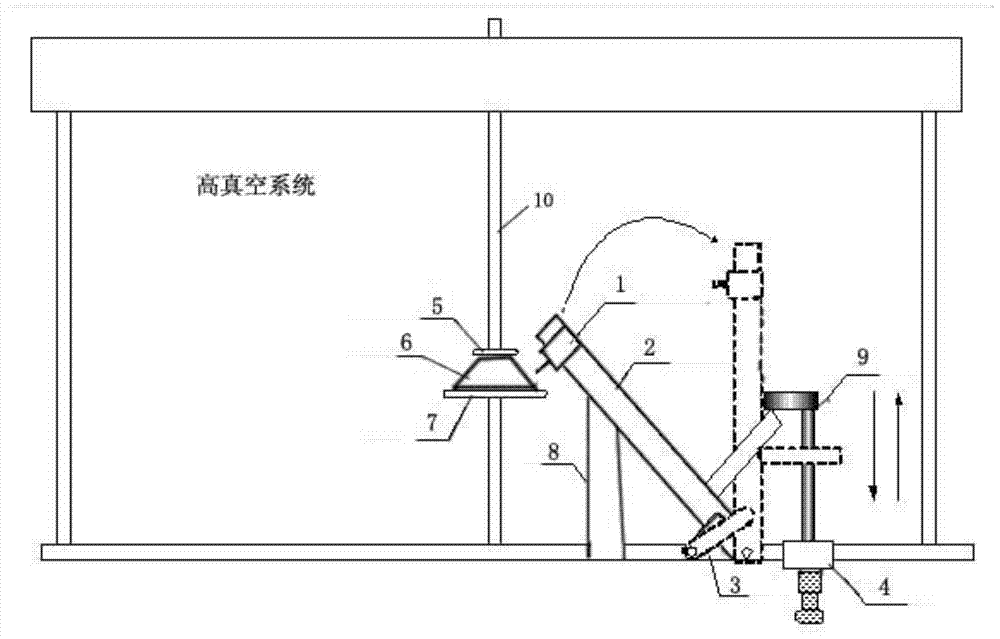

High-vacuum solid insulation surface charge measuring probe control system

ActiveCN104777373AKeep the distance constantVacuum is not affectedMeasurement instrument housingEngineeringHigh pressure

The invention discloses a high-vacuum solid insulation surface charge measuring probe control system and belongs to the field of electrostatic measurement. The measuring probe control system comprises an electrostatic capacitor probe bracket comprising a probe sliding track and a slope support, an electrostatic capacitor probe movement control mechanism comprising a spring mechanism and a pull-down connecting rod as well as a high-vacuum system, wherein in the high-vacuum system, a to-be-measured solid insulation test object is placed between a high-voltage electrode and a ground electrode; the pull-down connecting rod is in dynamic seal fixation with a bottom plate of the high-vacuum system through a magnetic fluid. An electrostatic capacitor probe is controlled to be away from or get close to the solid insulation test object by the aid of mechanical drive control components such as the spring mechanism, the pull-down connecting rod, a rotating shaft, a gear mechanism and the like, and the distance between the electrostatic capacitor probe and the solid insulation surface is kept constant by means of the slope support; high-vacuum dynamic seal is realized by the aid of a magnetic fluid sealing technology, control movement outside a vacuum testing cavity is transferred into the cavity, and meanwhile, the vacuum degree is not affected.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Coating thickness regulating mechanism and method for coating head

PendingCN108940720AUniform thicknessAdjust distance in real timeLiquid surface applicatorsCoatingsEngineeringFully automatic

The invention relates to the technical field of coater coating, in particular to a coating thickness regulating mechanism and method for a coating head. A scraper fine-tuning mechanism can regulate adistance between a scraper roller and a supporting roller in real time, so that the distance between the scraper roller and the supporting roller is kept constant, and therefore, the coating thicknessof a substrate surface is kept uniform, the whole thickness regulating process does not need artificial participation, is fully automatic; and moreover, the control is precise, so that labor efficiency and production quality are greatly improved.

Owner:常州市伟邦光电科技有限公司

Sperm freezing device

PendingCN110367245AQuality improvementKeep the distance constantDead animal preservationTimerSperm freezing

The invention relates to a sperm freezing device which comprises a tank body, a liquid level adjusting mechanism, a bracket, a timer and a controller, wherein an accommodation cavity is formed in thetank body; the accommodation cavity is internally provided with a partition plate for partitioning the accommodation cavity into a standby storage cavity and a freezing cavity; the inner wall of the freezing cavity is provided with a first position and a second position at an interval; the liquid level adjusting mechanism is mounted on the partition plate and is used for communicating the standbystorage cavity with the freezing cavity when the liquid level in the freezing cavity is lower than a preset value, and thus the liquid level in the freezing cavity is kept constant; the bracket is mounted on the inner wall of the freezing cavity in a sliding manner along a connection line direction of the first position and the second position; the bracket is used for holding sample cryopreservation tubes with sperm samples; the timer is used for setting fumigation time according to preset instructions; and the controller is electrically connected with the timer, and is used for controlling the bracket to move to the second position from the first position when the timer meets the fumigation time. Therefore, due to adoption of the sperm freezing device, the quality of frozen sperms is high.

Owner:REPRODUCTIVE & GENETIC HOSPITAL OF CITIC XIANGYA CO LTD

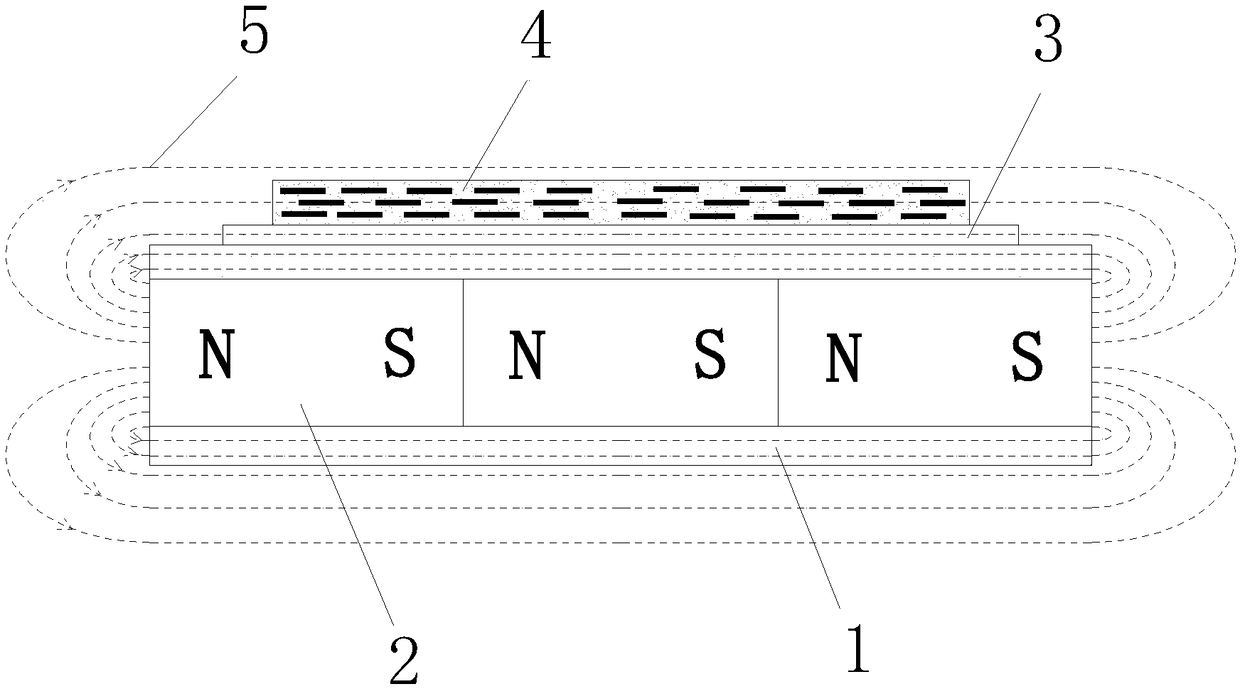

Sputtering target and method for producing same

PendingCN114651086AUniform thicknessSmall height differenceElectric discharge tubesVacuum evaporation coatingComposite material

The present invention relates to a sputtering target capable of using a warped cylindrical base material as a constituent material, and a method for manufacturing the same, and provides a novel method for manufacturing a sputtering target in which warpage of a cylindrical base material can be eliminated even if the axial length of the cylindrical target material is long or even if the cylindrical target material is heated when being filled with a bonding material. The present invention proposes a method for manufacturing a sputtering target, which is characterized in that the degree of warping of a cylindrical base material is measured, processing is performed for warping the cylindrical base material in a direction opposite to the direction in which the cylindrical base material is warped, and a plurality of cylindrical target materials are arranged on the outside of the processed cylindrical base material at intervals in the axial direction. And bonding the cylindrical base material and the cylindrical target material with a bonding material.

Owner:MITSUI MINING & SMELTING CO LTD

Dedicated pipeline welding device

InactiveCN107617838AKeep the distance constantQuality improvementWelding/cutting auxillary devicesAuxillary welding devicesCircular discStraight segment

The invention discloses a dedicated pipeline welding device. The device comprises a guide device, a welding gun, a clamping pipe sleeve, a straight segment, a flaring segment and a nut; the guide device comprises a disc, rollers fixedly arranged on the inner wall of the disc and two baffles arranged on the two ends of the disc; at least three rollers are evenly distributed, one of the two bafflesis provided with a gap, a connecting plate fixedly connected with the disc is arranged under the gap, the welding gun is fixedly arranged on the connecting plate, the welding gun comprises a cable, and the cable penetrates the gap and is wound on the disc, each baffle is divided into two parts, a locking device is fixedly arranged on the outer wall of each baffle, and two parts of each baffle areconnected through a locking clamp. Pipeline opening alignment and welding are integrated, unstability caused by the manual factor can be reduced, and welding quality stability is ensured.

Owner:UNIV FOR SCI & TECH SICHUAN

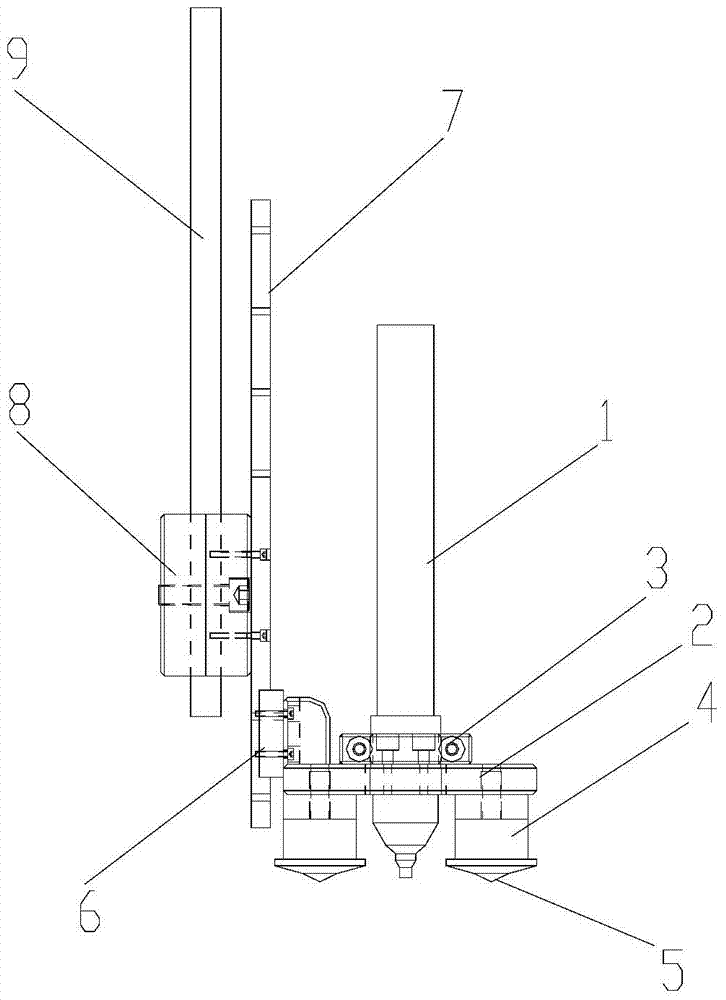

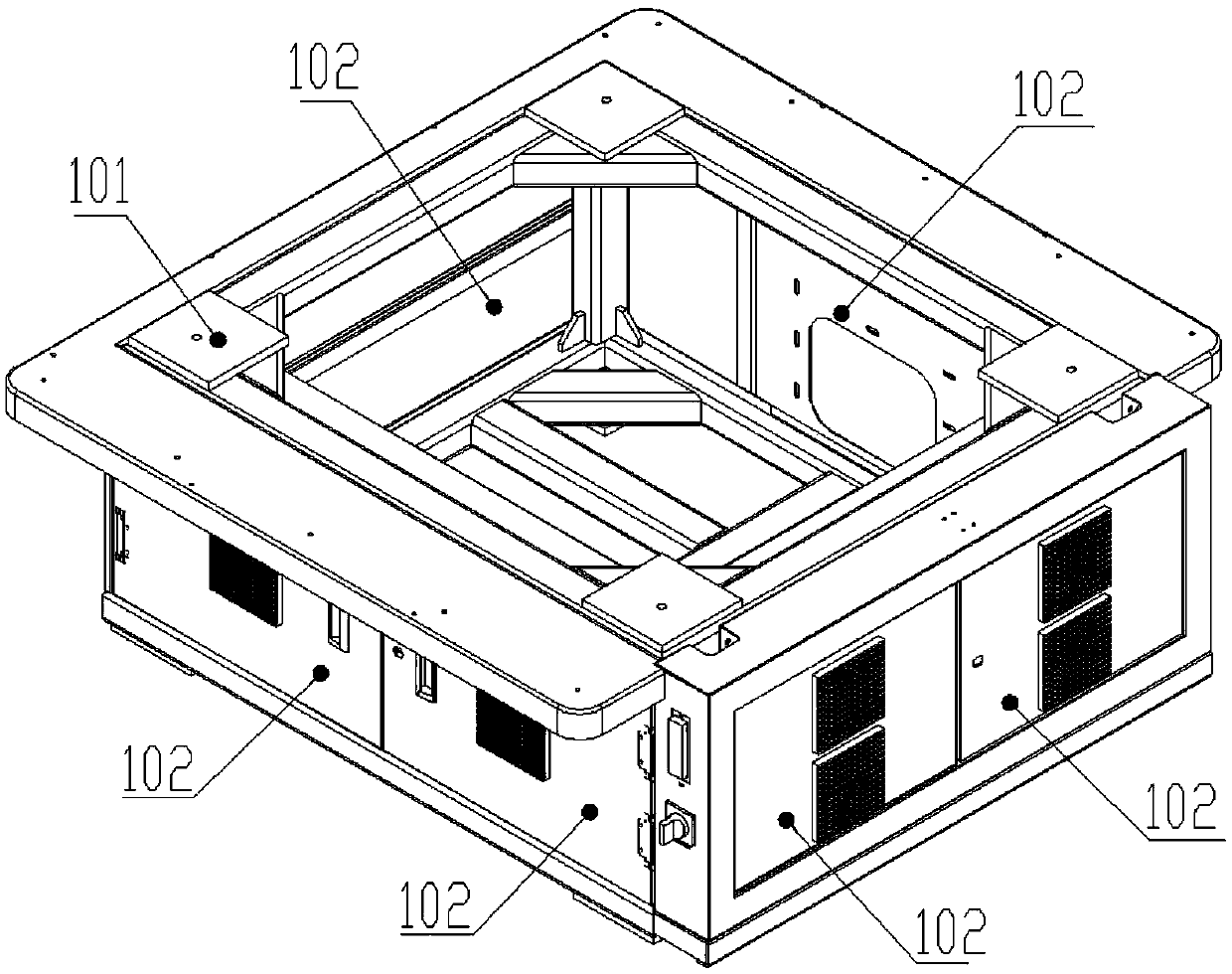

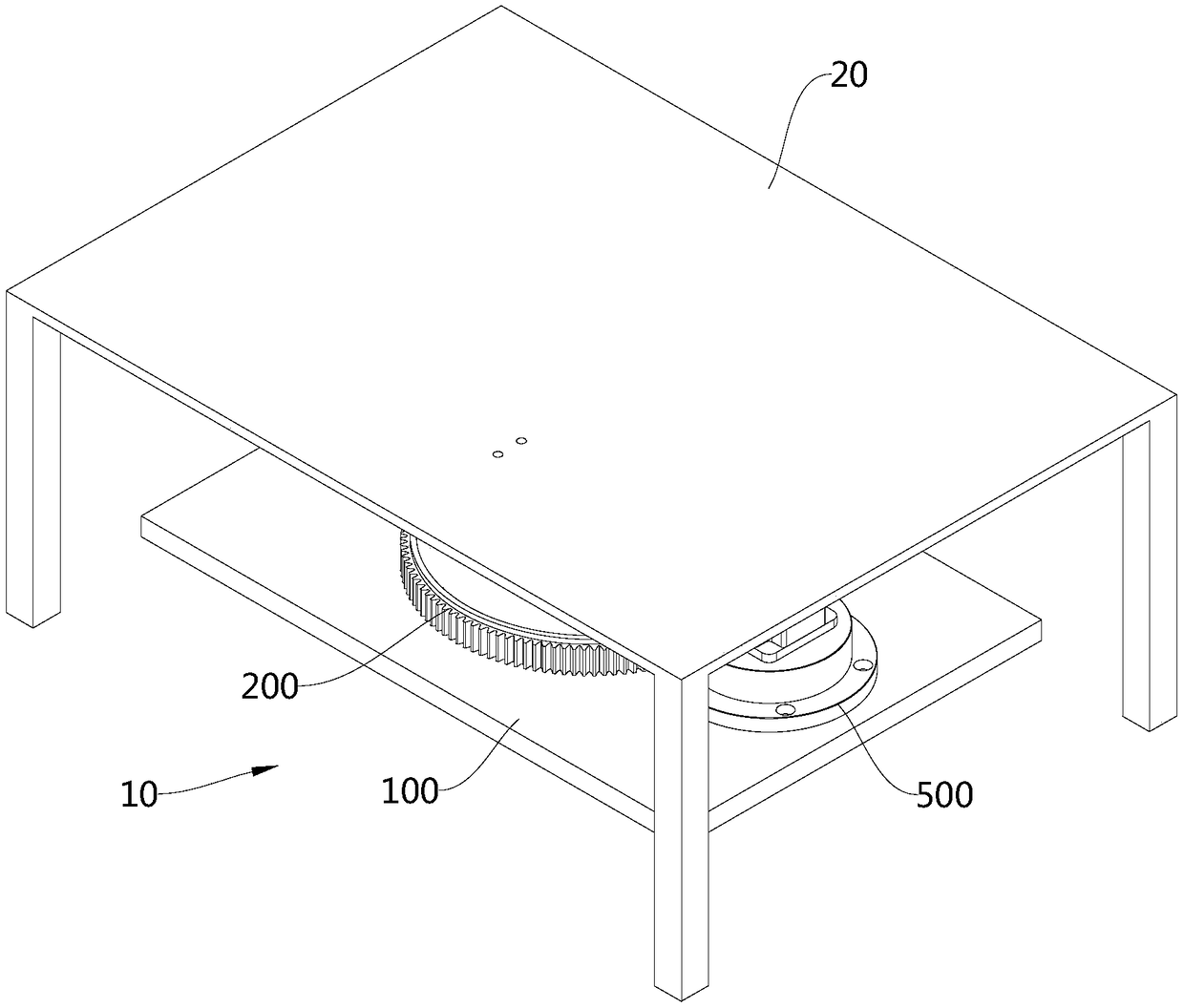

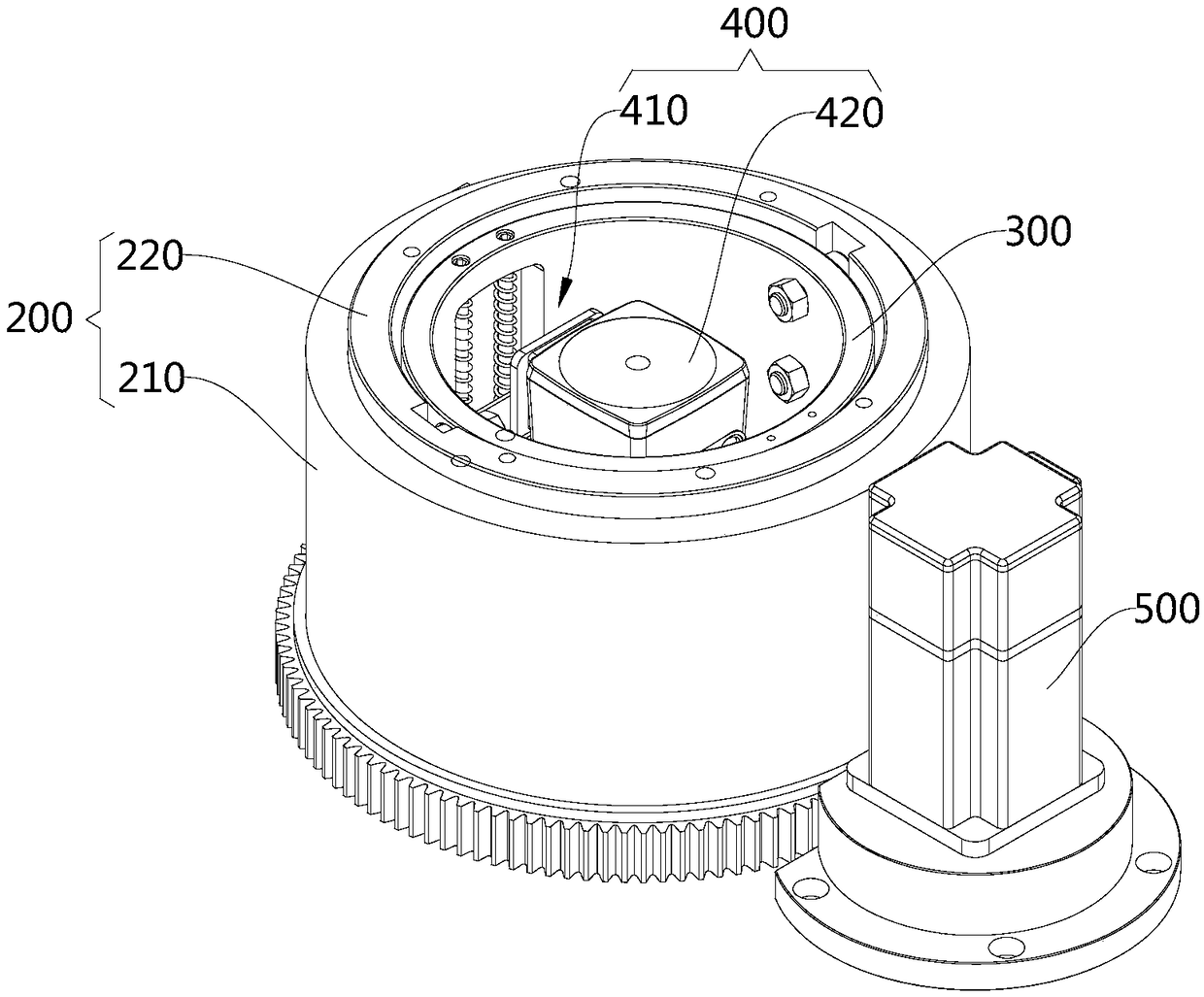

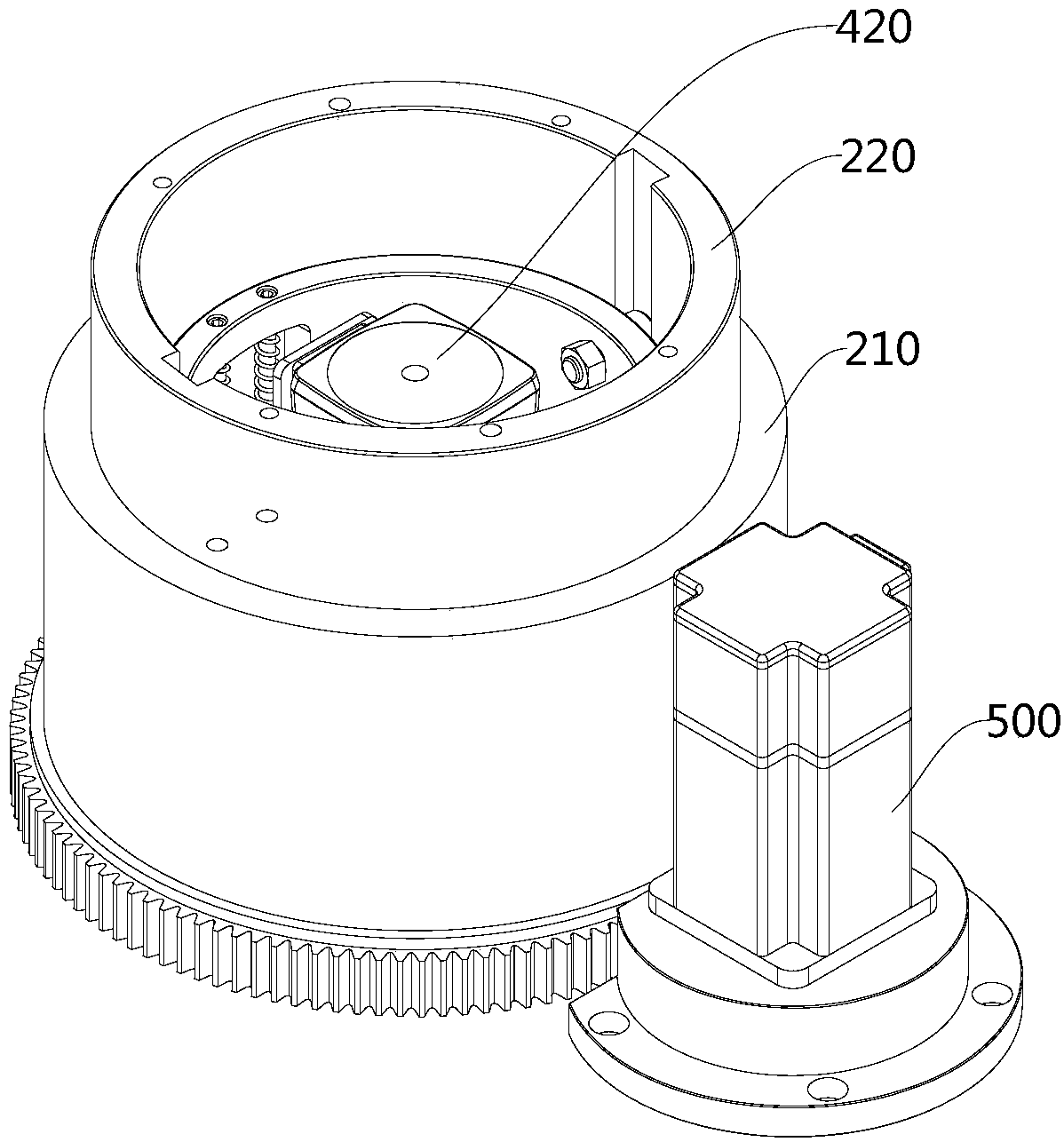

Lifting mechanism and automated guided vehicle

PendingCN108773814AAchieve liftRealize handlingLifting devicesVehicular energy storageAutomated guided vehicleIndustrial engineering

The invention discloses a lifting mechanism and an automated guided vehicle and relates to the technical field of automated logistics. The lifting mechanism provided by the invention comprises a foundation support, a lifting assembly, a guide assembly and a recognition assembly, and the guide assembly is arranged on the foundation support. The lifting assembly comprises a first lifting piece and asecond lifting piece, the first lifting piece is rotatably installed on the foundation support, the second lifting piece is matched with the first lifting piece and is located between the first lifting piece and the guide assembly, and the second lifting piece can move in the first direction when the first lifting piece rotates. The recognition assembly comprises a connection structure and a recognition piece, the recognition piece is connected with the guide assembly through the connection structure, and the second lifting piece can drive the recognition piece to move in the first direction.The invention further provides the automated guided vehicle comprising the lifting mechanism. By means of the lifting mechanism and the automated guided vehicle provided by the invention, lifting andcarrying of a goods shelf can be realized, and the stability and accuracy in the lifting and carrying processes can be guaranteed.

Owner:GUANGDONG JATEN ROBOT & AUTOMATION

High-pressure gas discharge lamp and method of manufacturing the same

InactiveCN1650393AKeep the distance constantAccurate meltingHigh-pressure discharge lampsCold cathode manufactureGas-discharge lampNoble gas

High pressure vapor discharge lamp provided with a discharge vessel. The discharge vessel encloses a discharge space provided with a filling of mercury and a rare gas, for example, in a gastight manner. An electrode is arranged in the discharge space for generating and maintaining a discharge therein, while the electrode comprises a electrode rod (1) having an enlarged head (2) at its end which projects into the discharge space. According to the invention, the enlarged head (2) comprises a preformed electrode projection (5) having an at least substantially conical shape.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Method for machining by lathing, and lathe

ActiveCN102481634AMultiple Turning ContoursShort processing timeLathesTurbinesRotational axisEngineering

The invention relates to a lathe (1), wherein the work piece (16) to be lathed with a tool (18) is clamped with the longitudinal axis of the work piece parallel to the rotational axis (29) of the rotating clamping device (15) such that the rotational axis (29) does not intersect the work piece (16), and that between two machining steps of the machining process by lathing, the position of the work piece (16) in the clamping device (15) is changed such that surface areas (30, 36) not previously machined are moved into the working area of the tool (18).

Owner:J G WEISSER SOHNE

Film tearing and cleaning device for LED display screen

PendingCN113385443AQuick clean upKeep the distance constantCleaning using toolsEngineeringMechanical engineering

The invention discloses a film tearing and cleaning device for an LED display screen, and belongs to the technical field of cleaning devices. The film tearing and cleaning device comprises a bearing plate, a first cleaning brush, second cleaning brushes, clamping plates, an LED display screen main body and a cleaning mechanism, four electric telescopic rods are fixedly connected to the upper end of the bearing plate, and a sliding hole is formed in the upper end of the bearing plate; the first cleaning brush is arranged above the bearing plate; the number of the second cleaning brushes is four, and the four second cleaning brushes are arranged above the bearing plate; the number of the clamping plates is two, and the two clamping plates are both arranged at the upper end of the bearing plate; the LED display screen main body is arranged at the upper end of the bearing plate; and the cleaning mechanism is arranged above the bearing plate, and finally, the first cleaning brush and the second cleaning brushes can be driven to rotate through rotation of a center gear and an edge gear, so that the first cleaning brush and the second cleaning brushes can quickly clean a transparent film on the LED display screen.

Owner:深圳市华立诺显示技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com