High-precision double-forming-mode 3D printer and forming method thereof

A 3D printer, high-precision technology, applied in the direction of 3D object support structure, coating device, additive manufacturing, etc., can solve the problems of difficult fine occasions, small inkjet volume, high cost, etc., to eliminate influence and improve conversion efficiency , the effect of saving the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention can be better understood from the following examples.

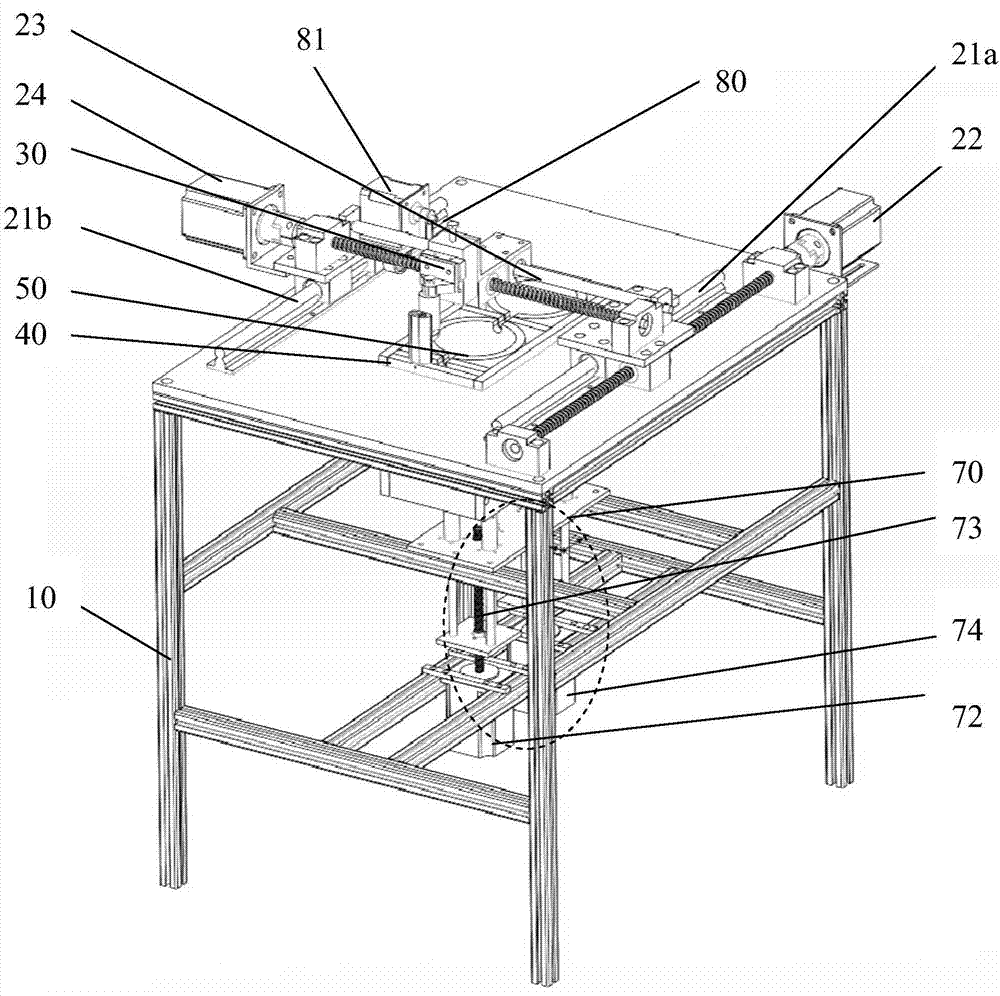

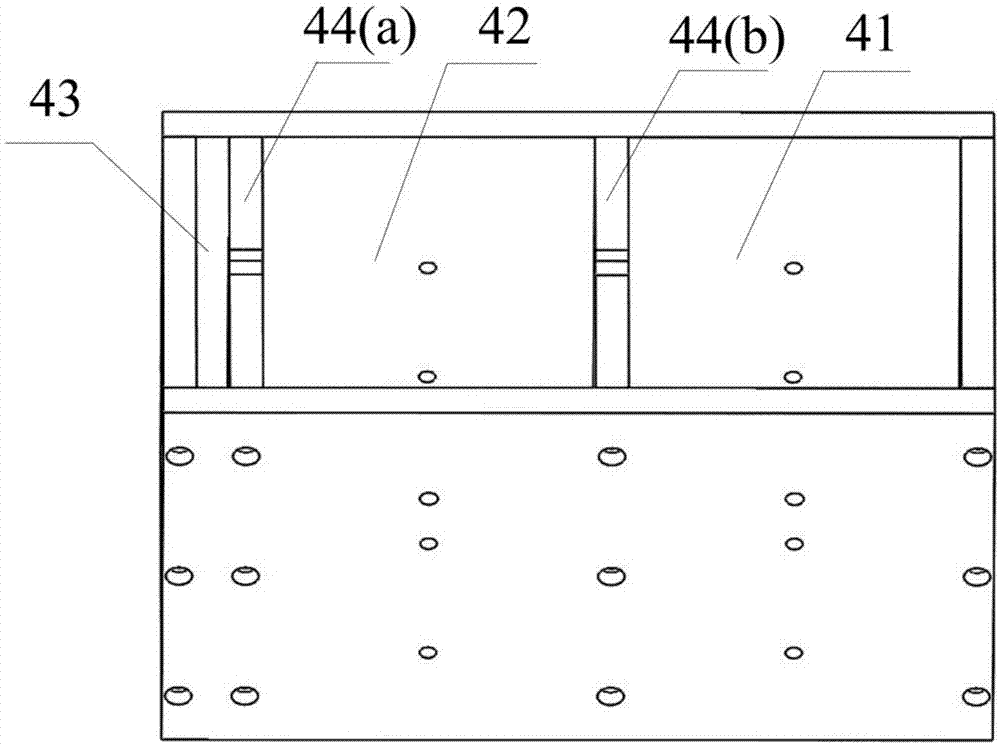

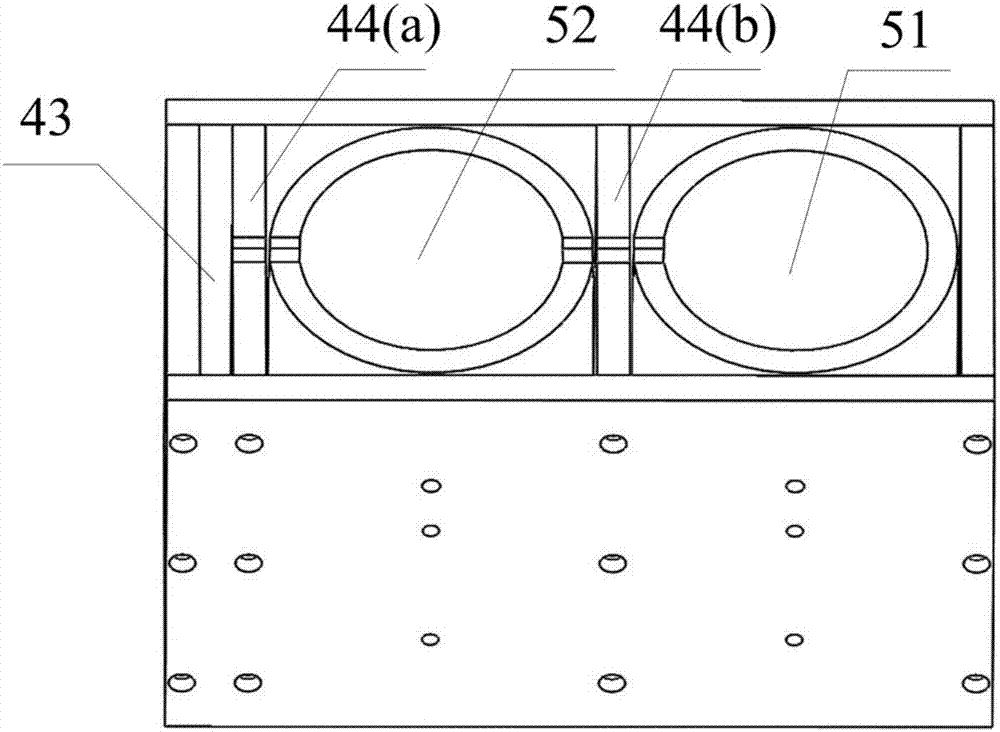

[0039] Such as figure 1 , 2 and image 3 As shown, the 3D printer includes a frame support structure 10, X-axis motion shafts 21a and 21b and their X-axis drive motors 22, Y-axis motion shafts 23 and their Y-axis drive motors 24 are installed on the frame support structure 10, loaded on the Y-axis The piezoelectric micro-spray head structure 30 on the shaft movement shaft 23, and the powder molding chamber body 40 embedded in the upper surface of the frame support structure 10, the side wall of the powder molding chamber body 40 is provided with screw holes, and the inside is installed with glue joints through screws. The upper part of the bin body 50, the powder molding bin body 40 and the glued molding bin body 50 are opened, and the lower part is respectively provided with a powder molding platform and a glued molding platform that can move up and down along the inside of the powder moldi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com