Winding device

A technology of winding and supporting devices, which is applied in the directions of transportation and packaging, conveying filamentous materials, and thin material processing, etc., which can solve the problems of high winding frequency and impossibility to compensate yarn tension fluctuations, etc., so as to improve quality and structure reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

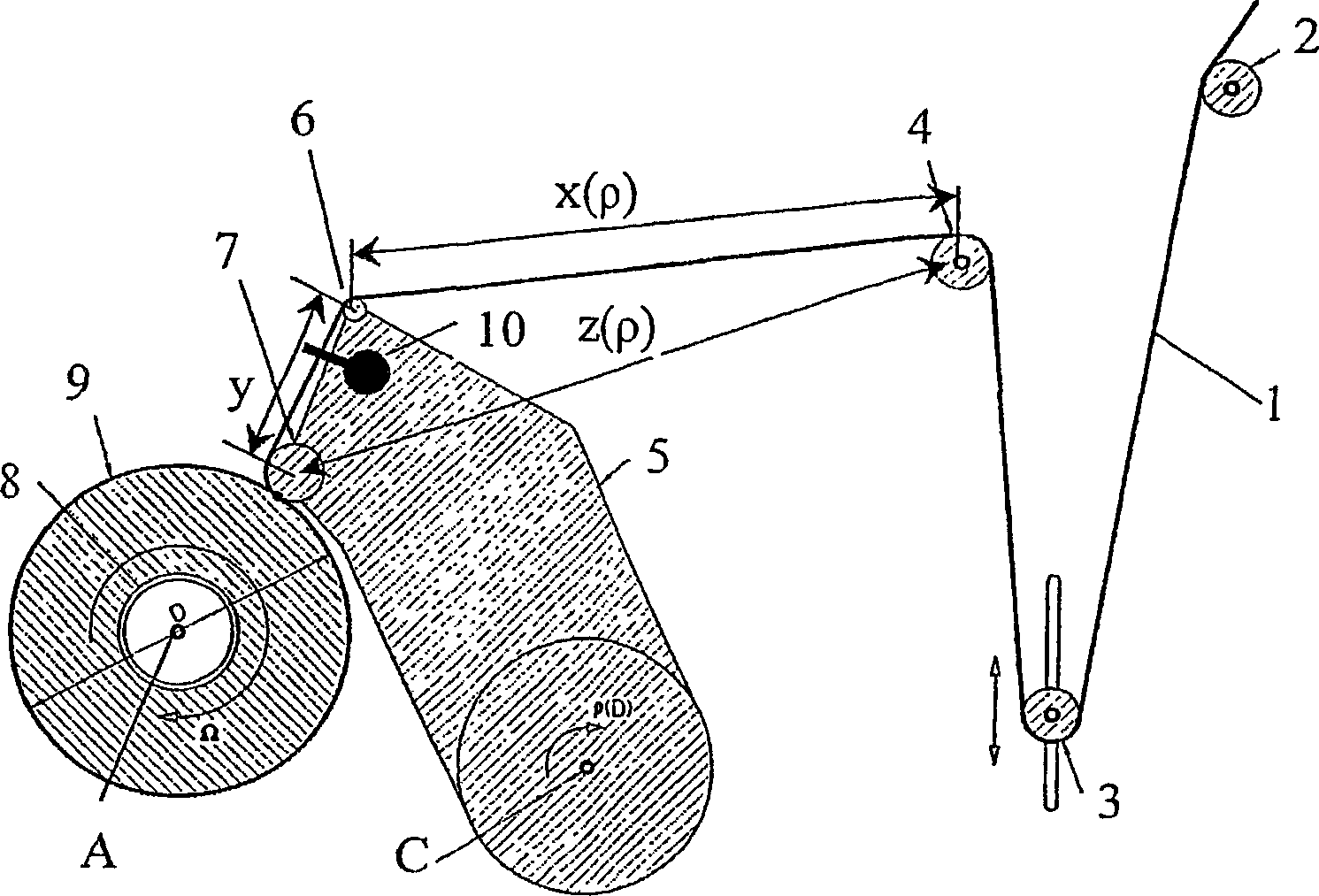

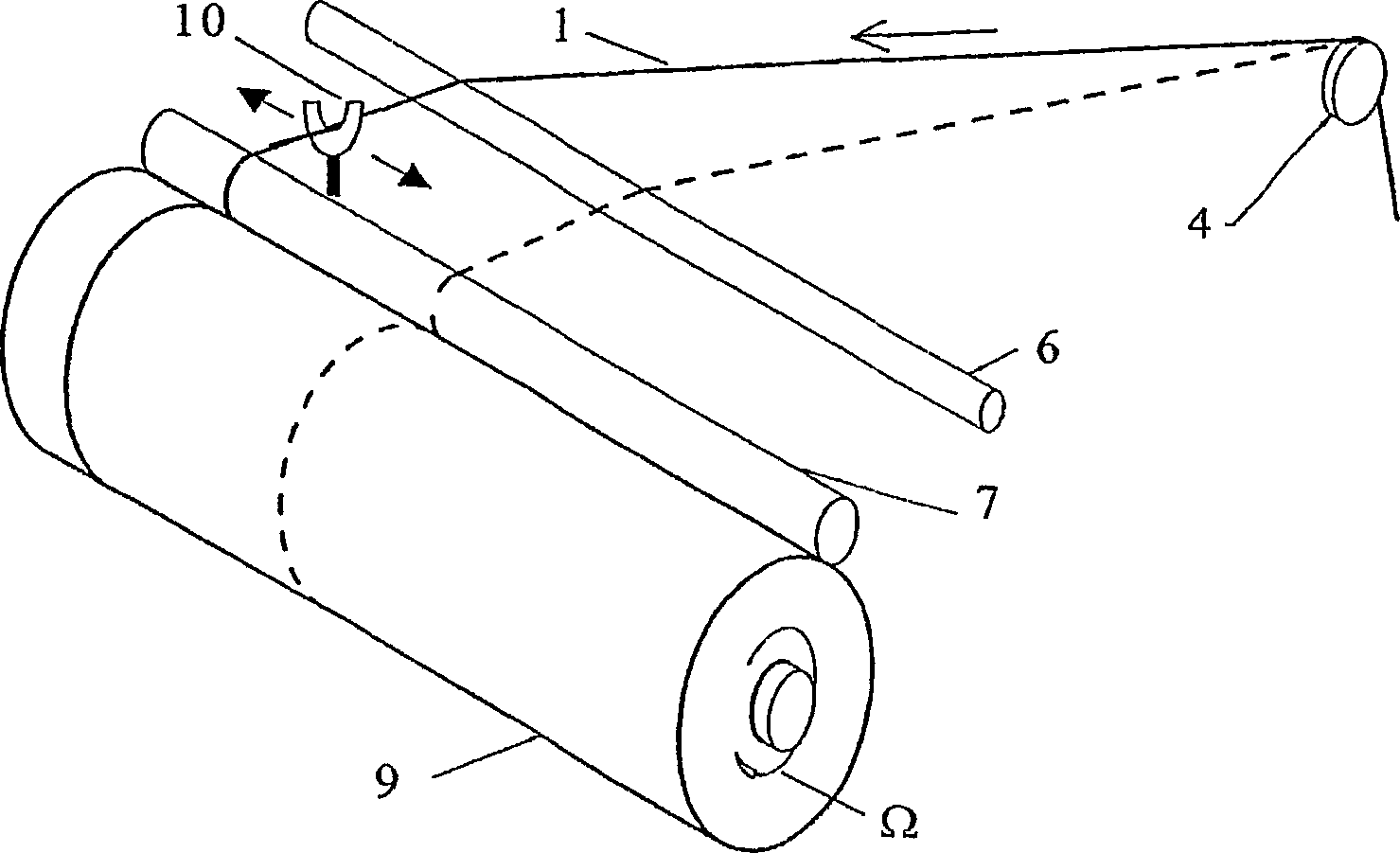

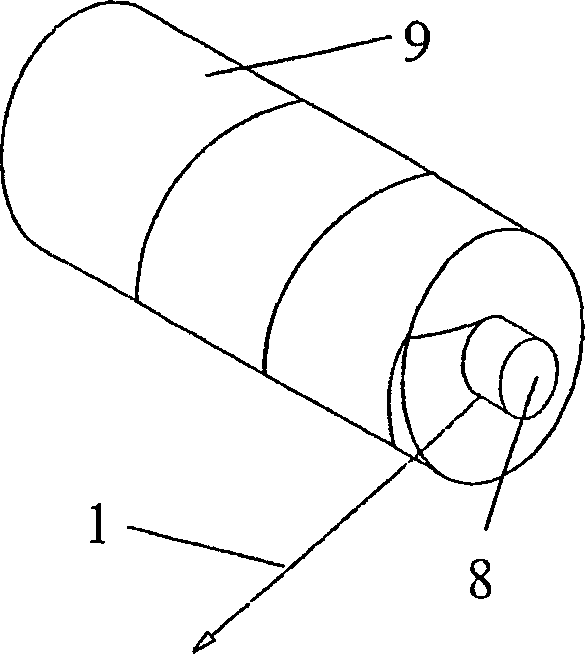

[0037] In FIG. 4A there is a first embodiment of the winding device according to the invention, which is an improvement of the known winding device according to FIG. 1 . During production, the yarn 1 or ribbon reaches the first turning guide roller 2 of the winding device. From there, the yarn 1 advances towards a yarn tension sensor 13 fitted with deflecting guide rollers. Embodiments of the yarn sensor 13 will be described in detail below. The yarn 1 advances from the yarn tension sensor 13 to a yarn support device 14 which may be a deflecting guide roller rotatably mounted on a support 15a of the control device 15 . The control device 15 additionally comprises a yarn deflecting device 6, for example, in this embodiment, a straight diverting bow, and also a pressure roller 7, which first presses the yarn 1 against the The surface of the core 8 is then pressed against the periphery of the forming bobbin 9 as the bobbin 9 is formed from the supplied yarn. The cartridge core...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com