Automatic bagging production line of rod-shaped foods

A production line and food technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of complex packaging process, increased production cost, complex production equipment, etc., to reduce storage, simplify production equipment structure, and reduce land occupation area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Specific examples of the present invention are given below. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims of the present application.

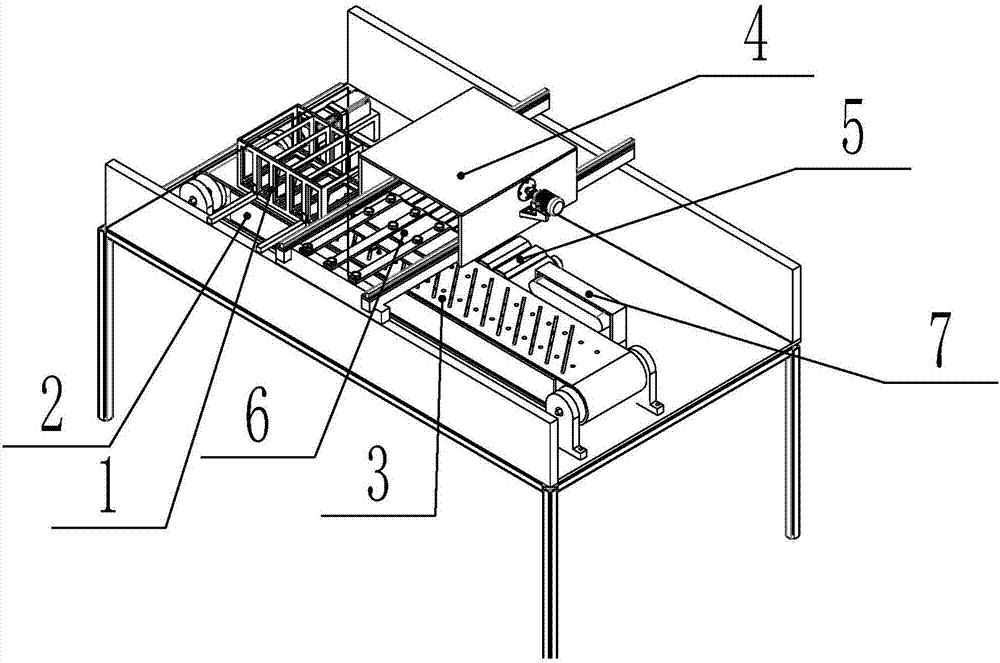

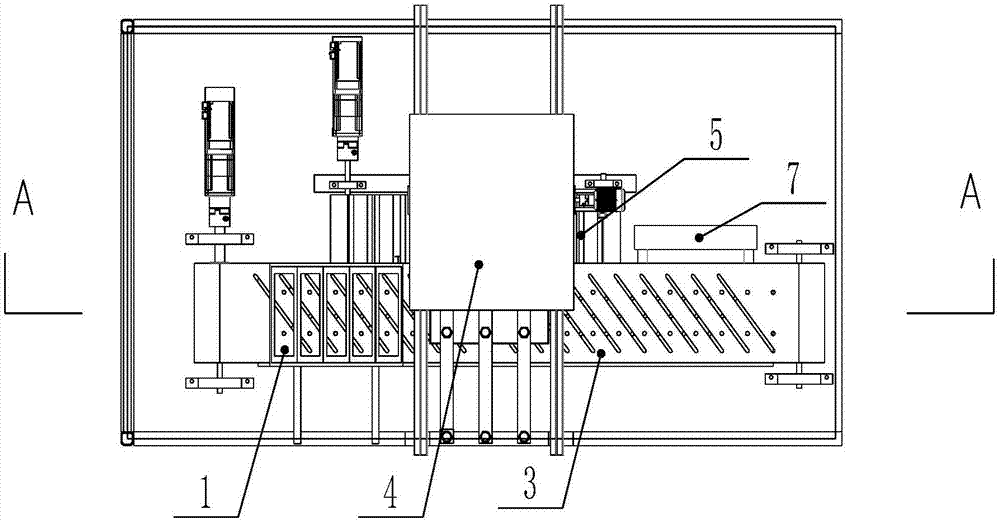

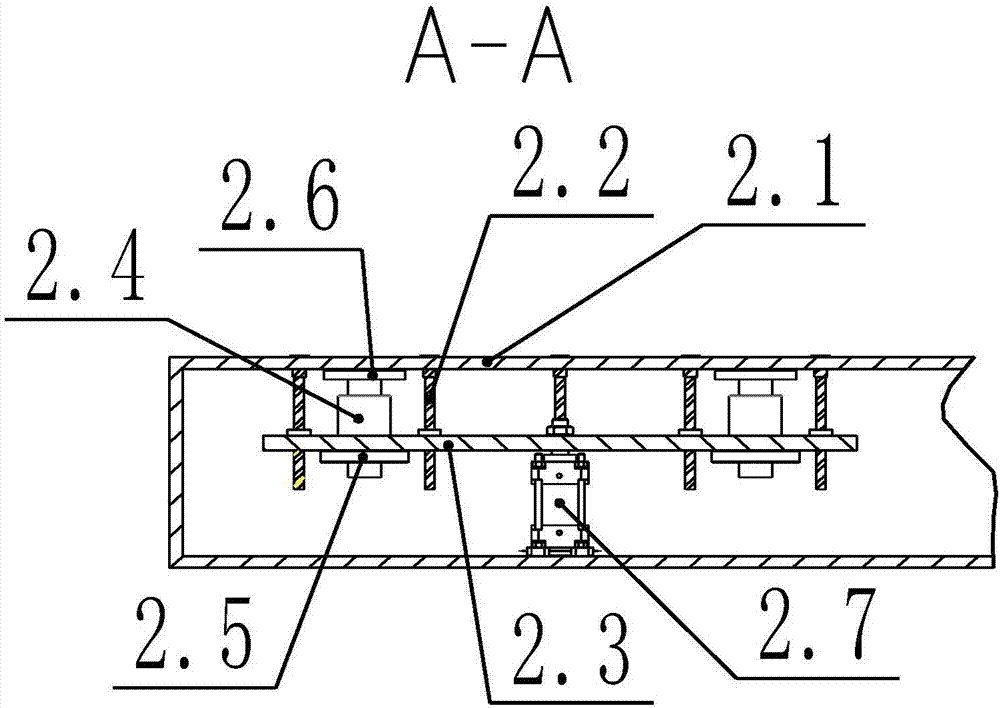

[0030] The invention provides a kind of stick food automatic bagging production line (see Figure 1-5 ), which is characterized in that the packaging bag holding frame body 1, the lower vacuum box 2, the conveying packaging bag belt 3, the pushing structure 4, the feeding belt 5, the upper vacuum box 6 and the heat sealing machine 7 of the production line;

[0031] The belt 3 for conveying packaging bags is installed on the frame of the production line for conveying packaging bags;

[0032] The packaging bag holding frame 1 is located at the beginning of the entire production line, above the conveyor belt 3 for packaging bags, and is used to place packaging bags; one side of the packaging bag is open, and the other side is sealed;

[0033...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com