Pipe welding device

A welding device and pipeline technology, applied in welding equipment, welding equipment, auxiliary equipment, etc., can solve the problems of difficult control of the distance between the welding torch and the welding port, unstable positioning welding quality, inconvenient welding operation, etc., to reduce instability High reliability, convenient welding operation, and stable welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below with reference to the accompanying drawings and embodiments, and the mode of the present invention includes but not limited to the following embodiments.

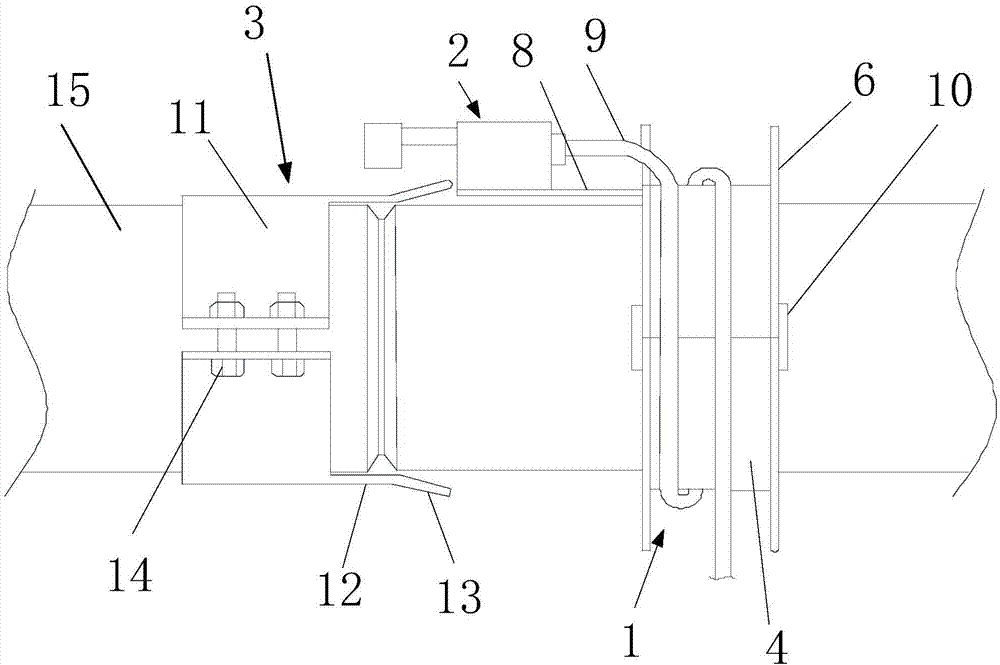

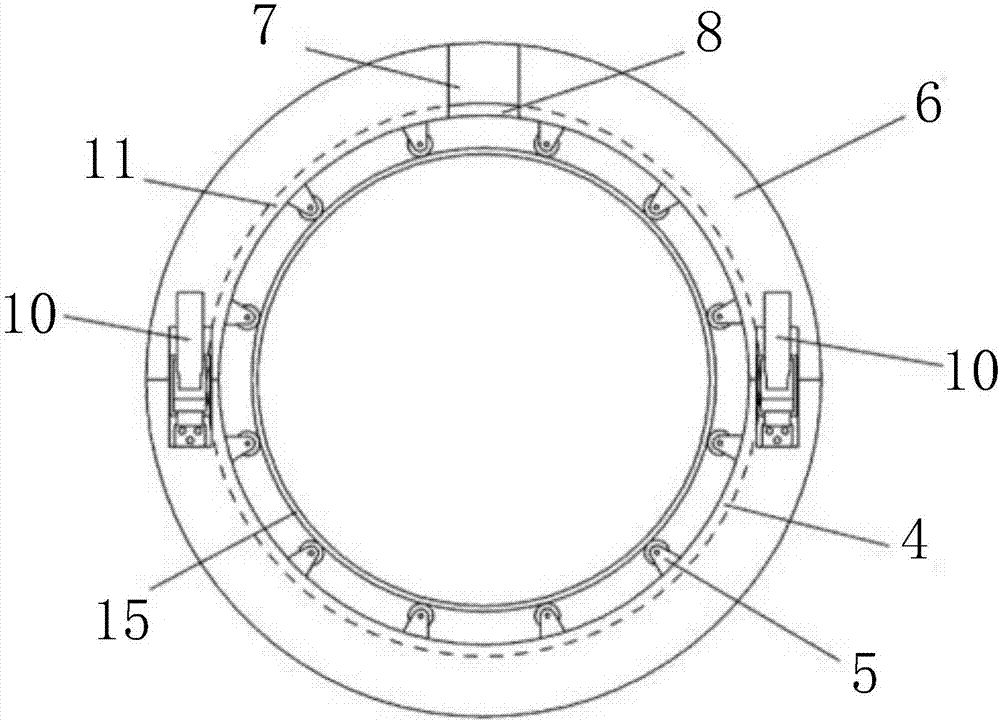

[0017] Such as figure 1 and 2 As shown, a pipe welding device includes a guide mechanism 1, an electric welding torch 2 and a mouth assembly mechanism 3, the guide mechanism 1 includes a disc 4, a roller 5 fixedly arranged on the inner wall of the disc 4, and a roller 5 arranged on the inner wall of the disc 4 two baffles 6 at both ends; the rollers 5 are at least three and arranged evenly, one of the two baffles 6 is provided with a notch 7, and directly below the notch 7 is provided with a disc 4 A connecting plate 8 fixedly connected; the electric welding gun 2 is fixedly arranged on the connecting plate 8; the electric welding gun 2 includes a connecting cable 9; the connecting cable 9 passes through the gap 7 and is coiled on the disc 4 The baffle plate 6 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com