High-pressure gas discharge lamp and method of manufacturing the same

A high-pressure gas, discharge lamp technology, used in the manufacture of gas discharge lamps, high-pressure discharge lamps, discharge tubes/lamps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

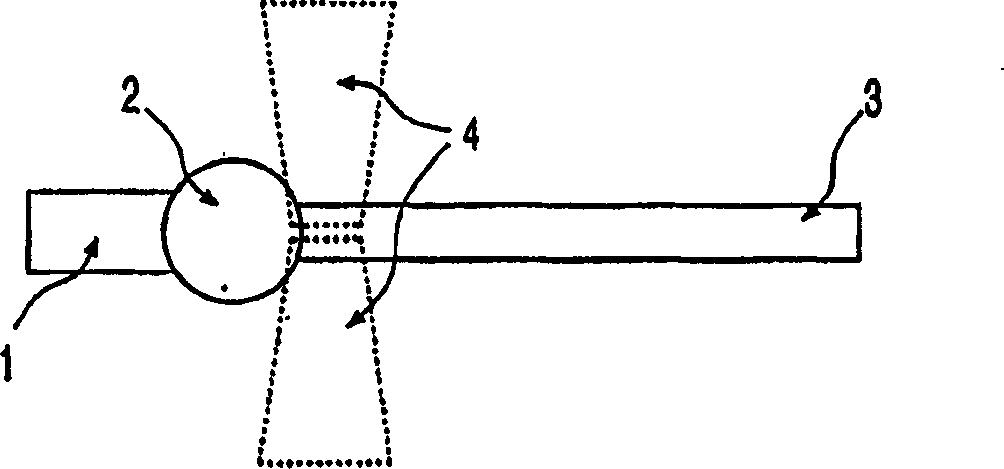

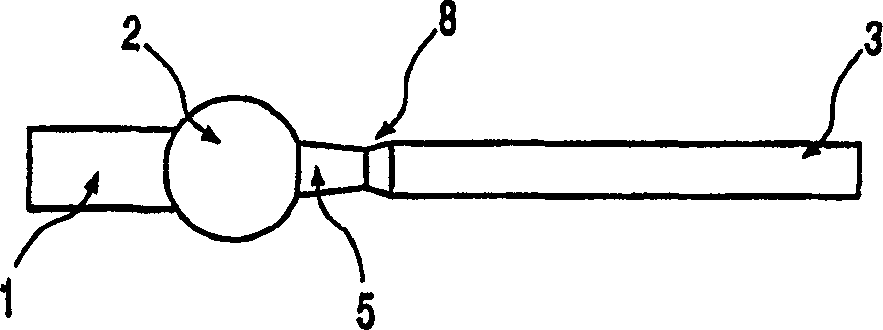

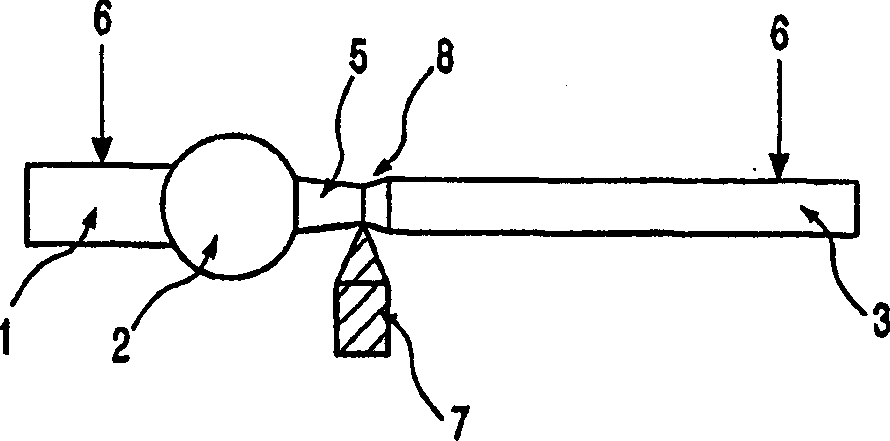

[0015] figure 1 The electrode of the high-pressure gas discharge lamp according to the invention is represented, which comprises an electrode shaft 1 whose free end extends into the discharge space and which has a widening spherical electrode head 2 . A tapered electrode protrusion is formed on this electrode head 2 in the following manner. The rod-shaped member 3 made of the same material as the electrode rod 1 is welded on the widened electrode head 2 of the electrode rod 1 by an energy source, for example with three lasers 4 , or by high-frequency heating or by a discharge arc, so that the lasers 4 Arranged around the end of the rod-shaped member 3 facing the widening electrode head 2 (i.e. viewed in a plane perpendicular to the rods 1, 3, see figure 1 ), that is, the lasers include 120° to each other. like figure 2 Said, said end of the rod-shaped member 3 is given a substantially conical shape, ie a reduced electrode protrusion 5 . The entire assembly is pressed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com