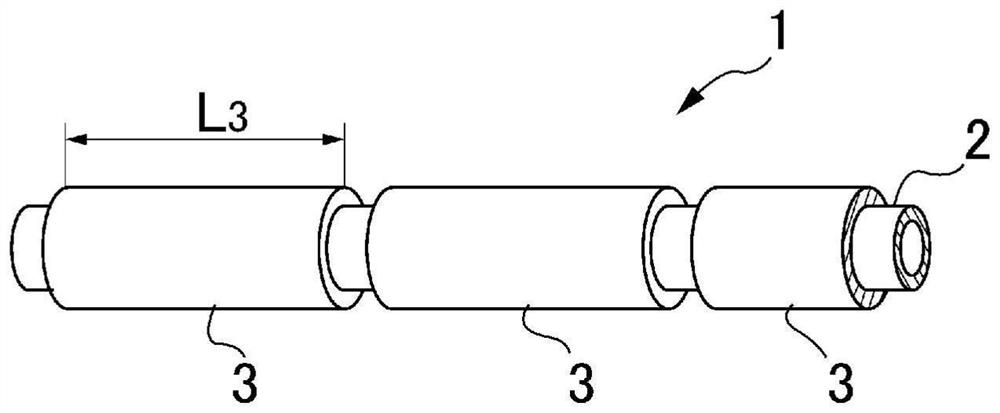

Sputtering target and method for producing same

A manufacturing method and sputtering target technology, applied in sputtering coating, vacuum evaporation coating, coating, etc., to achieve the effect of uniform axial distance, uniform thickness, and small height difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0117] The present invention is further illustrated by the following examples. However, the following examples are not intended to limit the present invention.

[0118]

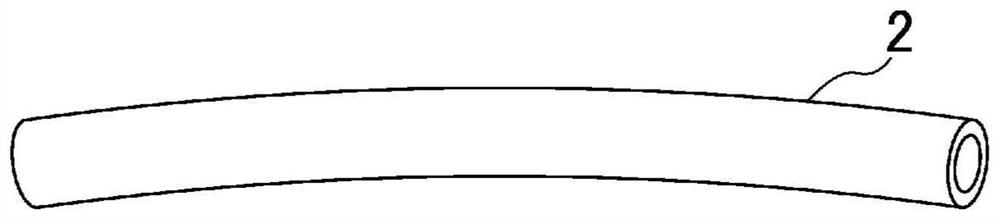

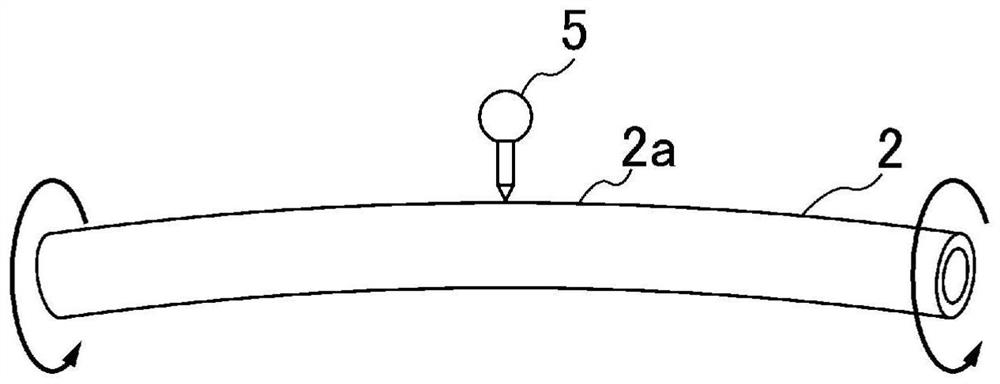

[0119] A cylindrical base material (length 3400mm, diameter 133mm, wall thickness 4mm) that is a recycled product is placed on a pedestal supported rotatably, and a dial indicator is installed horizontally and rotatably, and is suspended and fixed from above Abut the outer surface of the central part in the longitudinal direction of the cylindrical base material, make the cylindrical base material rotate once, and measure the reading of the above-mentioned dial indicator, and set the maximum value of the reading H max with the minimum value H min difference (H max -H min ) was measured as the warpage width X (initial).

[0120] Next, the cylindrical substrate was placed in an electric furnace and heated so that the surface temperature was kept at 230° C. for 1 hour, and the warpage width Y after heating...

Embodiment 2

[0140] In Example 1, except having changed the longest cylindrical target material to 850 mm, it carried out similarly to Example 1, manufactured the ITO cylindrical sputtering target (sample), and measured each value.

Embodiment 3

[0142] In Example 1, except having changed the longest cylindrical target material to 1100 mm, it carried out similarly to Example 1, manufactured the ITO cylindrical sputtering target (sample), and measured each value.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Axial length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com