Drum and method for assembling a tyre adapter on a wheel rim

A technology for building drums, joints, applied in the field of building drums and for assembling tire joints on rims

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

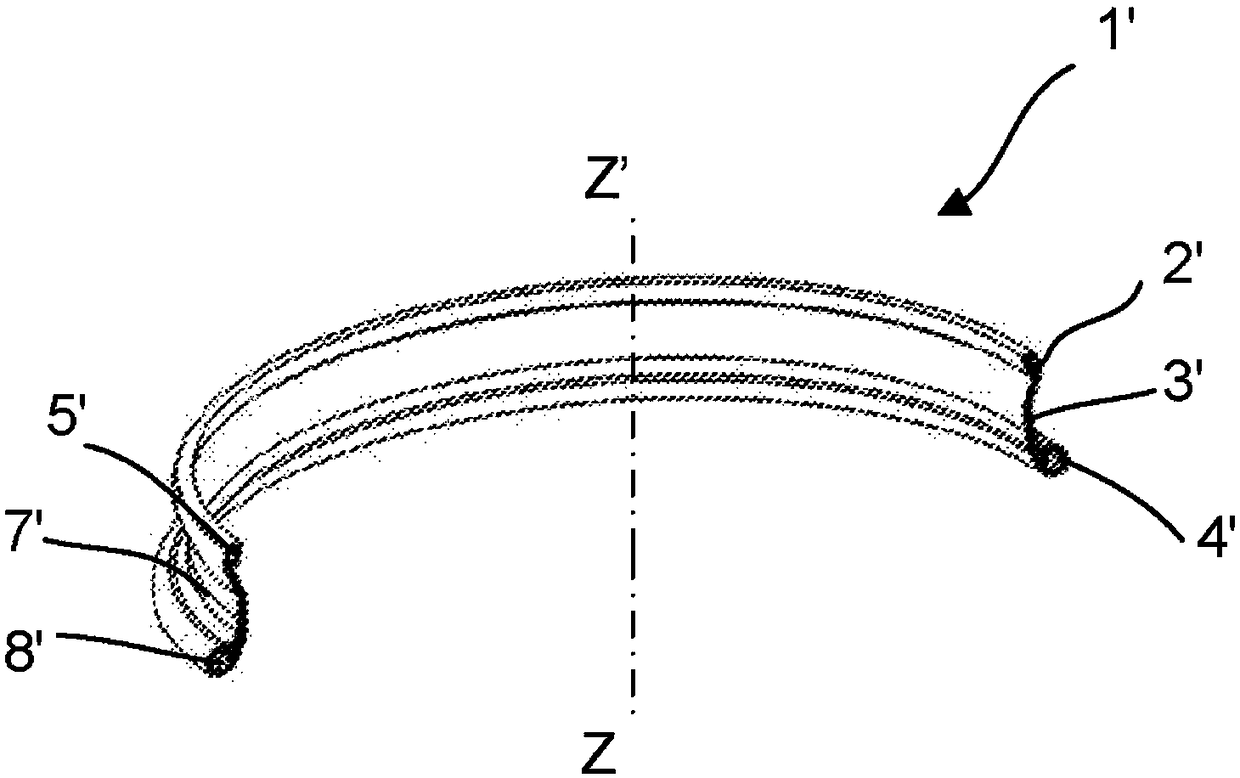

[0047] figure 1 The joint 1' is shown taken along a plane passing through the axis of symmetry Z-Z' of the joint 1'. Said joint 1' is intended to be mounted between a rim and a tire (neither shown) to form a tire assembly as described in document WO 00 / 78565 in the name of the inventor's company. For this purpose, the joint 1 ′ comprises a joint bead 2 ′ intended for fastening to the rim and a joint reinforcement 3 ′ which attaches the bead 2 'Connected to the joint reinforcement 4' which can be fixed around the bead of the tire. The joint 1' is a member having a circular overall shape and is rotationally symmetrical about the axis Z-Z'.

[0048] The reinforcement 3' of the joint 1' is formed based on a main ply with radially mutually parallel textile cords comprised in a rubber matrix, just like the carcass ply. This ply is arranged in such a way as to form a turn-up around the reinforcement 4' of the joint and on the other hand is anchored in the bead 2' of the joint 1', ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com