Linear floor drain and installation method thereof

An installation method and floor drain technology, which is applied in the field of bathroom floor drains, can solve the problems of increased manufacturing costs, low utilization rate of floor drains, water storage, etc., improve stability and reliability, solve universal problems, and simplify installation pipelines Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

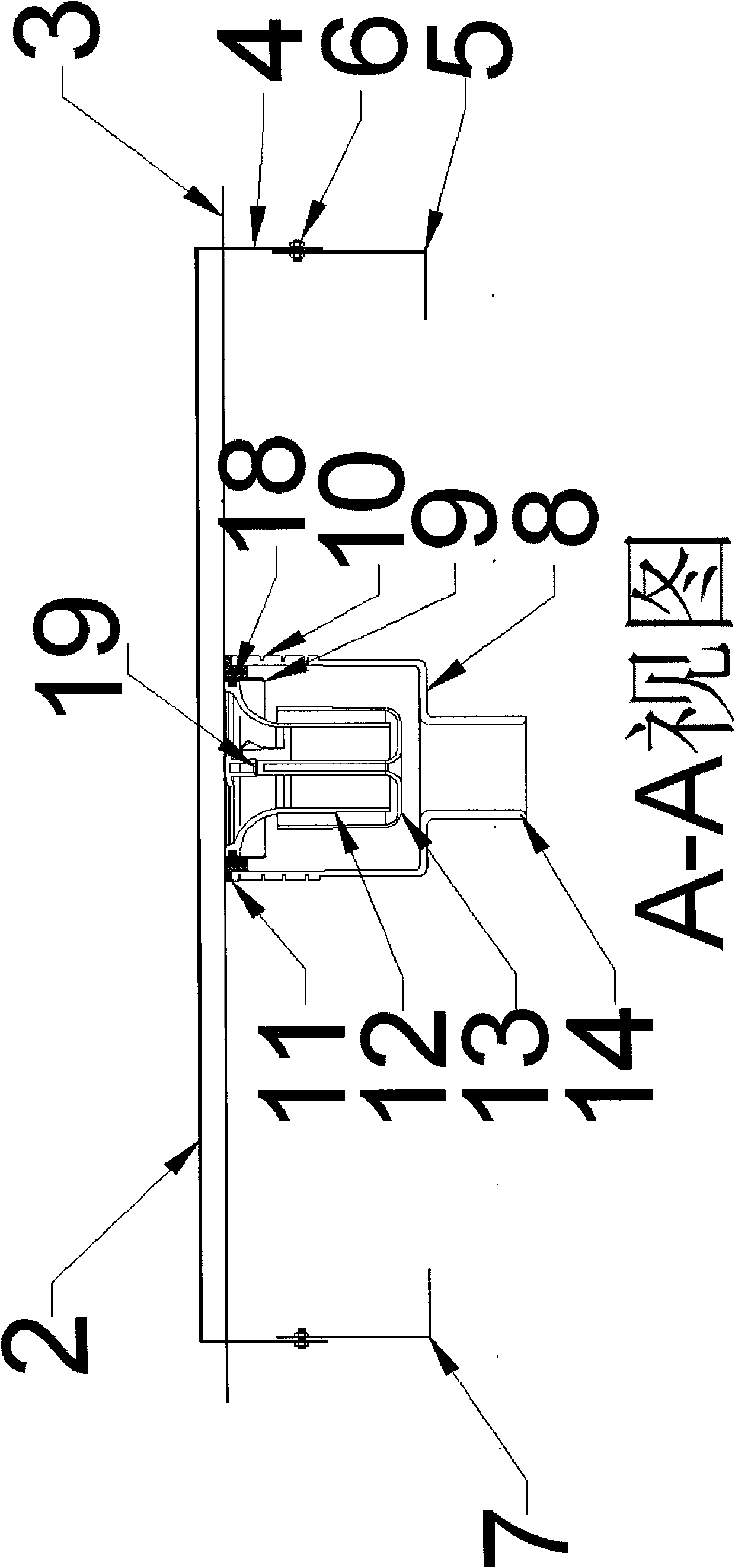

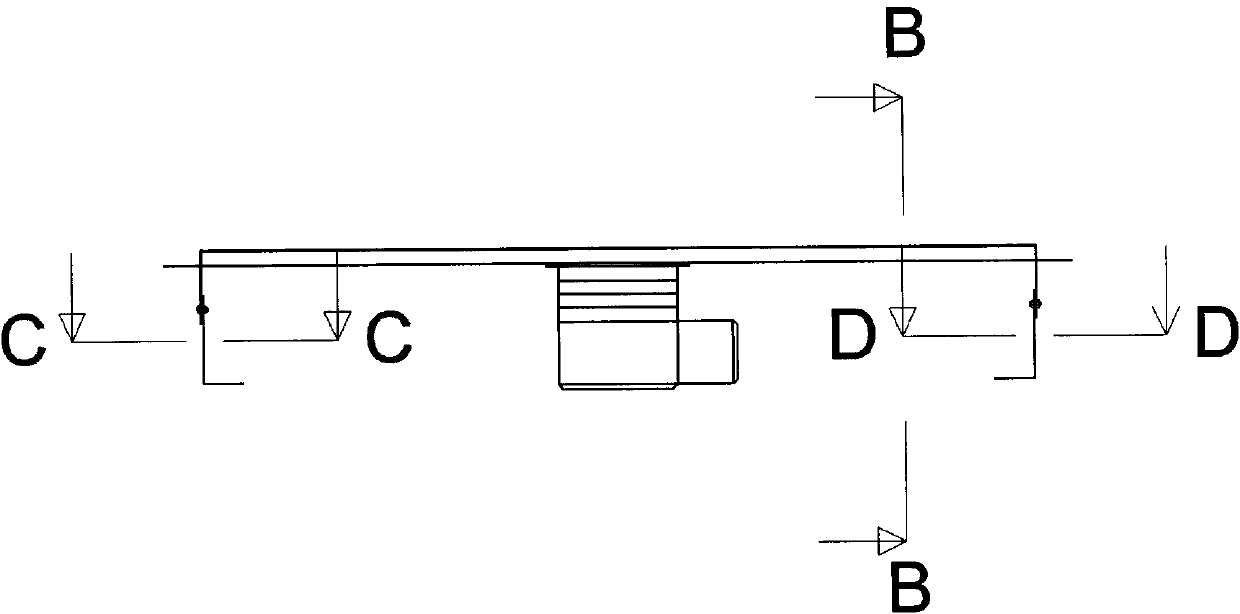

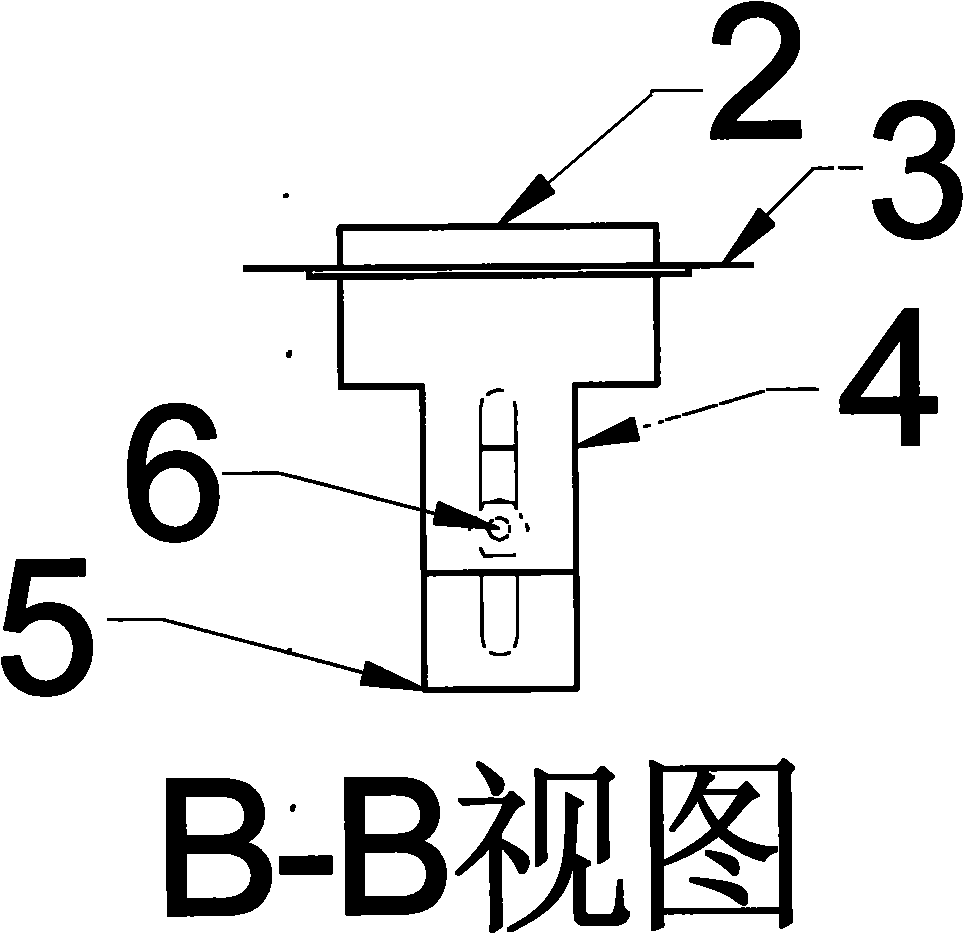

[0026] The embodiments of the present invention will be described in detail below in conjunction with the drawings.

[0027] See attached Figure 1-2 , The floor drain cover 1 is arranged on the floor drain main body 2. The cover is made of metal, such as stainless steel, and is lying in a groove on the top of the floor drain main body 2. The shape of the cover 1 is determined according to its installation position, such as a rectangular strip shape, or a special-shaped structure according to the installation position. However, when the cover 1 is formed in a rectangular strip shape, it can achieve a large drainage floor drain Therefore, it is preferable to use a rectangular strip cover.

[0028] The floor drain main body 2 is made of metal, such as stainless steel, and a waterproof connecting plate 3 is formed integrally with the outer periphery thereof, and the waterproof connecting plate 3 is used to connect with the flexible waterproof cloth 20. The floor drain main body 2 ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com