Bending long shaft turning device

A bending shaft and bending technology, which is applied in the field of turning and processing curved long shaft devices, can solve problems such as high cost, high technical requirements, and inability to realize transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In the preferred embodiment, this device is used for the external machining of seamless steel pipes for large-diameter high-pressure boilers, because national standards allow the axis of hot-rolled seamless steel pipes to have a certain curvature (less than 1‰), but usually large-diameter hot-rolled The surface quality of the outer circle of the rolled seamless steel pipe does not meet the requirements of the seamless steel pipe for large-diameter high-pressure boilers, and the outer circle of the steel pipe needs to be turned; this device does not need to turn the bent steel pipe into a straight steel pipe, but makes the steel pipe before and after turning Keeping the same bending curvature and complying with the national standard that the curvature of seamless steel pipes for large-diameter high-pressure boilers is less than 1‰ can greatly reduce the amount of machining and cutting, and the economic benefits are huge.

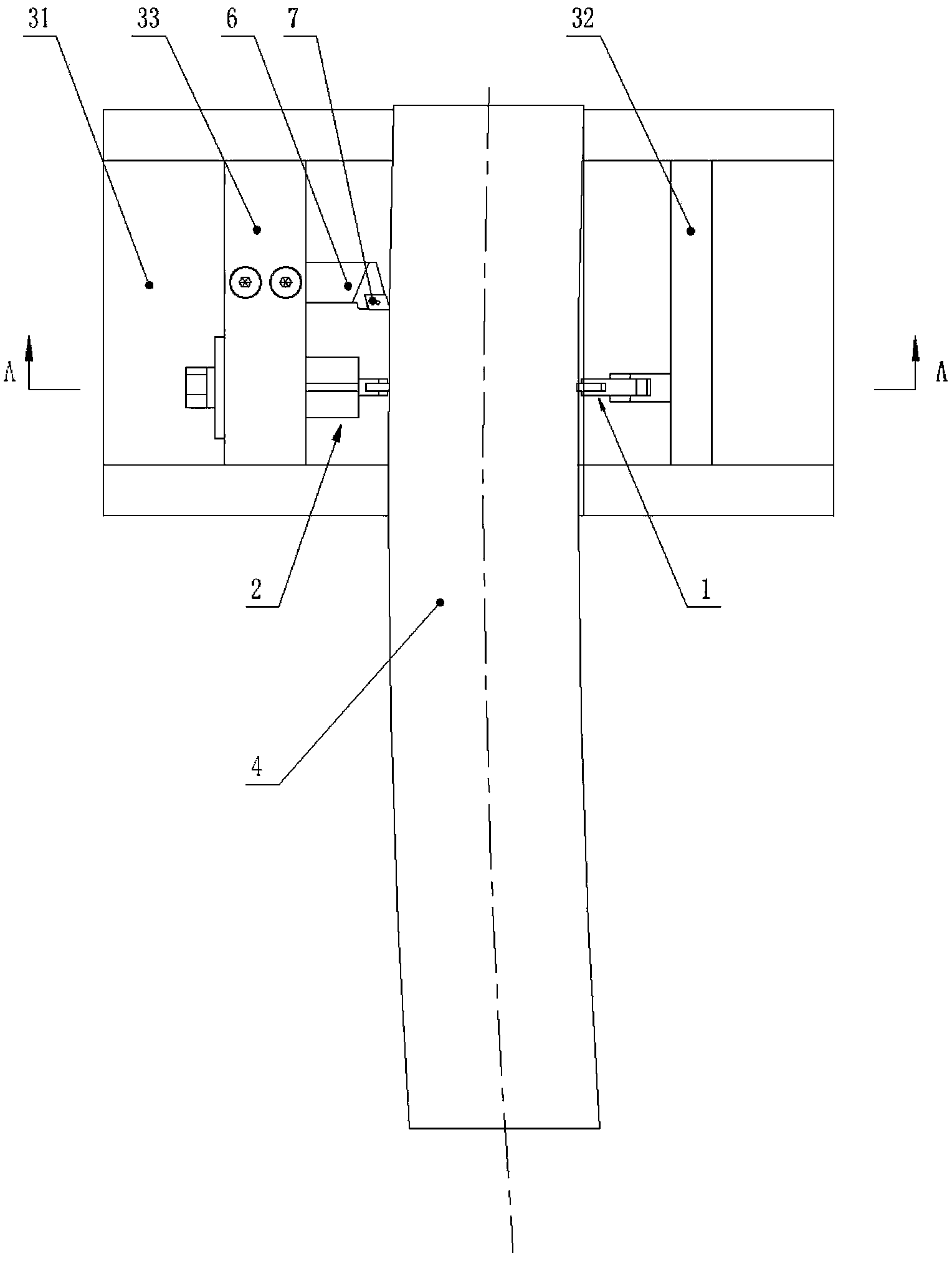

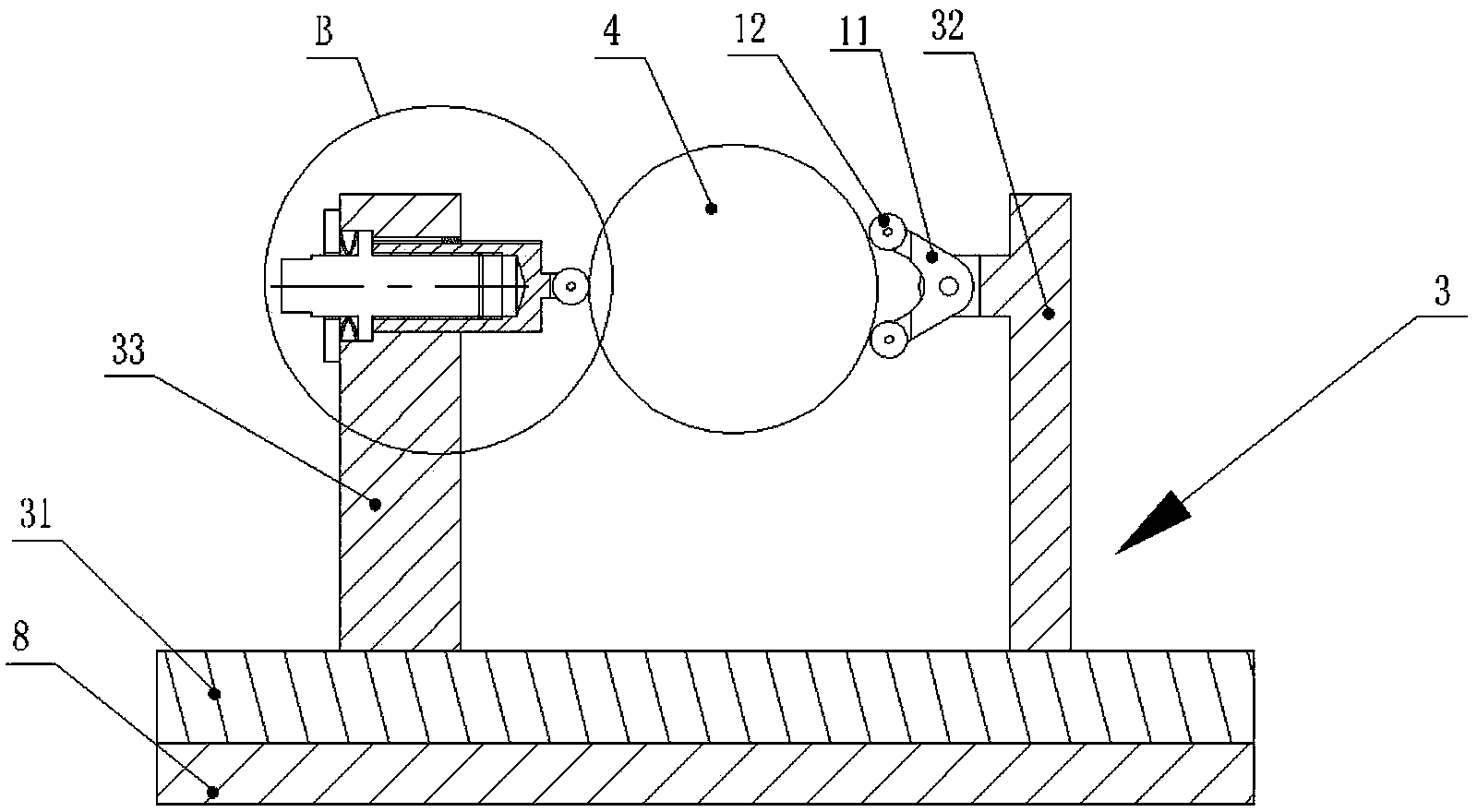

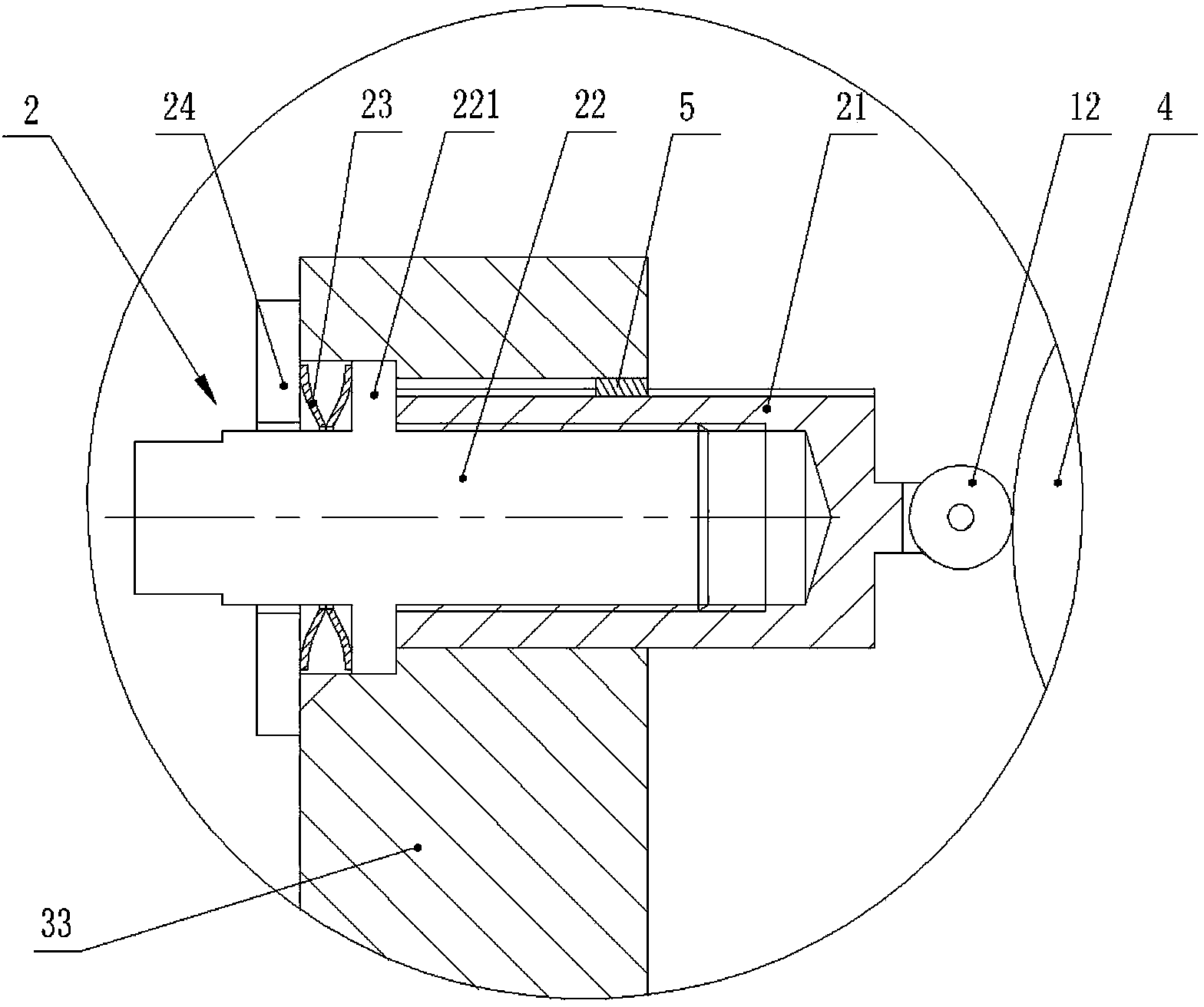

[0022] Such as Figure 1 to Figure 4 As shown, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com