Laser machining apparatus and its running and controlling methods

A technology of laser processing and laser processing head, which is applied in the direction of laser welding equipment, metal processing equipment, welding equipment, etc., and can solve the problem of extra cost of structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

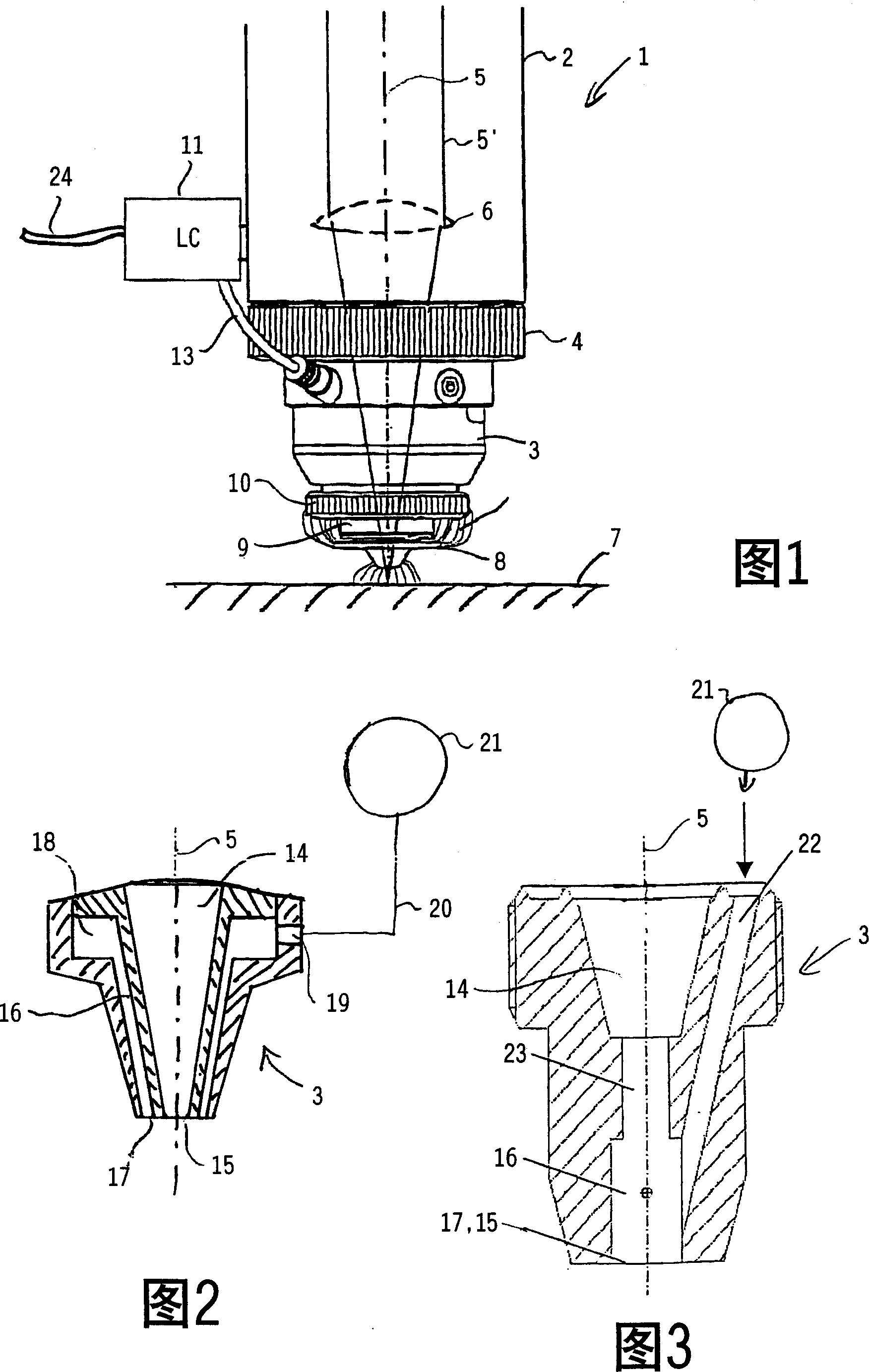

[0045] FIG. 1 shows a laser processing head 1 as used in a laser processing installation according to the invention. The laser machining head 1 has a housing 2 which carries a nozzle 3 at its lower end. The housing 2 and the nozzle 3 can be tightened against one another, eg by means of a knurled screw 4 . A working beam path 5 for a laser beam 5 ′ which is focused by means of a lens arrangement 6 arranged in the housing 2 passes through the housing 2 and the nozzle 3 . The focus of the laser beam 5 ′ lies outside the laser machining head 1 substantially on the surface of the workpiece 7 which is to be machined by means of the focused laser beam 5 ′. Cutting or welding processes and the like can be carried out in this way. Arranged at the lower end of the nozzle body 3 is a sensor electrode 8 made of an electrically conductive material, which is made of an electrically conductive material, in particular metal, for example copper. This sensor electrode 8 is held by a ceramic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com