Boiler induced-draft fan soot blower

A technology of soot blowing device and induced draft fan, which is applied to induced draft, components of pumping device for elastic fluid, mechanical equipment, etc., can solve problems such as unsatisfactory effect, loose ground bolts, equipment damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

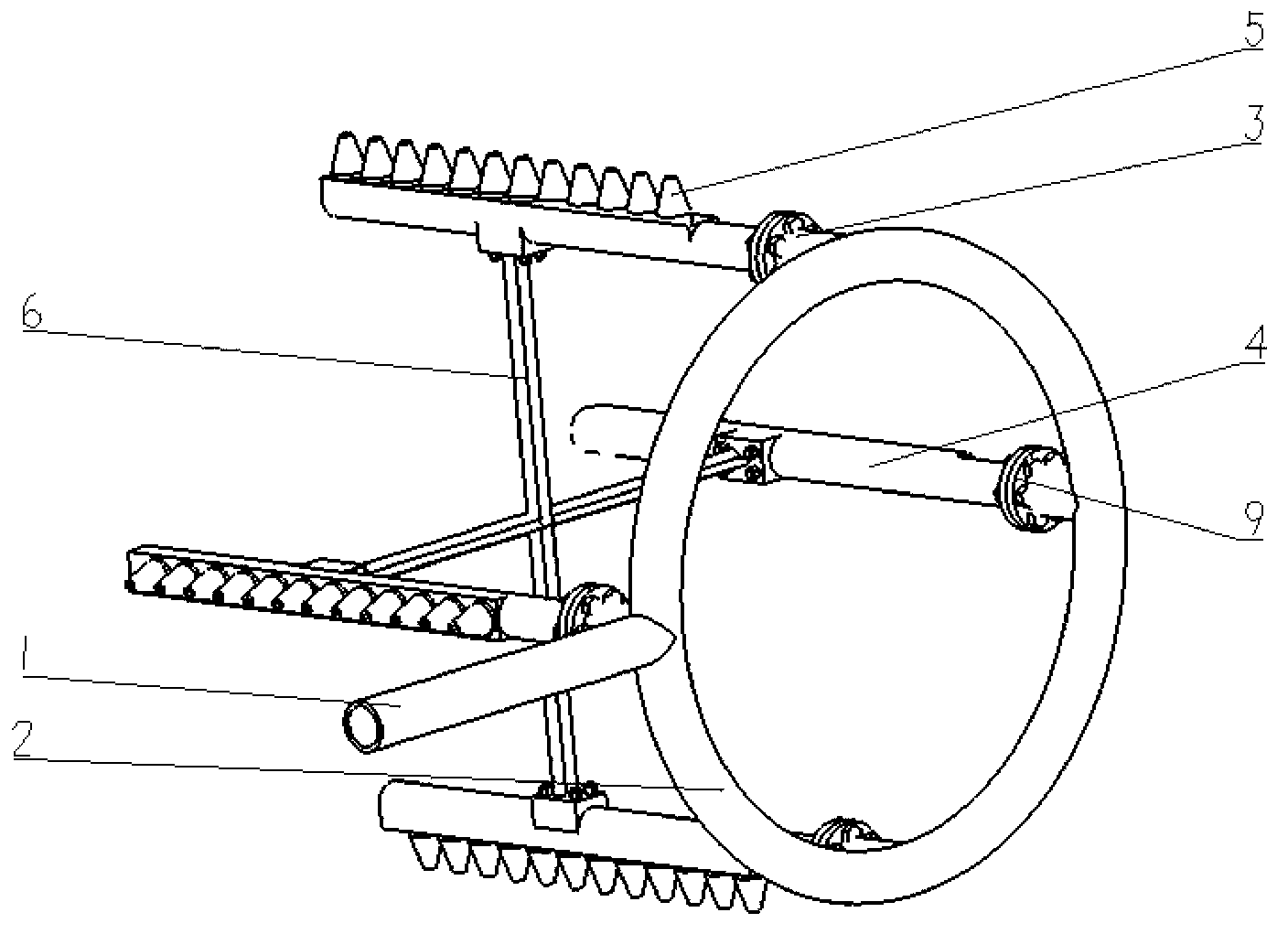

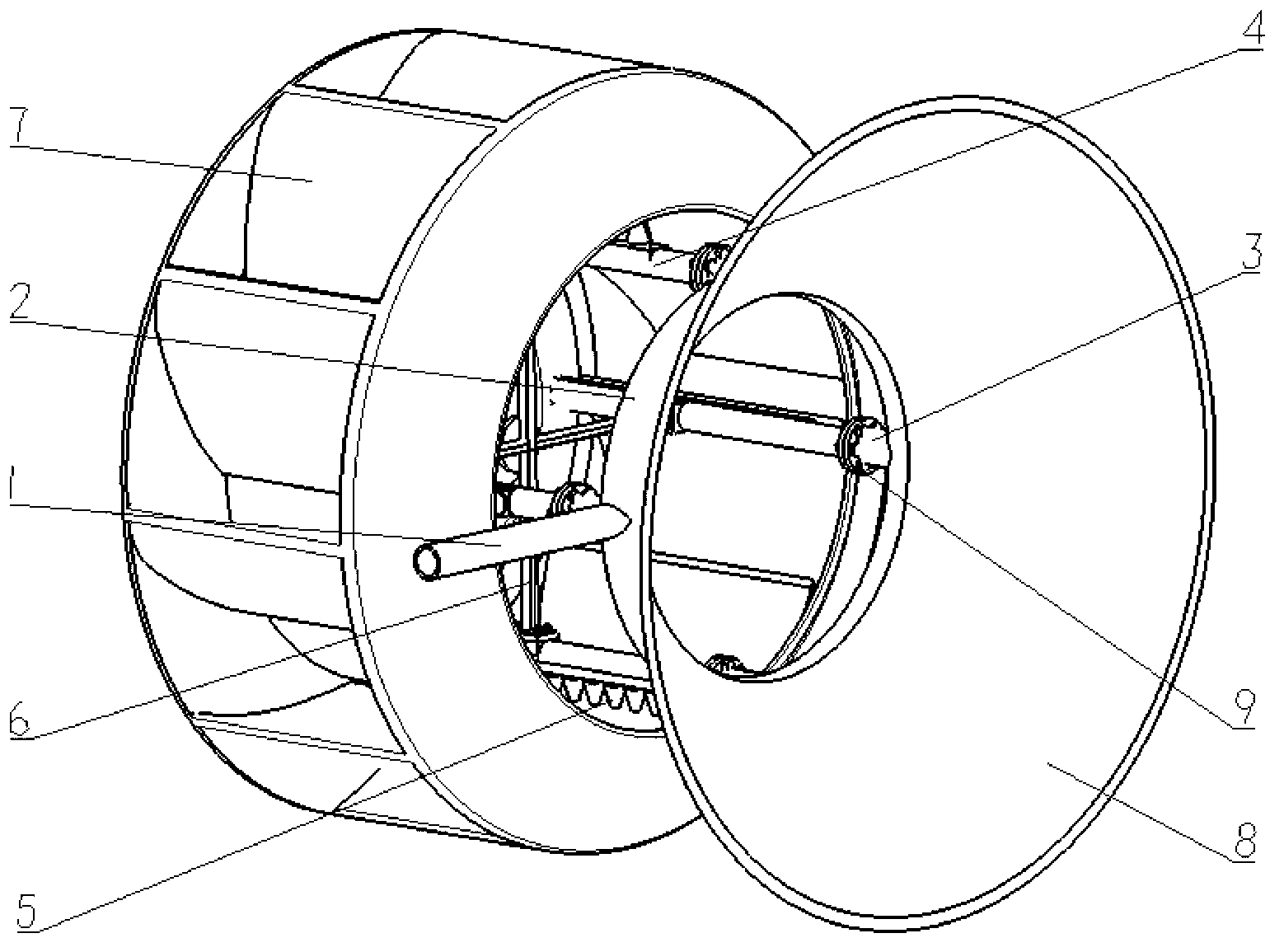

[0024] Attached below figure 1 , attached figure 2 And attached Figure 5 The working process of a boiler induced draft fan soot blowing device of the present invention is further described in detail through specific embodiments:

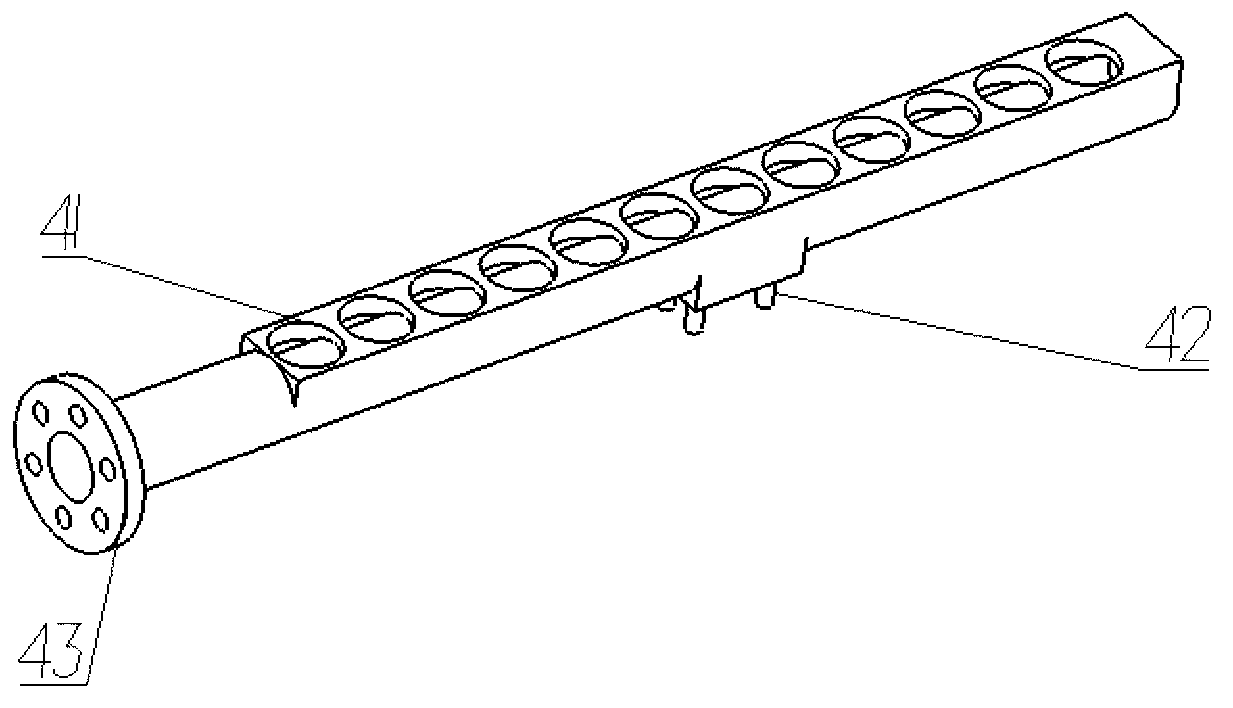

[0025] The high-pressure steam or air enters the air distribution pipe 2 through the inlet pipe 1, distributes the high-pressure steam or air to 4 or 2 outlet pipes through the air distribution pipe, and then enters the nozzle pipe. A row of tapered nozzles 5 is installed on the side of the nozzle pipe. Facing the impeller of the induced draft fan and keeping an appropriate distance from the blades of the impeller, the high-pressure steam or air is blown out after being accelerated through the tapered nozzle 5, and directly impacts on the inner side of the blade of the induced draft fan impeller 7, and the impeller 7 of the induced draft fan is blown out by the strong air flow. The dust on the blades is blown away; the nozzle pipe 4 is equipped w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com