Laser processing machine for machining workpieces and machine method for machining workpieces using a laser beam

A technology of laser processing and mechanical methods, applied in the fields of processing workpieces, sheet metal, and computer program products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

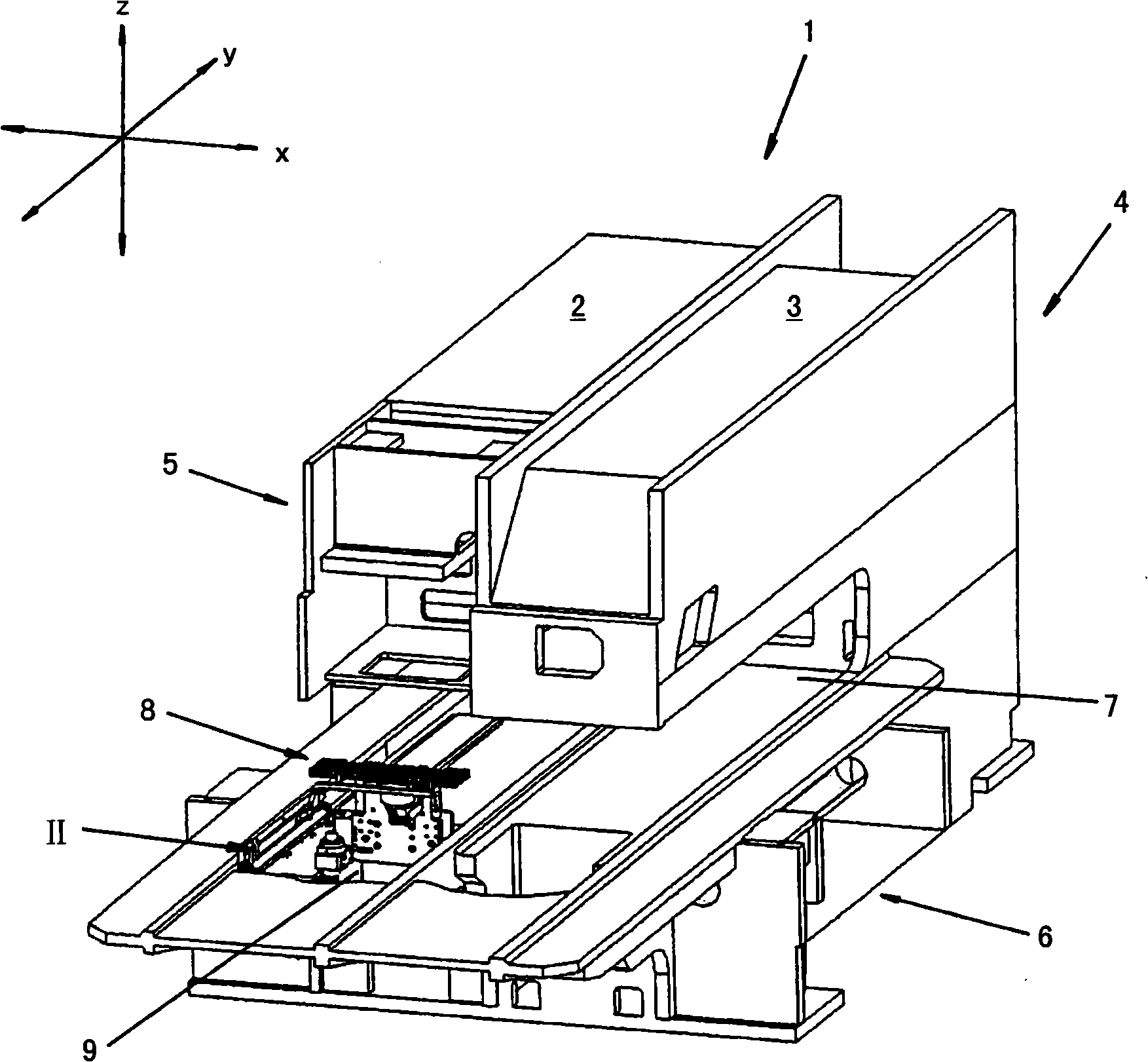

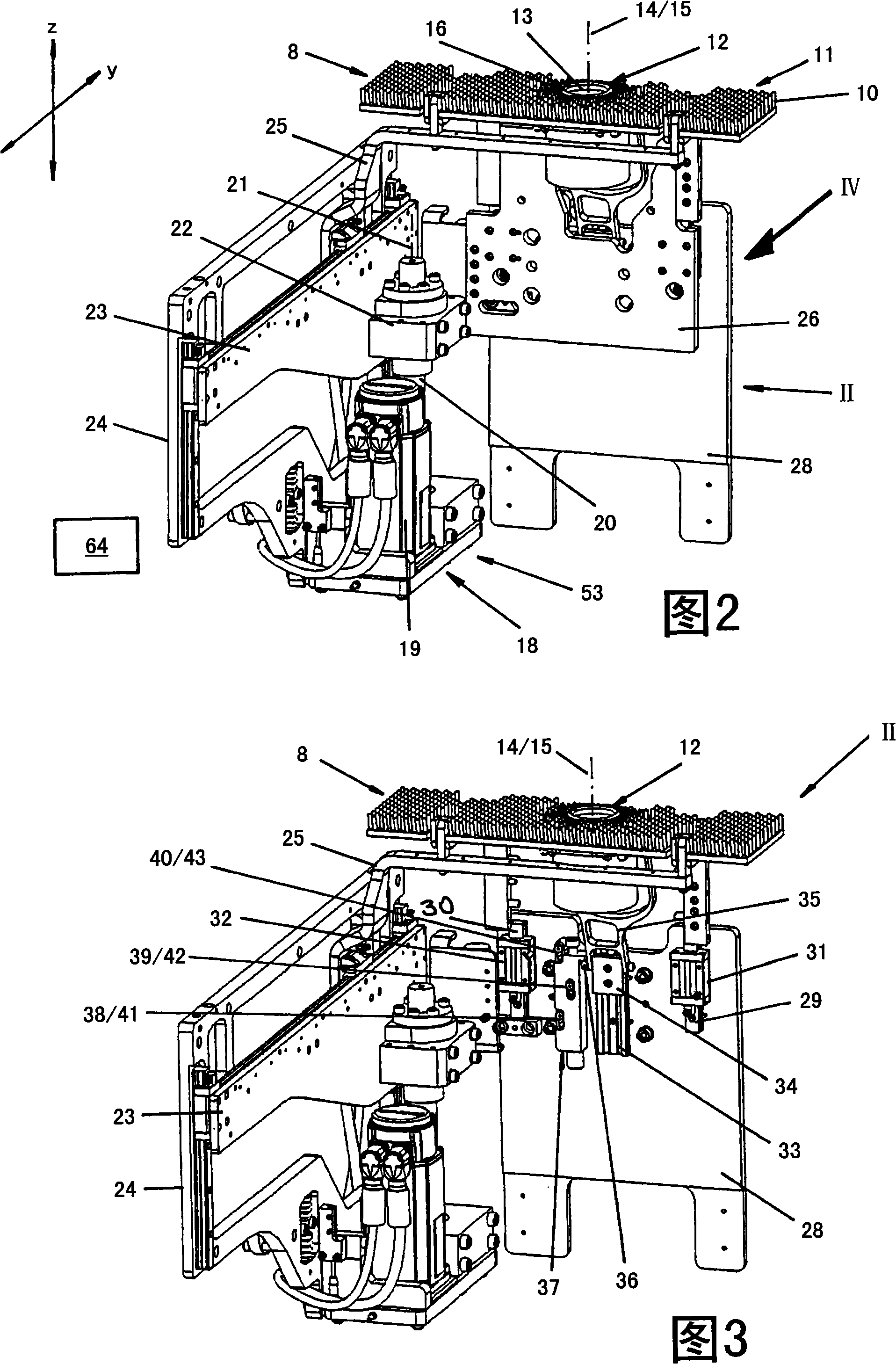

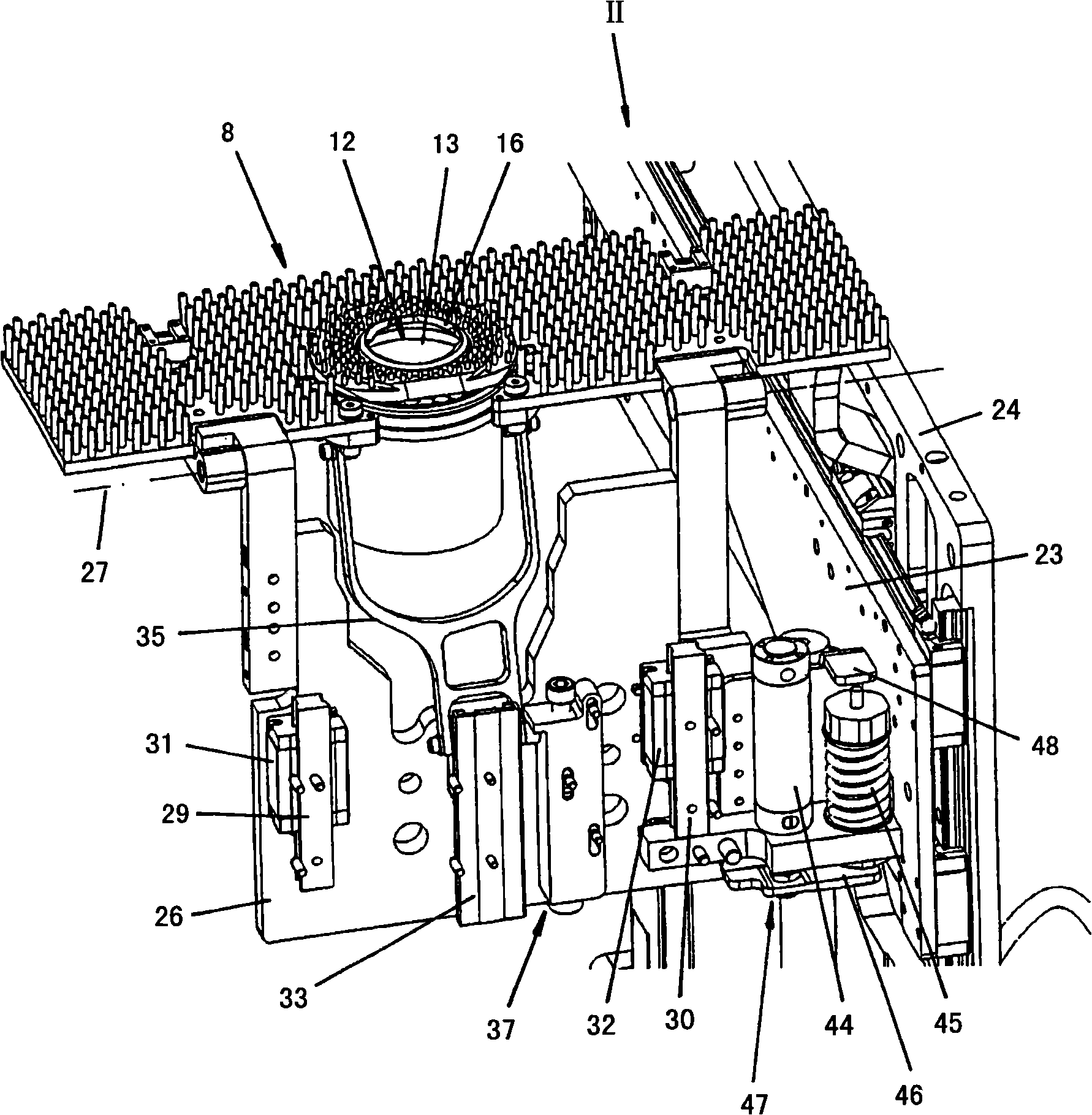

[0040] according to figure 1 , a laser processing equipment 1 is in the form of a combination equipment, including a unit 2 for laser cutting metal sheets and a unit 3 for punching metal sheets combined therewith. The common equipment rack 4 has a C-shape and includes upper rack legs 5 and lower rack legs 6 . The punch (not shown) of the unit 3 for blanking and the laser machining head (also not shown) for laser cutting workpieces and sheet metal are mounted side by side at the free end of the upper frame leg 5 . Both the punch and the laser processing head have a traditional structure. The laser processing head is movable on the upper frame leg 5 along the three axes of the x / y / z coordinate system, but only relatively short distances in each direction.

[0041] A coordinate guide (not shown) of conventional construction is accommodated in the throat region 7 of the C-shaped equipment frame 4 . The sheet metal to be processed is fixed on a coordinate guide by means of a con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com