Coaxial casing pipe assembling device and method

A pairing and casing technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of long time spent on coaxial assembly of pipes, inability to operate synchronously on pipes, and inability to perform four-way adjustments at the same time. Achieve the effect of improving the efficiency of group pairing, reducing the difficulty of group pairing, and reducing the number of adjustments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

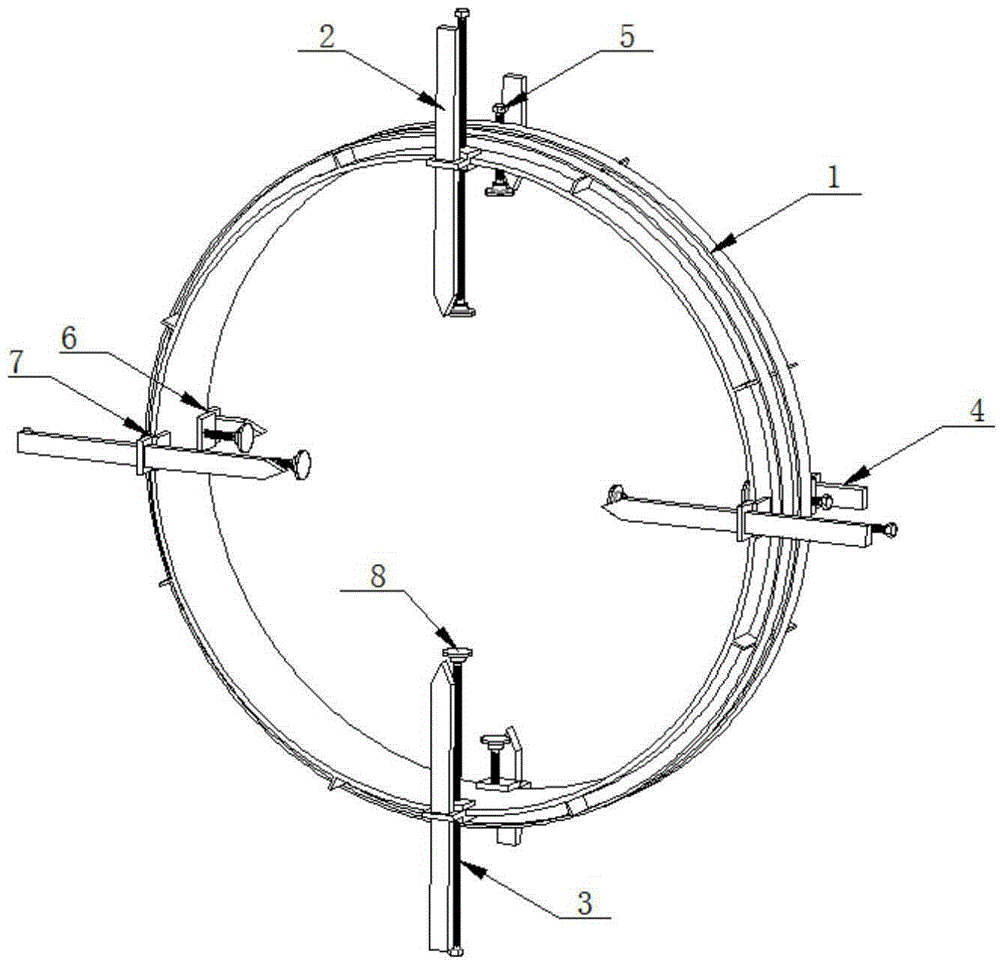

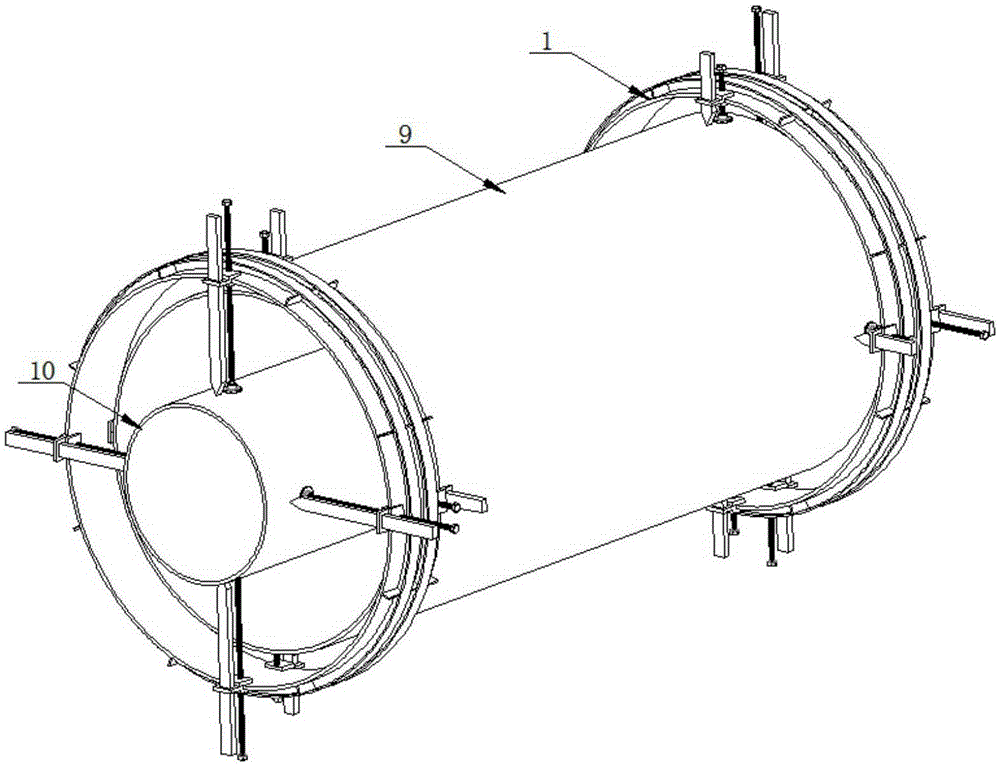

[0020] A coaxial casing pairing device, including an annular positioning ring 1, a long adjustment device and a short adjustment device, the annular positioning ring is a cylindrical structure, and several ribs are arranged at intervals on its outer peripheral surface, the long adjustment device and the short adjustment device The devices are respectively installed on both sides of the annular positioning ring through fixtures. The long adjustment device and the short adjustment device are arranged at even intervals along the circumference of the annular positioning ring. The annular positioning ring and the outer sleeve 9 are positioned and connected by the short adjustment device. The position of the tube 10 is adjusted by the length adjusting device.

[0021] The fixture includes an engaging part 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com