Boring and Rolling Compound Tool

A compound cutting tool and boring tool technology, which is applied in the direction of cutting tools used in lathes, manufacturing tools, tool holder accessories, etc., can solve the problems of not having a guiding function and failing to meet tolerance requirements, and achieve short auxiliary time and high production efficiency , the effect of process concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

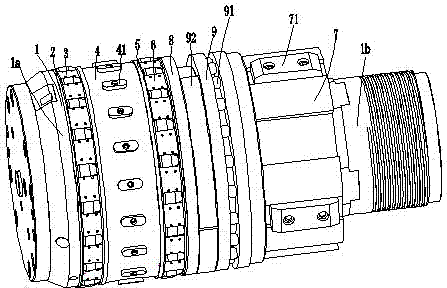

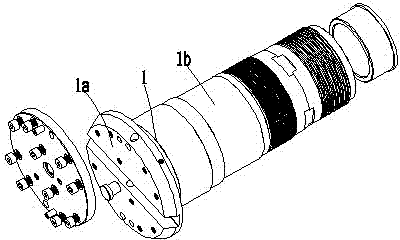

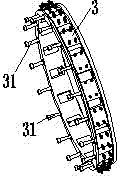

[0026] Such as Figure 1 to Figure 9 As shown, the symbol numbers are explained as follows: mandrel 1, cutterhead body 1a, shaft extension cylinder 1b, front raceway 2, front retainer 3, first connecting screw 31, middle sleeve 4, first guide block 41, rear Raceway 5, rear retainer 6, support sleeve 7, second guide block 71, distance sleeve 8, bearing sleeve 81, seat cushion 9, second connecting screw 91, semicircle adjustment pad 92.

[0027] In the embodiment of the present invention, the boring-rolling compound tool includes a rolling part and a boring tool part. The boring tool part includes a mandrel 1. The front end of the mandrel 1 is formed with a cutter body 1a equipped with a boring tool. The shaft extension cylinder 1b; the rolling part includes the front raceway 2, the front cage 3, the middle sleeve 4, the rear raceway 5 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com