A new type of circular weft machine and its knitting process for producing human-shaped pantyhose

A kind of craft and pantyhose technology, which is applied in the field of new circular weft machine and its knitting technology, can solve the problems of inconsistent thickness, etc., and achieve the effects of strong practicability, novel structure and accurate needle pressing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention takes the processing of human-shaped pantyhose with a trouser leg width of 10 centimeters and a trouser leg width of 15 to 25 centimeters as a specific example, and takes the workshop of Quanzhou Luojiang Hongshuo Machinery Co., Ltd. as the implementation site of the technical solution to provide the following specific technologies Program.

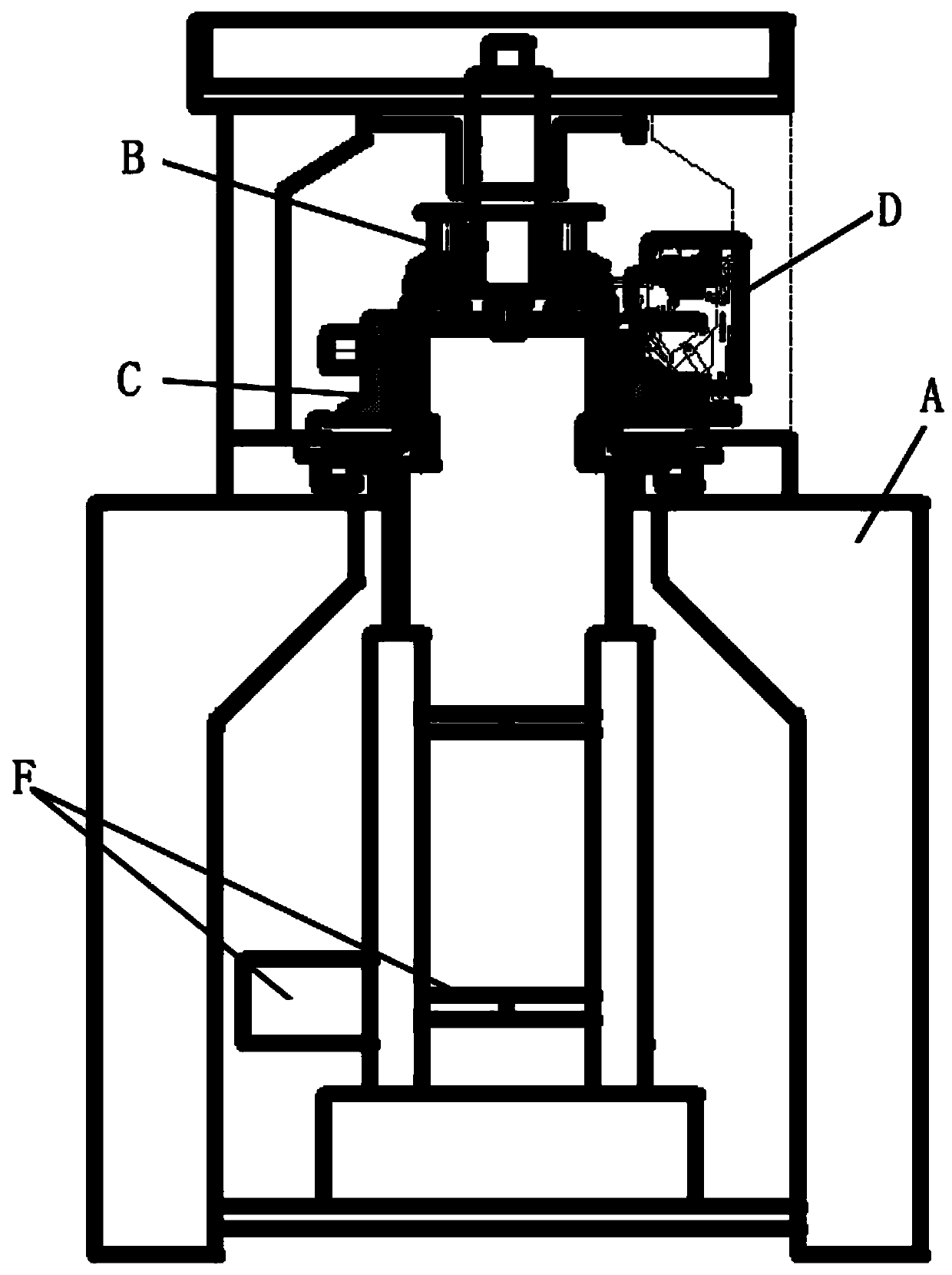

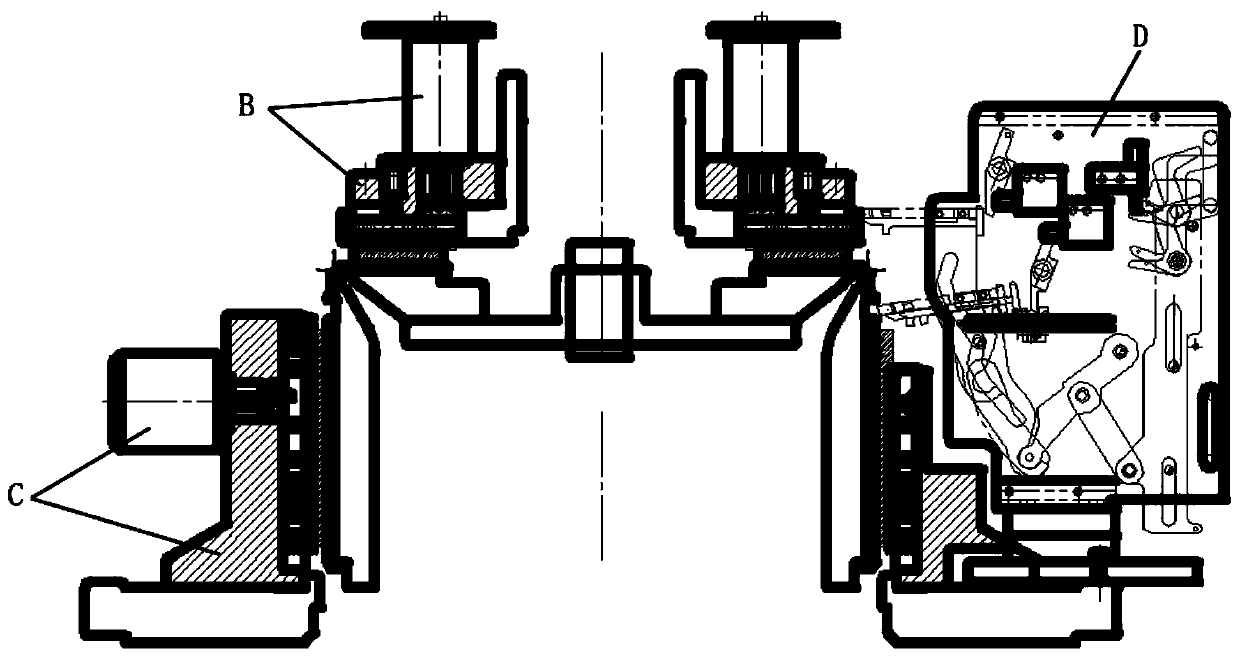

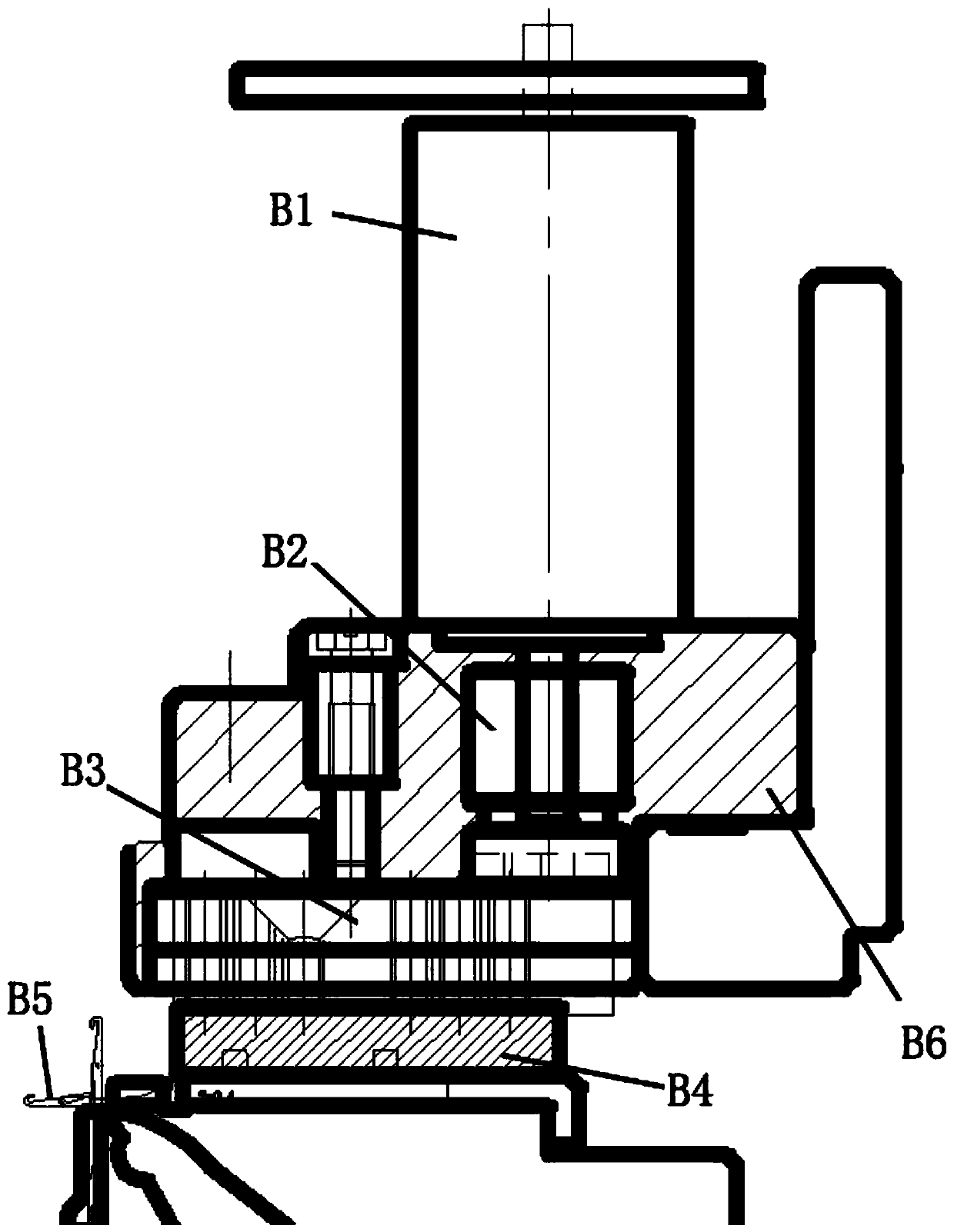

[0061] Such as figure 1 , figure 2 As shown, a new circular weft machine and its knitting process for producing human-shaped pantyhose are composed of a frame A, a ring creel, an upper disk knitting mechanism B, a lower disk knitting mechanism C, a thread trimming mechanism D, Composed of trouser leg weaving mechanism and cloth rolling mechanism F, it is characterized in that,

[0062] The ring-shaped yarn creel is erected directly above the frame A, the fabric rolling mechanism F is installed on the inner bottom of the frame A, and the top of the frame A is equipped with an upper disk weaving mechanism B a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com