Scroll compressor vortex plate, compressor adopting scroll compressor vortex plate and air conditioner

A scroll compressor and scroll technology, which is applied in the field of compressor scrolls, can solve the problems of inability to completely discharge the high-pressure gas in the center of the pump body, serious thermal deformation of the profile line, and abnormal jamming of the dynamic and static discs, etc., to increase oil storage And lubricating and cooling ability, reducing the effect of thermal deformation, improving the effect of high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

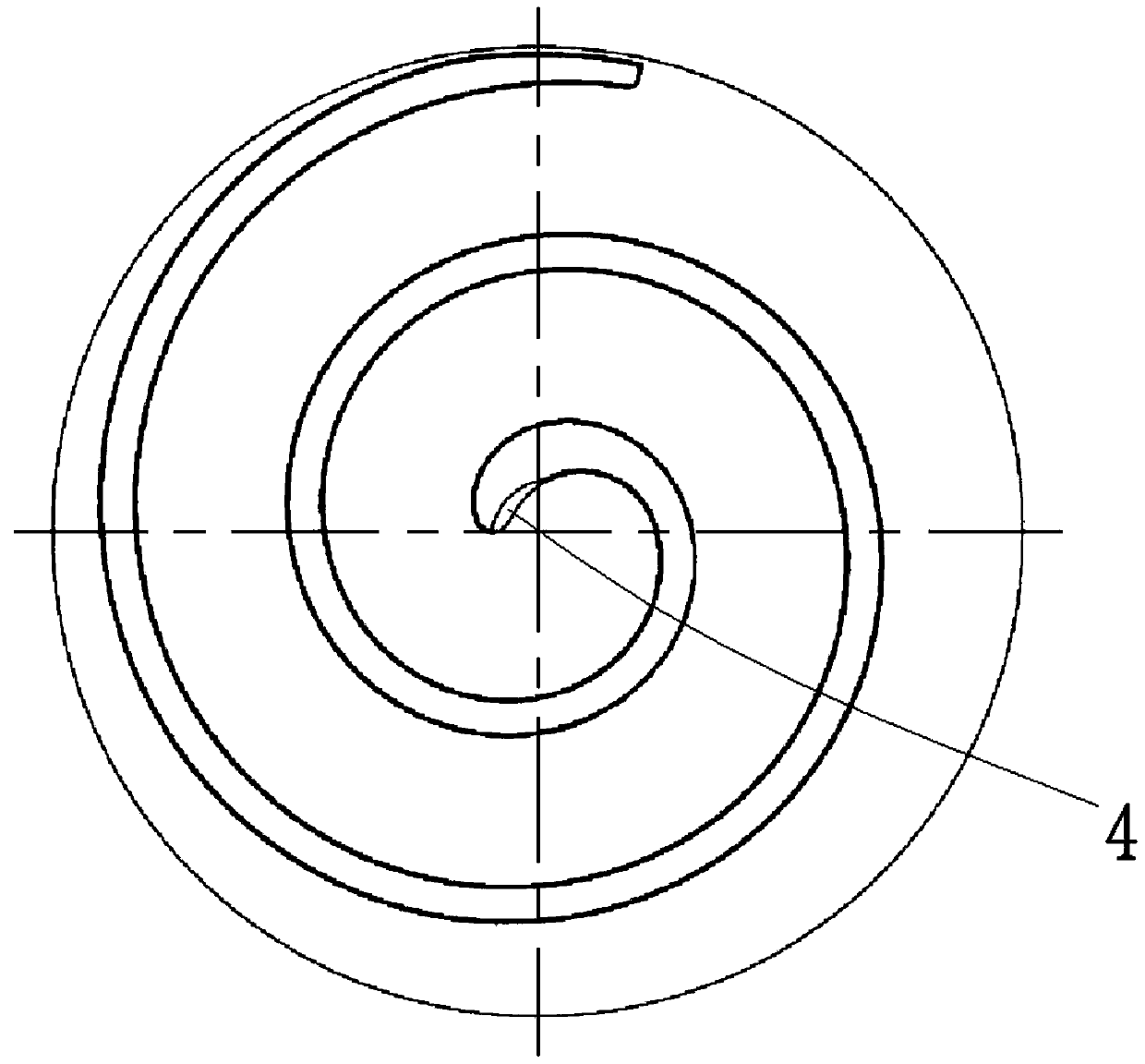

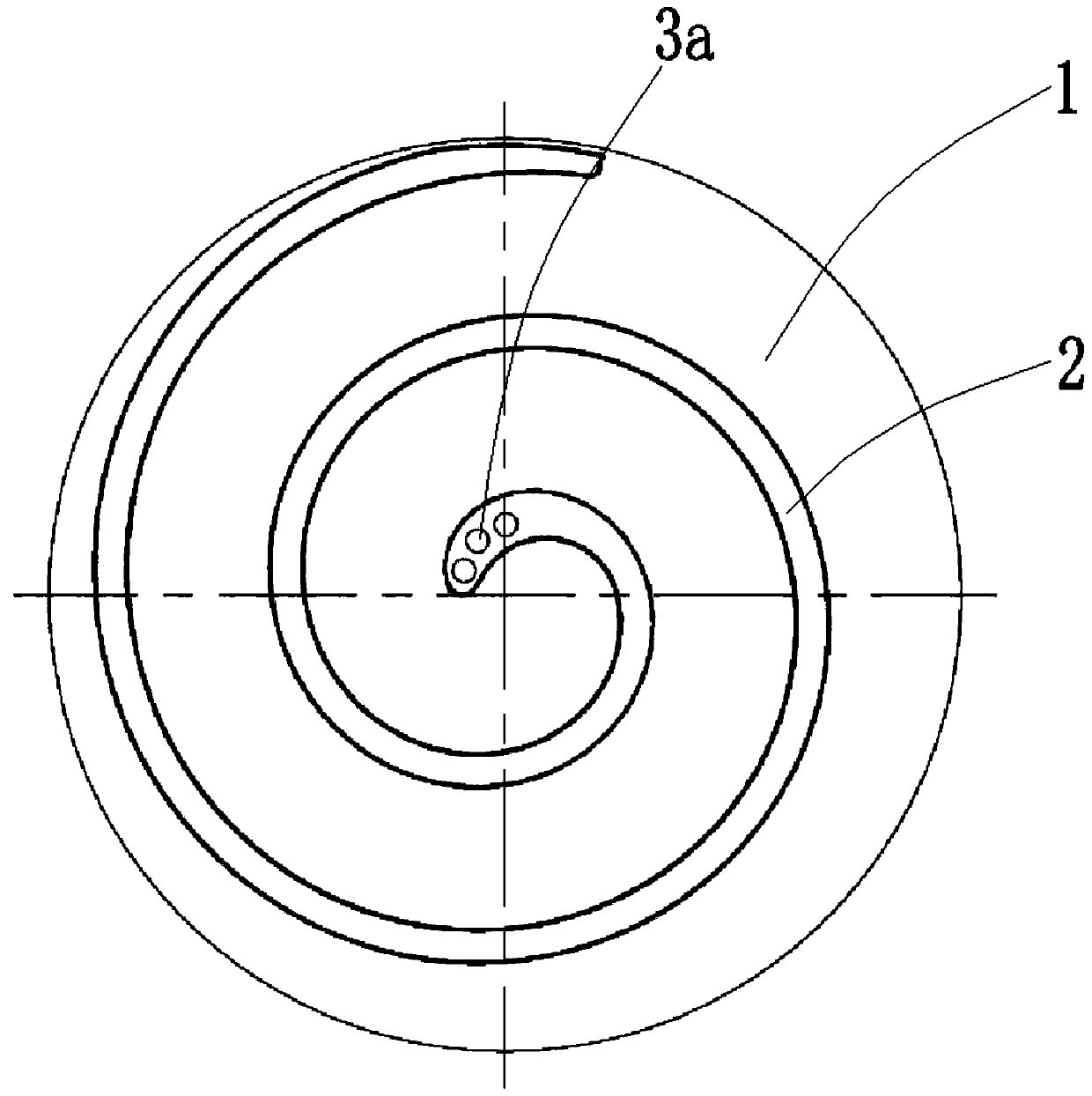

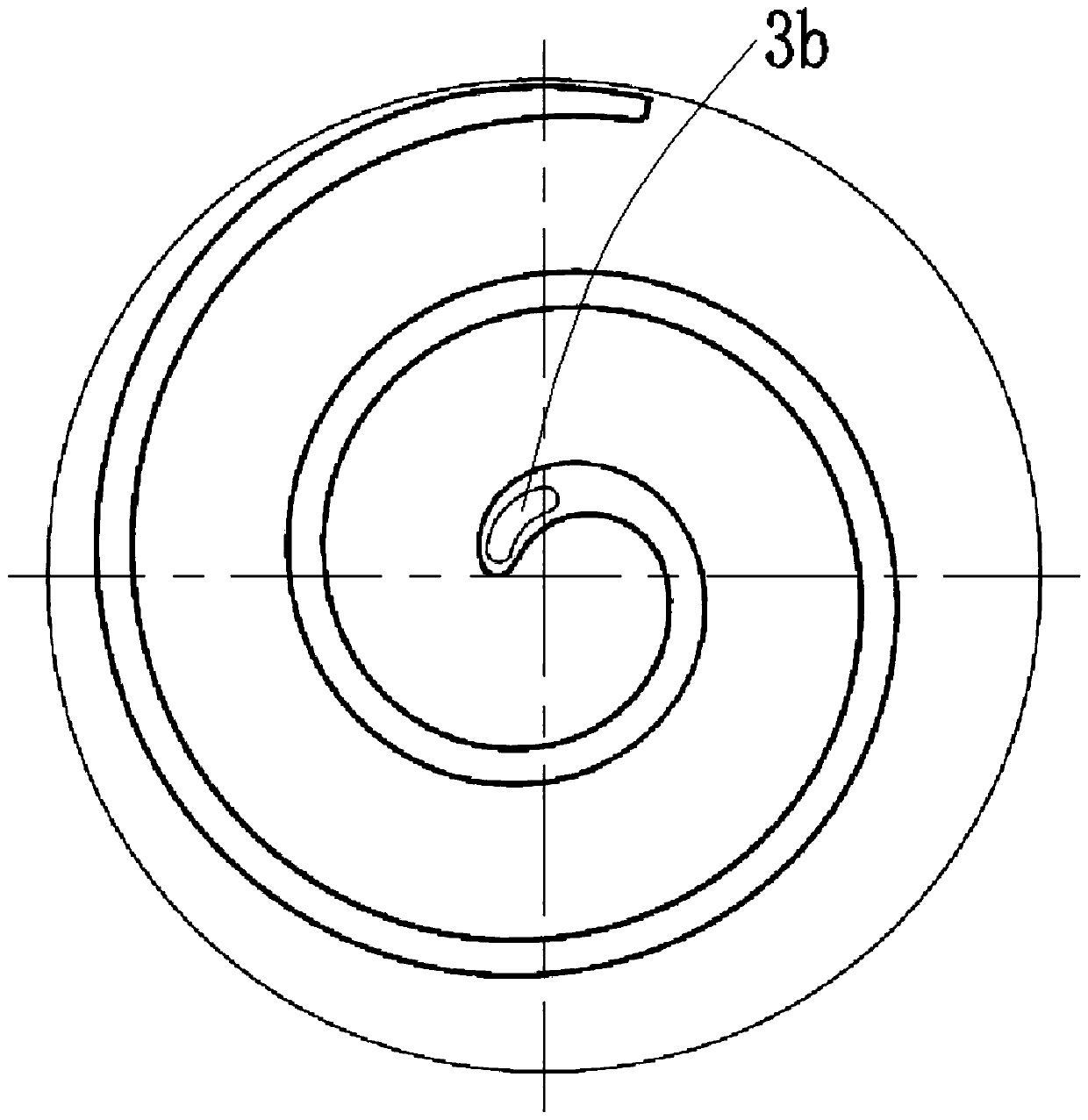

[0043] A vortex of a scroll compressor, adding oil storage holes to the end face of the high-pressure section of the scroll blade can reduce the influence of thermal deformation of the scroll blade, increase the lubrication capacity, effectively reduce the temperature of the high-pressure section and the center, and reduce the current There are abnormal reliability problems caused by thermal deformation in the center of the molded line, and the ability of the electric compressor to resist high temperature is improved, such as figure 1 , figure 2 , image 3 As shown, specifically set to the following structure:

[0044] The scroll structure of the scroll compressor in this embodiment can be applied to the moving disk and the static disk, which is basically the same as the scroll structure of the existing scroll compressor, including the scroll end plate 1 and the scroll blade 2. The rotary vane 2 is arranged at one end surface of the scroll end plate 1. The difference is tha...

Embodiment 2

[0051] This embodiment is further optimized on the basis of the above-mentioned embodiments, further to better realize the present invention, especially adopt the following configuration structure:

[0052] Because the highest temperature of the scroll blade 2 is generally at its center, therefore, in order to improve the cooling and lubricating ability of the center, the setting position of the oil storage hole is selected at the center of the adjacent scroll blade 2, which is not One point but one section, and oil storage holes can be set in this section.

[0053] The increase of the oil storage hole appropriately reduces the center wall thickness of the scroll blade 2, appropriately enhances the center elastic deformation capacity of the scroll blade 2, and increases the center oil storage and lubrication cooling capacity of the scroll blade 2 at the same time, which is beneficial to the scroll blade 2. The central heat of the rotating blade 2 is dissipated in time, which c...

Embodiment 3

[0060] This embodiment provides a compressor on the basis of Embodiment 2, and particularly adopts the following structure:

[0061] This kind of compressor includes a moving disk and a static disk, wherein one or both of the moving disk and the static disk adopt the structure of the scroll compressor scroll in Embodiment 2, such as the moving disk and the static disk All adopt the scroll structure of the scroll compressor in Embodiment 2, the movable disk includes the movable scroll end plate and the movable scroll blade, and the static disk includes the fixed scroll end plate and the fixed scroll blade. The scroll vane 2 of the scroll compressor scroll has oil storage holes on the end surface, which has good thermal deformation capacity and good heat dissipation capacity, which can improve the high temperature resistance of the compressor, especially the dynamic disc and static disc. When the scroll compressor scroll structure is used, the compressor can obtain the best high...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com