Composite structure friction material and preparation method thereof

A composite structure and friction material technology, applied in textiles, papermaking, non-woven fabrics, etc., can solve problems such as poor mechanical properties, thermal conductivity, and poor interlayer shear performance, achieve high interlayer shear performance, and avoid cracking and delamination. , the effect of excellent friction performance and comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] This embodiment provides a composite structure friction material and a preparation method thereof.

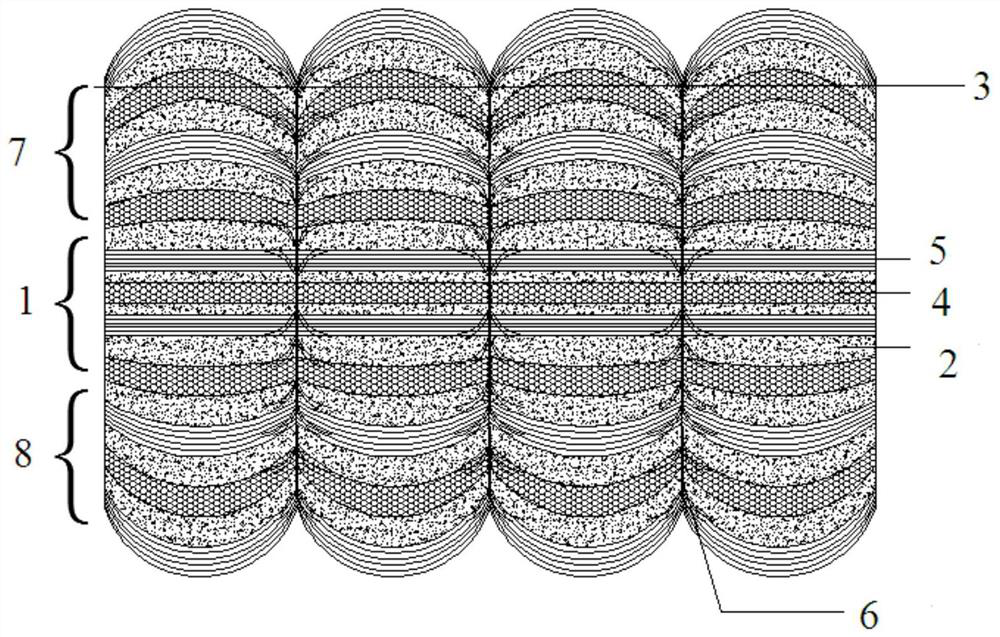

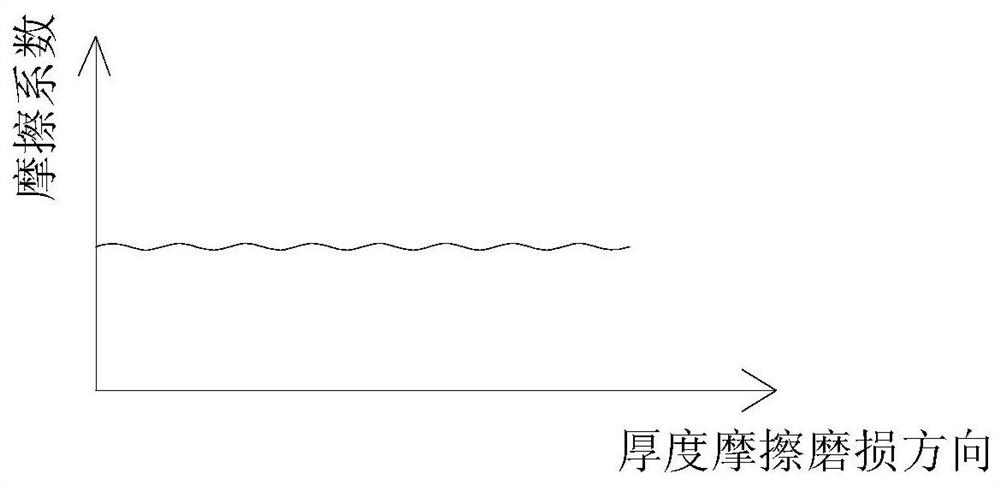

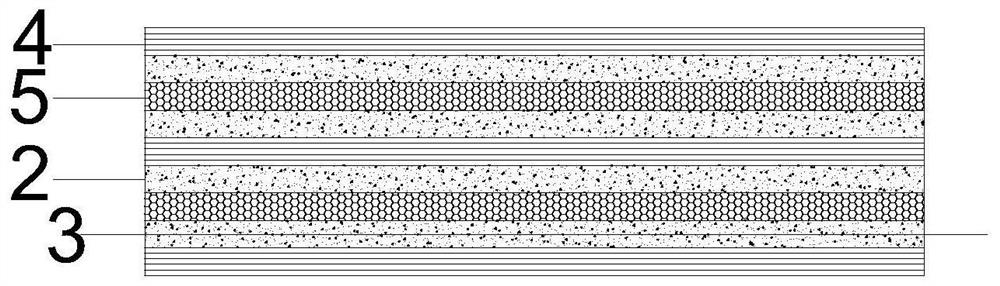

[0058] The composite structural friction material prepared in this example includes an inner layer group and two outer layer groups, the part near the friction surface is the outer layer group, the part far from the friction surface is the inner layer group, and the inner layer group is carbon fiber straight The outer layer group is a carbon fiber corrugated continuous reinforced friction layer group. The inner and outer plies are connected by needle-punched carbon fibers. The carbon fiber precursor used is pre-oxygen filament.

[0059] In the friction material prepared in this example, the inner layer group is a structural layer group, which is a three-dimensional acupuncture three-dimensional structure formed by cyclic layup of a flat non-woven fabric and a flat mesh tire after compaction and needle punching; the outer layer group is a friction material. The layer gr...

Embodiment 2

[0083] This embodiment provides another composite structure friction material and a preparation method thereof.

[0084] The friction material prepared in this example includes an inner layer group and two outer layer groups, the part near the friction surface is the outer layer group, the part far from the friction surface is the inner layer group, and the inner layer group is a straight continuous carbon fiber. The reinforcement structure layer group, the two outer layer groups are carbon fiber corrugated continuous reinforcement friction layer groups. The inner and outer plies are connected by needle-punched carbon fibers. The carbon fiber precursor used is pre-oxygen filament.

[0085] The inner layer group of the friction material prepared in this example is a structural layer group, which is a three-dimensional acupuncture three-dimensional structure formed by cyclic layup of a flat non-woven fabric and a flat mesh tire and then compacted and acupuncture, and the outer ...

Embodiment 3

[0102] This embodiment provides another composite structure friction material and a preparation method thereof.

[0103] The friction material prepared in this example includes an inner layer group and two outer layer groups, the part near the friction surface is the outer layer group, the part far from the friction surface is the inner layer group, and the inner layer group is a straight continuous carbon fiber. The reinforcement structure layer group, the two outer layer groups are carbon fiber corrugated continuous reinforcement friction layer groups. The inner and outer plies are connected by needle-punched carbon fibers. The carbon fiber precursor used is pre-oxygen filament.

[0104] The inner layer group of the friction material prepared in this example is a structural layer group, which is a three-dimensional acupuncture three-dimensional structure formed by cyclic layup of a flat non-woven fabric and a flat mesh tire and then compacted and acupuncture, and the outer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com