A kind of preparation method of symmetrical rigid-flex board

A rigid-flex board, symmetrical technology, applied in the direction of electrical connection formation of printed components, assembly of printed circuits with electrical components, etc., to achieve stable production and supply, increase hole design density, and simplify complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

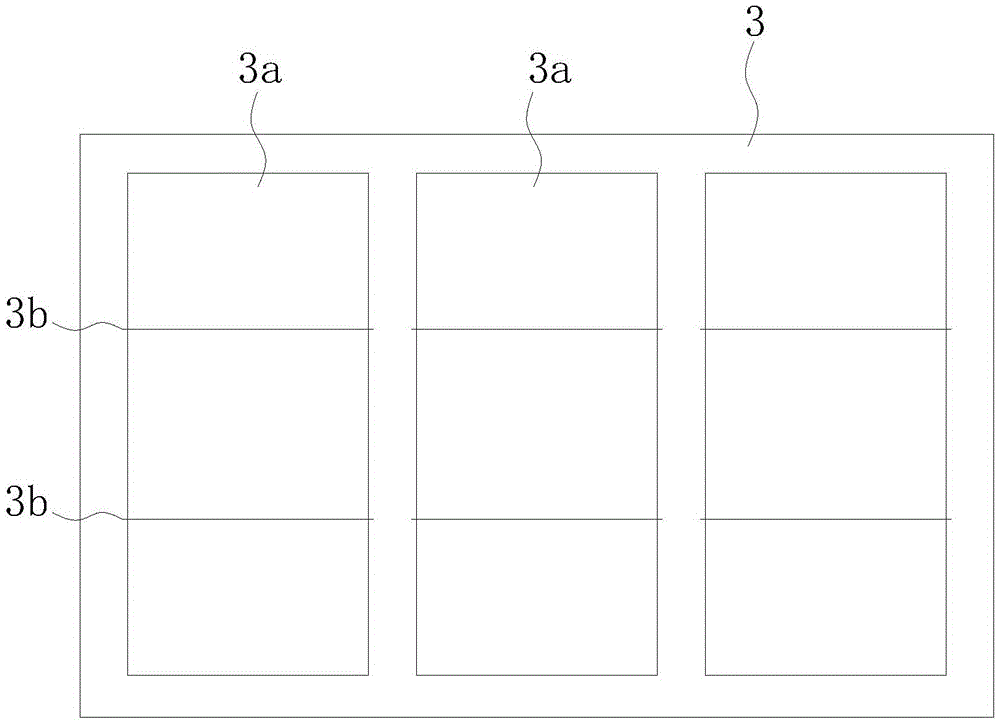

[0027] refer to Figure 1 to Figure 7 Shown, a kind of preparation method of symmetrical rigid-flex board of the present invention, this method comprises the following steps:

[0028] (1) Prepare a flexible copper-clad laminate, and divide the flexible copper-clad laminate into several flexible units spaced apart according to product specifications; the preparation of the flexible copper-clad laminate is specifically:

[0029] (a) Drill holes on the flexible copper-clad base material of the inner layer. After the holes are drilled, they are cleaned by a wet method, and then electroless plating and electroplating are performed to complete the metallization of the inner layer holes; the flexible copper-clad substrate described in this embodiment The copper-clad substrate is a double-sided copper-clad substrate, and the dielectric layer in the substrate is polyimide or liquid crystal polymer. Flexible copper-clad substrates can also be selected as single-sided copper-clad substr...

Embodiment 1

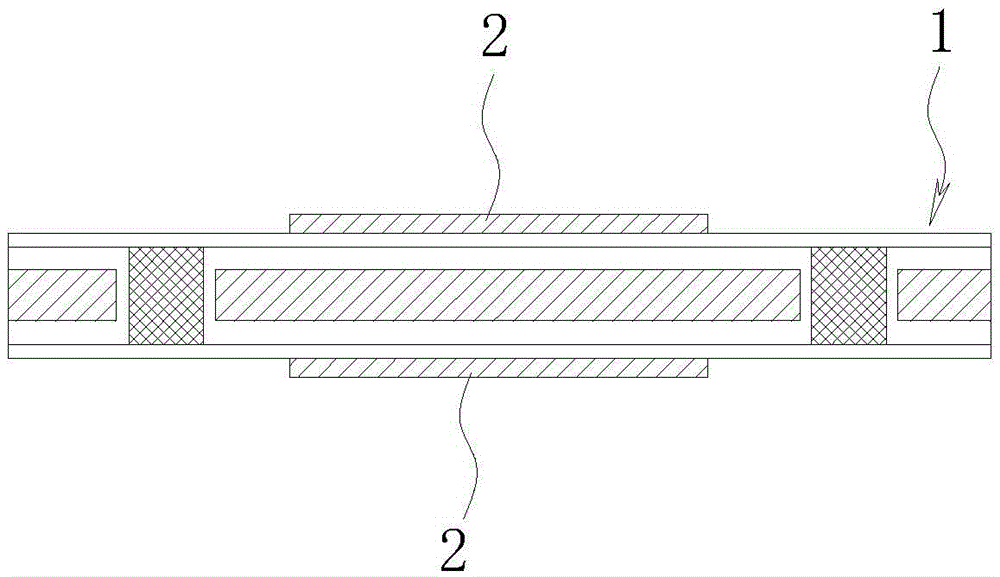

[0041] refer to Figure 2 to Figure 7 As shown, a four-layer rigid-flex board and a hole interconnection processing method are provided.

[0042] Use a cutting machine to cut flexible double-sided copper-clad laminates, rigid single-sided copper-clad laminates, thermosetting adhesives, and polyimide cover films that are suitable for the processing size. At the same time, according to the product specifications, the flexible double-sided copper-clad laminate and the rigid single-sided copper-clad laminate are divided into several flexible units and rigid units that are spaced apart from each other.

[0043] Step 1: Carry out numerical control drilling on the inner flexible double-sided copper-clad substrate, then use potassium permanganate solution to clean the drilled holes, and then perform electroless plating and electroplating to complete the metallization of the inner holes; The dielectric layer of the flexible copper-clad substrate used is polyimide.

[0044] Step 2: Co...

Embodiment 2

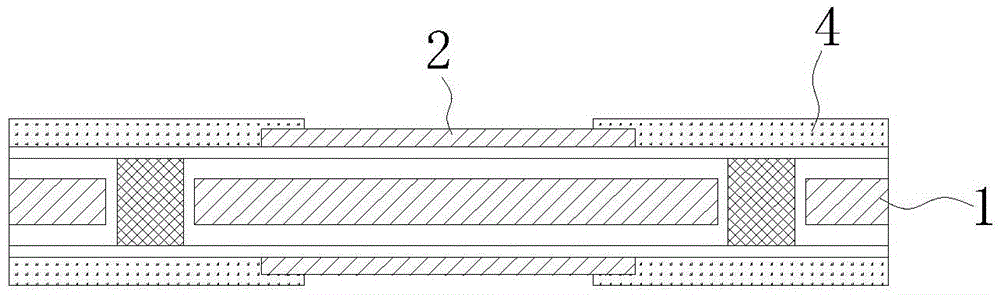

[0051] refer to Figure 2 to Figure 7 and Figure 8 with Figure 9 As shown, a six-layer rigid-flex board and a hole interconnection processing method are provided.

[0052] Use a cutting machine to cut flexible double-sided copper-clad laminates, rigid single-sided copper-clad laminates, thermosetting adhesives, and polyimide cover films that are suitable for the processing size. At the same time, according to the product specifications, the flexible double-sided copper-clad laminate and the rigid single-sided copper-clad laminate are divided into several flexible units and rigid units that are spaced apart from each other.

[0053] Step 1: Carry out numerical control drilling on the inner flexible double-sided copper-clad substrate, then use potassium permanganate solution to clean the drilled holes, and then perform electroless plating and electroplating to complete the metallization of the inner holes; The dielectric layer of the flexible copper-clad substrate used is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com